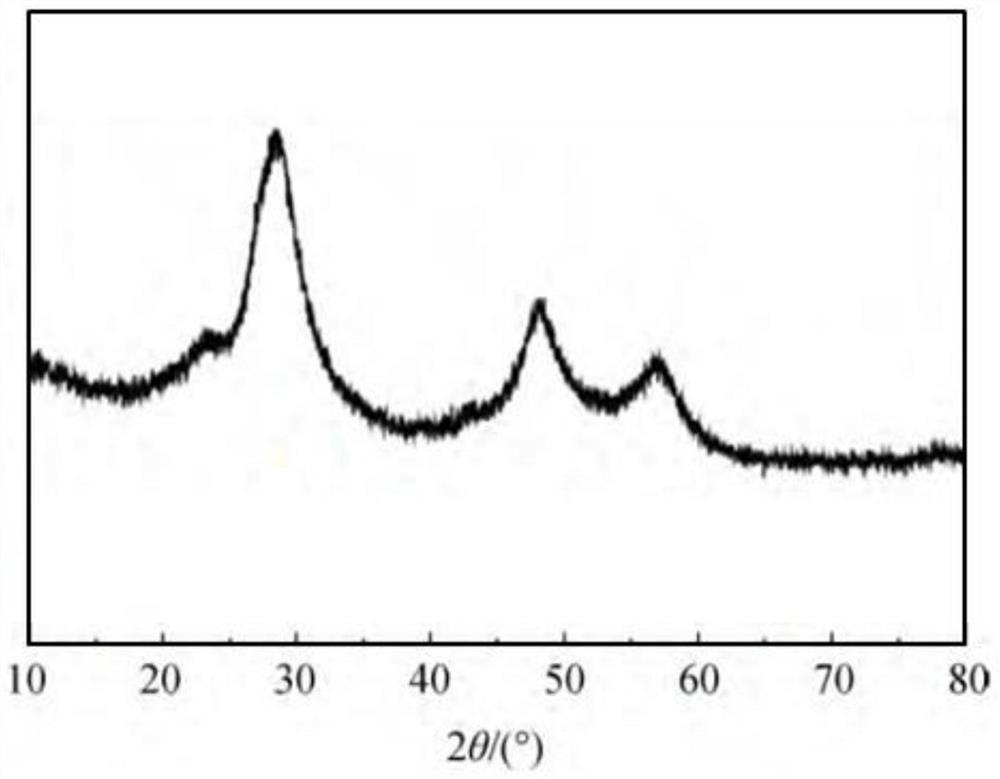

A kind of preparation method and application of nitrogen-doped nano-zns/graphene photocatalytic material

A photocatalytic material and graphene technology, which is applied in the field of photocatalytic degradation of organic pollutants, can solve problems such as improving photocatalytic efficiency, and achieve the effects of improving electron conduction efficiency, improving visible light photocatalytic activity, and reducing band gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Disperse 0.3g of graphene oxide in a mixed solution of 30ml of deionized water and ethanol, and ultrasonically disperse for 30 minutes to obtain a uniformly dispersed graphene oxide dispersion;

[0030] (2) Dissolve an appropriate amount of zinc nitrate in deionized water, stir and dissolve to obtain a 0.3mol / L zinc salt solution;

[0031] (3) Dissolve an appropriate amount of 2-methylimidazole in deionized water, stir and dissolve to obtain a 1mol / L 2-methylimidazole solution;

[0032] (4) Mix the solutions obtained in the above steps (1), (2) and (3). The molar ratio of zinc salt to 2-methylimidazole in the resulting mixture is 1:3. Magnetic stirring was performed for 6 hours, and the resulting product was centrifuged, washed with deionized water and ethanol several times, and dried to obtain the ZIF-8@graphene oxide composite;

[0033] (5) Put the ZIF-8@graphene oxide compound prepared above into the high temperature zone of the dual temperature zone tube furnac...

Embodiment 2

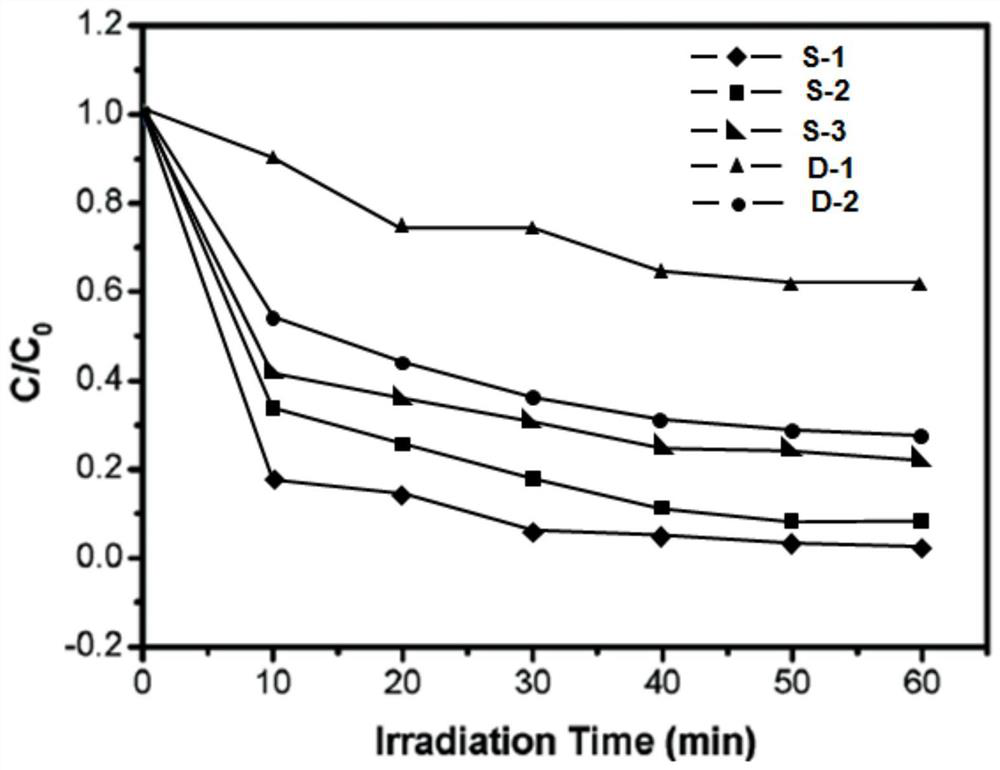

[0035] The addition of graphene oxide was adjusted so that the mass ratio of ZnS and graphene in the finally obtained photocatalytic material was 1:1, other conditions were the same as in Example 1, and the obtained photocatalytic material was designated as numbering S-2.

Embodiment 3

[0037] The addition of graphene oxide was adjusted so that the mass ratio of ZnS and graphene in the finally obtained photocatalytic material was 1:3, and other conditions were the same as in Example 1, and the resulting photocatalytic material was designated as numbering S-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com