Hollow microsphere core-shell catalyst as well as preparation method and application thereof

A technology of core-shell catalysts and hollow microspheres, applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of being easily affected by carbon deposition, low catalyst sublimation temperature, and low catalytic efficiency, and achieve Good catalytic effect, shorten the diffusion time, increase the effect of the outer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

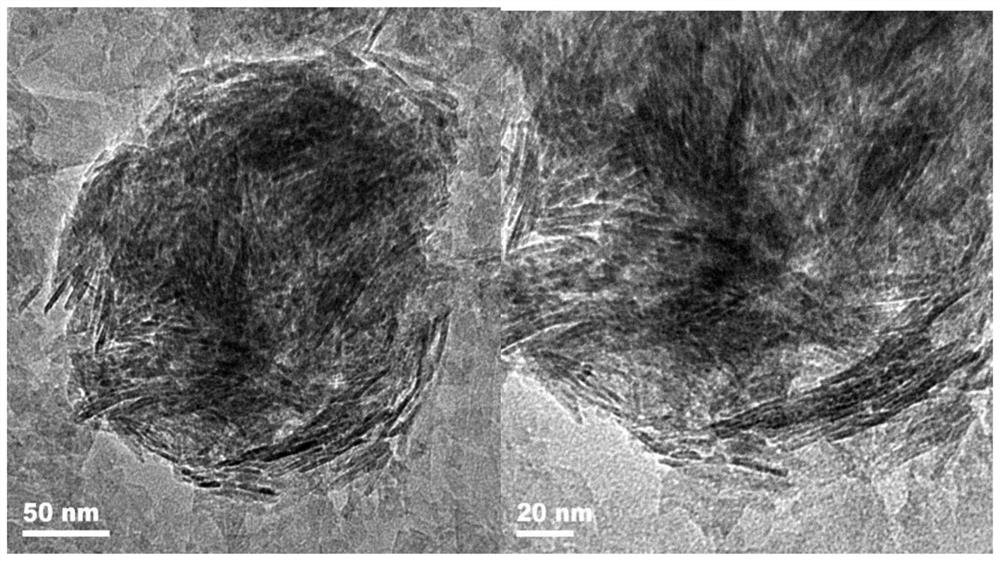

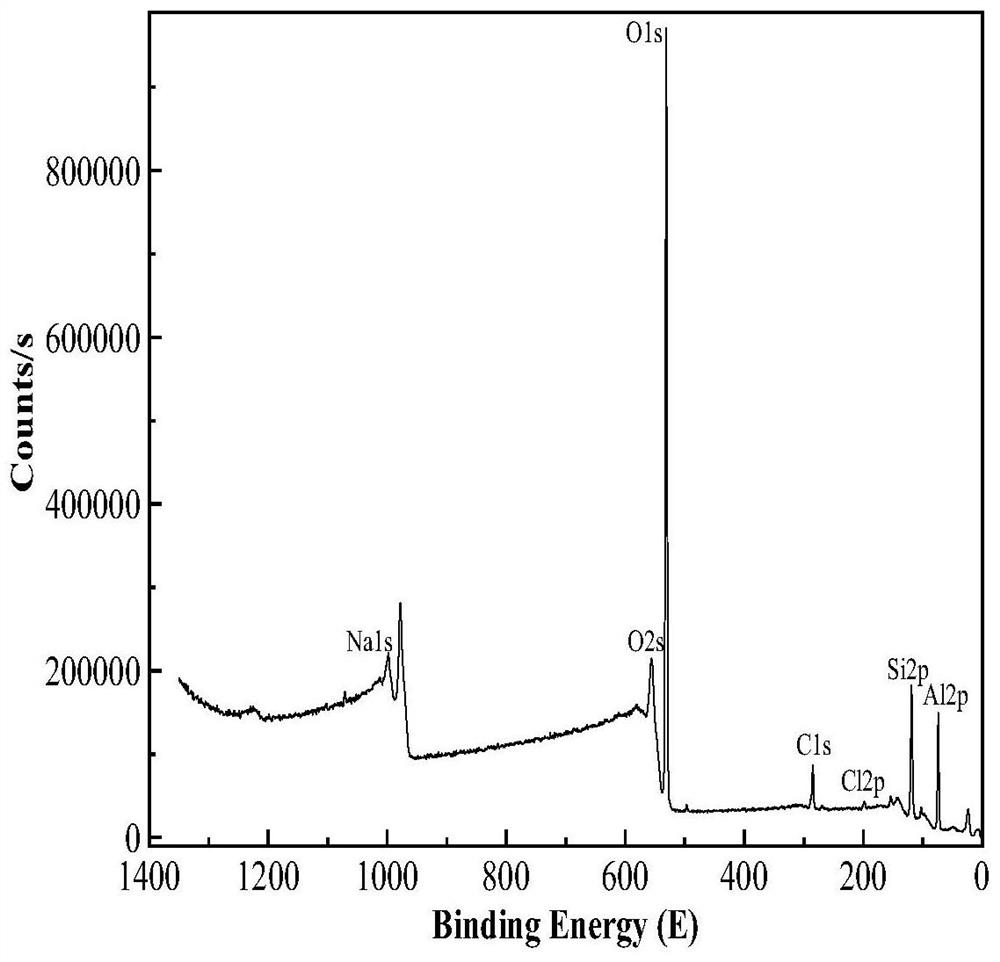

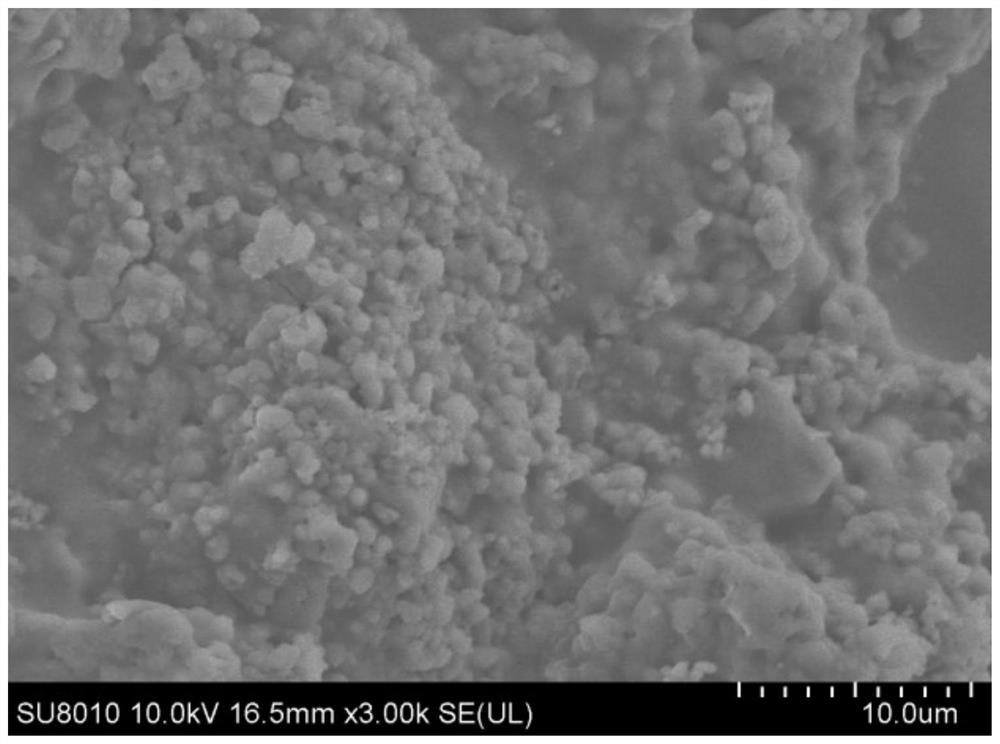

Embodiment 1

[0041] (1) Configure a 1mol / L glucose solution, take 70mL of the solution after it is completely dissolved, place it in a 100mL tetrafluoroethylene-lined reactor, conduct a hydrothermal reaction at 180°C for 5h, and wait until the reactor temperature is cooled to room temperature to obtain Brown product - carbon globules. The obtained product was alternately washed four times with absolute ethanol and deionized water, dried at 80° C. for 5 h, and then reserved for use.

[0042] (2) According to the molar ratio of the reactants tetraethyl orthosilicate, aluminum oxide, tetrapropylammonium hydroxide and deionized water as 25:0.668:9:480, prepare the ZSM-5 precursor with a silicon-aluminum ratio of 25 liquid.

[0043] Take 0.2g of carbon pellets, add them to 20mL of absolute ethanol, then add them to 60mL of ZSM-5 precursor solution, add NaOH, adjust pH=10, let stand at room temperature for 8h, filter, wash, and then place it Dry in an oven at 80°C for 5 hours to obtain the ZSM...

Embodiment 2

[0049] The difference with Example 1 is:

[0050] In step (2), according to Al 2 o 3 :TPAOH:TEOS:H 2 The molar ratio of O=0.5:9:25:480 (Si / Al ratio is 50) prepares ZSM-5 precursor solution, obtains Si:Al=50 ZSM-5 hollow microsphere;

[0051] In step (4), in AlCl 3 The immersion time in the solution is 4h, take NaCl and AlCl 3 The masses are 0.0976g and 0.2224g respectively, and the load of the double salt is 8wt%.

[0052] During detection and analysis, the reaction temperature was 180°C, the amount of catalyst was 0.5g, the ratio of reactants was 1:2, and the yield of disproportionation to prepare dimethyldichlorosilane was 70.68%.

Embodiment 3

[0054] The difference with Example 1 is:

[0055] In step (2), according to Al 2 o 3 :TPAOH:TEOS:H 2 The molar ratio of O=0.333:9:25:480 (Si / Al ratio is 75) prepares ZSM-5 precursor liquid, obtains the ZSM-5 hollow microsphere of Si:Al=75;

[0056] In step (4), in AlCl 3 The immersion time in the solution is 3h, weigh NaCl and AlCl 3 The masses are 0.1464g and 0.3336g respectively, and the load of the double salt is 12wt%.

[0057] During detection and analysis, the reaction temperature was 240°C, the amount of catalyst was 0.7g, the ratio of reactants was 1:1, and the yield of disproportionation to prepare dimethyldichlorosilane was 72.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com