Mining hard alloy

A cemented carbide and mining technology, applied in the field of cemented carbide, can solve the problems of low work efficiency, many varieties of cemented carbide drill bits, and cannot effectively solve the problems of toughness and wear resistance of cemented carbide, so as to improve work efficiency, The effect of improving rock drilling efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

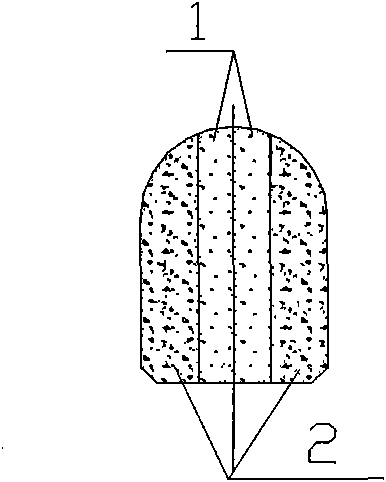

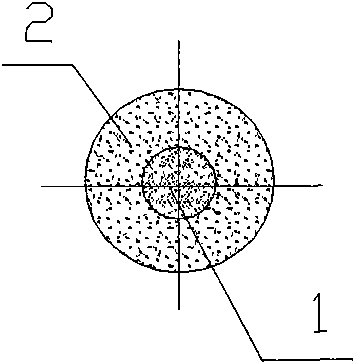

[0011] Example 1. Such as figure 1 , 2 As shown, the whole cemented carbide adopts two layers, and the content of cobalt in the raw material of the inner layer 1 is higher than that of the outer layer 3 . For example, the content of cobalt in the raw material of the inner layer 1 is 9-11%, and that of the outer layer 3 is 5-8%.

Embodiment 2

[0012] Example 2. Such as figure 1 , 2 As shown, the whole cemented carbide adopts two layers, and the content of cobalt in the raw material of the inner layer 1 is lower than that of the outer layer 3 . For example, the content of cobalt in the raw material of the inner layer 1 is 5-8%, and that of the outer layer 3 is 9-11%.

Embodiment 3

[0013] Example 3. On the basis of Example 1 or 2, the particle size of the raw material of the inner layer 1 is smaller than or smaller than that of the outer layer 3 . For example, the particle size of the inner layer 1 is 0.8-1.5um, and the particle size of the outer layer 3 is 1.6-3um; or the particle size of the inner layer 1 is 1.6-3um, and the particle size of the outer layer 3 is 0.8-1.5um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com