An alkali-modified alumina material having a high specific surface area, a preparing method thereof and applications of the material

A technology with high specific surface area and specific surface area, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc. High specific surface area, stable structure and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

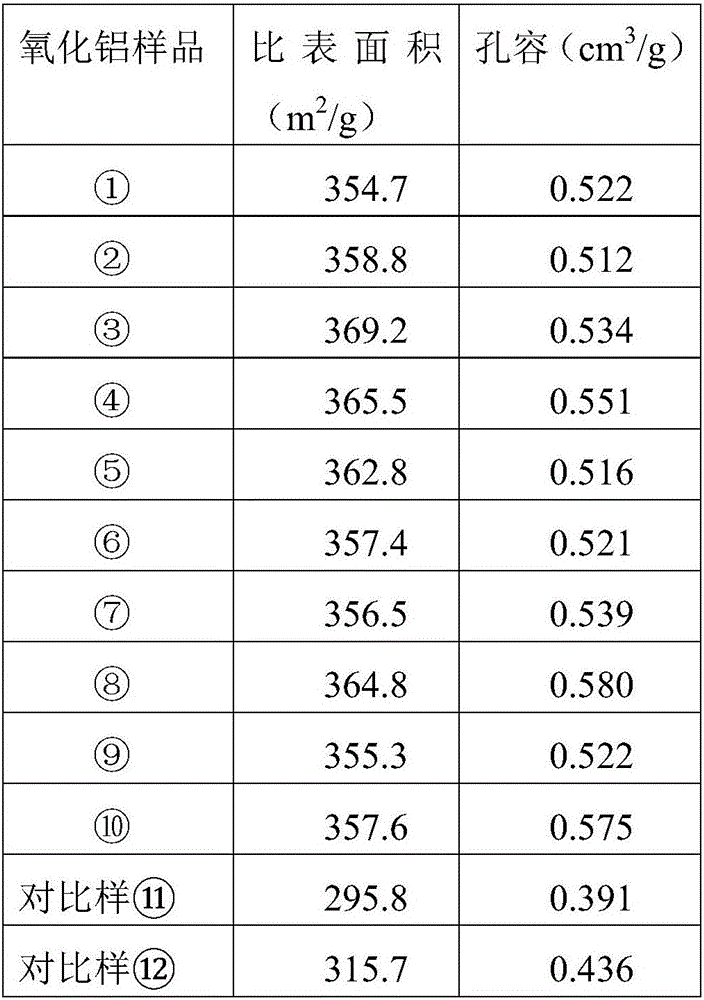

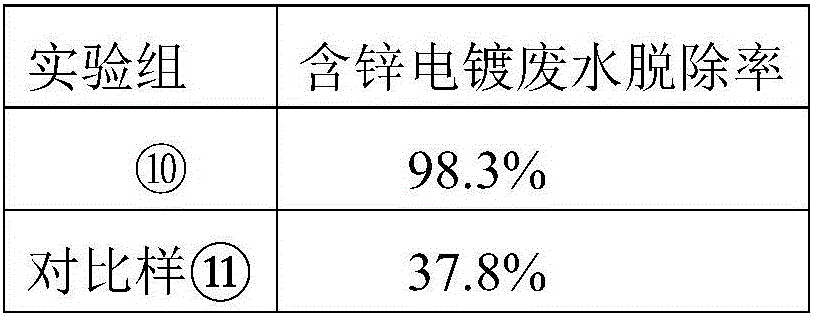

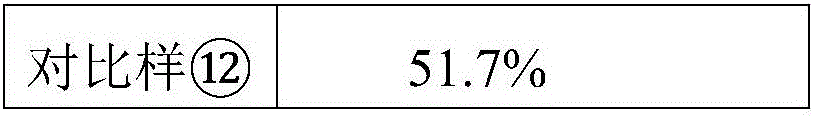

Examples

Embodiment 1

[0030] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to 90:10 mass percentage, and mix them evenly; configure 2% EDTA aqueous solution, use sodium hydroxide to adjust the pH value of the aqueous solution to 11, so that EDTA is completely dissolved ; Spray the prepared aqueous solution into the uniformly mixed powder, and granulate through discs to obtain 2.0-3.0mm granule moldings. Introduce water vapor at 105°C, keep for 1 hour, dry at 80°C, and roast at 350°C to prepare alumina material ①.

Embodiment 2

[0032] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to 40:60 mass percentage, and mix them evenly; configure 5% EDTA disodium aqueous solution, use sodium carbonate to adjust the pH value of the aqueous solution to 9, and make EDTA di The sodium is completely dissolved; the prepared aqueous solution is sprayed into the uniformly mixed powder, and granulated by a drum to obtain a granule shaped product of 4.0-6.0 mm. Introduce water vapor at 125°C, keep for 5 hours, dry at 150°C, and roast at 600°C to prepare alumina material②.

Embodiment 3

[0034] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to the mass percentage of 50:50, and mix them evenly; configure 20% tetrasodium EDTA aqueous solution, use sodium bicarbonate to adjust the pH value of the aqueous solution to 9, and make EDTA The tetrasodium is completely dissolved; the prepared aqueous solution is sprayed into the uniformly mixed powder, and granulated by a sugar coating machine to obtain 3.0-5.0mm granule moldings. Introduce water vapor at 110°C, keep for 5 hours, dry at 110°C, and bake at 400°C to prepare the alumina material③.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com