Polypyrrolone/polyimide composite porous catalytic film and preparation method thereof

A technology of polyimide and polypyrrole, which is applied in the field of polypyrrole/polyimide composite porous catalytic membrane and its preparation, can solve problems such as limitations in use performance, and achieve cost reduction, multiple active centers, and good mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

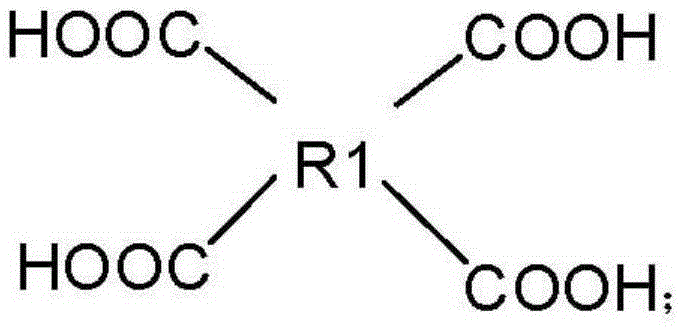

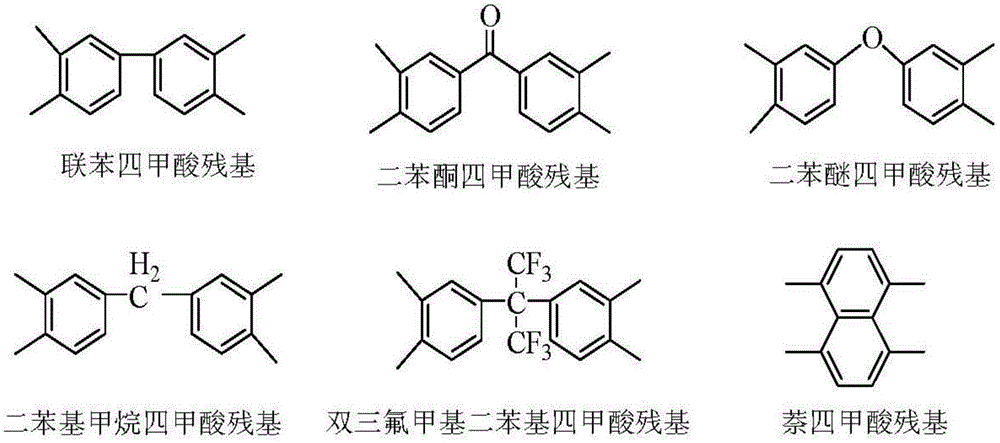

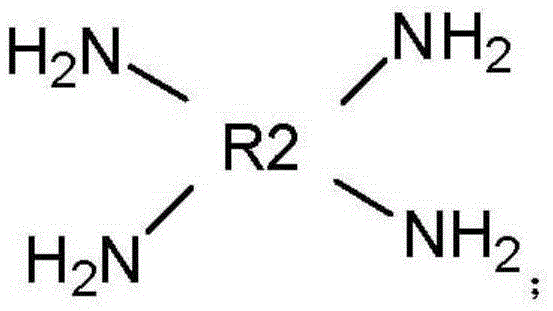

[0049] In the preparation of the polypyrrone precursor solution in step (1), exemplary tetraacid monomers include, but are not limited to, 3,3′,5,5′-biphenyltetracarboxylic acid, 3,3′,4, 4'-Biphenyltetracarboxylic acid, 3,3',5,5'-benzophenone tetracarboxylic acid, 3,3',4,4'-benzophenone tetracarboxylic acid, 2,3,3',4'- Diphenyl ether tetracarboxylic acid, 3,3',5,5'-diphenyl ether tetracarboxylic acid, 3,3',4,4'-diphenyl ether tetracarboxylic acid, 3,3',5,5'-diphenyl ether tetracarboxylic acid Methyl methane tetracarboxylic acid, 3,3',4,4'-diphenylmethane tetracarboxylic acid, 2,2',3,3'-diphenylmethane tetracarboxylic acid, 2,2',3,4-diphenyl Methyl methane tetracarboxylic acid, 3,3',4,4'-bistrifluoromethyldiphenyltetracarboxylic acid, 3,3',5,5'-bistrifluoromethyldiphenyltetracarboxylic acid, 2,2 ',3,3'-bistrifluoromethyldiphenyltetracarboxylic acid, 2,2',4,4'-bistrifluoromethyldiphenyltetracarboxylic acid, 2,3,3',4'-bis Trifluoromethyldiphenyltetracarboxylic acid, 1,4,5,8-nap...

Embodiment 1

[0120] Under the condition of lower than 25° C., A1 and B1 monomers with a molar ratio of 1:1 were dissolved in C1, and magnetically stirred for 2 hours to obtain a polypyrrolene precursor solution with a mass concentration of 15%. The polyamic acid solution is mainly prepared from D1 and E1, wherein the molar ratio of D1, E1 to benzoic acid is 1:2:0.5; finally a polyamic acid (PAA) solution with a mass concentration of 20% is obtained. Then the PAA solution is added to the above-mentioned polypyrrolone precursor solution, and then the metal component: F1, pore-forming agent: G1; the polypyrrole precursor solution, the polyamic acid solution, the The mass ratio of the metal component to the pore-forming agent is: 100:50:10:20. Stir for 4 hours to make it evenly mixed to obtain a spinning mixture.

[0121] The spinning mixed solution was subjected to electrospinning, the spinning voltage was controlled at 15kV, and the distance from the spinning nozzle to the opposite electrod...

Embodiment 2

[0123] Under the condition of lower than 25° C., A2 and B2 monomers with a molar ratio of 1:1 were dissolved in C2, and magnetically stirred for 2 hours to obtain a polypyrrolone precursor solution with a mass concentration of 25%. The polyamic acid solution is mainly prepared from D2 and E2, wherein the molar ratio of D2, E2 and benzoic acid is 1:1:0.5; finally a polyamic acid (PAA) solution with a mass concentration of 15% is obtained. Then the PAA solution is added to the above-mentioned polypyrrole precursor solution, and then the metal component: F2, pore-forming agent: G2 are added in sequence; the polypyrrole precursor solution, the polyamic acid solution, the The mass ratio of the metal component to the pore-forming agent is: 100:80:5:10. Stir for 4 hours to make it evenly mixed to obtain a spinning mixture.

[0124] Electrospinning was carried out on the above-mentioned spinning mixed liquid, the spinning voltage was controlled at 40 kV, and the distance from the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com