Nitrogen-doped porous nano biochar, preparation method and application thereof

A nitrogen-doped and biochar technology is applied in the field of agricultural and forestry waste resource utilization and environmental treatment, which can solve problems such as pollution, waste of resources and the environment, and achieve the effects of cumbersome operation process, high preparation cost, and abundant active centers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for synthesizing nitrogen-doped porous nano-biochar of the present invention comprises the following steps:

[0038] The discarded apple leaves collected in the farmland are cleaned, dried and ground into powder. Then, the leaf powder and NaOH are mixed evenly in a ratio of 1:3 by mass and spread in a porcelain boat. 2 Under the protection of the atmosphere, it was heated to 400 °C for 2 hours in a muffle furnace at a rate of 3 to 5 °C / min to make it fully carbonized, and then heated to 500 to 700 °C at the same heating rate for 2 to 3 hours. The sample reacts with NaOH at high temperature. At this stage, NaOH can be used as an activator to increase the porosity and specific surface area of biochar. When the temperature of the muffle furnace drops to room temperature, the black reactants after sintering are collected, and then 1 mol / The nitrogen-doped porous nano-biochar was obtained by washing the black samples after washing with 1 L of HCl solution twice,...

example 1

[0041] 1), will be as figure 1 The discarded apple leaves shown were collected, washed with deionized water, dried in an oven at 80° C. for 24 h, and then ground into powder with a mortar.

[0042] 2), then mix 1g of leaf powder with 3g of NaOH and spread it in the porcelain boat. 2 Under the protection of the atmosphere, in a muffle furnace at a heating rate of 5 °C / min, heat to 400 °C for 2 h.

[0043] 3), then heat up to 500°C at a heating rate of 5°C / min, and keep the temperature for 3h. When the temperature of the muffle furnace drops to room temperature, collect the black reactants after sintering, then wash with 1 mol / L HCl twice, and then wash twice with deionized water, collect the black samples after cleaning, and dry them at 80 °C spare.

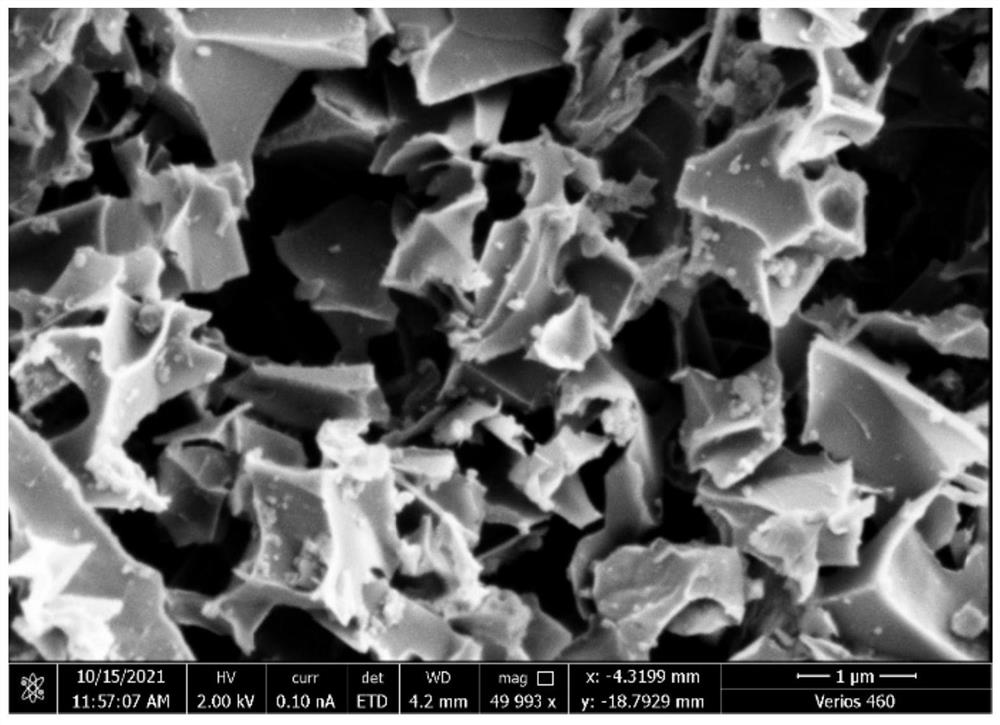

[0044] 4), figure 2 It can be seen that the SEM photograph of BC-500 °C shows that it is a 3D porous sheet-like structure with a sheet thickness of about 45 nm. Figure 5 It can be seen that C at BC-500°C 1s The XPS spectr...

example 2

[0046] 1), will be as figure 1 The discarded apple leaves shown were collected, washed with deionized water, dried in an oven at 80° C. for 24 h, and then ground into powder with a mortar.

[0047] 2), mix 1g leaf powder and 3g NaOH evenly and spread in the porcelain boat, in N 2 Under the protection of the atmosphere, in a muffle furnace at a heating rate of 5 °C / min, heat to 400 °C for 2 h.

[0048] 3), then heat up to 600°C at a heating rate of 5°C / min, and keep the temperature for 3h. When the temperature of the muffle furnace drops to room temperature, collect the black reactants after sintering, then wash with 1 mol / L HCl twice, and then wash twice with deionized water, collect the black samples after cleaning, and dry them at 80 °C spare.

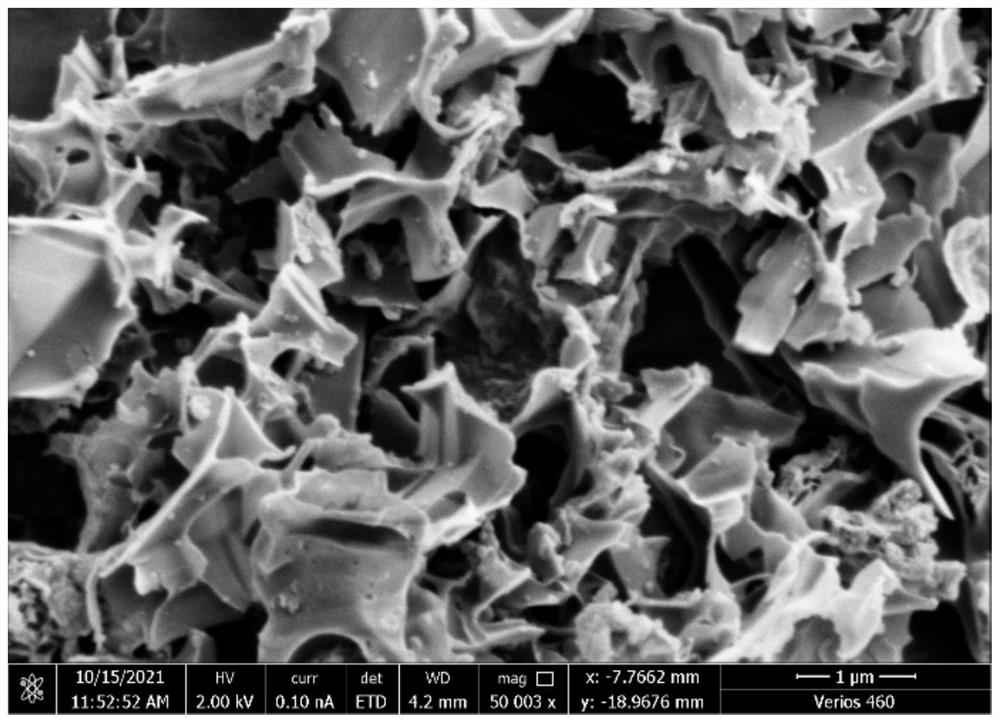

[0049] 4), image 3 It can be seen that the SEM image of BC-600 °C shows that it is a 3D porous sheet-like structure with a sheet thickness of about 30 nm. Figure 5 It can be seen that C at BC-600°C 1s The XPS spectrum is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com