Preparation method of catalyst for epoxidation of 1-butene to prepare 1,2-epoxybutane

A technology of butylene oxide and catalyst, which is applied in the field of catalyst preparation for epoxidation of 1-butene, can solve the problems of cumbersome and complicated catalyst preparation procedures, unsolved problems such as hydrolysis of organic titanium sources, and inability to improve catalytic activity, and achieve good catalytic performance. High activity, good catalytic effect, high titanium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

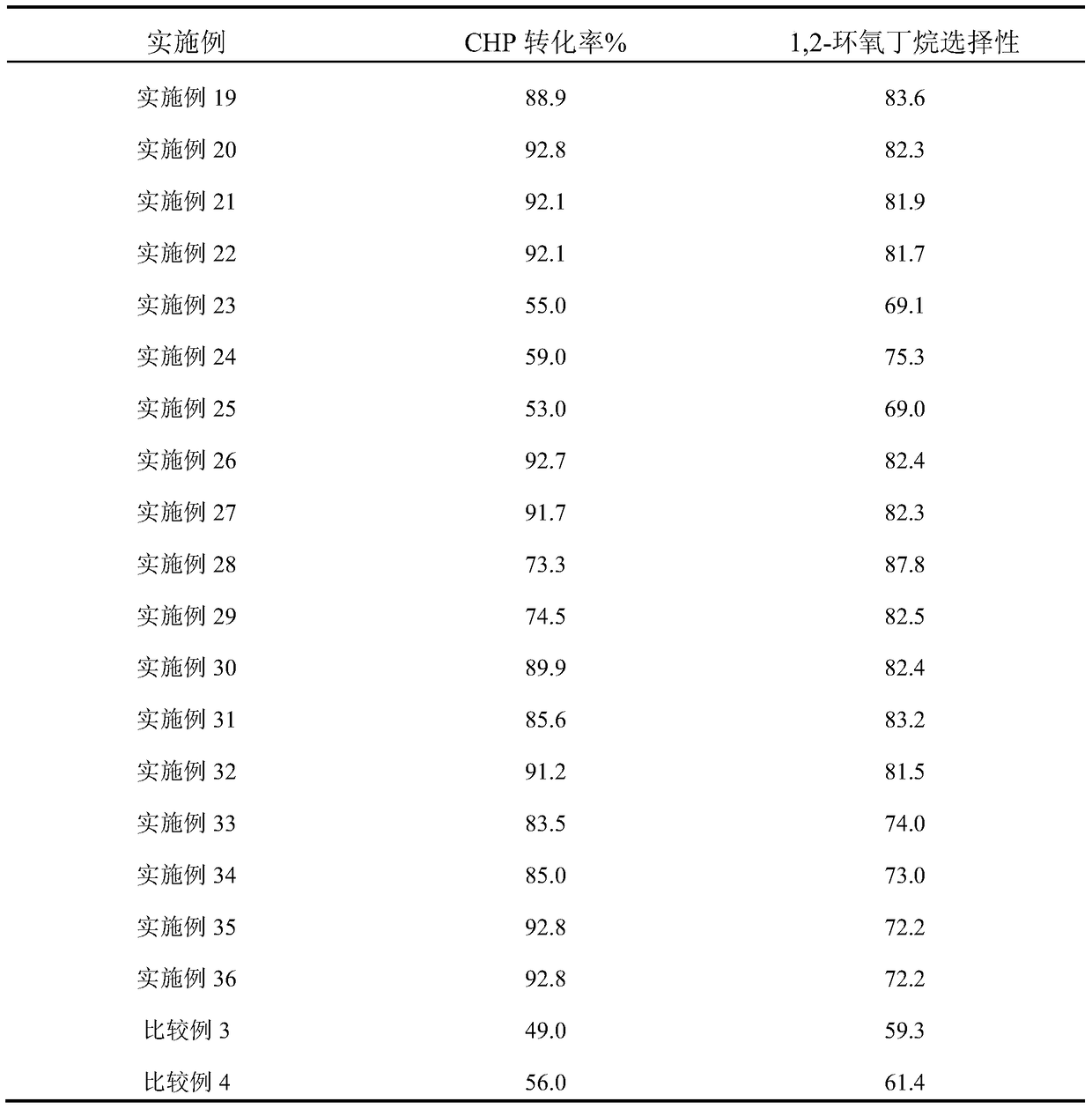

Examples

Embodiment 1

[0032] Weigh 23.0g tetraethyl orthosilicate, 1.0g butyl titanate, and 20.3g lauryl polyoxyethylene ether; stir and dissolve 24.5g lauryl polyoxyethylene ether in 100ml absolute ethanol, heat Stir for 1 h; slowly add 23.0 g of ethyl orthosilicate dropwise to the three-neck flask under stirring; half an hour later slowly add 4.0 g of butyl titanate dropwise, and finally do not add absolute ethanol to 220 ml. The pH of the reaction system was measured to be 2.0 with a magnetic pH meter, and the temperature was controlled to stir at 75° C. for 24 hours. After cooling and standing for 3 hours, the crystalline product was separated; after drying at 110°C, it was calcined in a muffle furnace at 550°C for 6 hours to obtain the original titanium-silicon molecular sieve catalyst powder.

[0033] The raw titanium-silicon molecular sieve powder obtained above was pressed into tablets and sieved, and the 20-40 mesh particles were packed into a fixed-bed reactor in a catalyst evaluation dev...

Embodiment 2

[0036] The preparation method of titanium silicon molecular sieve is operated with embodiment 1. Take 1.4g of tetrabutyl titanate.

[0037] The relative molar content of the components is:

[0038] SiO 2 / TiO 2 =23 Template / SiO 2 =0.37

Embodiment 3

[0040] The preparation method of titanium silicon molecular sieve is operated with embodiment 1. Take 2g of tetrabutyl titanate.

[0041] The relative molar content of the components is:

[0042] SiO 2 / TiO 2 =16 Template / SiO 2 =0.37

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com