Continuous asynchronous rolling device of magnesium alloy sheet strip coil

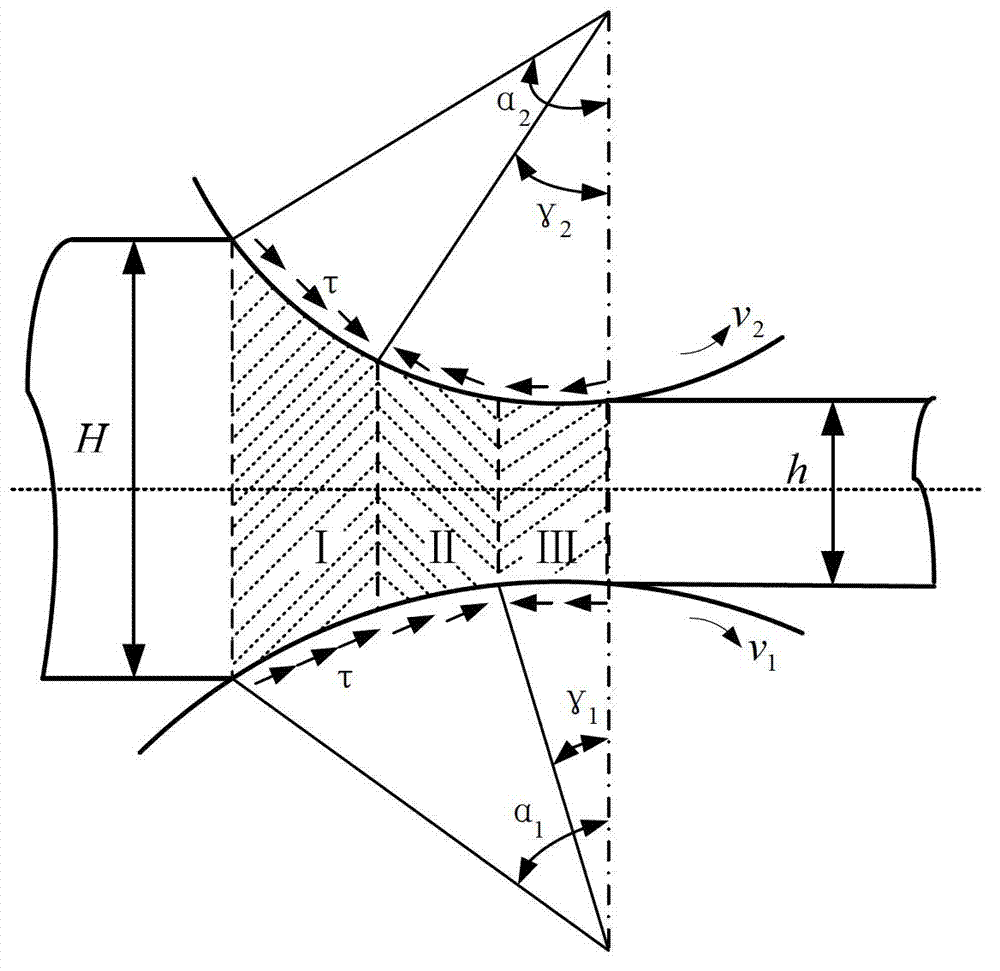

A kind of asynchronous rolling, thin strip technology, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as poor plastic deformation ability, fracture, etc., to reduce rolling pressure, reduce rolling passes, reduce Effect of rolling pressure and rolling torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

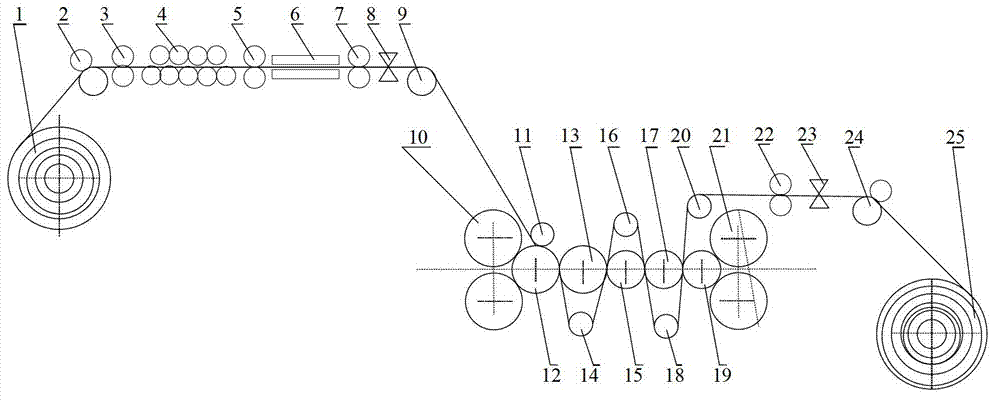

[0030] After the magnesium alloy coil to be rolled is confirmed, it is placed on the uncoiler 1 for threading, the strap of the strip is opened, and the uncoiler is started to pass the first deflection pinch roller 2 and the first tension pinch roller 3. Send the strip to the straightening machine 4 for straightening, pass through the second tension pinch roller 5, and enter the online heating device 6, and the heated strip pass through the third tension pinch roller 7, and enter the first thickness gauge 8 to measure the thickness of the incoming material. After passing through the first guide roll 9 and the second guide roll 11, the coil enters the first work roll 12 and the second work roll 13 for asynchronous rolling, and passes through the second guide roll 14 to enter the second The second work roll 13 and the third work roll 15 carry out asynchronous rolling, pass through the third guide roll 16, enter the third work roll 15 and the fourth work roll 17 for asynchronous r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com