Diamond compact and preparation method thereof

A technology of diamond composite sheet and diamond layer, applied in the field of diamond composite sheet and its preparation, can solve problems such as insufficient densification of diamond composite sheet, and achieve the effects of fine grain size, alleviating abnormal growth and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] According to one aspect of the present invention, a kind of preparation method of above-mentioned diamond compact, described method comprises the following steps:

[0053] (a) Preparation of powder: mixing the diamond layer raw materials and adding a dispersant, then vibrating, mixing and filtering in a benzene solution to obtain a mixed powder, and then vacuum drying the mixed powder to obtain a diamond layer powder;

[0054] (b) Substrate preparation: fully mix the raw materials of the tungsten carbide / cobalt cemented carbide layer, and hot press sinter to obtain the tungsten carbide / cobalt cemented carbide substrate;

[0055] (c) Composite sheet assembly: the diamond layer powder obtained in step (a) is pre-pressed and assembled with a tungsten carbide / cobalt cemented carbide substrate to obtain a diamond composite;

[0056] (d) High-temperature and high-pressure synthesis: use a six-sided top press to perform high-temperature and high-pressure synthesis on the diamo...

Embodiment 1

[0068] A diamond compact, which includes a diamond layer and a tungsten carbide / cobalt cemented carbide layer;

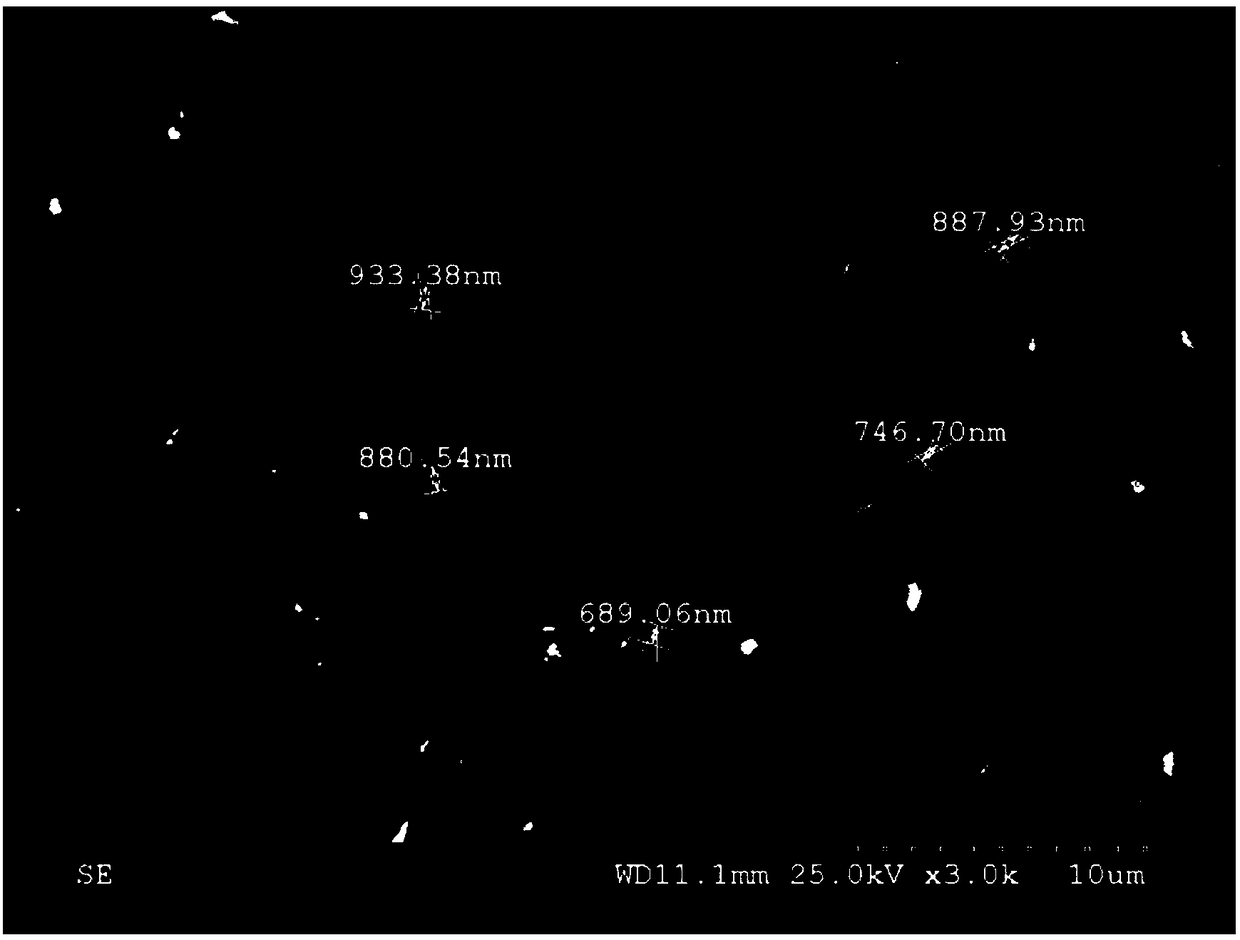

[0069] The diamond layer is mainly composed of the following raw materials in parts by weight: 77 parts of diamond powder with a particle size of 0.1 μm, 15 parts of a binder with a particle size of 0.1 μm and 8 parts of a grain inhibitor with a particle size of 0.1 μm,

[0070] The above-mentioned grain inhibitor is composed of SiC, WC and cBN, and the volume ratio of the three is 3:1:2;

[0071] The above-mentioned binder is a mixture of Ti, Ni and Cr, and its mass ratio is 5:1:3;

[0072] The tungsten carbide / cobalt cemented carbide layer is mainly composed of the following raw materials in parts by weight: 75 parts of tungsten carbide powder, 15 parts of cobalt powder and 10 parts of diamond micropowder,

[0073] The particle size of the above-mentioned diamond micropowder is 10 μm;

[0074] The preparation method of described diamond compact comprises the fol...

Embodiment 2

[0082] A diamond compact, which includes a diamond layer and a tungsten carbide / cobalt cemented carbide layer;

[0083] The diamond layer is mainly composed of the following raw materials in parts by weight: 89 parts of diamond powder with a particle size of 1 μm, 10 parts of a binder with a particle size of 0.5 μm and 1 part of a grain inhibitor with a particle size of 0.5 μm,

[0084] The above-mentioned grain inhibitor is composed of SiC, WC and cBN, and the volume ratio of the three is 2:3:1;

[0085] The above binder is SiO 2 and TiC in a mass ratio of 3:1;

[0086] The tungsten carbide / cobalt cemented carbide layer is mainly composed of the following raw materials in parts by weight: 80 parts of tungsten carbide powder, 10 parts of cobalt powder and 10 parts of diamond micropowder,

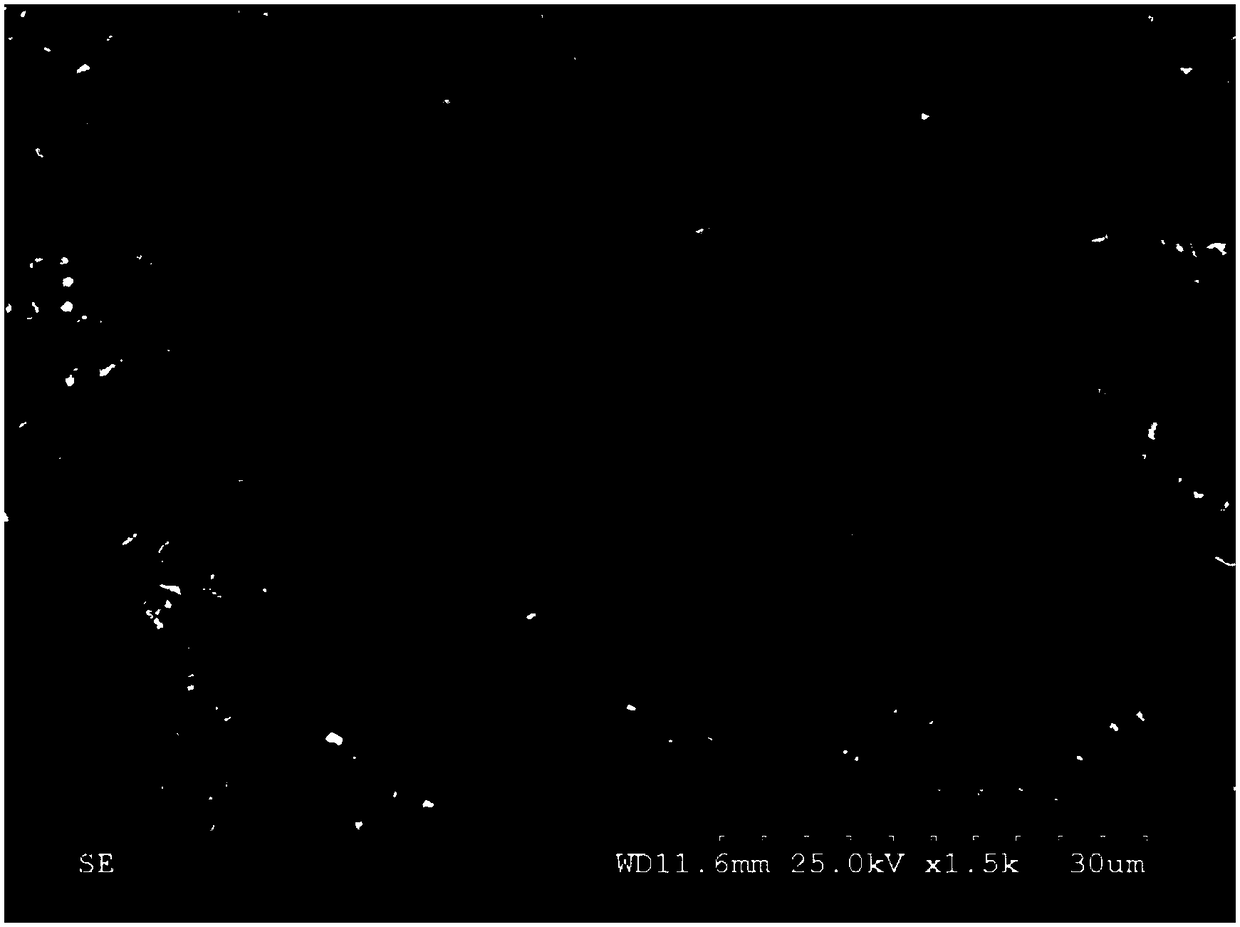

[0087] The particle size of the above-mentioned diamond micropowder is 30 μm;

[0088] The preparation method of described diamond compact comprises the following steps:

[0089] (a) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com