Oxygen reduction reaction catalyst and preparation method thereof

A catalyst and reaction technology, applied in the field of electrochemistry, can solve the problems of complex reduction process and cumbersome synthesis steps, and achieve the effect of enhancing oxygen reduction activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 10mL 0.05mol / L ethanol solution of phenanthroline to 5mL 0.05mol / L K 2 PtCl 4 The aqueous solution was mixed evenly, and the resulting mixed solution was heated and stirred in a water bath at 80°C for 1 hour to make the Pt 2+ Fully complex with o-phenanthroline to form o-phenanthroline-Pt(II) complex precipitation, then use a 1:1 ratio of hydrated ethanol mixture for centrifugation and washing 4 times, then pour it into a magnetic boat and dry it in a 60°C oven ; Finally, put the magnetic boat into a tube furnace, calcinate at 200° C. for 2 hours under hydrogen, centrifuge, wash, and dry in vacuum to obtain the product.

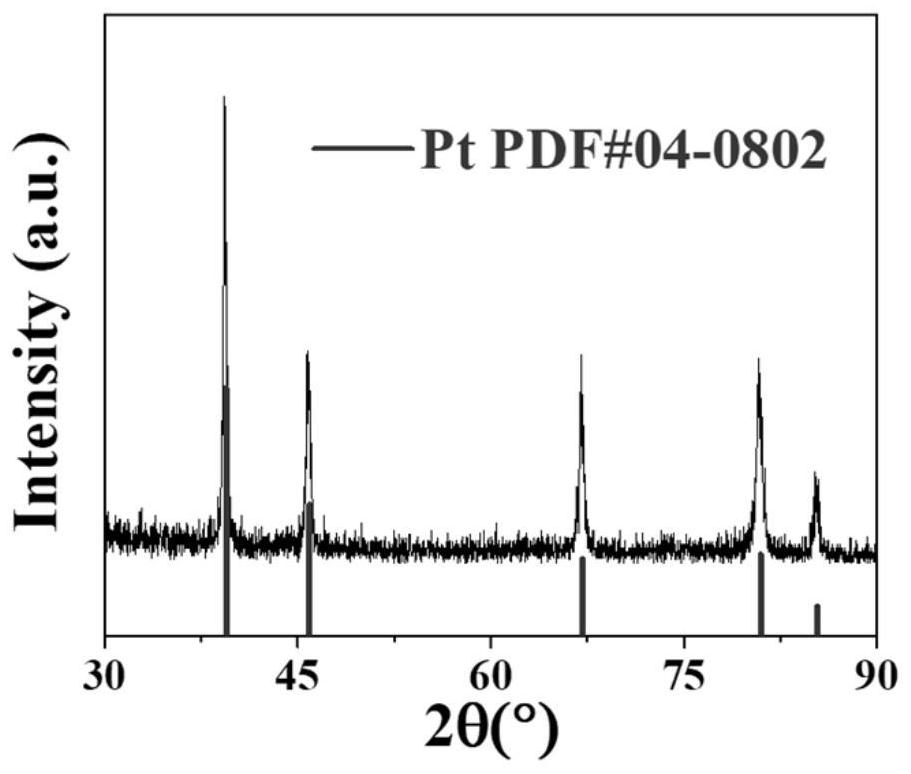

[0026] Depend on figure 1 It can be seen that the obtained product is Pt.

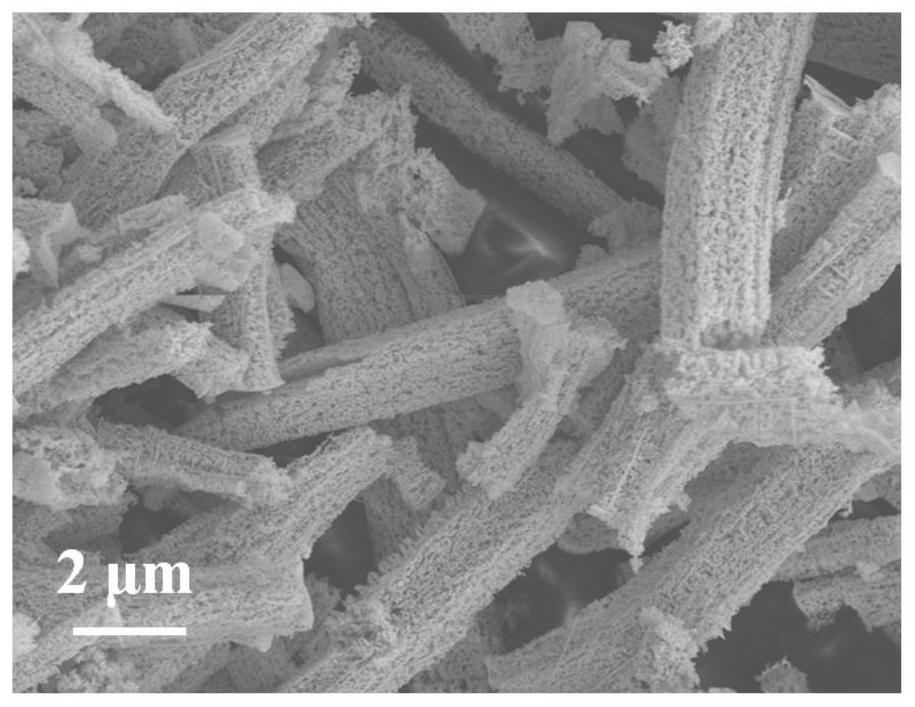

[0027] Depend on figure 2 It can be seen that the obtained product is a one-dimensional rod-like structure.

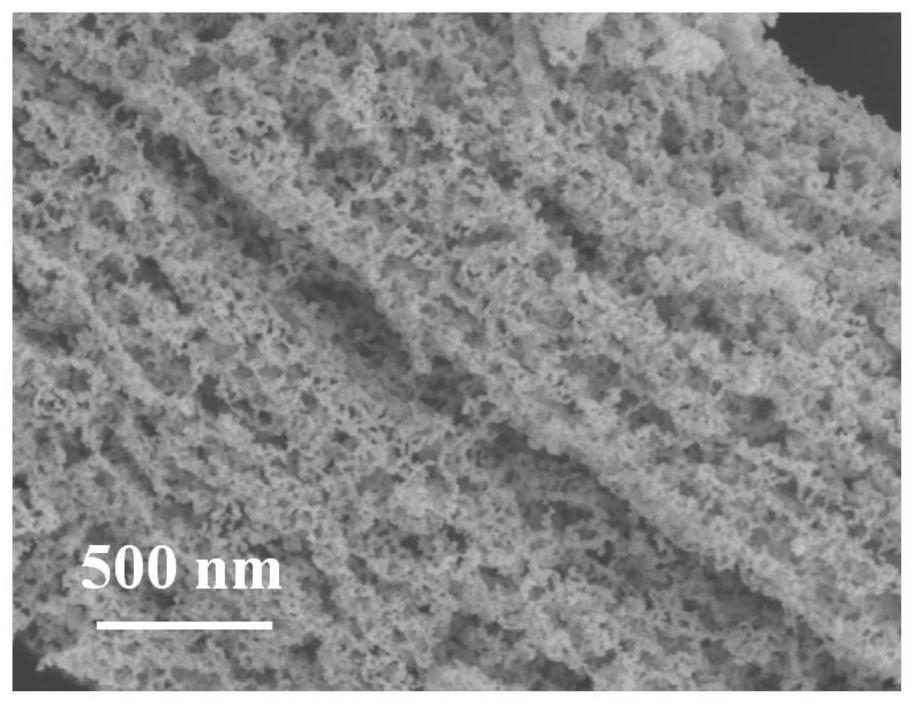

[0028] pass image 3 After observation, it can be seen that the surface of Pt nanorods is rough and has many holes.

[0029] The porous Pt nanorods prepared...

Embodiment 2

[0032] Pour 30mL of 0.05mol / L ethanol solution of phenanthroline into 15mL of 0.05mol / L K 2 PtCl 4 The aqueous solution was mixed evenly, and the resulting mixed solution was heated and stirred in a water bath at 80°C for 1 hour to make the Pt 2+ Fully complex with o-phenanthroline to form o-phenanthroline-Pt(II) complex precipitation, then use a 1:1 ratio of hydrated ethanol mixture for centrifugation and washing 4 times, then pour it into a magnetic boat and dry it in a 60°C oven ; Finally, the magnetic boat was put into a tube furnace, calcined at 200° C. for 2 hours under hydrogen conditions, centrifuged, washed, and vacuum-dried to obtain the product porous Pt nanorods, see Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com