Novel graphene three-dimensional skeleton porous photocatalysis film preparation method

A technology of three-dimensional skeleton and photocatalytic film, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of losing high specific surface area of graphene and unfavorable long-term Operation, membrane fouling and other problems, to achieve the effect of large specific surface area, superior electrical conductivity, and improved membrane passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: preparing the semiconductor photocatalytic material required for the photocatalytic film;

[0026] Take Cu 2 O or Cu 2 Take the synthesis of O-CuO nanowires as an example, add 250ml deionized water to a 500ml three-neck flask, then add 85.63g NaOH and dissolve it completely, then add 0.44g CuSO 4 ·5H 2 O, pass nitrogen atmosphere protection into the reactor, stir at 500rpm for 20 minutes to obtain a uniform solution; then add 2.14ml of ethylenediamine and 0.18ml of hydrazine hydrate in sequence, keep at 80°C for 60 minutes to obtain a red Cu nanowires; finally obtain Cu by adjusting the oxidation temperature or time of Cu nanowires in an environment with a humidity of 65% to 70%. 2 O or Cu 2 O-CuO nanowires.

[0027] Step 2: Assembly of nanowire / graphene oxide three-dimensional framework porous membrane material

[0028] Take Cu 2 O nanowire / graphene oxide film assembly as an example, a certain mass of Cu 2 O nanowires were added to 30ml graphene oxide s...

Embodiment 2

[0034] Take Cu 2 O-TiO 2 Synthesis of nanowires as an example

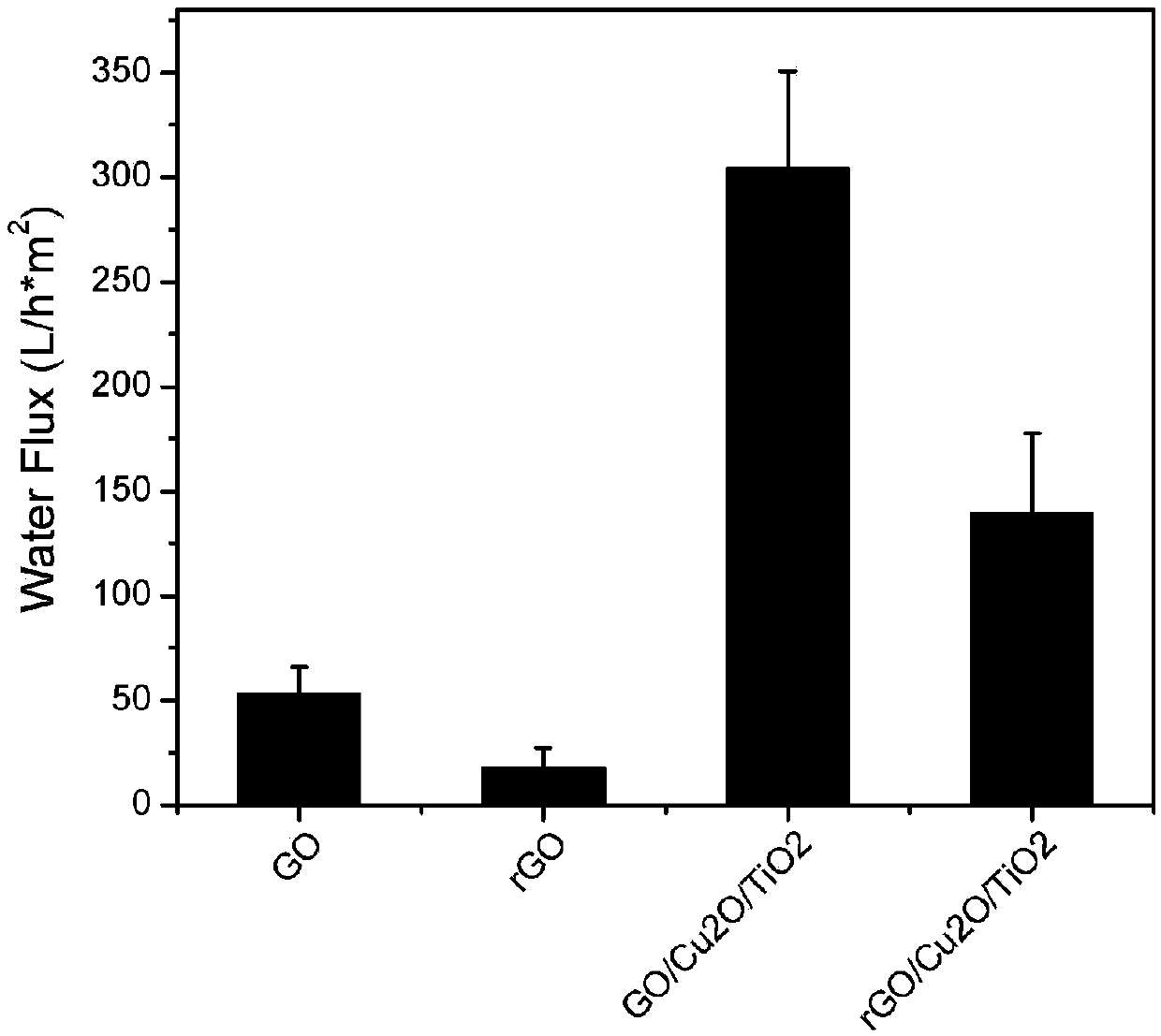

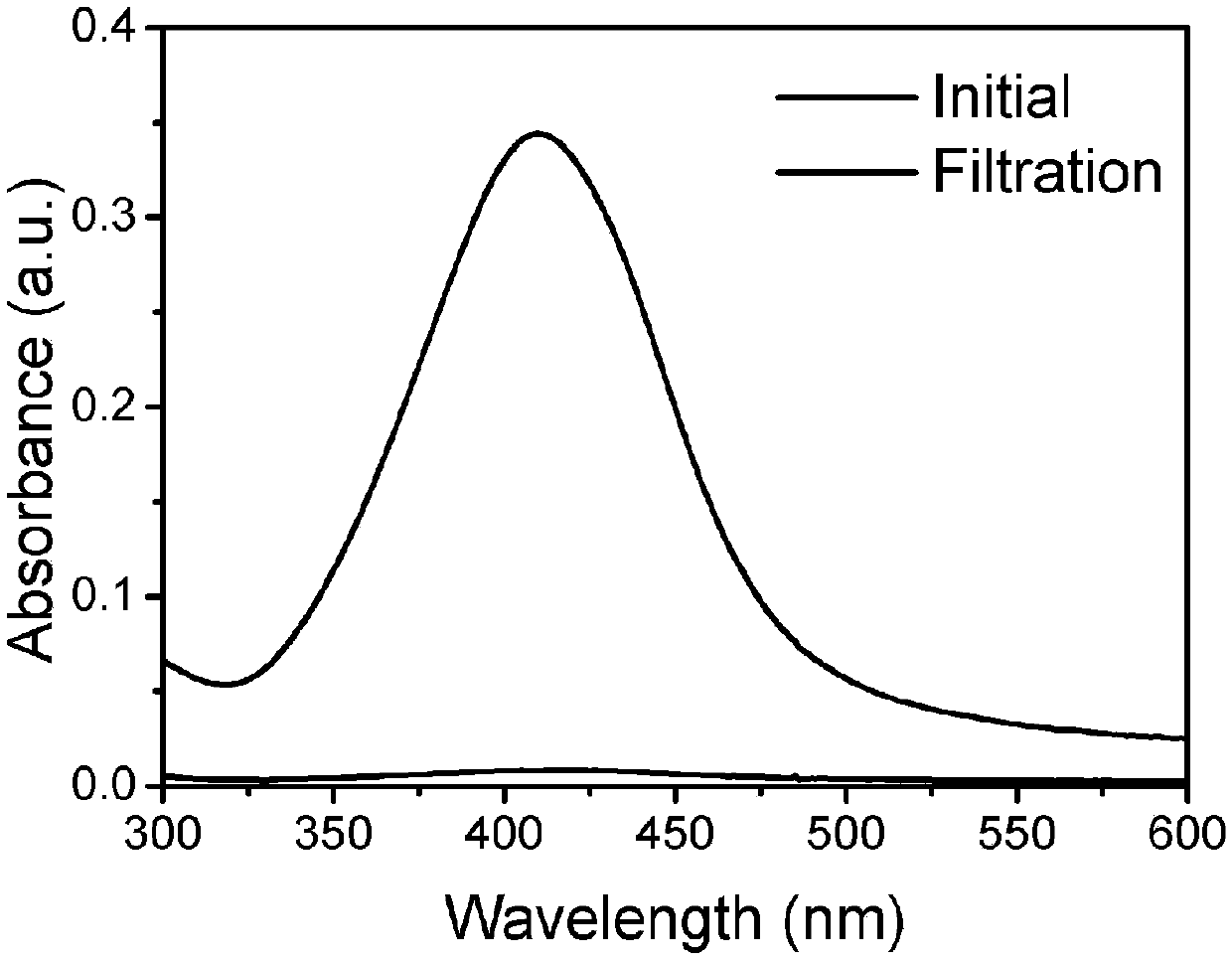

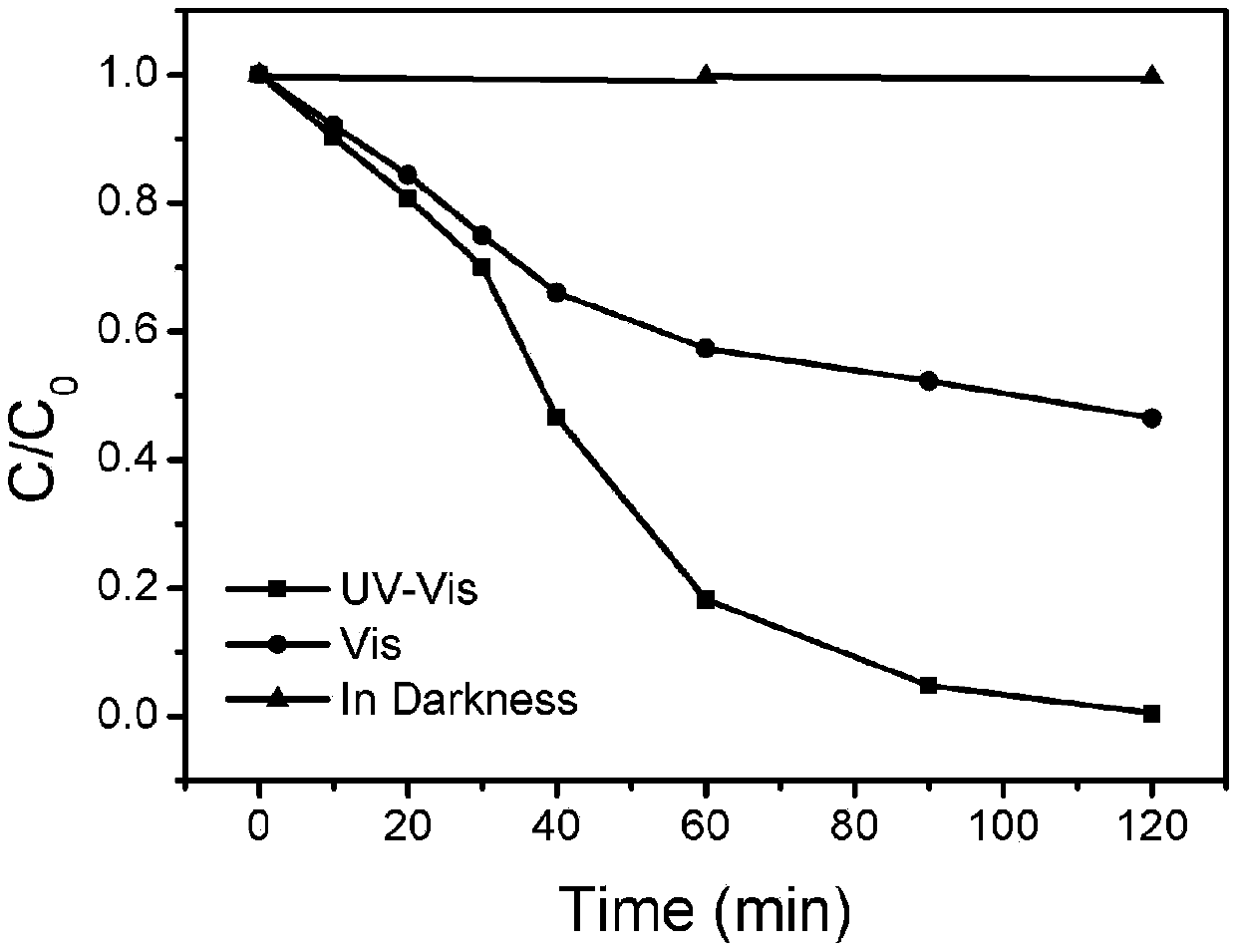

[0035] In order to verify the beneficial effect of the present invention, the inventor used Cu 2 O and TiO 2 nanowires as an example, the assembled Cu 2 O-TiO 2 Compared with the traditional photocatalytic composite membrane, the nanowire / graphene three-dimensional porous photocatalytic membrane has superior electrical conductivity and larger specific surface area, which provides a more effective diffusion path for pollutants to enter the membrane framework, and provides a new way for photocatalysis. The reaction provides more active centers, increases the reflection of incident light and improves the utilization of light; Cu 2 O-TiO 2 Nanowire / graphene forms heterogeneous knots to enhance photocatalytic performance; as a filter membrane, the constructed pores maintain excellent separation performance while improving membrane passability. This project lays the foundation for the development of efficient, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com