Method for manufacturing nanometer tungsten/cobalt carbide composite powder

A technology of nano-tungsten carbide and composite powder, which is applied in the large-scale industrial preparation of nano-structured ultra-fine tungsten carbide/cobalt composite powder, the preparation of ultra-fine nano-powder, and the preparation of nano-tungsten-based composite powder series materials. Solve the problems that the carbon content of the composite powder is difficult to control, and the particles are easy to aggregate and grow, so as to achieve the effect of increasing the surface tension of the droplet, increasing the viscosity of the solution, and reducing the processing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

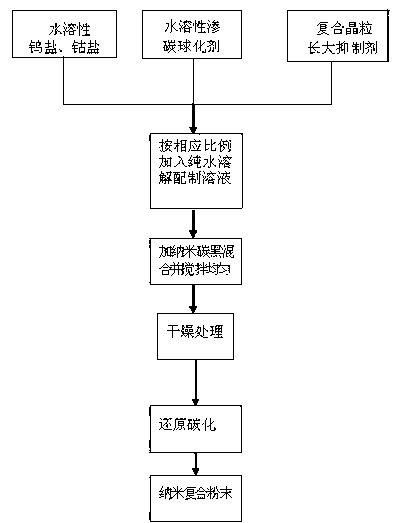

Method used

Image

Examples

example 1

[0040] Step 1: Mix 55kg of ammonium metatungstate (AMT), 40kg of Co(NO3) 2 , 3kg of polyethylene glycol (PEG) and 2kg of water-soluble vanadium salt are dissolved in 300kg of water to prepare a mixed aqueous solution;

[0041] Step 2: Add 1 kg of nano-carbon black to the mixed aqueous solution obtained in step 1, and stir for 30 minutes at a speed of 10 rpm so that it can be mixed evenly;

[0042] Step 3: The mixed aqueous solution obtained in step 2 is subjected to rapid low-temperature spray drying, the inlet temperature of the low-temperature drying is 150°C, and the outlet temperature is only 70°C, so that ultrafine tungsten-cobalt composite salt precursor powder can be obtained;

[0043] Step 4: The precursor powder obtained in step 3 is subjected to reduction synthesis and carbon adjustment at a temperature of 900° C. to prepare a tungsten carbide / cobalt composite powder material with a nanostructure.

[0044] The average grain size of the tungsten carbide / cobalt compos...

example 2

[0046] Step 1: Dissolve 92kg of ammonium paratungstate (APT), 3kg of cobalt oxalate, 3kg of polyvinyl alcohol (PVA) and 2kg of water-soluble vanadium salt in 400kg of water to prepare a mixed aqueous solution;

[0047] Step 2: Add 3kg of nano carbon black to the mixed aqueous solution obtained in step 1, stir for 40 minutes at a speed of 20 rpm, so that it can be mixed uniformly;

[0048] Step 3: The mixed aqueous solution obtained in step 2 is subjected to rapid low-temperature spray drying, the inlet temperature of the low-temperature drying is 200°C, and the outlet temperature is only 90°C, so that ultrafine tungsten-cobalt composite salt precursor powder can be obtained;

[0049] Step 4: The precursor powder obtained in step 3 is subjected to reduction synthesis and carbon adjustment at a temperature of 900° C. to prepare a tungsten carbide / cobalt composite powder material with a nanostructure.

[0050] The average grain size of the tungsten carbide / cobalt composite powder...

example 3

[0052] Step 1: Mix 62kg of ammonium paratungstate (APT), 30kg of CoCl 2 1. Dissolve 6kg of starch and 2kg of water-soluble chromium salt in 500kg of water to prepare a mixed aqueous solution;

[0053] Step 2: Add 8kg of nano-carbon black to the mixed aqueous solution obtained in step 1, stir at a speed of 30 rpm for 60 minutes, so that it can be mixed uniformly;

[0054] Step 3: The mixed aqueous solution obtained in step 2 is subjected to rapid low-temperature spray drying, the inlet temperature of the low-temperature drying is 180°C, and the outlet temperature is only 80°C, so that ultrafine tungsten-cobalt composite salt precursor powder can be obtained;

[0055] Step 4: The precursor powder obtained in step 3 is subjected to reduction synthesis and carbon adjustment at a temperature of 1000° C. to prepare a tungsten carbide / cobalt composite powder material with a nanostructure.

[0056] Through Example 3, the average grain size of the tungsten carbide / cobalt composite pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com