Preparation method for low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve

A technology of mordenite and low silicon-aluminum ratio, which is applied in the field of preparation of low-silicon-aluminum ratio nanosheet flower cluster mordenite molecular sieves, to achieve the effects of large specific surface area, accelerated reaction rate, and low silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) At room temperature, first add 0.8501g of sodium metaaluminate and 1.6593g of sodium hydroxide to 46.67g of deionized water, then slowly add 31.1111g of silica sol (25wt%) into the solution, and age for 30min under stirring at room temperature to form Uniform white colloid;

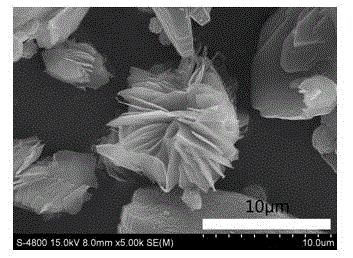

[0015] 2) Transfer 80.2914g of the white colloid obtained in step 1) to a 100ml PTFE-lined stainless steel reactor, and conduct a hydrothermal reaction at a temperature of 170°C for 4 days. The obtained reaction product is vacuum filtered and washed with deionized water Until the pH value of the washing solution is equal to 7.5, dry at a temperature of 120°C for more than 12 hours, and finally heat up to 550°C for 6 hours at a heating rate of 5°C / min to obtain 7.0 g of nano-flake clustered mordenite molecular sieves; (see attached figure 1 )

Embodiment 2

[0017] 1) At room temperature, first add 0.7286g of sodium metaaluminate and 1.4222g of sodium hydroxide into 60.0g of deionized water, then slowly add 26.6667g of silica sol (25wt%) into the solution, and age for 30min under stirring at room temperature to form Uniform 88.8175g white colloid;

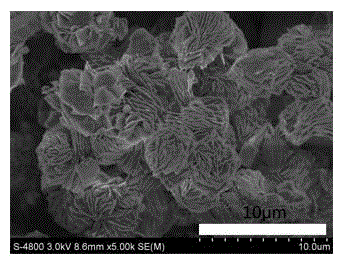

[0018] 2) Transfer the white colloid obtained in step 1) to a 100ml PTFE-lined stainless steel reactor, and conduct a hydrothermal reaction at a temperature of 170°C for 4 days. The obtained reaction product is vacuum filtered and washed with deionized water until it is washed. The pH value of the liquid is equal to 7.5, dried at a temperature of 120°C for more than 12 hours, and finally heated to 550°C for 6 hours at a heating rate of 5°C / min to obtain 5.5g of nano-flake clustered mordenite molecular sieves; (see attached figure 2 )

Embodiment 3

[0020] 1) At room temperature, first add 0.5829g of sodium metaaluminate and 1.1378g of sodium hydroxide to 64.0g of deionized water, then slowly add 21.3333g of silica sol (25wt%) into the solution, and age for 30min under stirring at room temperature to form Uniform 87.054g white colloid;

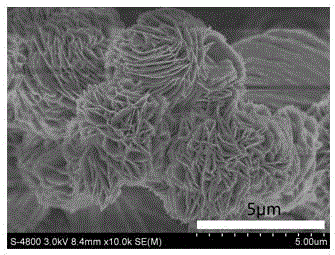

[0021] 2) Transfer the white colloid obtained in step 1) to a 100ml PTFE-lined stainless steel reactor, and conduct a hydrothermal reaction at a temperature of 170°C for 4 days. The obtained reaction product is vacuum filtered and washed with deionized water until it is washed. The pH value of the liquid is equal to 8, dried at a temperature of 120°C for more than 12 hours, and finally heated to 550°C at a heating rate of 5°C / min and calcined for 6 hours to obtain 4.0 g of nano-flake cluster mordenite molecular sieves; (see attached image 3 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com