Method for preparing thin-layer graphene/transition metal fluoride composite positive electrode active material by using antibiotic bacteria residue

A technology of antibiotic slag and thin-layer graphene, which is applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of low conductivity and poor cycle stability of transition metal fluorides, and achieve rapid charge transmission , Improve electrical conductivity, realize the effect of energy utilization and high-value utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Using oxytetracycline slag as the carbon precursor, take 30g of dry antibiotic slag raw material, first disperse it into 120mL of 20wt.% HF acid solution, stir for 4h, and then add it to 120mL of 18wt.% HCl acid solution after suction filtration solution, stirred for 4h, suction filtered and washed (referring to water washing, the washing of the acid treatment process in the following cases all refers to water washing) and then dried after neutralization to obtain dry bacterial residue (pretreated bacterial residue).

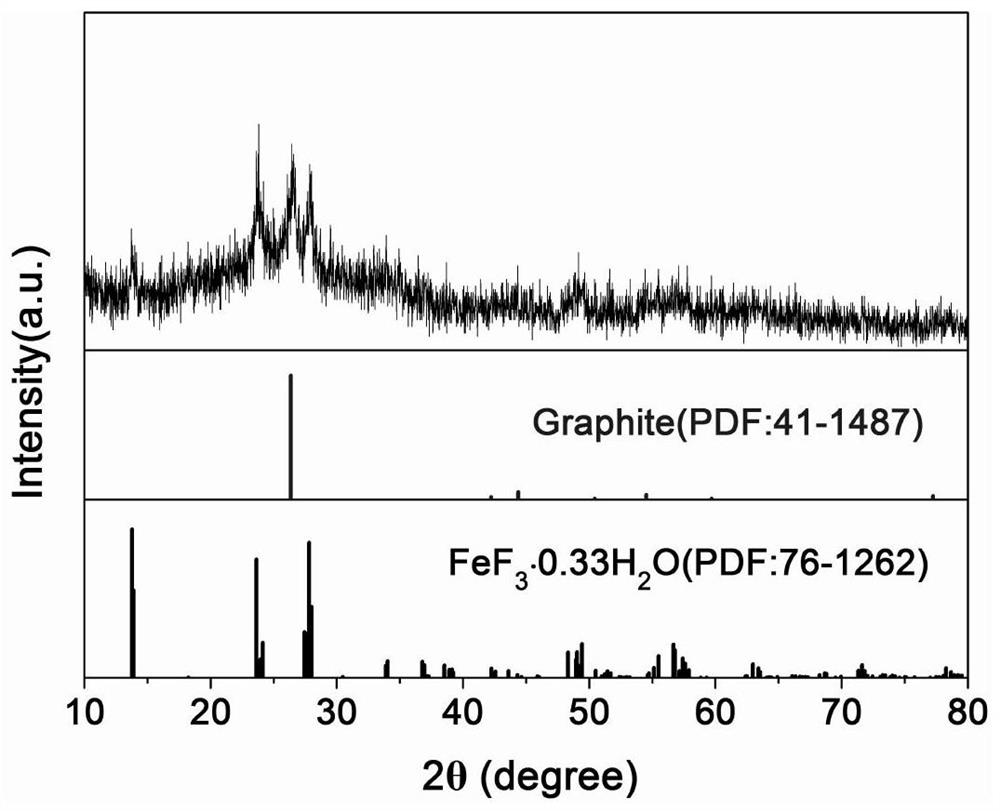

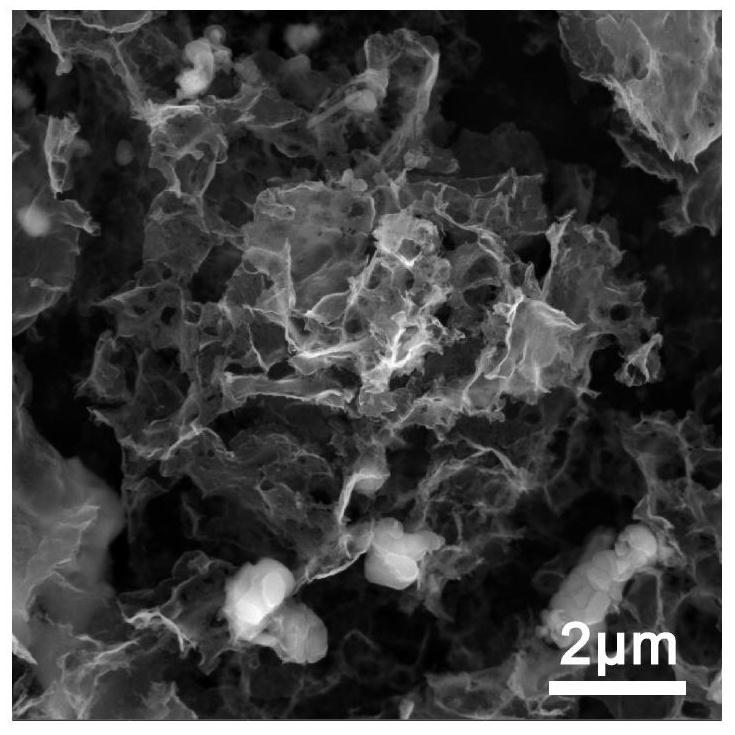

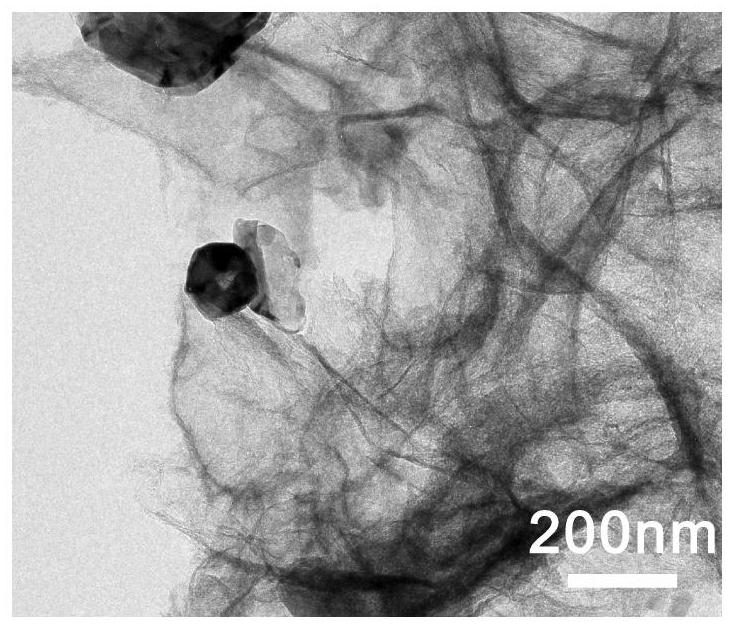

[0081] Take 2g of dried fungal residue powder (pretreated fungal residue), add it to 20mL water, stir for 5min, add 3g of NaOH, and heat it at 200°C for 12h. Carry out solid-liquid separation to the hydrothermal system, obtain the solution part (bacteria residue liquid), add 2gFe(NO 3 ) 3 .9H 2 O, after stirring for 10 minutes, stir and evaporate to dryness at 100°C, place in a tube furnace filled with argon, first calcinate at 500°C for 2h, continue to...

Embodiment 2

[0085] Compared with Example 1, the difference mainly lies in the amount of iron salt in the alkali of the control liquefaction process and the heat treatment process, specifically:

[0086] Using oxytetracycline slag as the carbon precursor, take 30g of dry antibiotic slag raw material, first disperse it into 120mL of 20wt.% HF acid solution, stir for 4h, and then add it to 120mL of 18wt.% HCl acid solution after suction filtration solution, stirred for 4 hours, filtered with suction, washed neutral and then dried to obtain dry scum (pretreated scum).

[0087] Take 2g of dried fungus residue powder (pretreated fungus residue), add it to 20mL water, stir for 5min, add 1g of NaOH, and heat it at 200°C for 12h. Add 1gFe(NO 3 ) 3 .9H 2 O, after stirring for 10 minutes, stir and evaporate to dryness at 100°C, place in a tube furnace filled with argon, first calcinate at 500°C for 2h, continue to heat up to 800°C for 2h (heating rate is 5°C / min), cool to room temperature and tak...

Embodiment 3

[0090] Compared with Example 1, the difference mainly lies in the amount of iron salt in the alkali of the control liquefaction process and the heat treatment process, specifically:

[0091] Using oxytetracycline slag as the carbon precursor, take 30g of dry antibiotic slag raw material, first disperse it into 120mL of 20wt.% HF acid solution, stir for 4h, and then add it to 120mL of 18wt.% HCl acid solution after suction filtration In the solution, stir for 4 hours, filter with suction and wash neutral, then dry with suction to obtain dry bacteria residue (pretreated bacteria residue). Take 2g of dried fungus residue powder (pretreated fungus residue), add it to 20mL water, stir for 5min, add 4g of NaOH, and heat at 200°C for 12h. Add 6gFe(NO 3 ) 3 .9H 2 O, after stirring for 10 minutes, stir and evaporate to dryness at 100°C, place in a tube furnace filled with argon, first calcinate at 500°C for 2h, continue to heat up to 800°C for 2h (heating rate is 5°C / min), cool to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com