Novel delay element

A technology of delaying medicine and delaying body, which is applied in the directions of weapon accessories, fuzes, timing fuzes, etc., can solve the problems of polluting the environment, increasing production costs, and cumbersome manufacturing process of lead core delaying body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

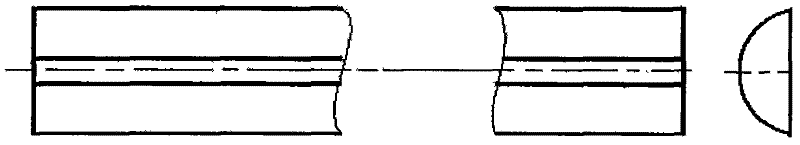

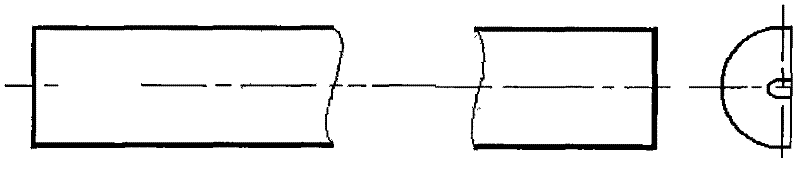

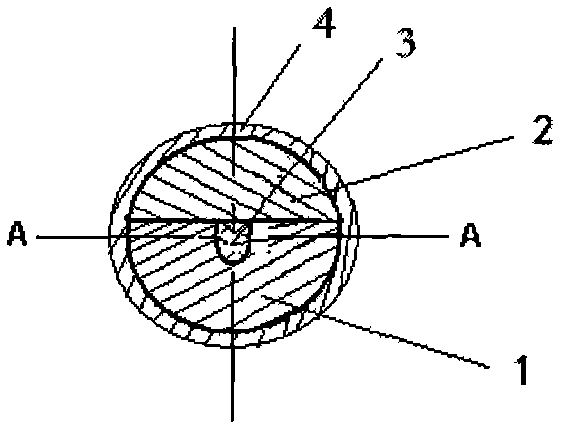

[0019] Make plastic strip 1 with groove and plastic strip 2 without groove with plastic extruder, each length is 2m, φ5.0mm-5.5mm. Determine the composition and ratio of the delay medicine according to the delay period, weigh the oxidant and combustion agent, and mix them evenly. Dissolve nitrocellulose with acetone, the mass ratio is nitrocellulose: acetone = 10:90, and make nitrocellulose glue. Add the glue solution to the delay medicine, mix well, and form a paste. Smear the delay medicine into the groove along the grooved plane with a scraper, and scrape off the delay medicine on the outer surface of the groove until all the grooves on the plastic stick are filled with the delay ointment. Let dry in a slotted plastic stick ( figure 1 ) plane with glue, put the plastic rod without groove ( figure 2 ) glued together to form a round rod ( image 3 ). Wrap the plastic stick with self-adhesive tape 4 ( image 3 ), Serve.

[0020] Cut 10mm and make by the extension body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com