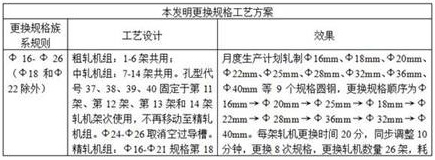

Process method for rapid replacement of round steel rolling specifications based on double bar production line

A round steel rolling and production line technology, which is applied in the field of quick replacement of round steel rolling specifications, can solve problems such as large temperature drop of rolled pieces, and achieve the effects of reduced production costs, reduced failure rate of steel stacking process, and compact rolling connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Production specification: Ф25 round steel

[0036] Steel grade: Q235B

[0037] Rolling mills used: stands 1 to 14

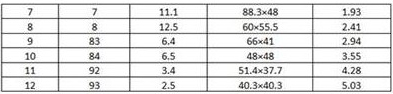

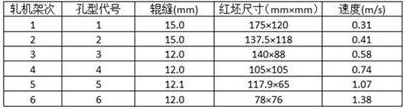

[0038] Table 4 Ф25mm round bar rolling schedule

[0039]

[0040] Production furnace number: 2013680, 2013683, 2013684, 2013685, 2013687

[0041] Heating in a 160 billet heating furnace to a rolling start temperature of 1000°C-1020°C, rolling into the 1st to 6th stands of the rough rolling mill, and entering the 7th to 14th stands of the middle rolling mill for rolling after the 1# pendulum shear head. The rolling operation of the rough rolling and intermediate rolling mills was stable, and there was no fluctuation in rolling tension and shaking of the rolled piece; the finished product was produced from the 14th stand, and the diameter and out-of-roundness of the round steel were measured by the caliper gauge, and the 3# combined shearing and shearing was carried out. Cut into 10 double-length pieces, put the double-length pieces on the cooling bed ...

Embodiment 2

[0043] Production specification: Ф30 round steel

[0044] Steel grade: 45

[0045] Rolling mills used: stands 1 to 14

[0046] Table 5 Ф30mm round bar rolling schedule

[0047]

[0048] Production furnace number: 2904208, 1903509, 1903509, 1903503, 1903503

[0049] Heating in a 160 billet heating furnace to the starting rolling temperature of 1040°C-1060°C, rolling into the 1st to 6th stands of the rough rolling mill, and entering the 7th to 14th stands of the middle rolling mill for rolling after the 1# pendulum shear head. The rolling operation of the rough rolling and intermediate rolling mills was stable, and there was no fluctuation in rolling tension and shaking of the rolled piece; the finished product was produced from the 14th stand, and the diameter and out-of-roundness of the round steel were measured by the caliper gauge, and the 3# combined shearing and shearing was carried out. Cut into 6 double-length pieces, put the double-length pieces on the cooling bed...

Embodiment 3

[0051] Production specification: Ф40 round steel

[0052] Steel grade: Q345B

[0053] Rolling mills used: racks 1 to 12

[0054] Table 6 Ф40mm round bar rolling schedule

[0055]

[0056]

[0057] Production furnace number: 3905344, 2904533, 3905341

[0058] Heating in a 160 billet heating furnace to a rolling start temperature of 1050°C-1070°C, rolling into the 1st to 6th stands of the rough rolling mill, and entering the 7th to 12th stands of the middle rolling mill for rolling after the 1# pendulum shear head. The rolling operation of the steel in the rough rolling and intermediate rolling units was stable, and there was no rolling tension fluctuation and rolled piece shaking; the finished product was produced from the 12th stand, and the diameter and out-of-roundness of the round steel were measured by the caliper gauge, and the 3# combined shearing and shearing Cut into 4 double lengths, the double lengths are placed on the cooling bed for natural cooling, the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com