Novel perovskite and crystalline silicon back passivation laminated solar cell and manufacturing method thereof

A stacked solar and perovskite technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., to achieve the effect of improving conversion efficiency, steep absorption edge, and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

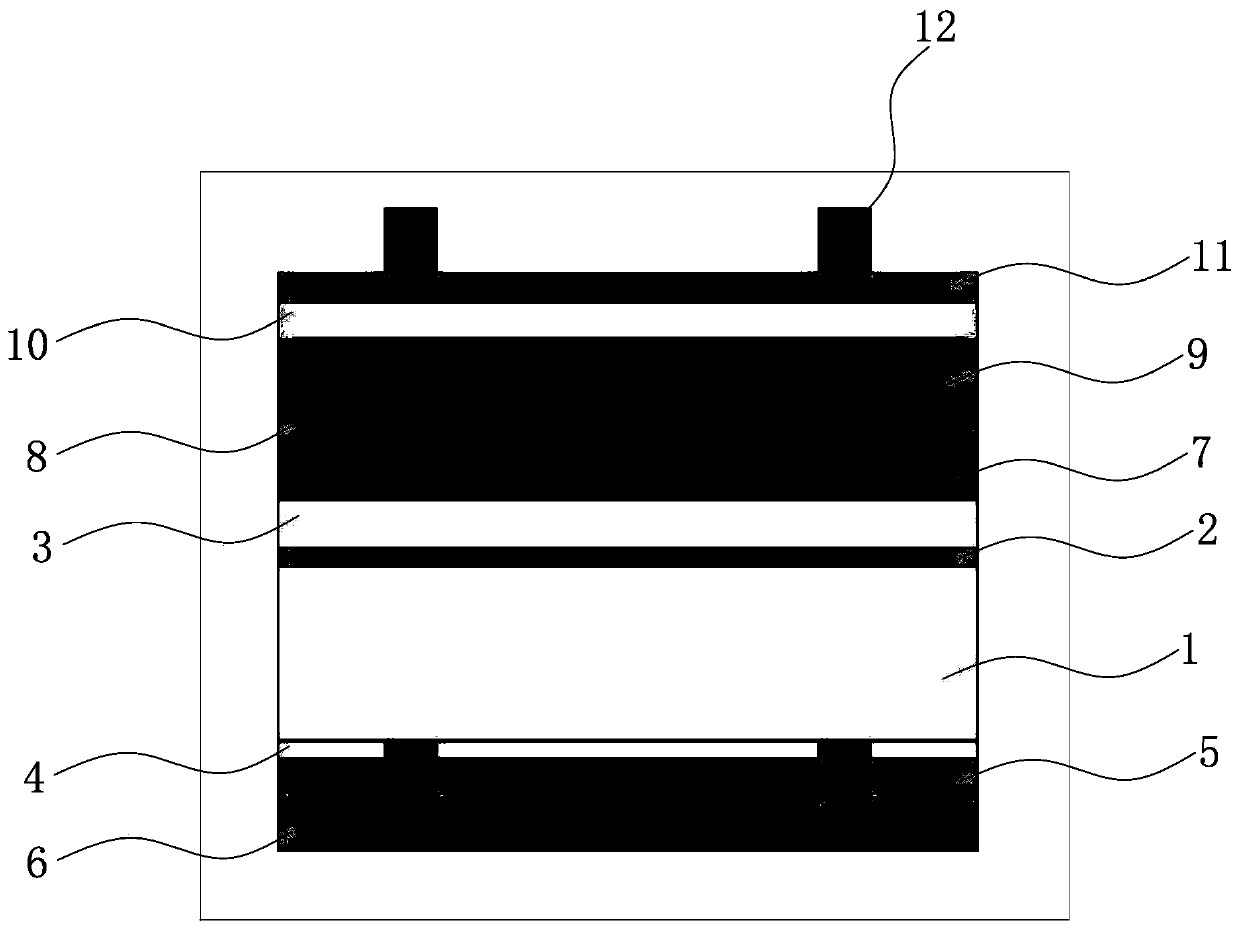

[0033] This embodiment provides a method for manufacturing a novel solar cell based on perovskite and crystalline silicon rear passivation tandem solar cell and a novel tandem solar cell based on perovskite and crystalline silicon rear passivation manufactured by the method.

[0034] Such as figure 1 As shown, a novel method for preparing a stacked solar cell based on perovskite and crystalline silicon back passivation includes the following steps:

[0035] Step 1: Texturing, using a P-type monocrystalline silicon wafer as a silicon substrate, placing it in a texturing solution for texturing treatment, the texturing solution used is based on the mass ratio KOH:texturing additive:H 2 The ratio of O=20:3:160 is prepared, the temperature is 80°C, and then it is cleaned in hydrofluoric acid with a mass fraction of 5%, and the surface of the silicon chip is cleaned to obtain a P-type silicon substrate 1. The texturizing additive here is It refers to the addition of chemical additi...

Embodiment 2

[0048] This embodiment provides a method for manufacturing a novel solar cell based on perovskite and crystalline silicon rear passivation tandem solar cell and a novel tandem solar cell based on perovskite and crystalline silicon rear passivation manufactured by the method.

[0049] Such as figure 1 As shown, a novel method for preparing a stacked solar cell based on perovskite and crystalline silicon back passivation includes the following steps:

[0050] Step 1: Texturing, using a P-type monocrystalline silicon wafer as a silicon substrate, placing it in a texturing solution for texturing treatment, the texturing solution used is based on the mass ratio KOH:texturing additive:H 2 The ratio of O=20:3:160 is prepared, the temperature is 80° C., and then cleaned in hydrofluoric acid with a mass fraction of 2%, the surface of the silicon wafer is cleaned, and a P-type silicon substrate 1 is obtained;

[0051] Step 2: film deposition, using LPCVD equipment or PECVD equipment to...

Embodiment 3

[0061] This embodiment provides a method for manufacturing a novel solar cell based on perovskite and crystalline silicon rear passivation tandem solar cell and a novel tandem solar cell based on perovskite and crystalline silicon rear passivation manufactured by the method.

[0062] Such as figure 1 As shown, a novel method for preparing a stacked solar cell based on perovskite and crystalline silicon back passivation includes the following steps:

[0063] Step 1: Texturing, using a P-type monocrystalline silicon wafer as a silicon substrate, placing it in a texturing solution for texturing treatment, the texturing solution used is based on the mass ratio KOH:texturing additive:H 2 The ratio of O=20:3:160 is prepared, the temperature is 80° C., and then cleaned in hydrofluoric acid with a mass fraction of 4%, the surface of the silicon wafer is cleaned, and the P-type silicon substrate 1 is obtained;

[0064] Step 2: thin film deposition, using LPCVD equipment or PECVD equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com