Patents

Literature

46results about How to "Difference in thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

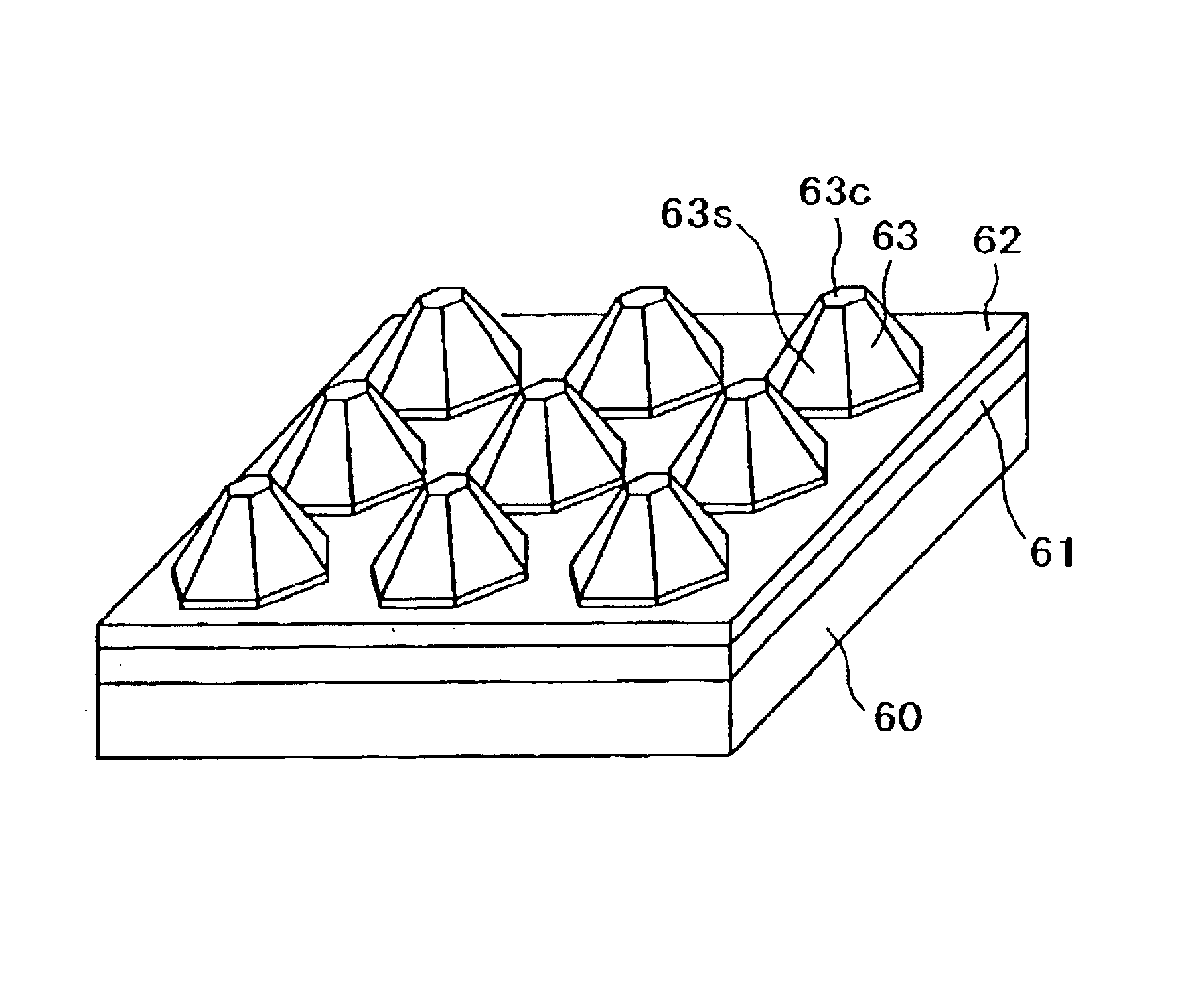

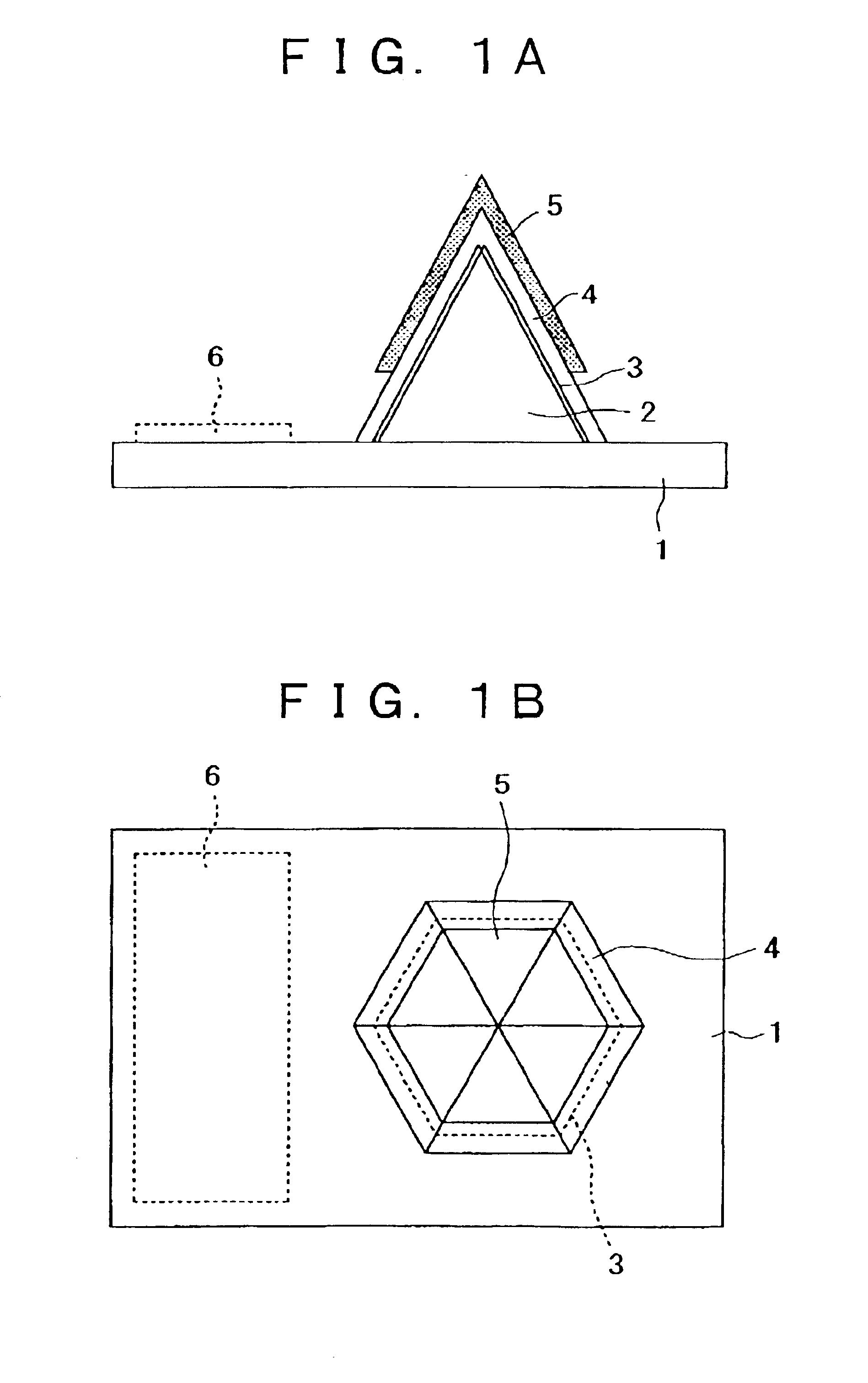

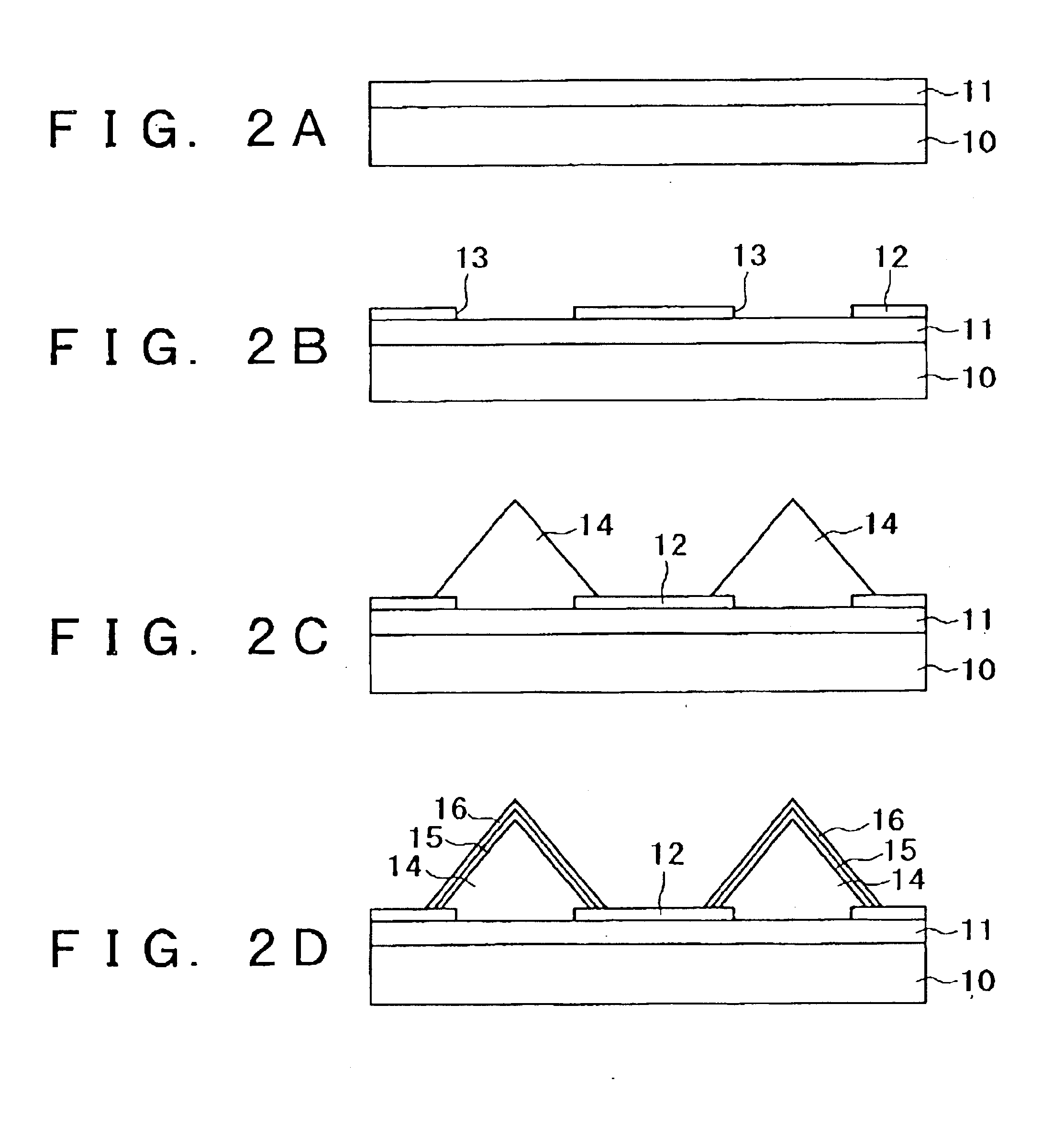

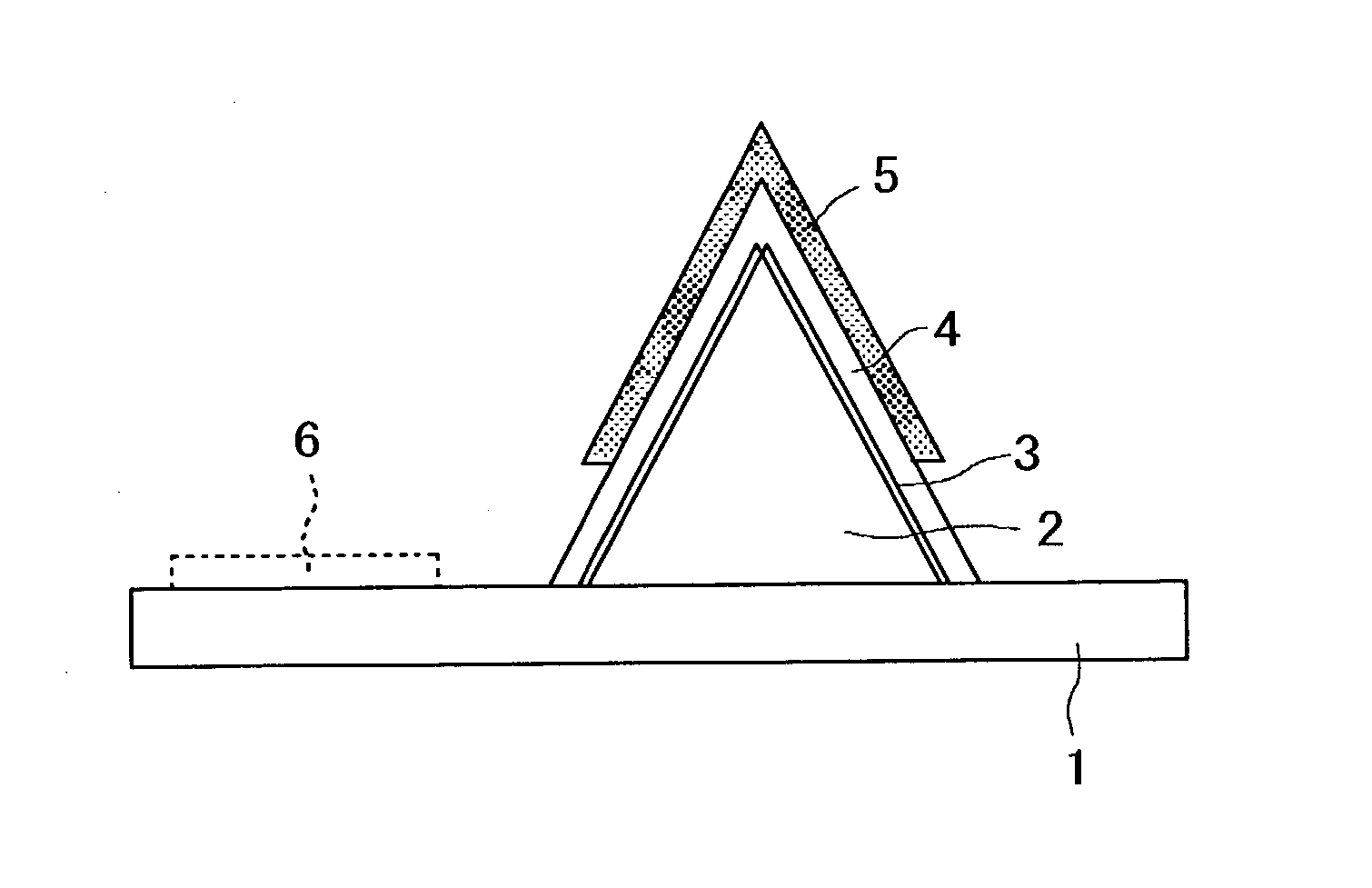

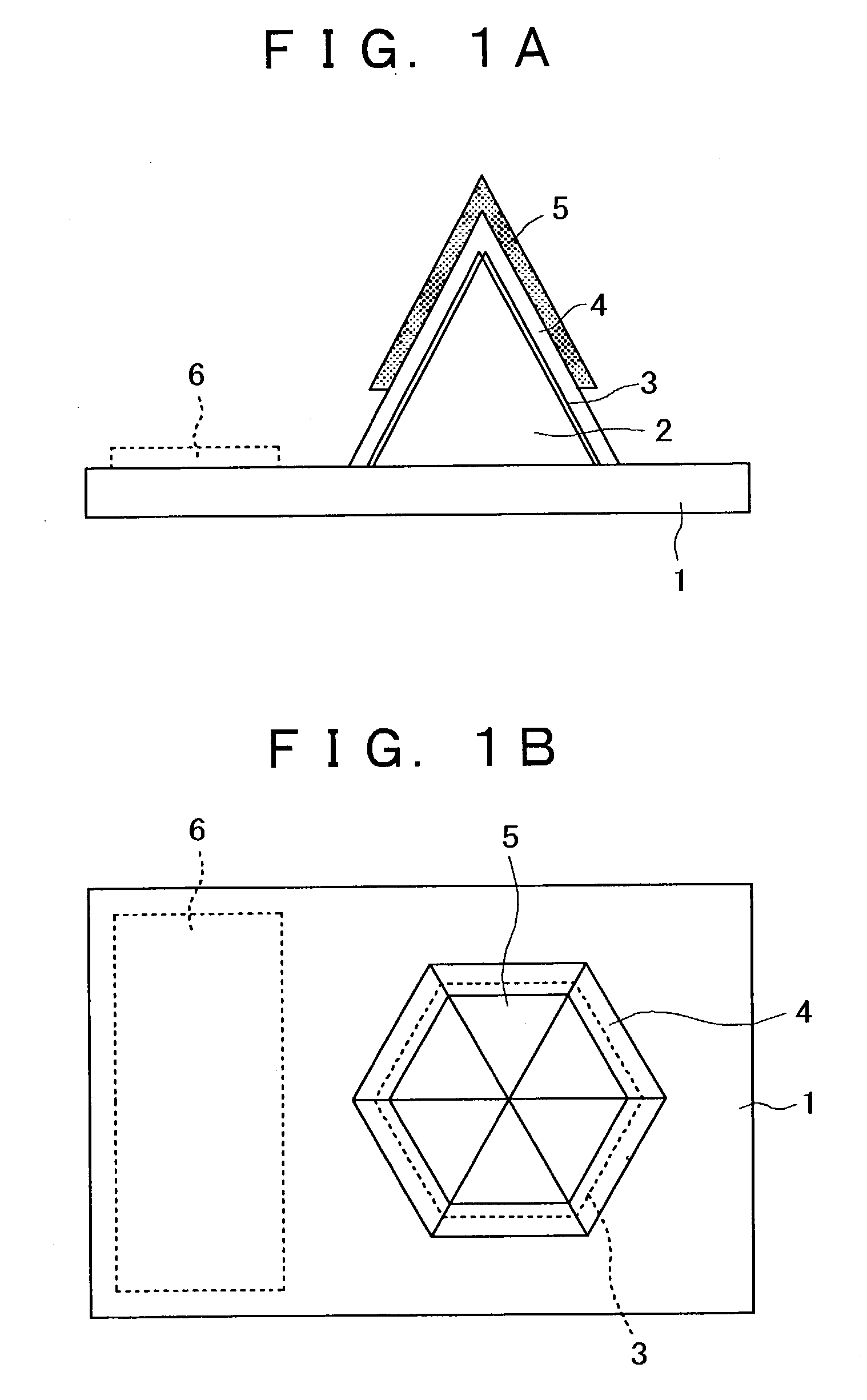

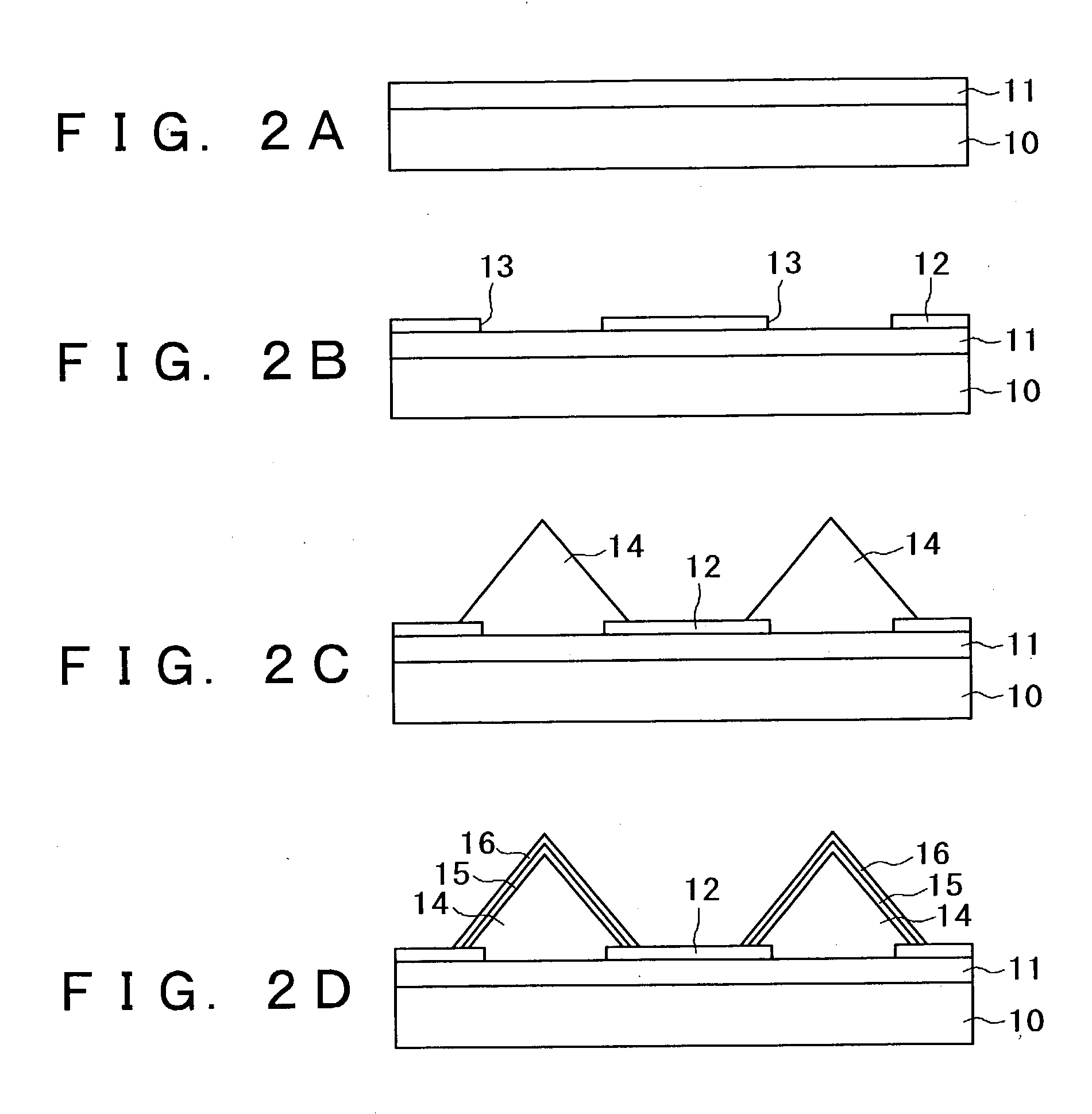

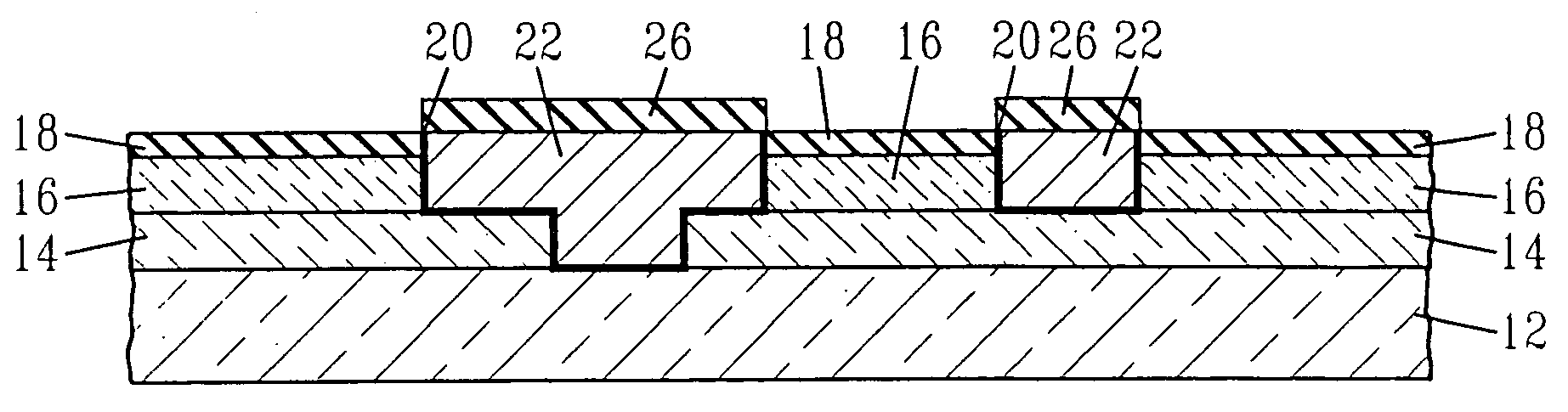

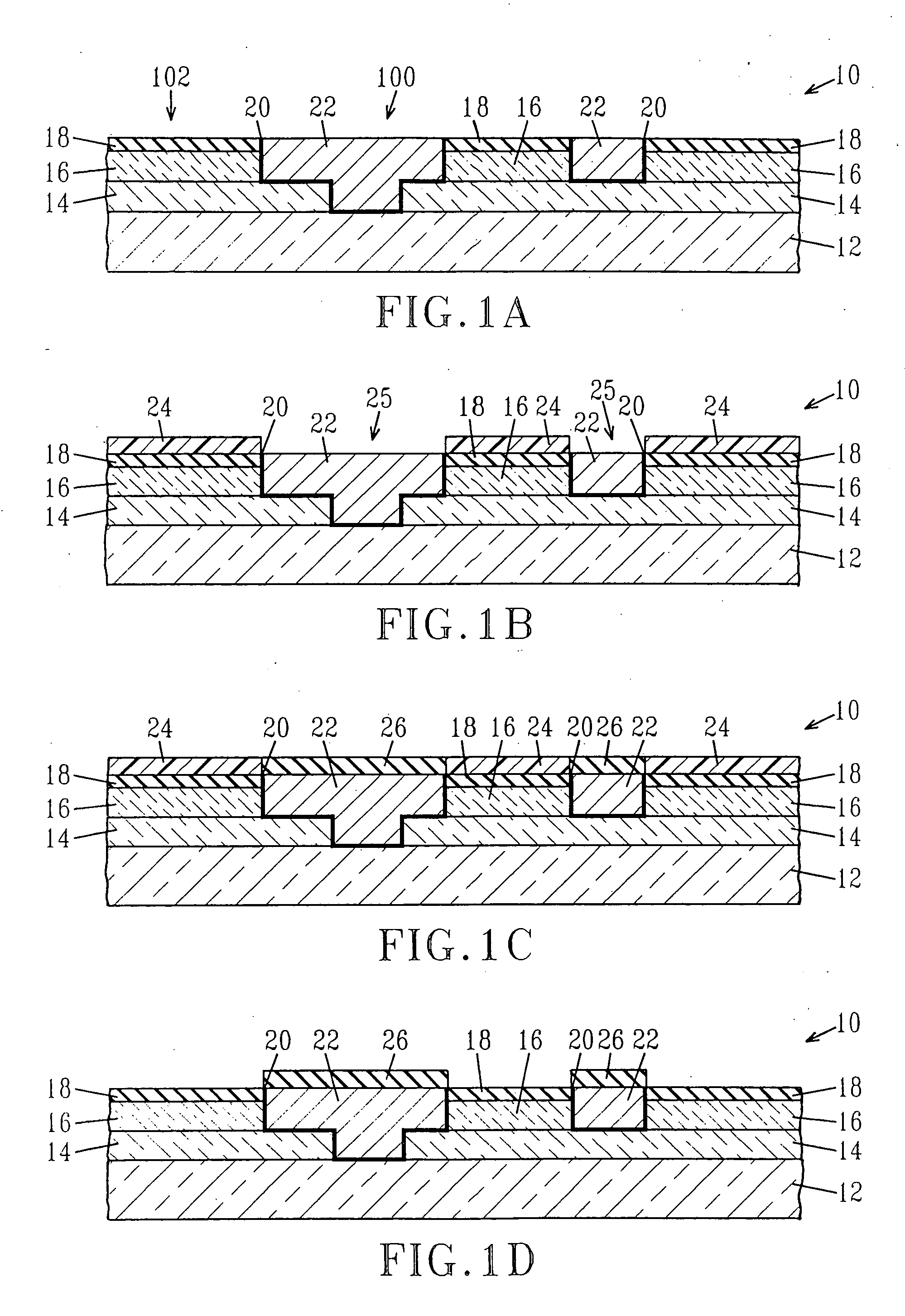

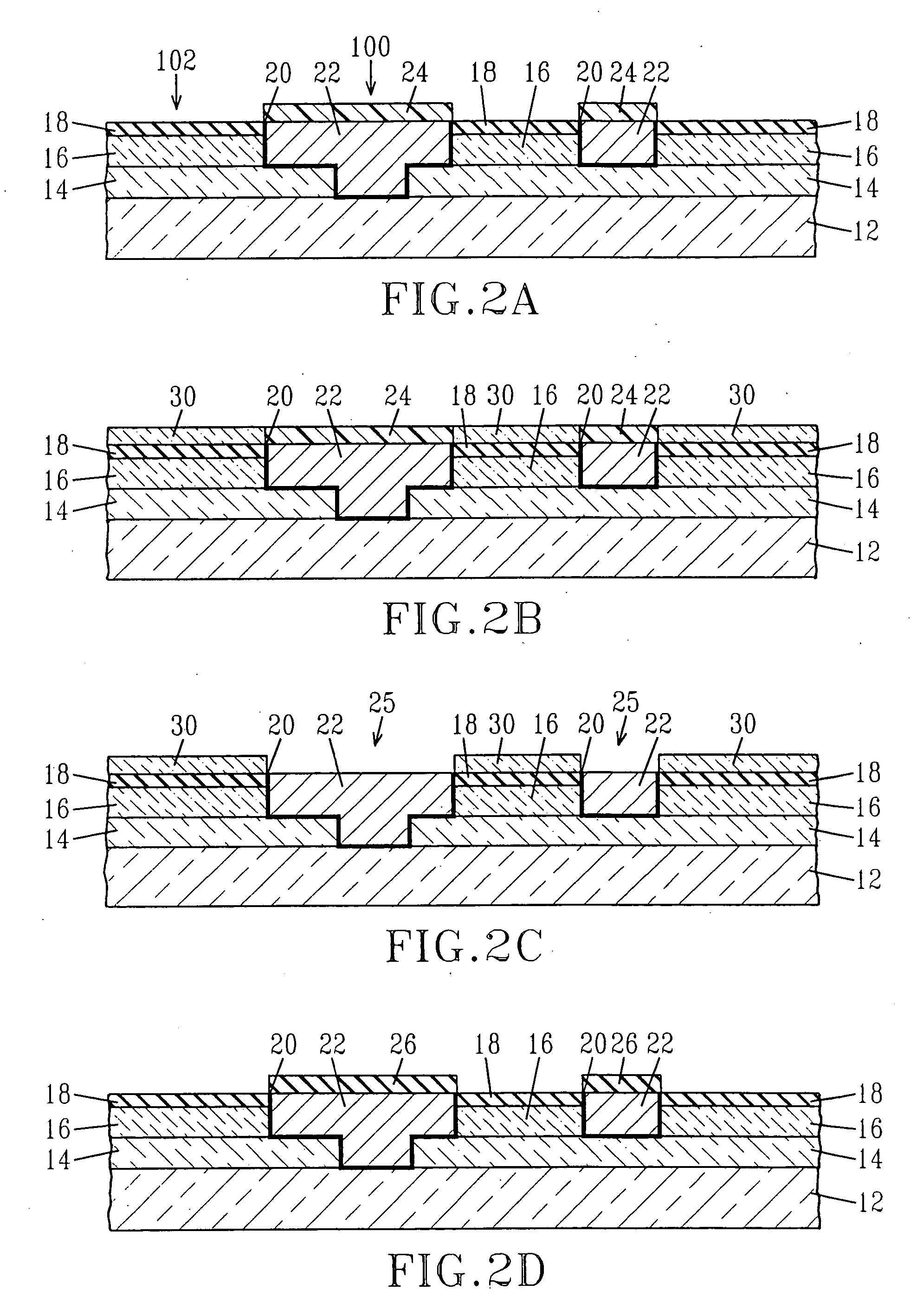

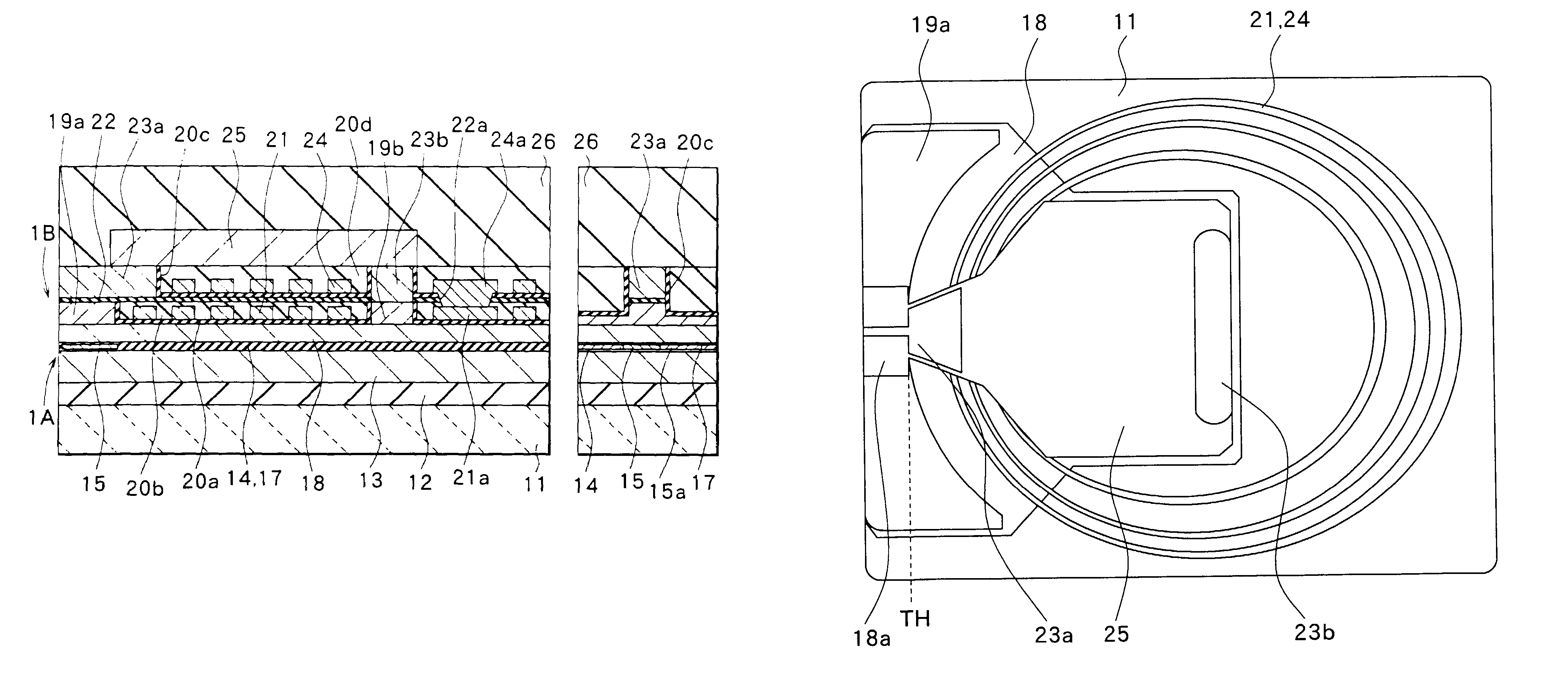

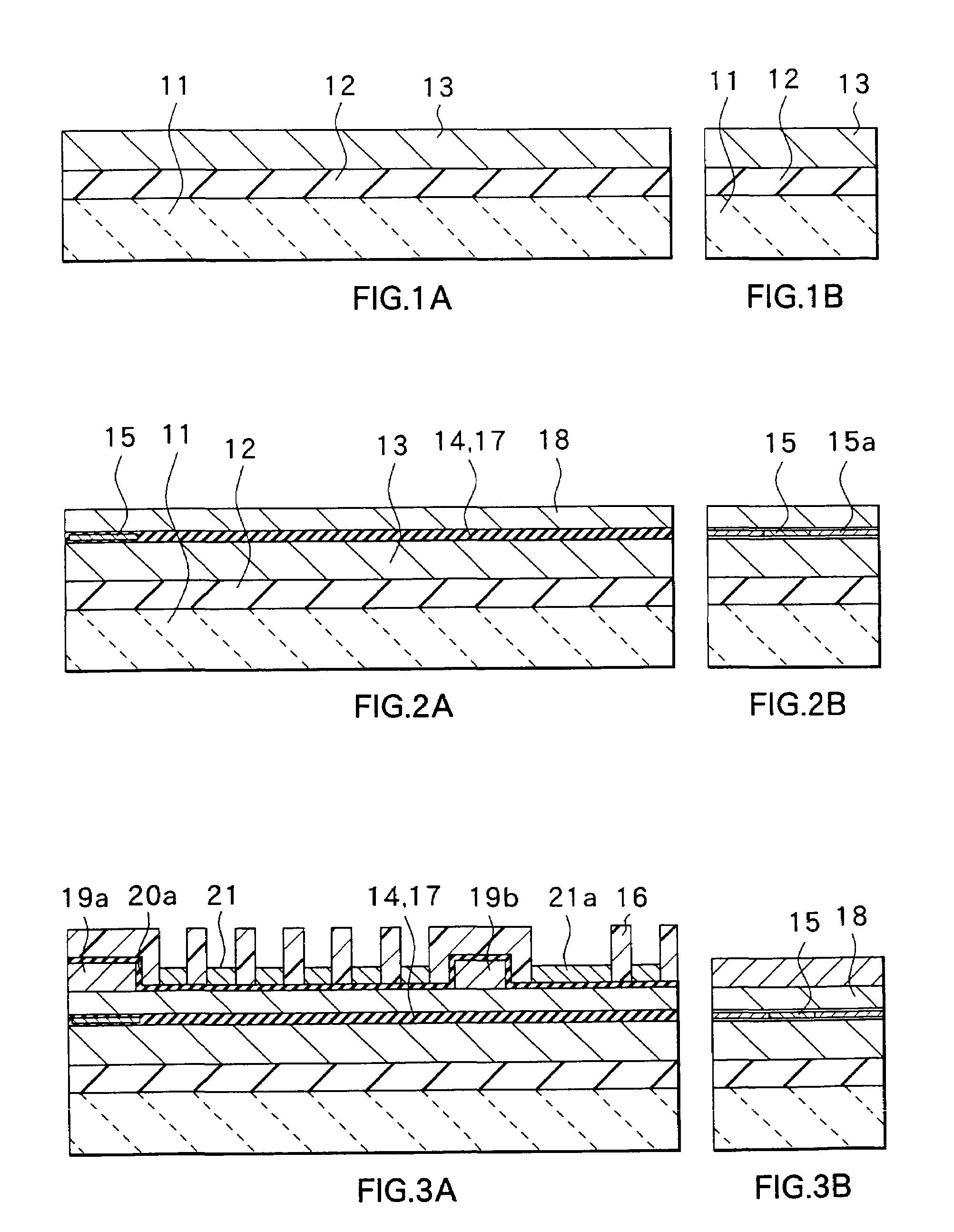

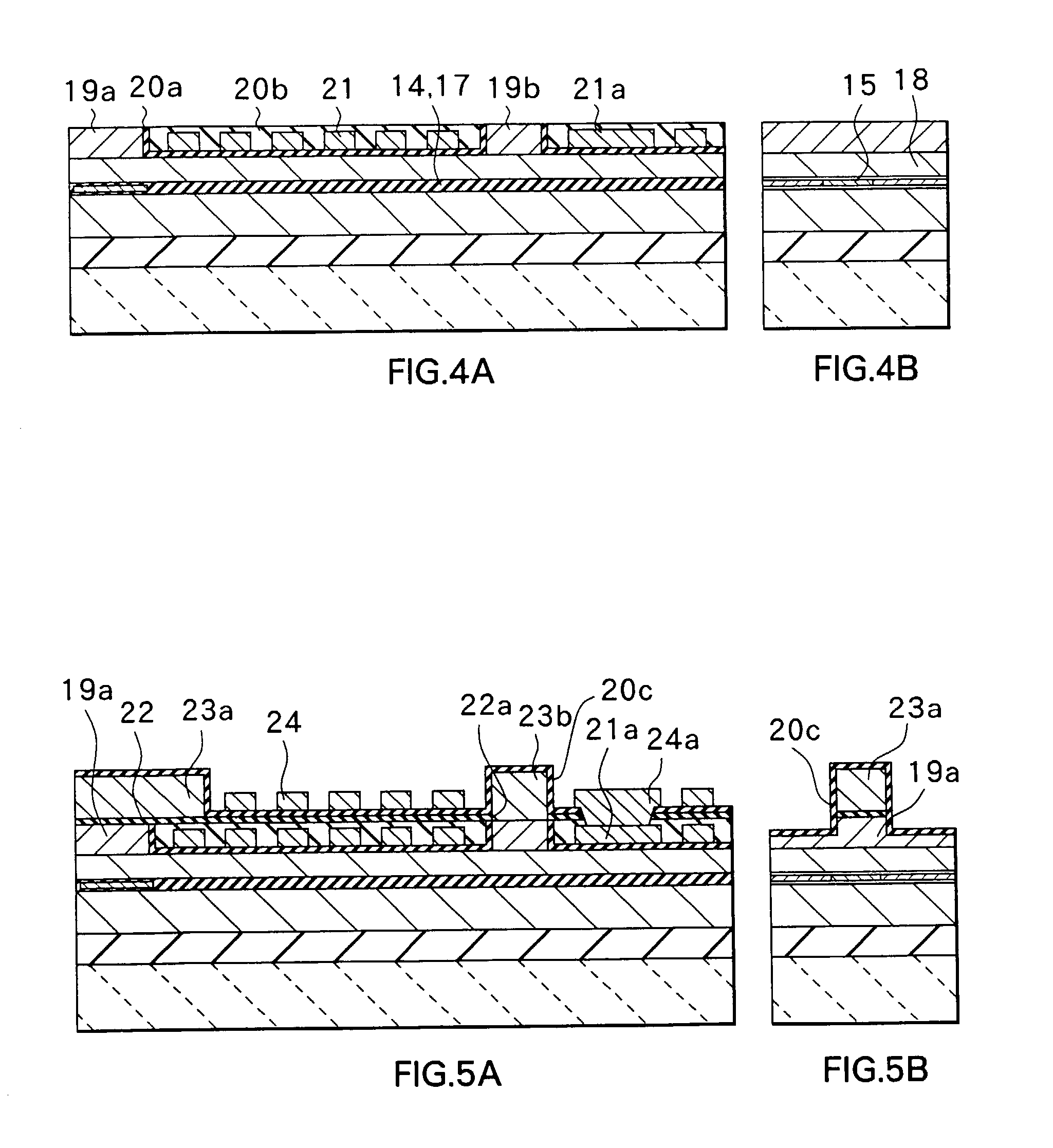

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

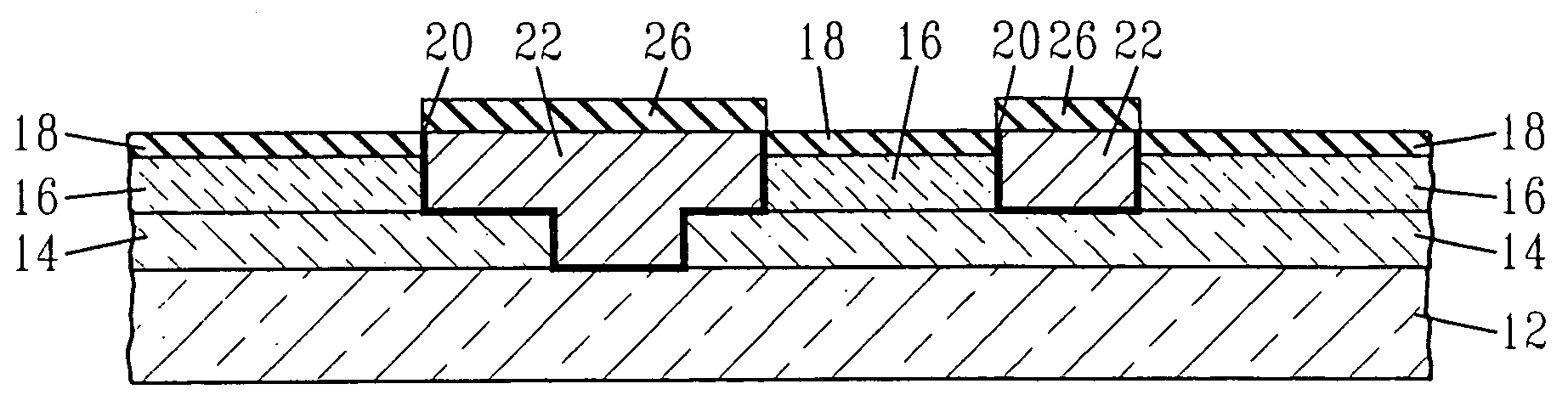

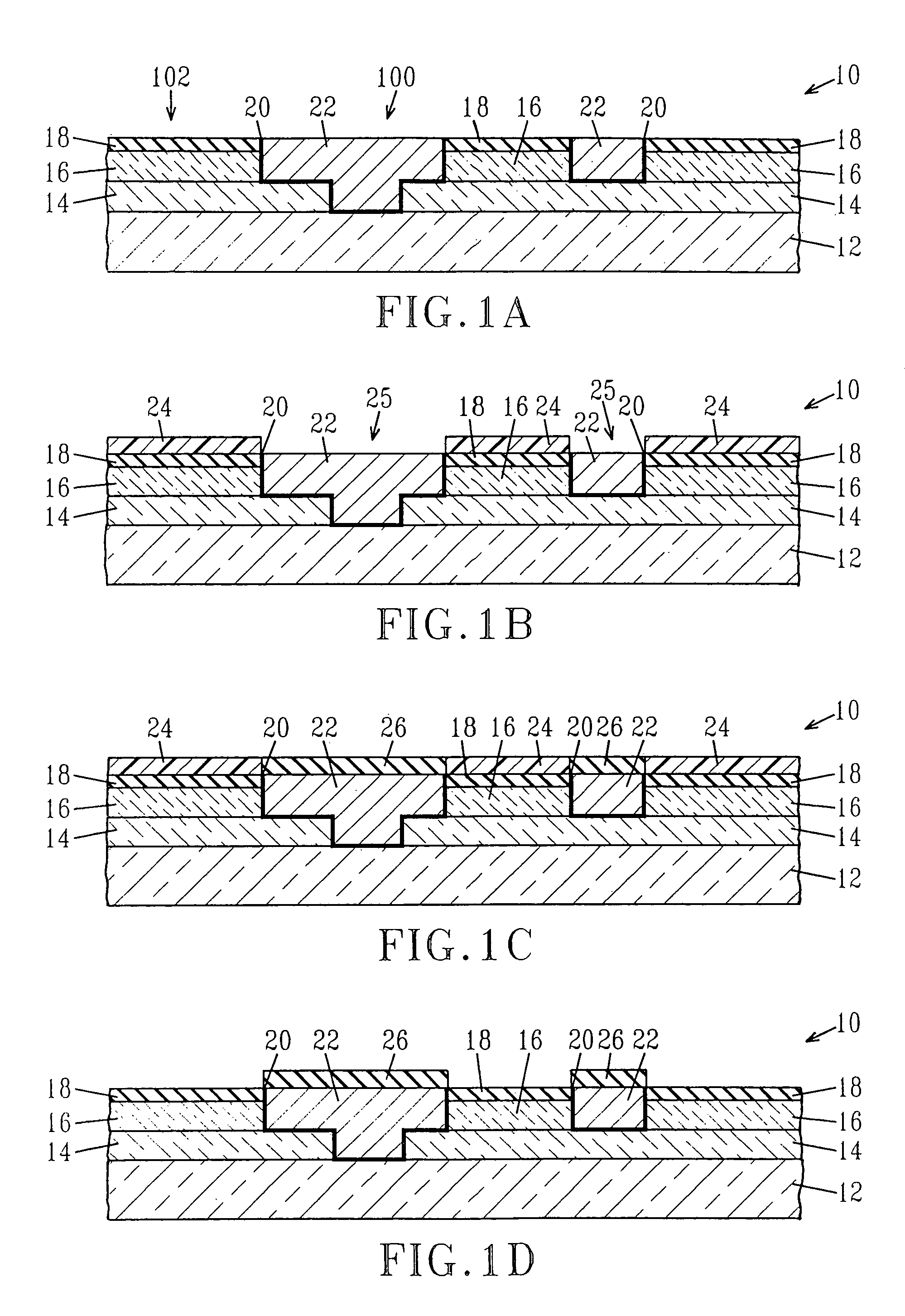

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

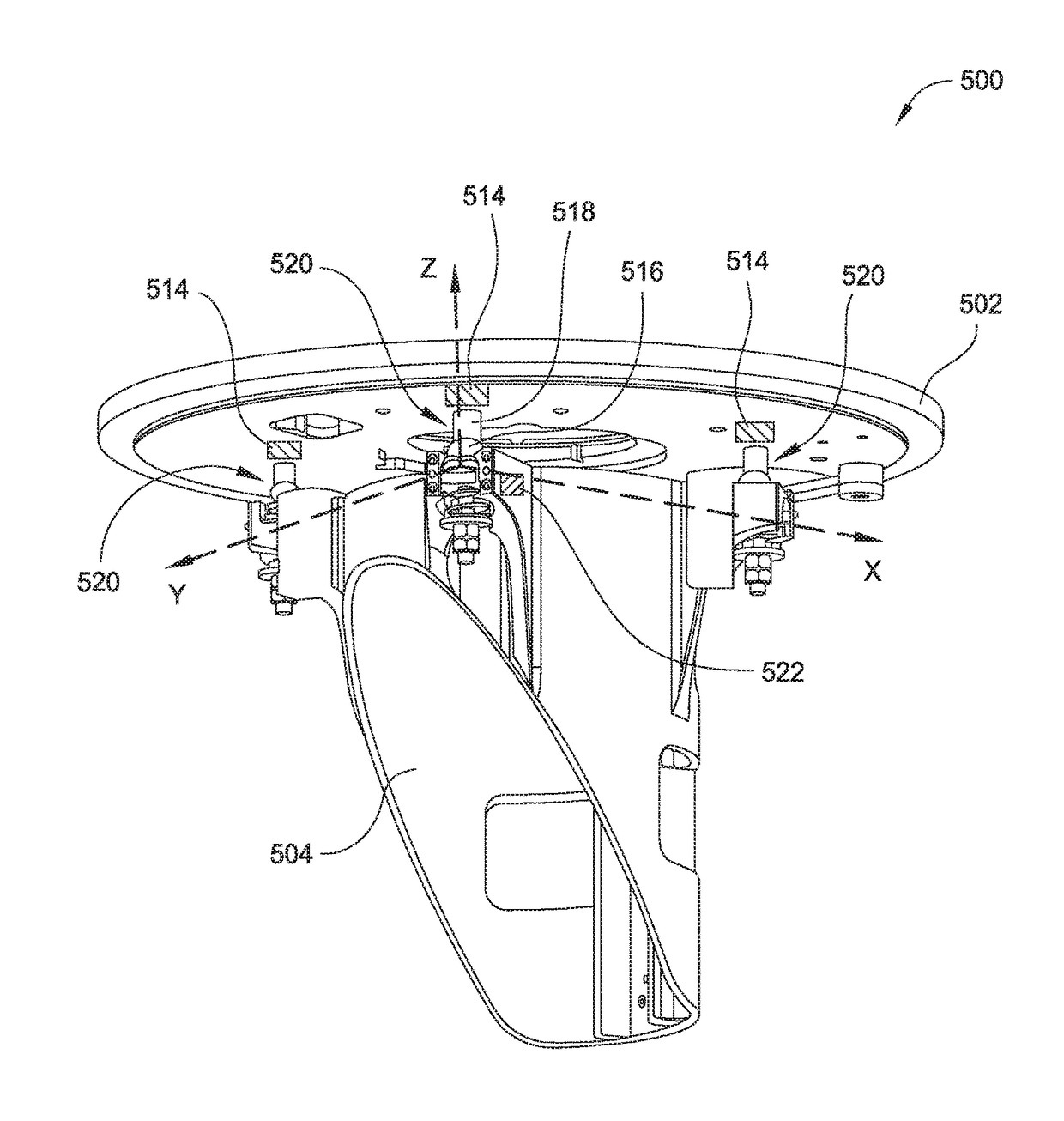

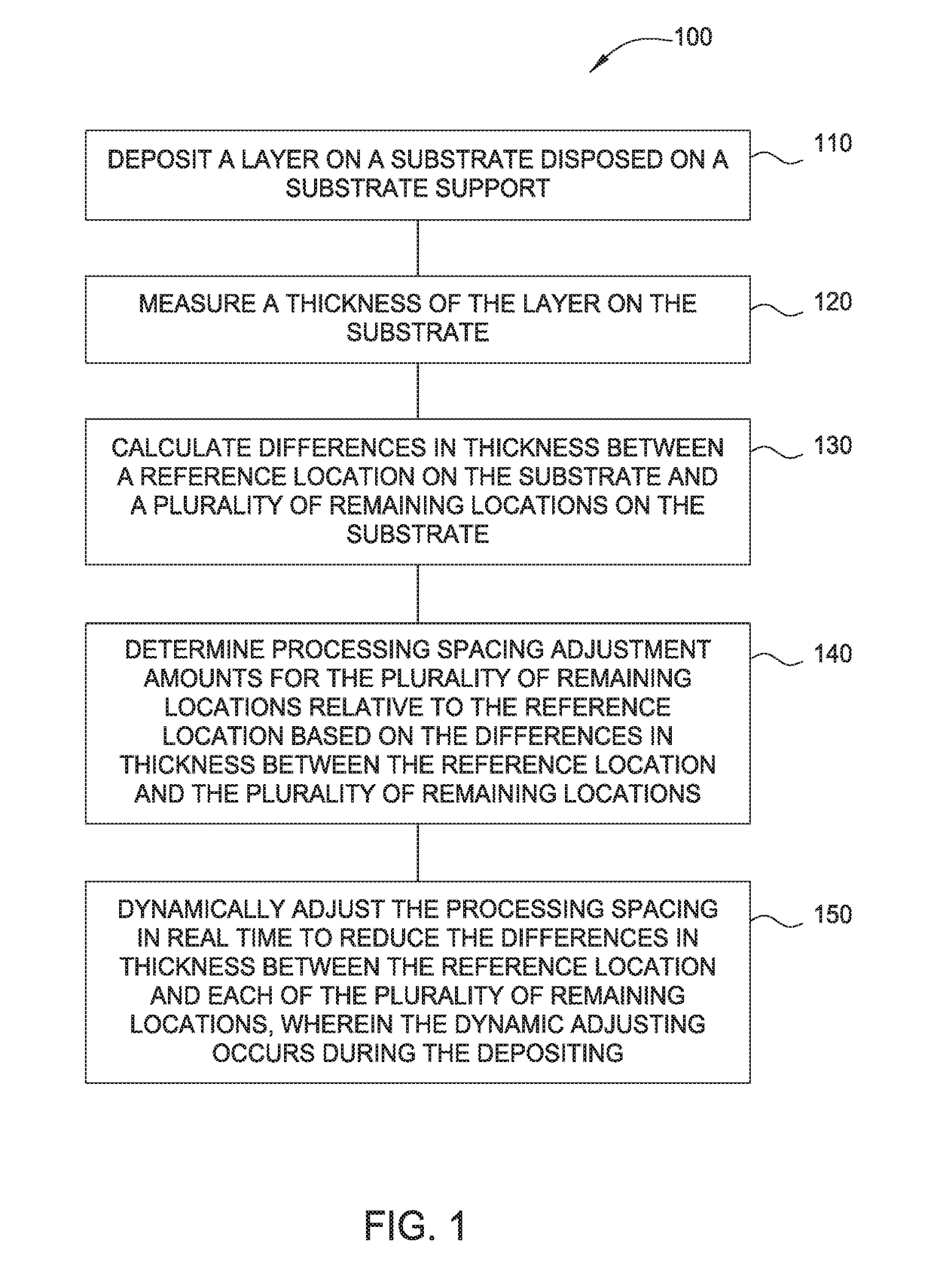

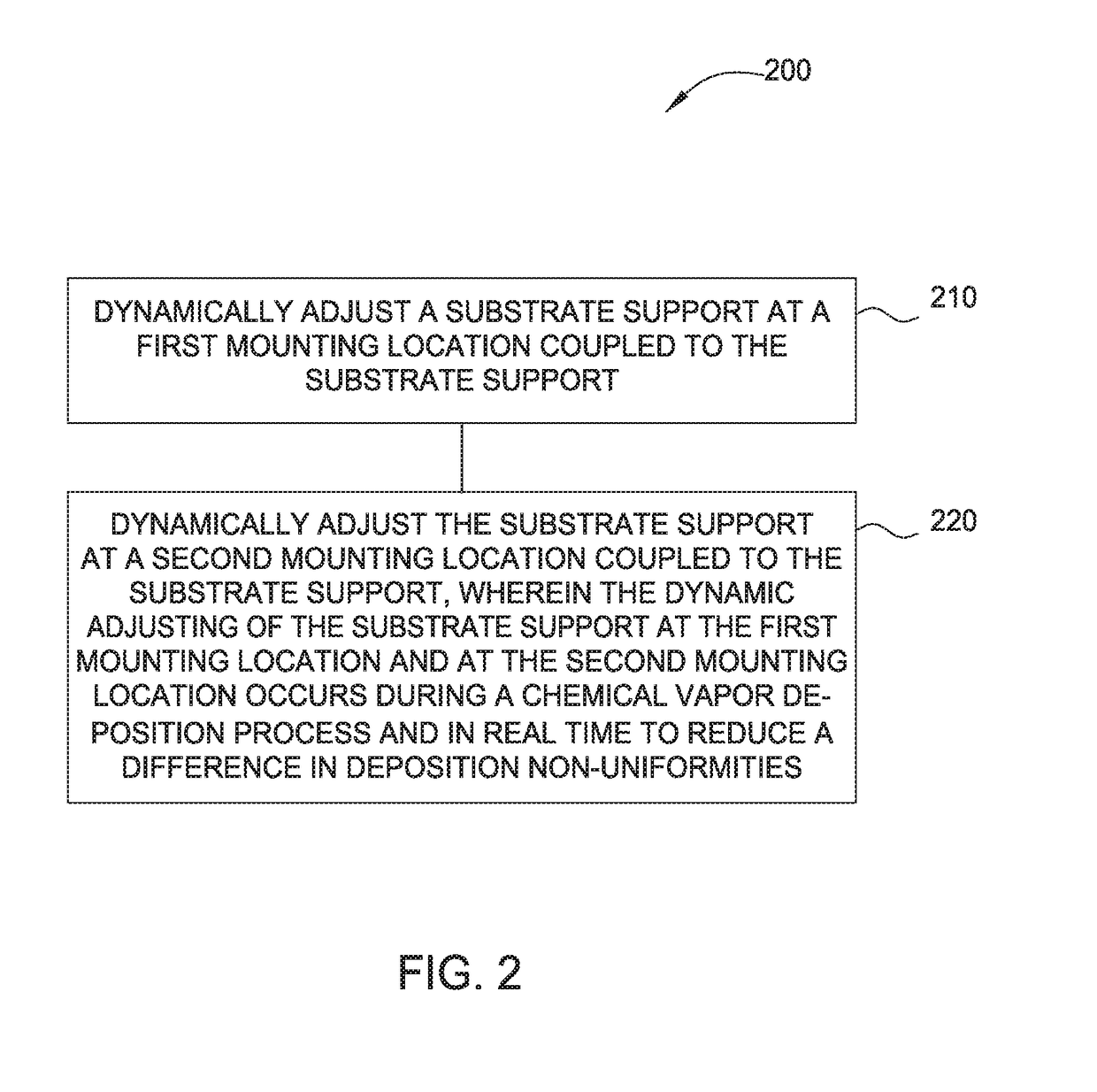

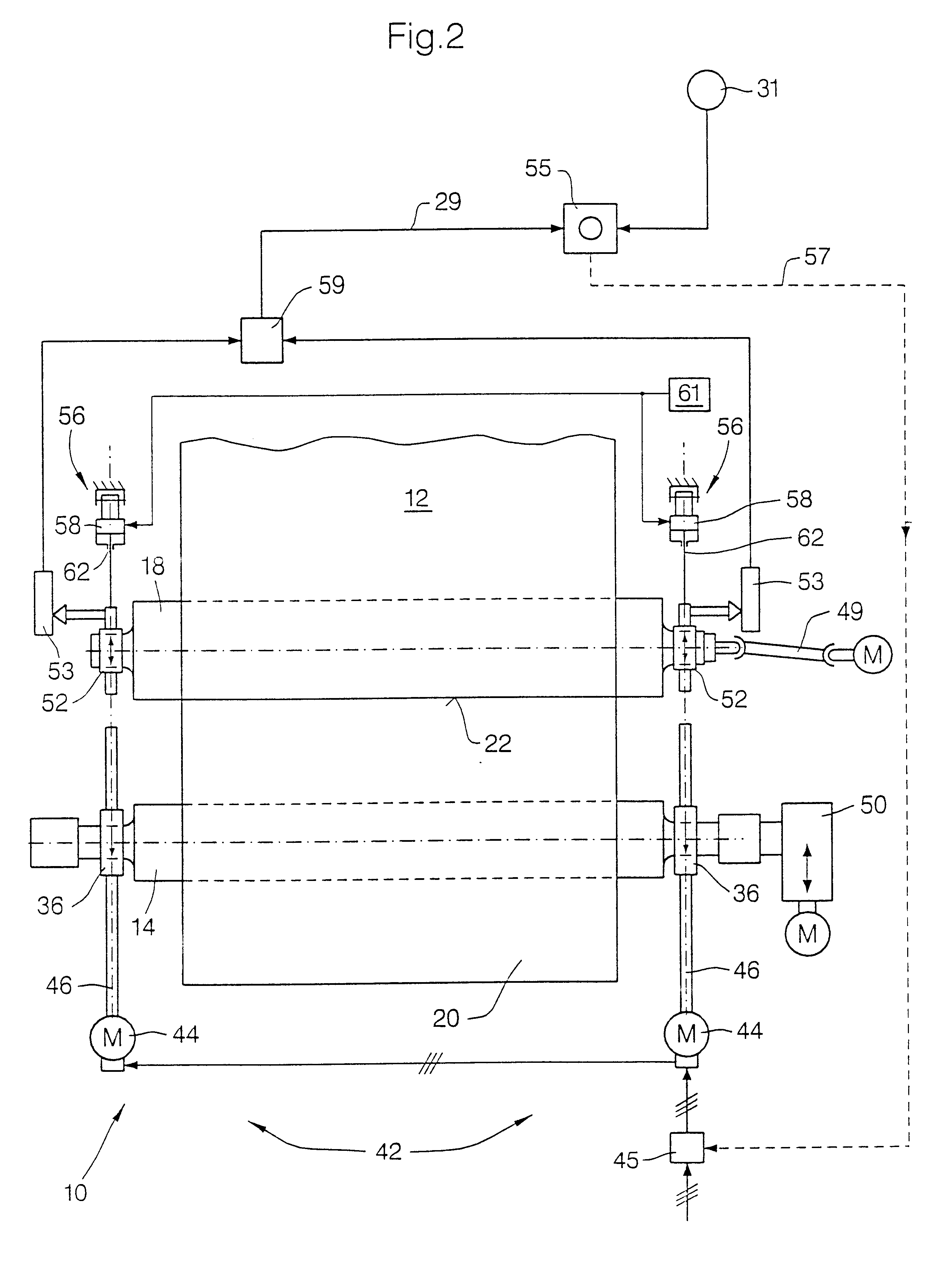

Dynamic wafer leveling/tilting/swiveling during a chemical vapor deposition process

ActiveUS20170309528A1Good film uniformityImprove the deposition effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGas phaseDegrees of freedom

The implementations described herein generally relate to the dynamic, real-time control of the process spacing between a substrate support and a gas distribution medium during a deposition process. Multiple dimensional degrees of freedom are utilized to change the angle and spacing of the substrate plane with respect to the gas distributing medium at any time during the deposition process. As such, the substrate and / or substrate support may be leveled, tilted, swiveled, wobbled, and / or moved during the deposition process to achieve improved film uniformity. Furthermore, the independent tuning of each layer may be had due to continuous variations in the leveling of the substrate plane with respect to the showerhead to average effective deposition on the substrate, thus improving overall stack deposition performance.

Owner:APPLIED MATERIALS INC

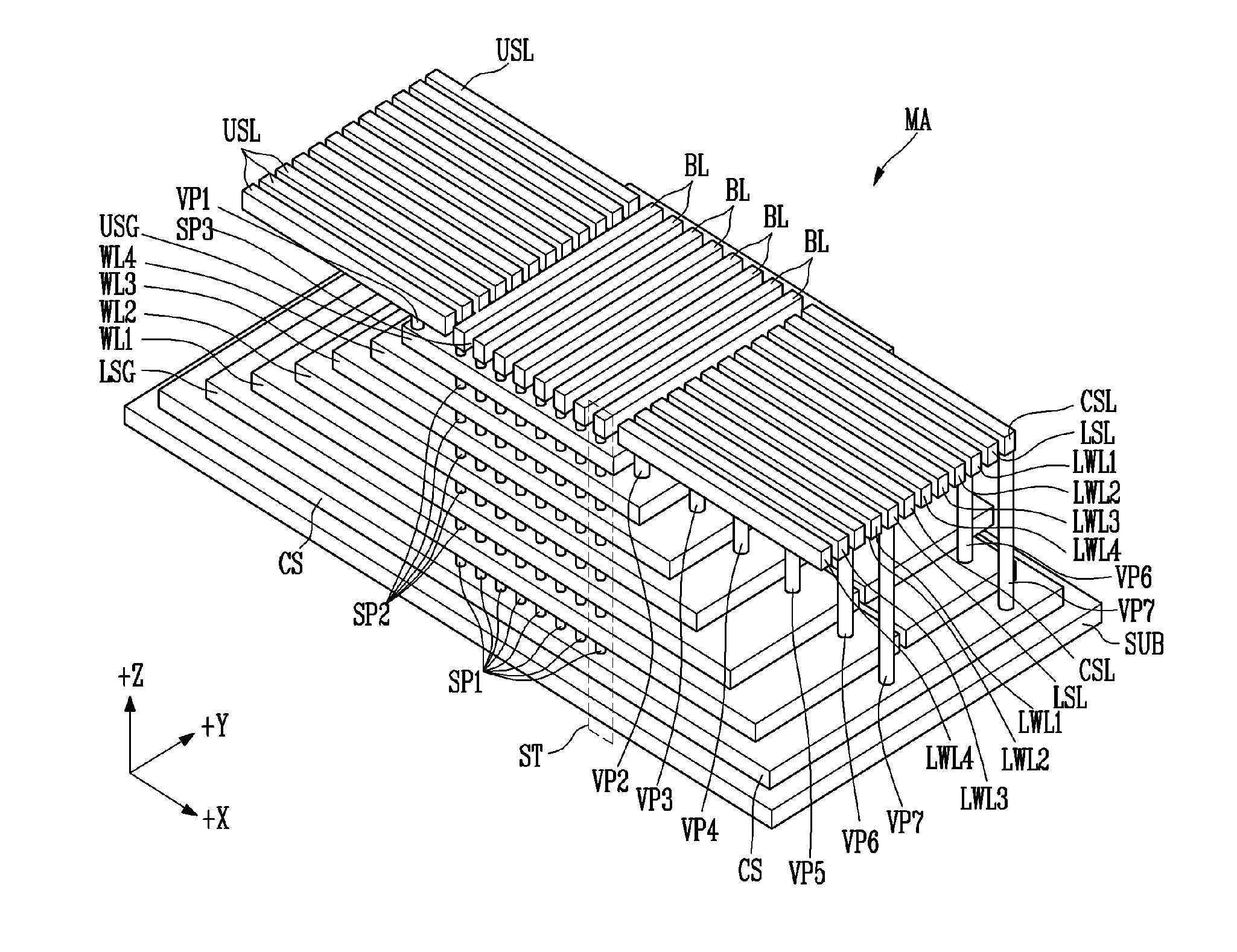

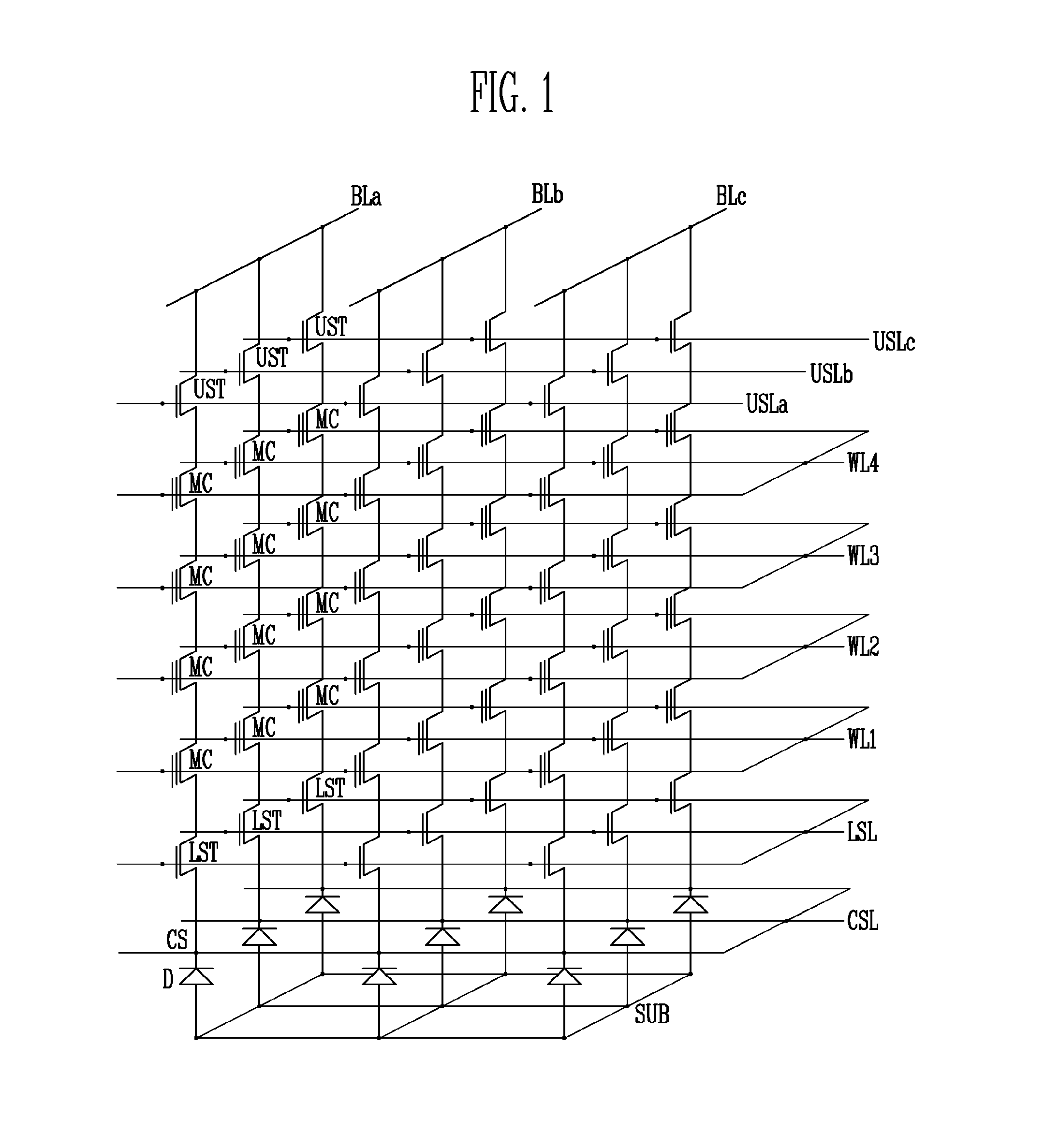

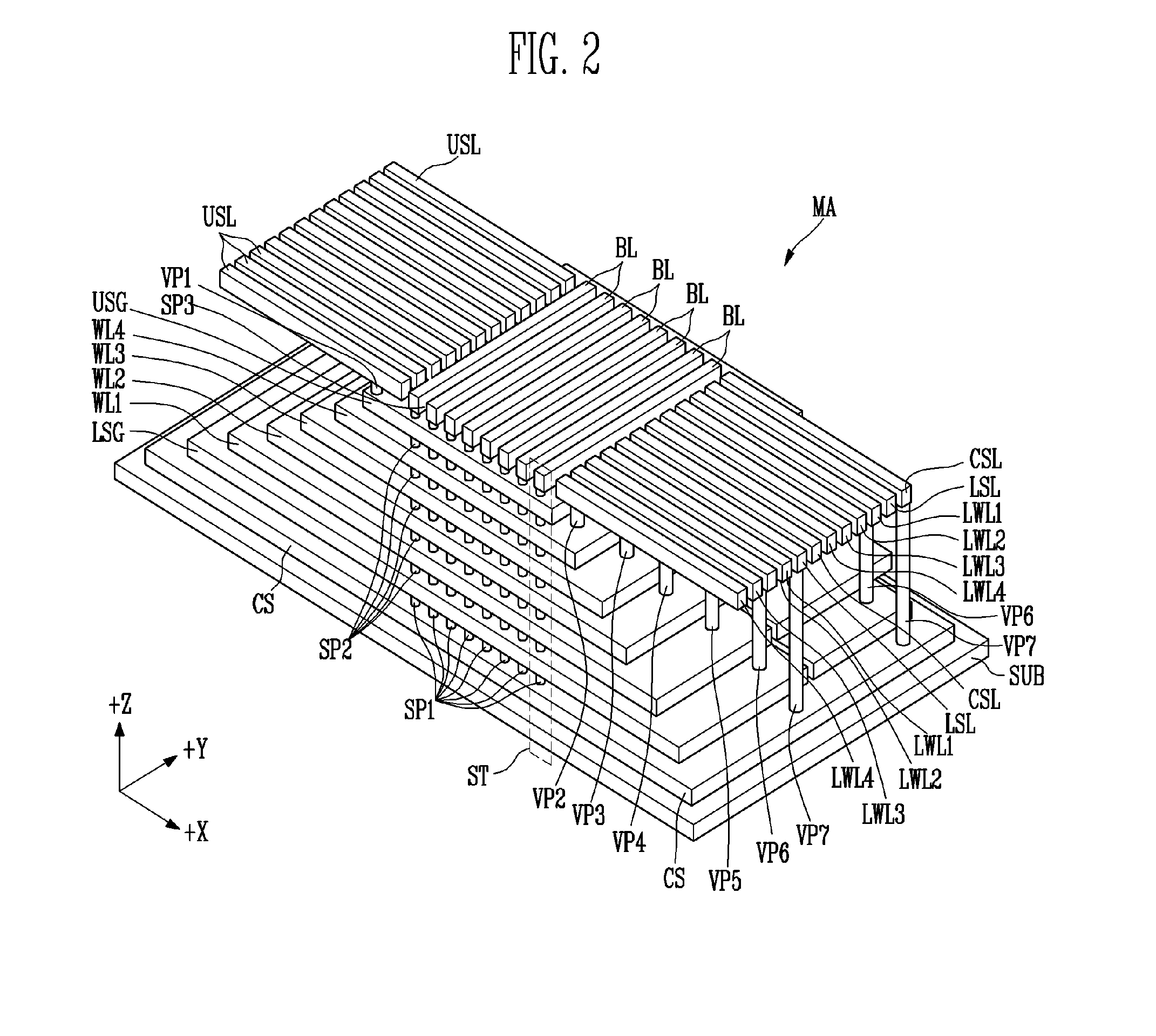

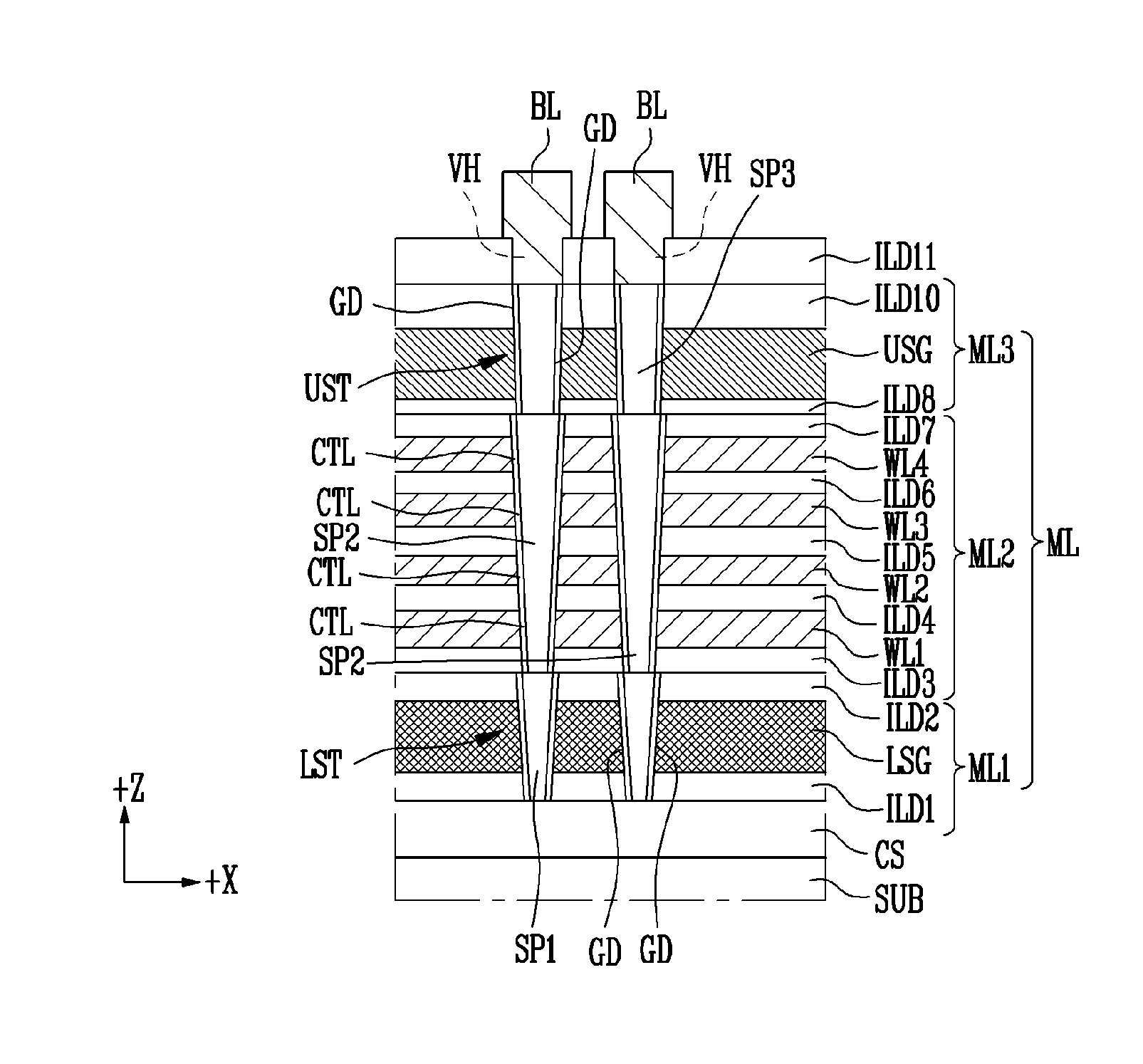

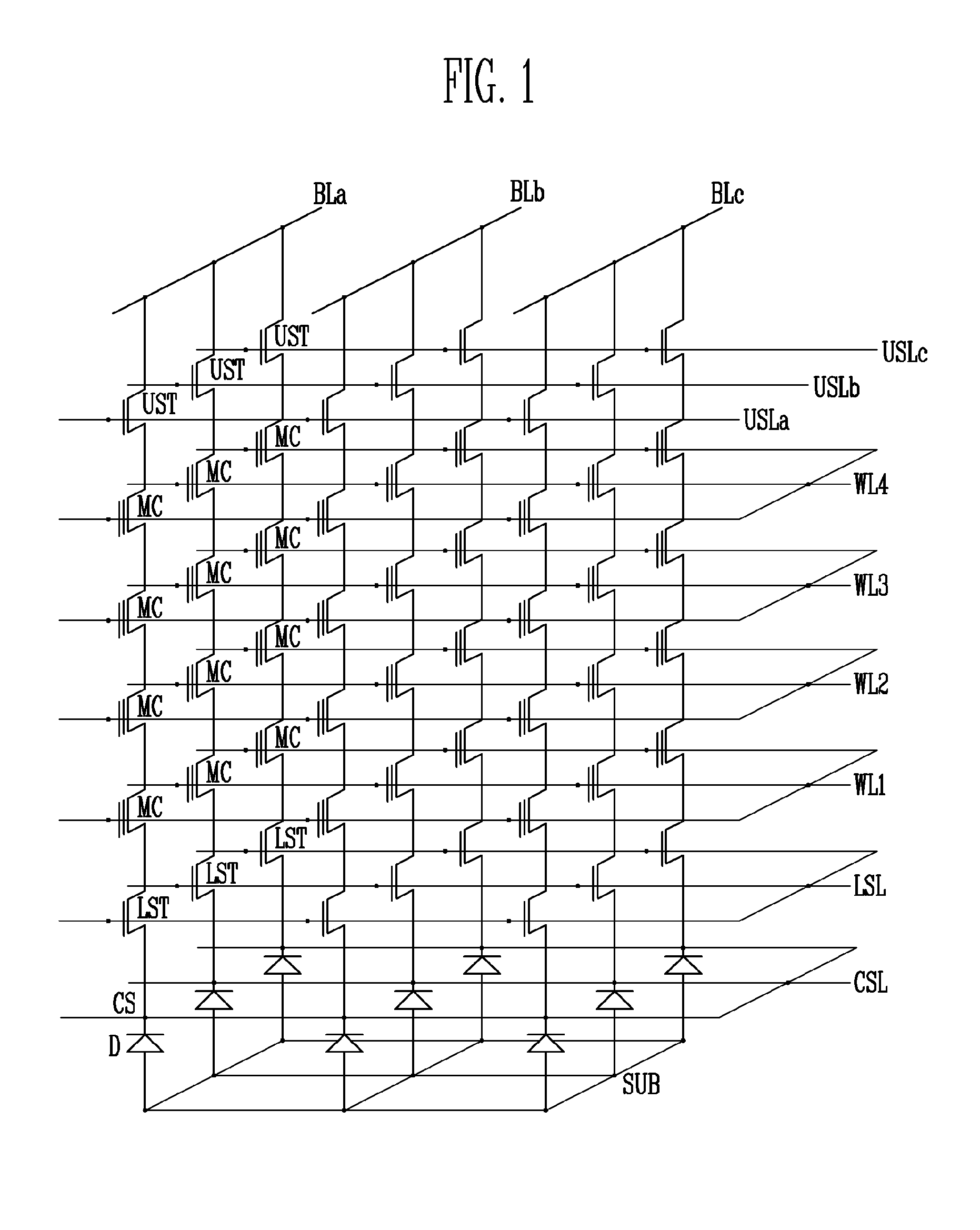

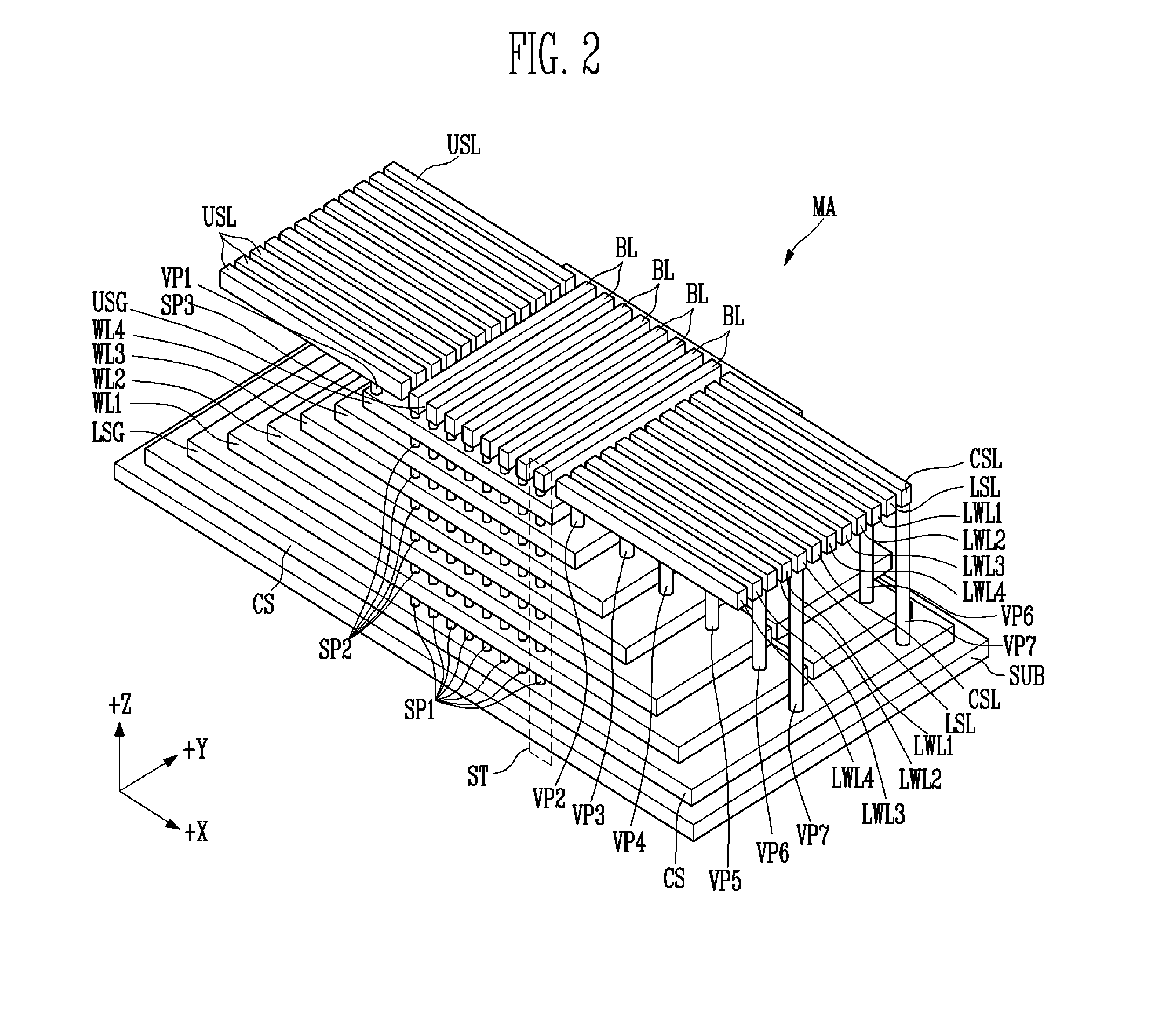

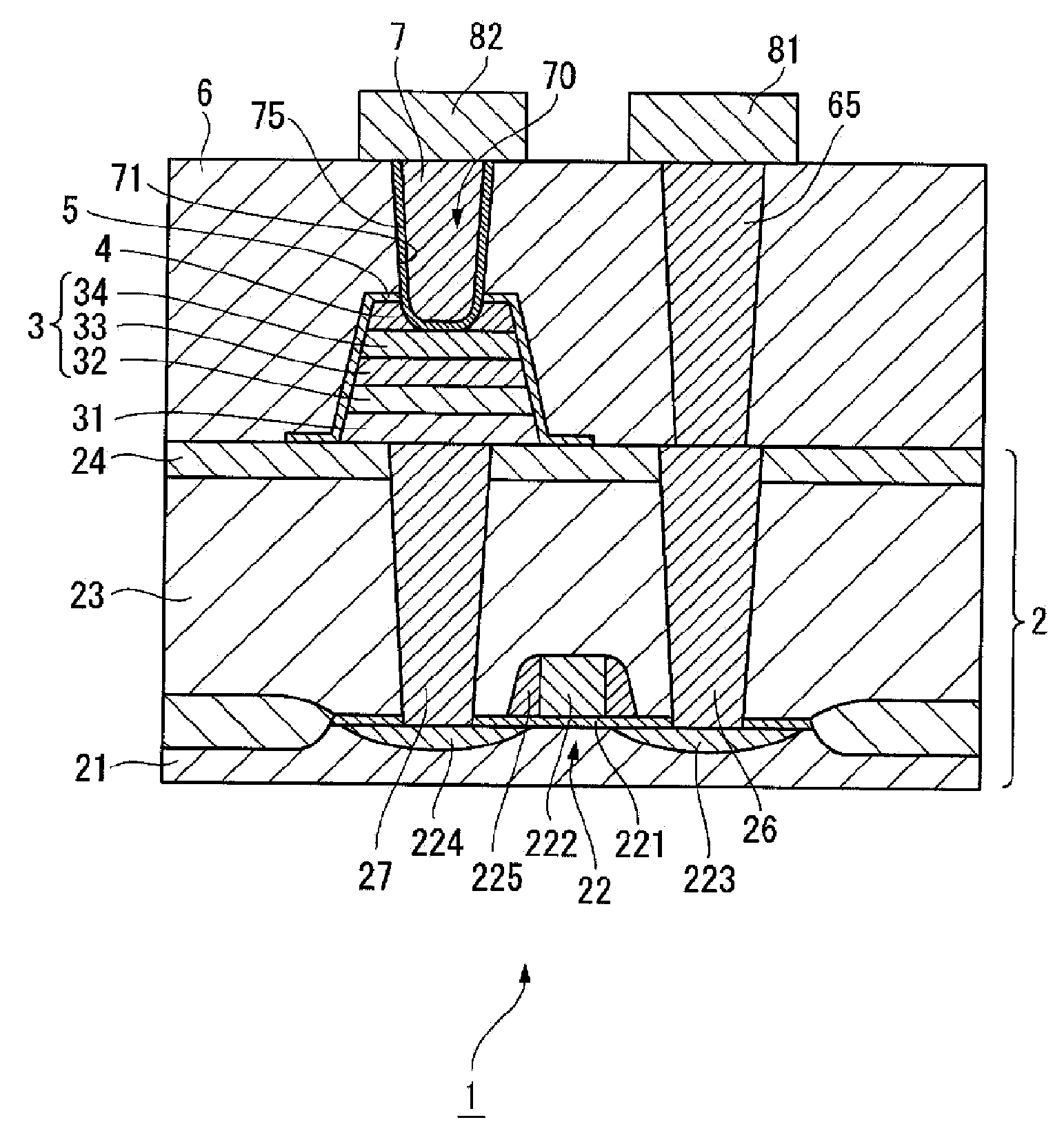

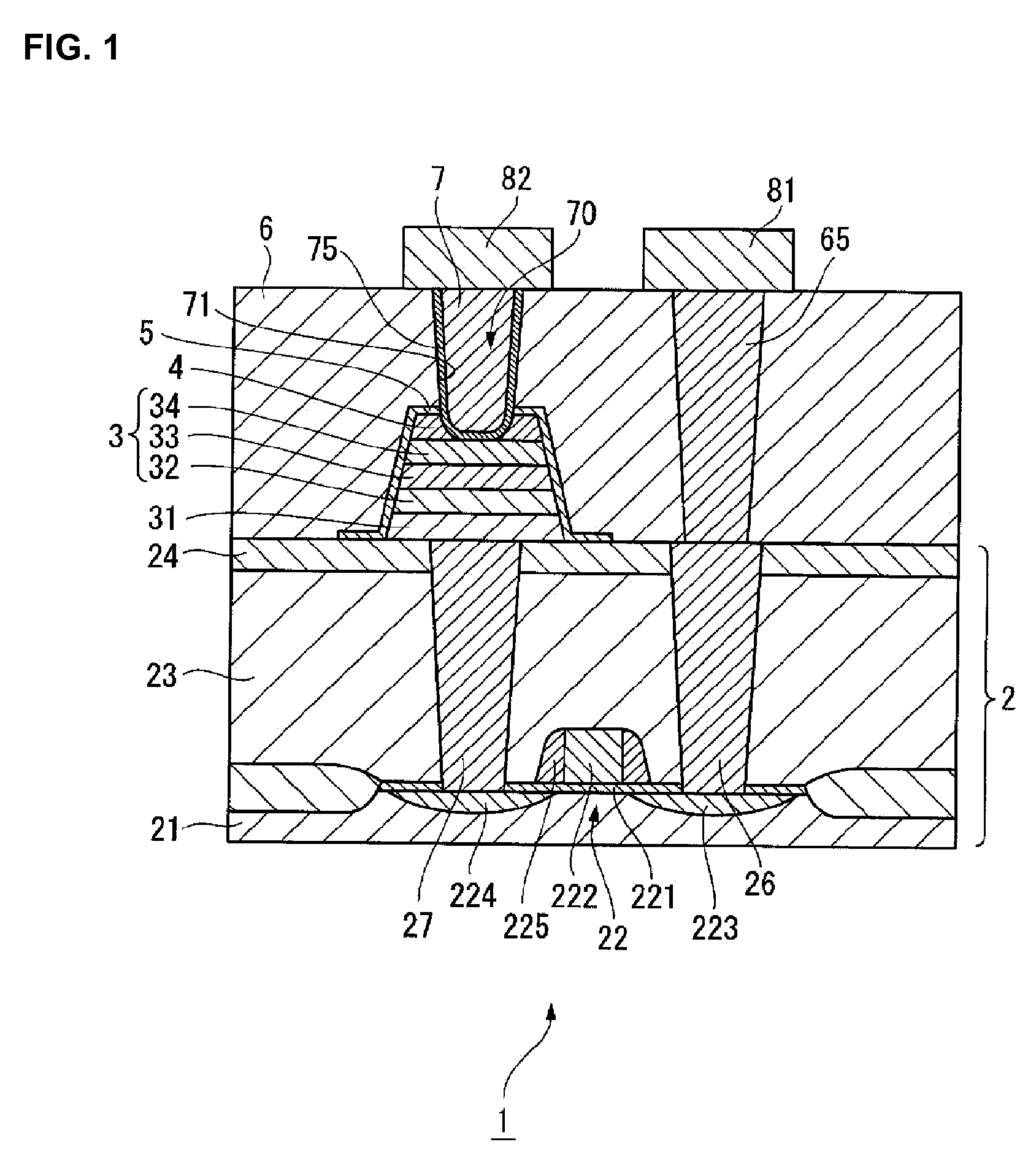

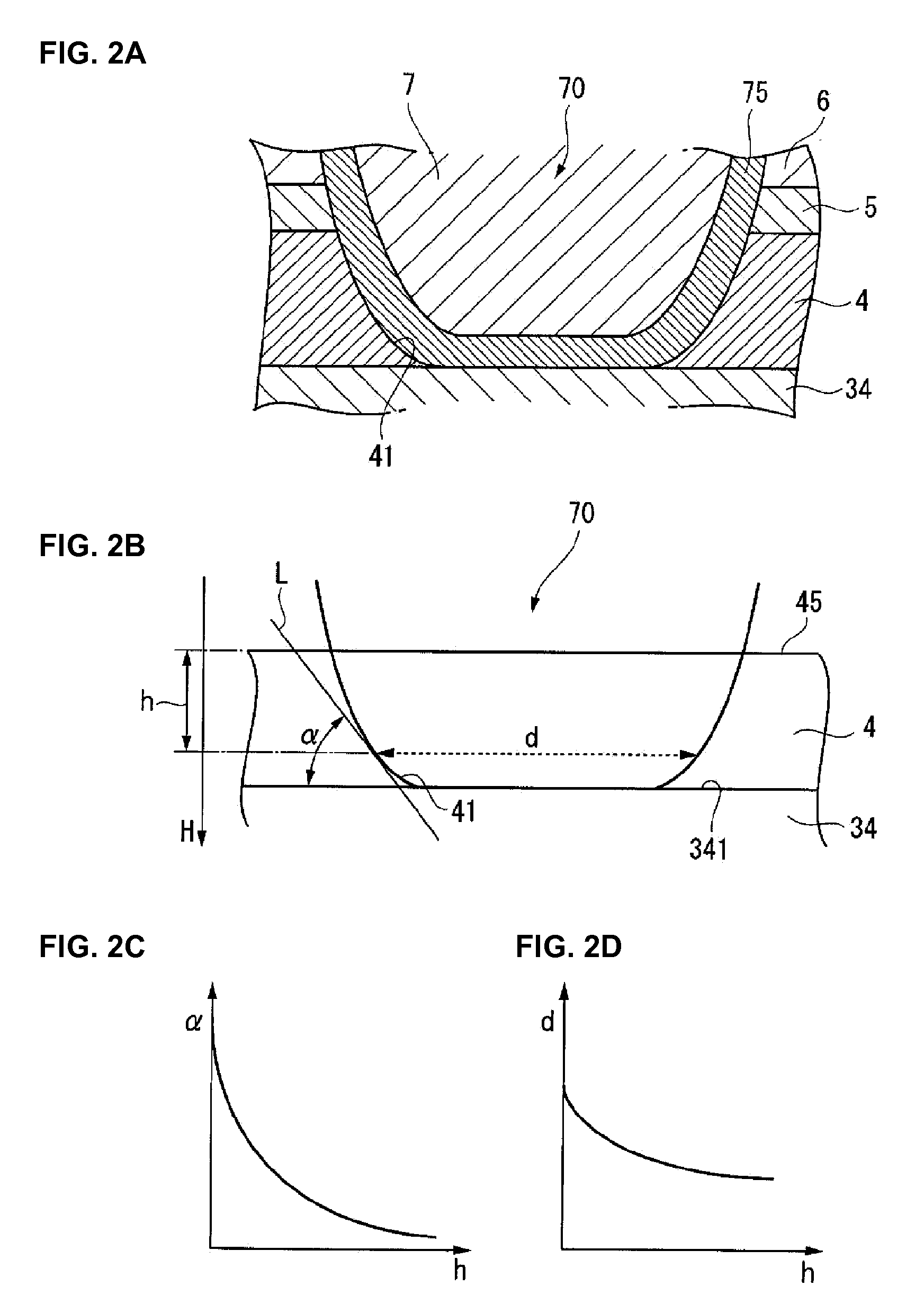

Semiconductor memory device and method of manufacturing the same

ActiveUS20120211823A1Well formedDifference in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

A semiconductor memory device includes a lower select transistor formed within a semiconductor substrate, memory cells stacked over the lower select transistors, and an upper select transistor formed over the memory cells.

Owner:SK HYNIX INC

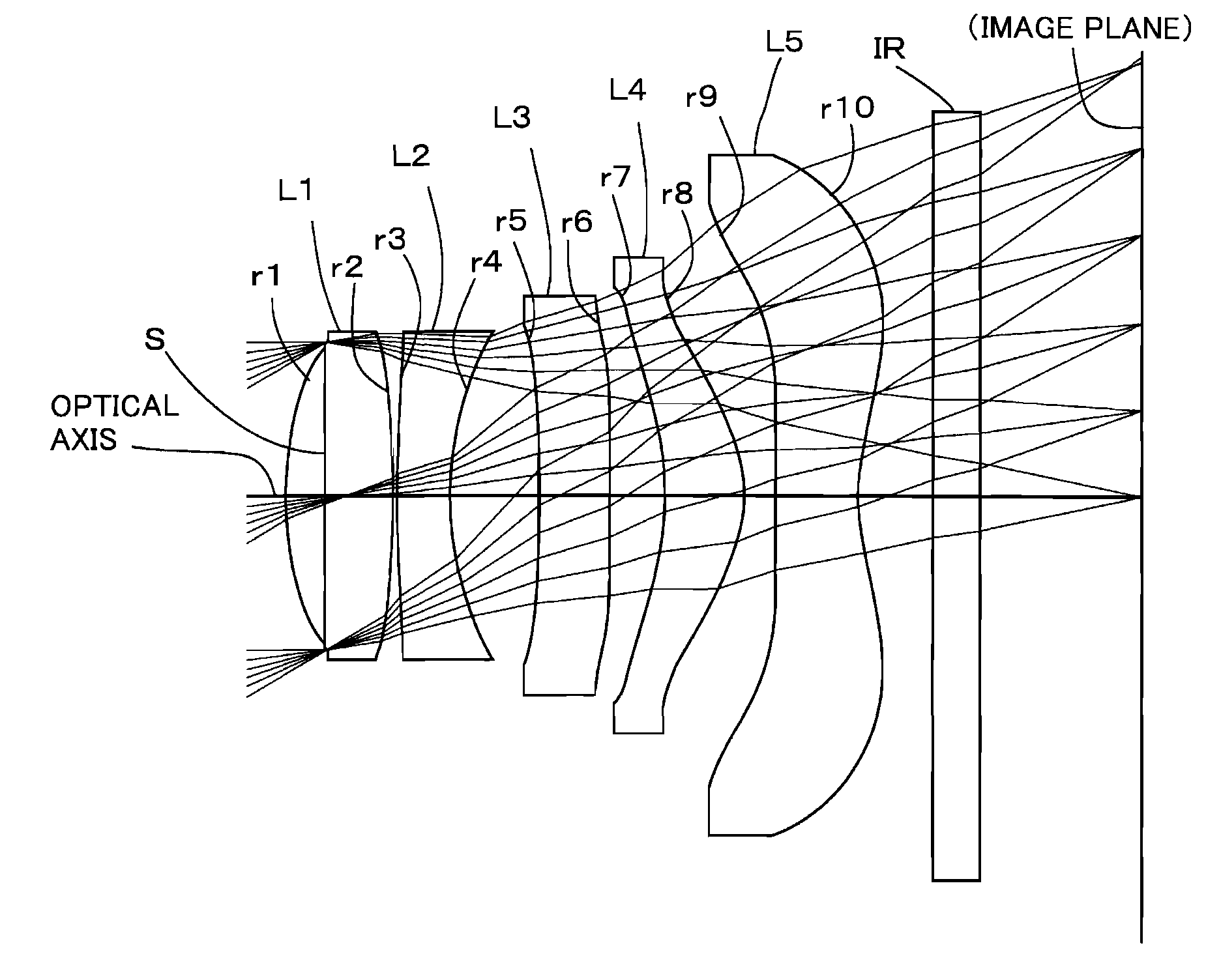

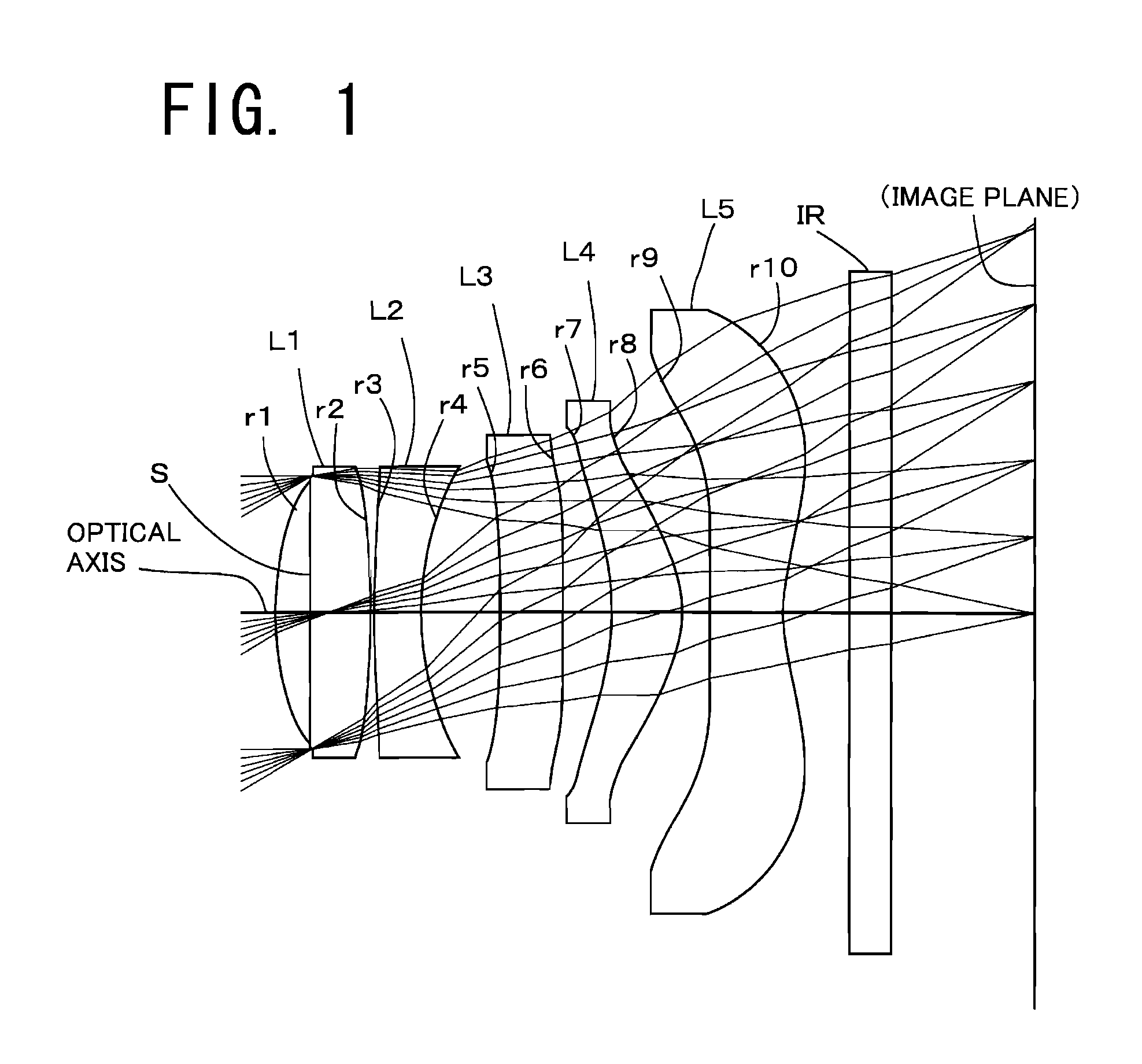

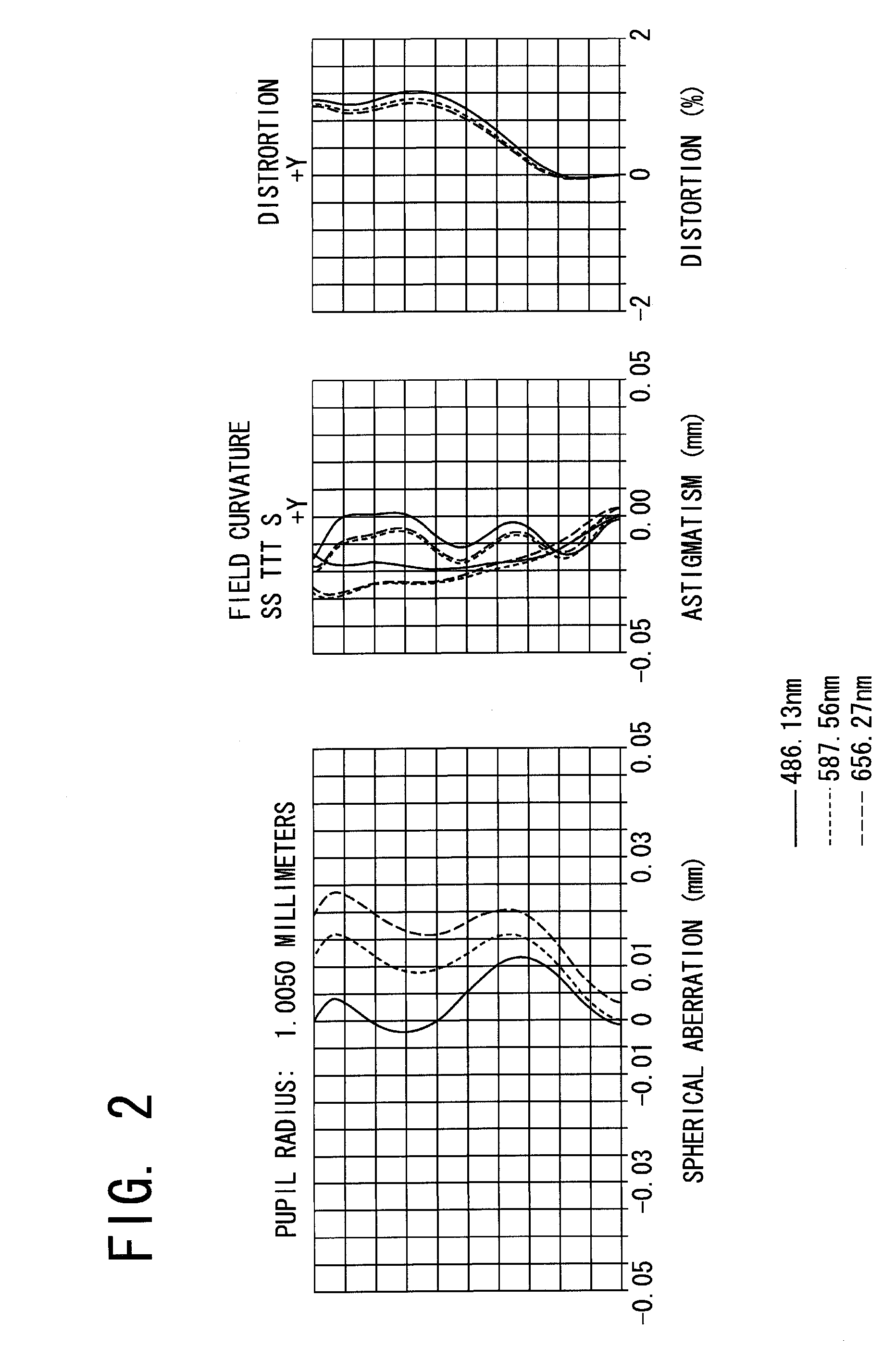

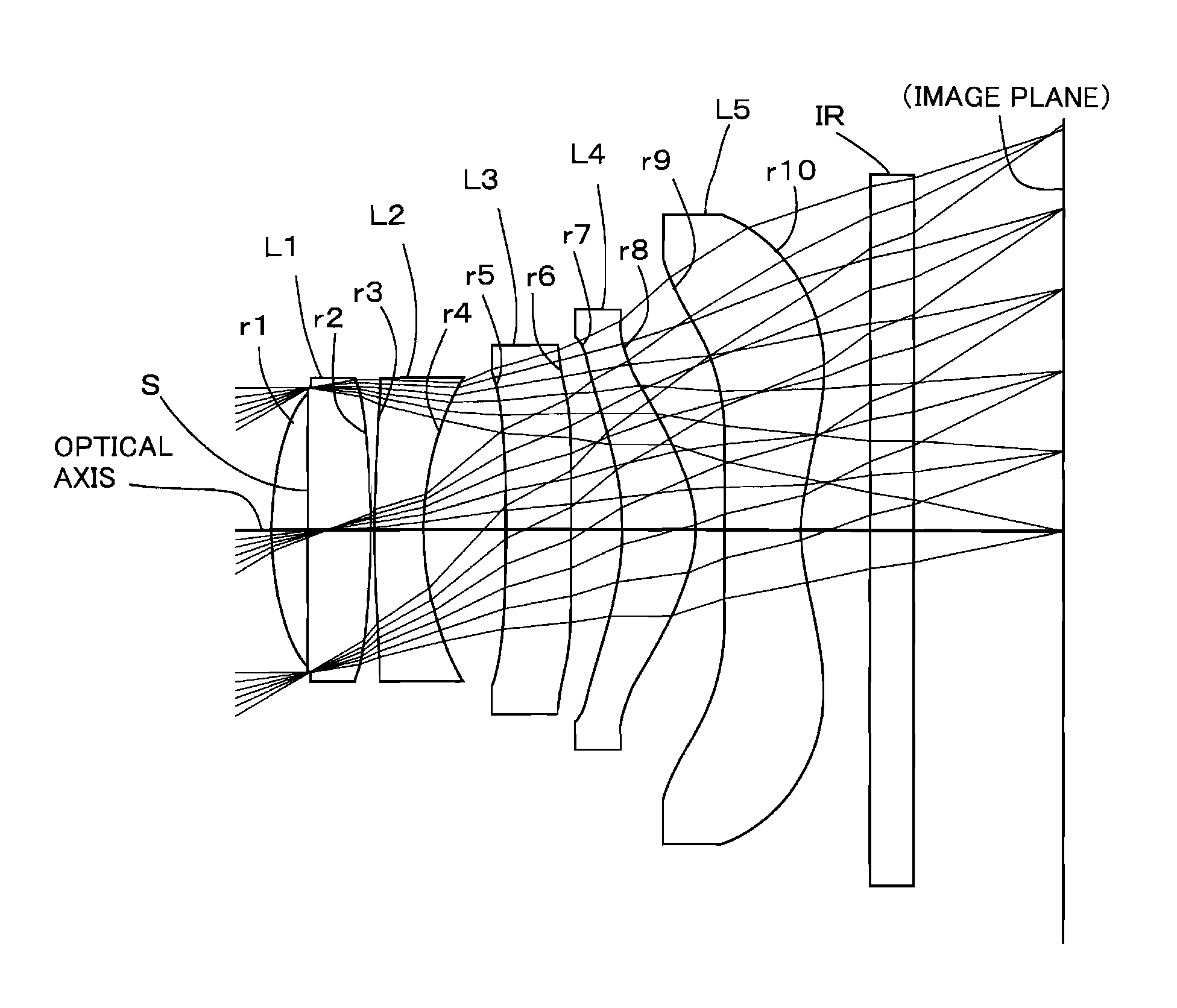

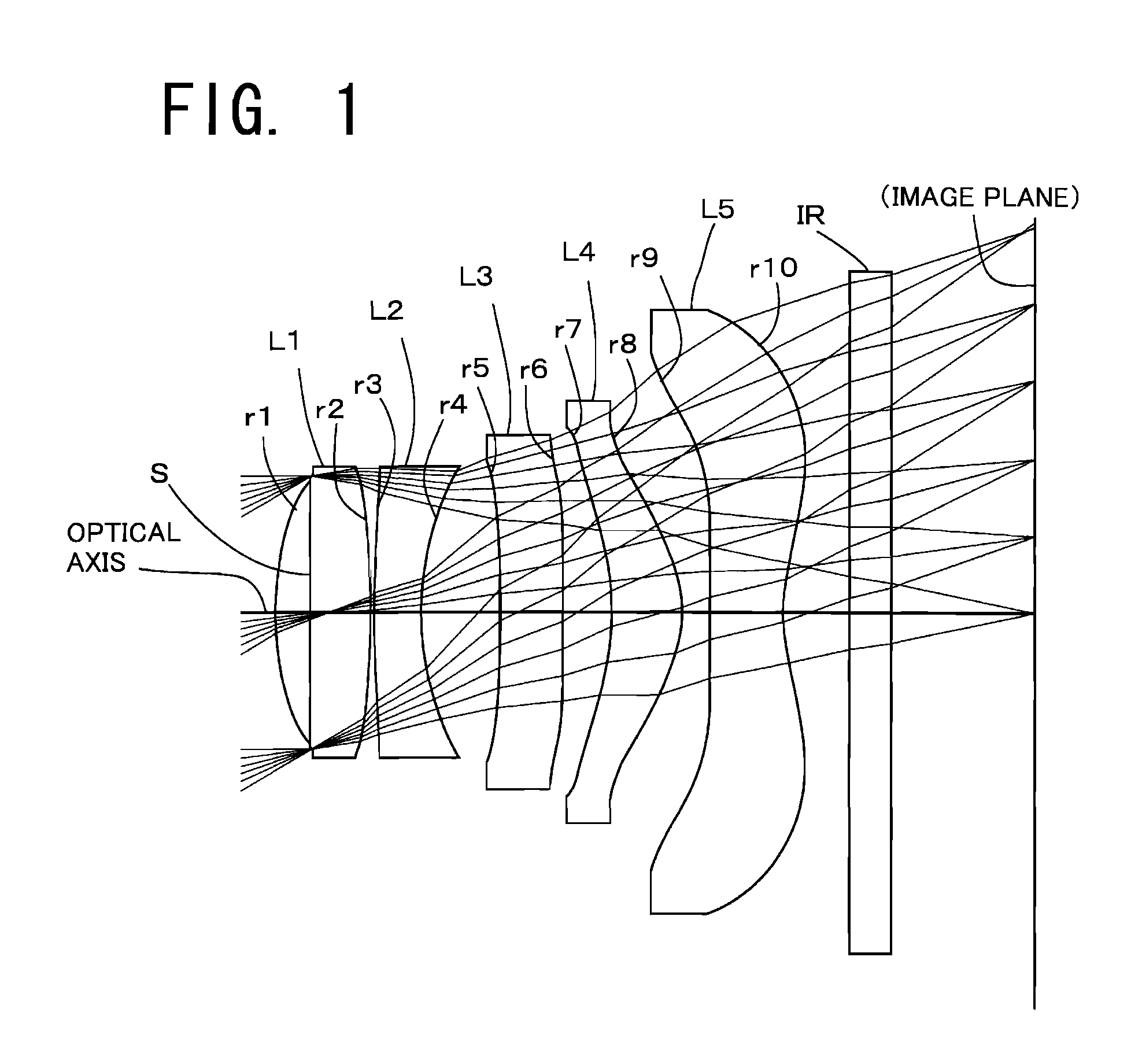

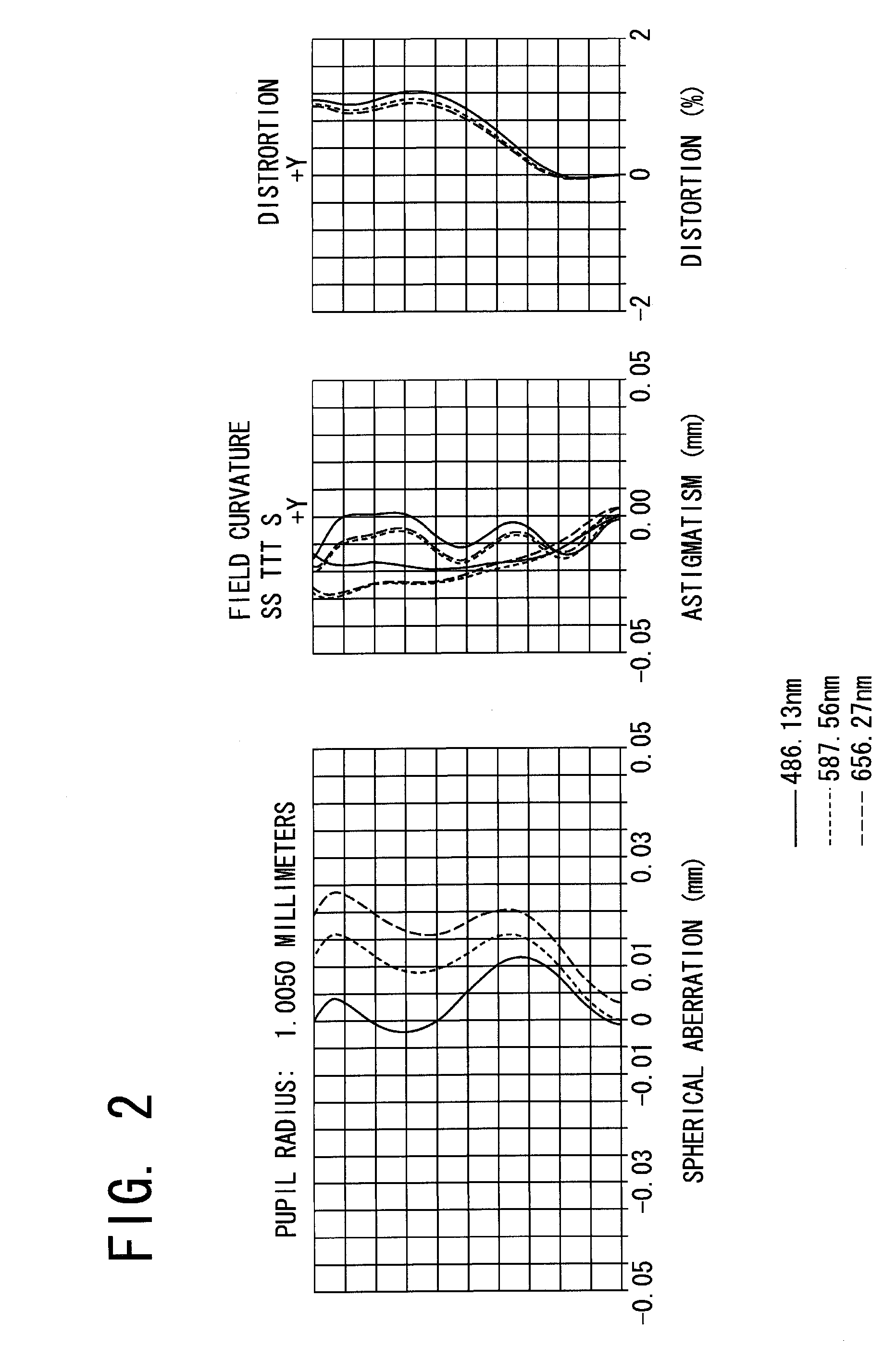

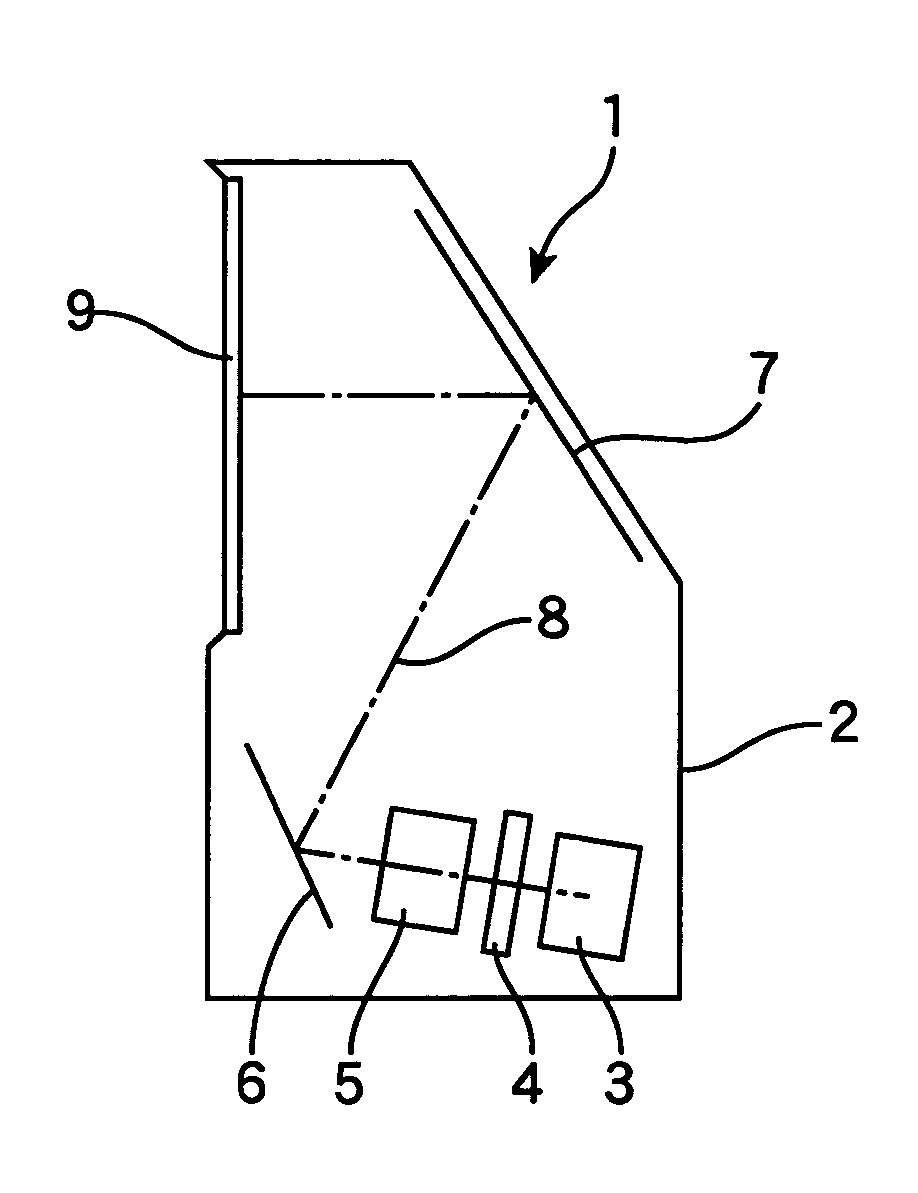

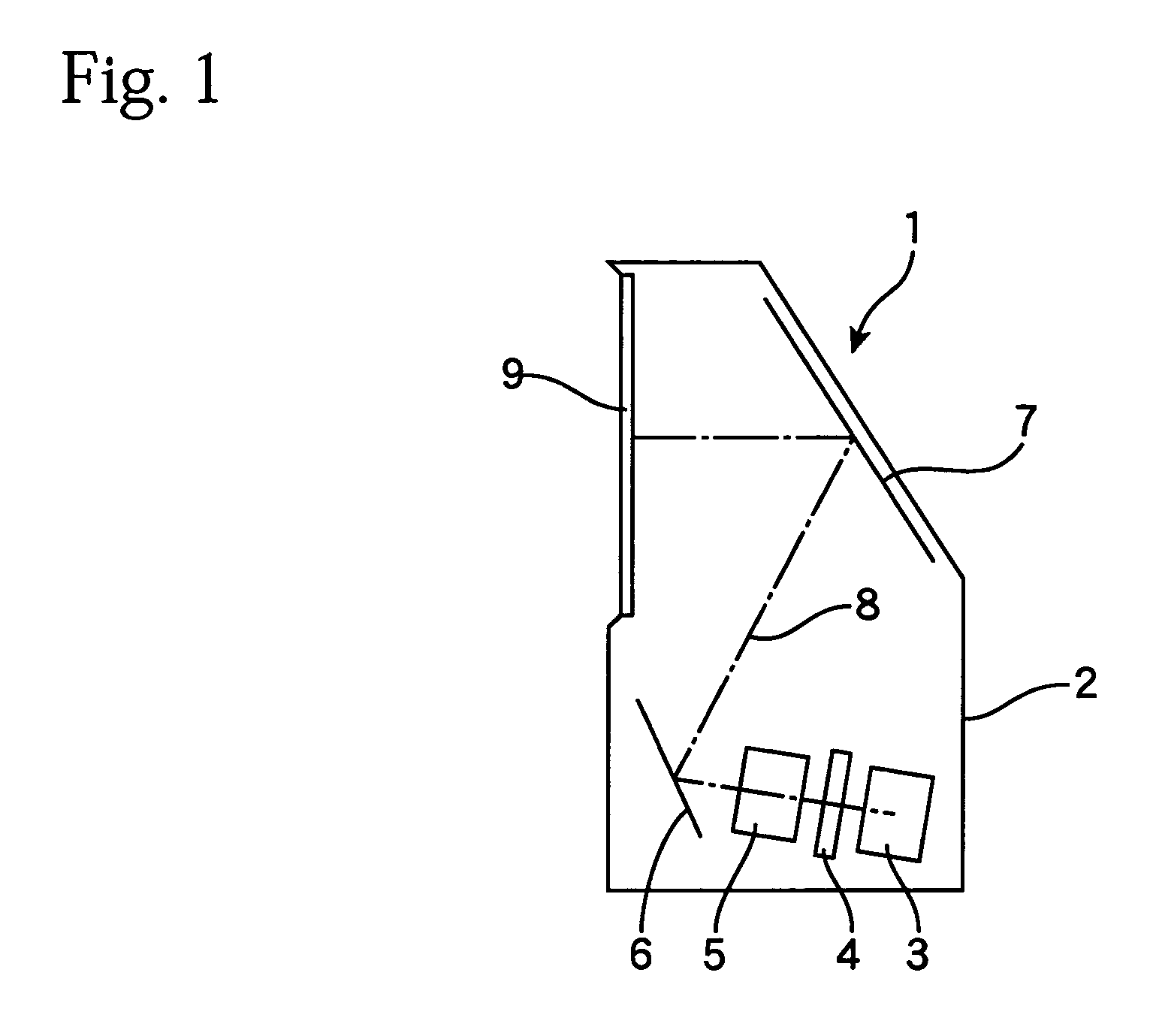

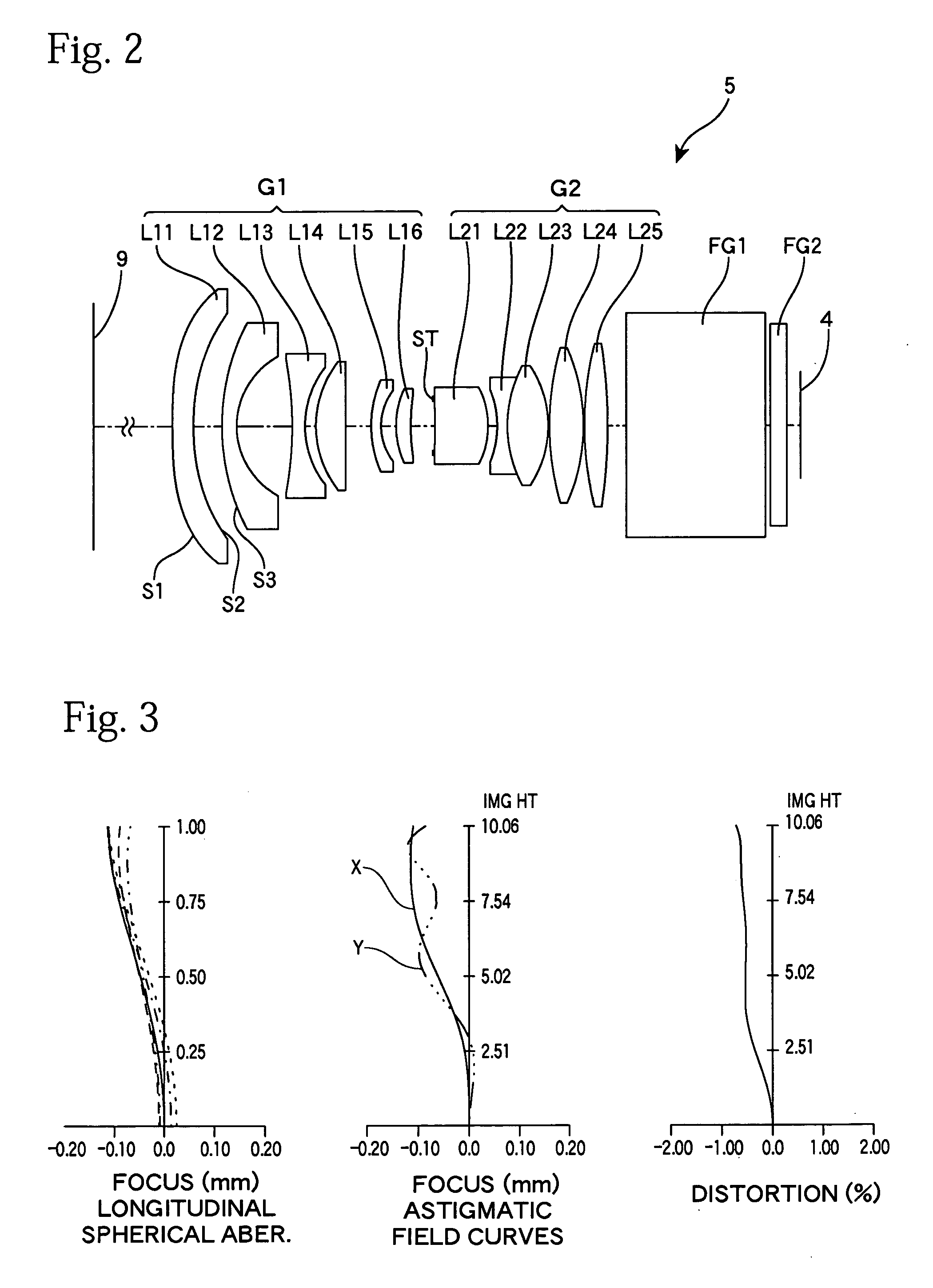

Imaging lens unit

A compact low-cost imaging lens unit for a solid-state image sensor which corrects various aberrations adequately and produces a high-resolution high-definition image. The components of the unit are arranged from an object side to an image side in the following order: an aperture stop, a first lens with positive refractive power having a convex surface facing the object side, a second lens with negative refractive power having a convex surface facing the object side near an optical axis, a third lens with negative refractive power having a convex surface facing the object side near the optical axis, a fourth lens as a meniscus lens with positive refractive power having a convex surface facing the image side near the optical axis; and a fifth lens with negative refractive power having a concave surface facing the image side near the optical axis.

Owner:TOKYO VISIONARY OPTICS CO LTD

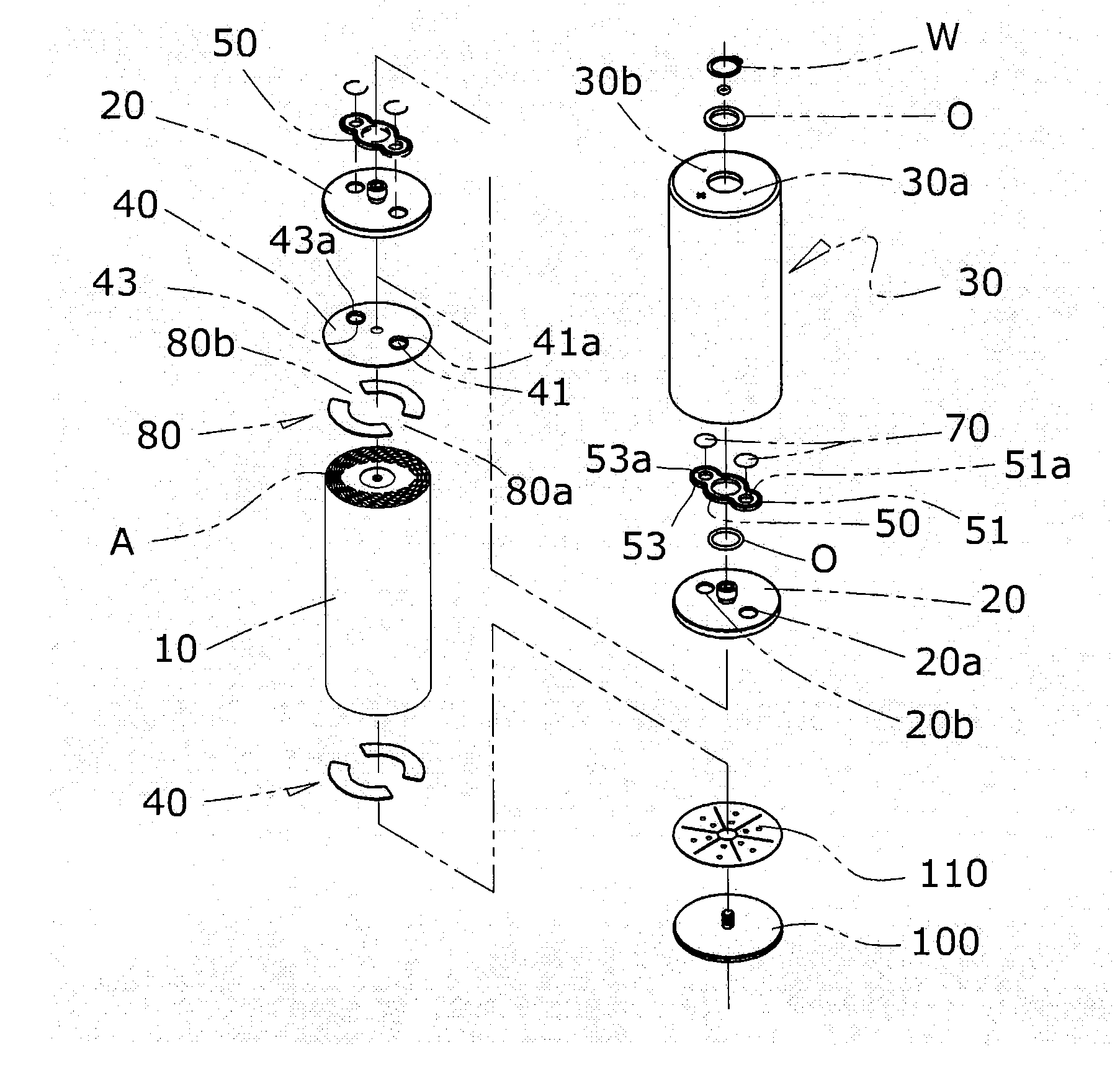

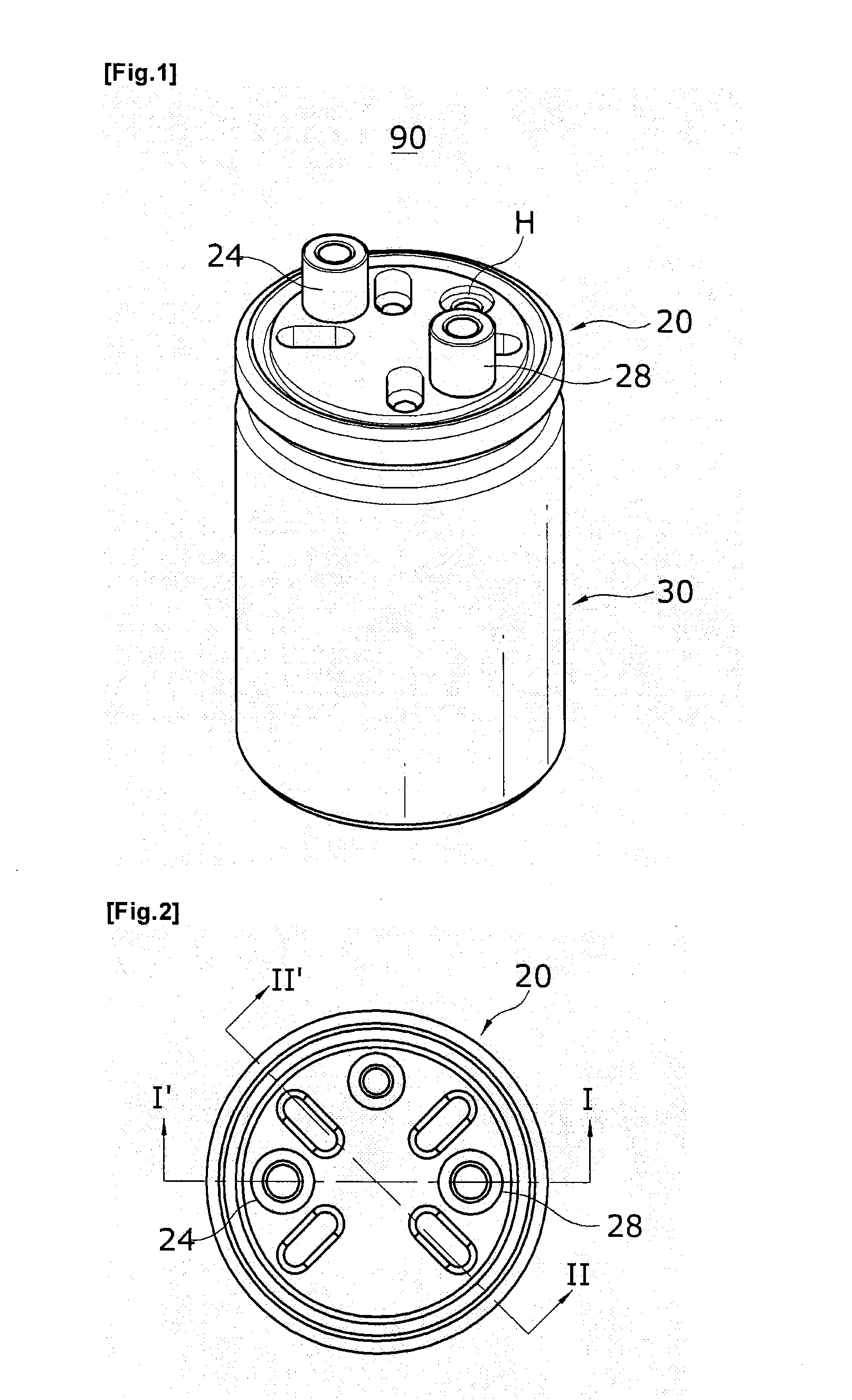

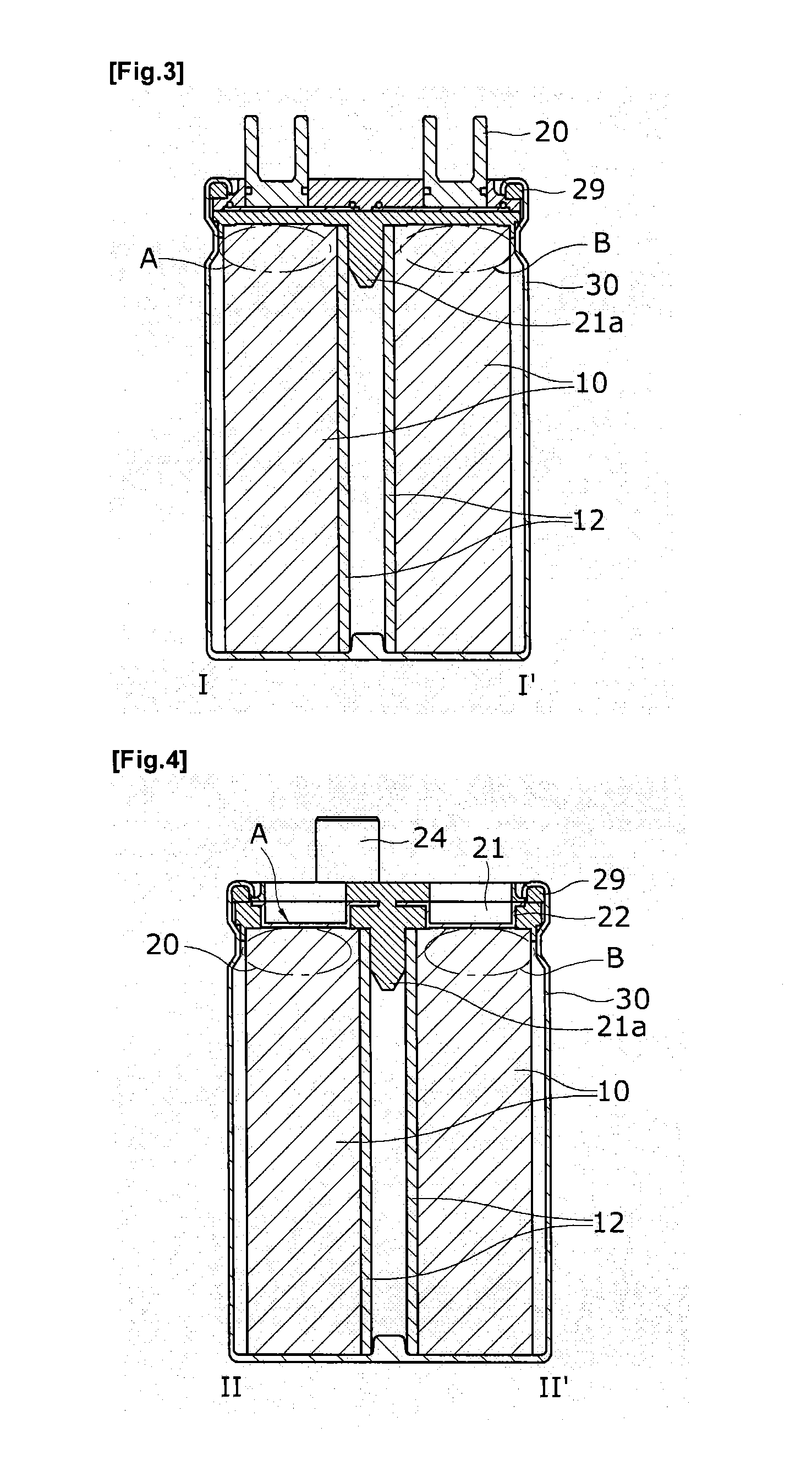

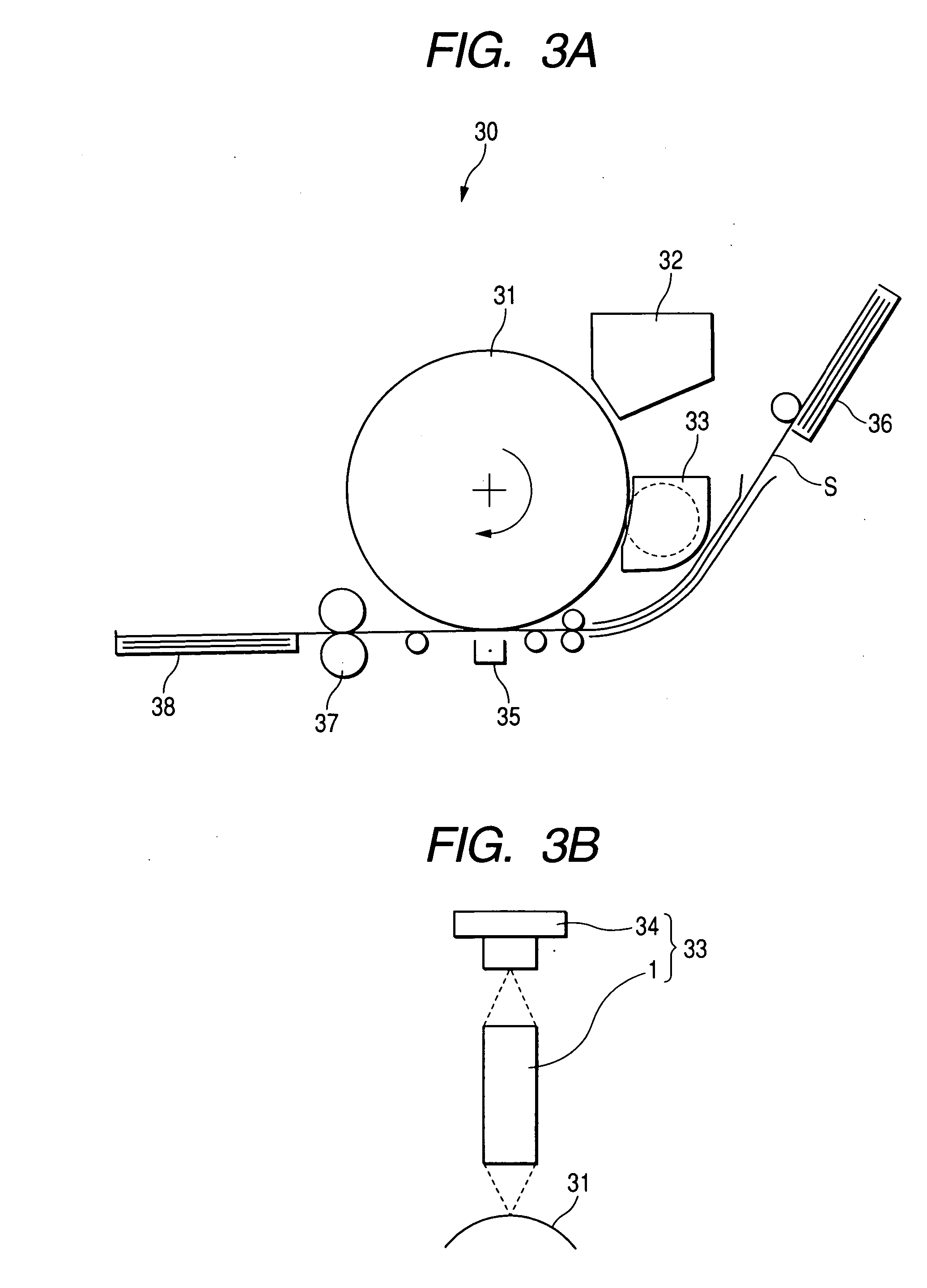

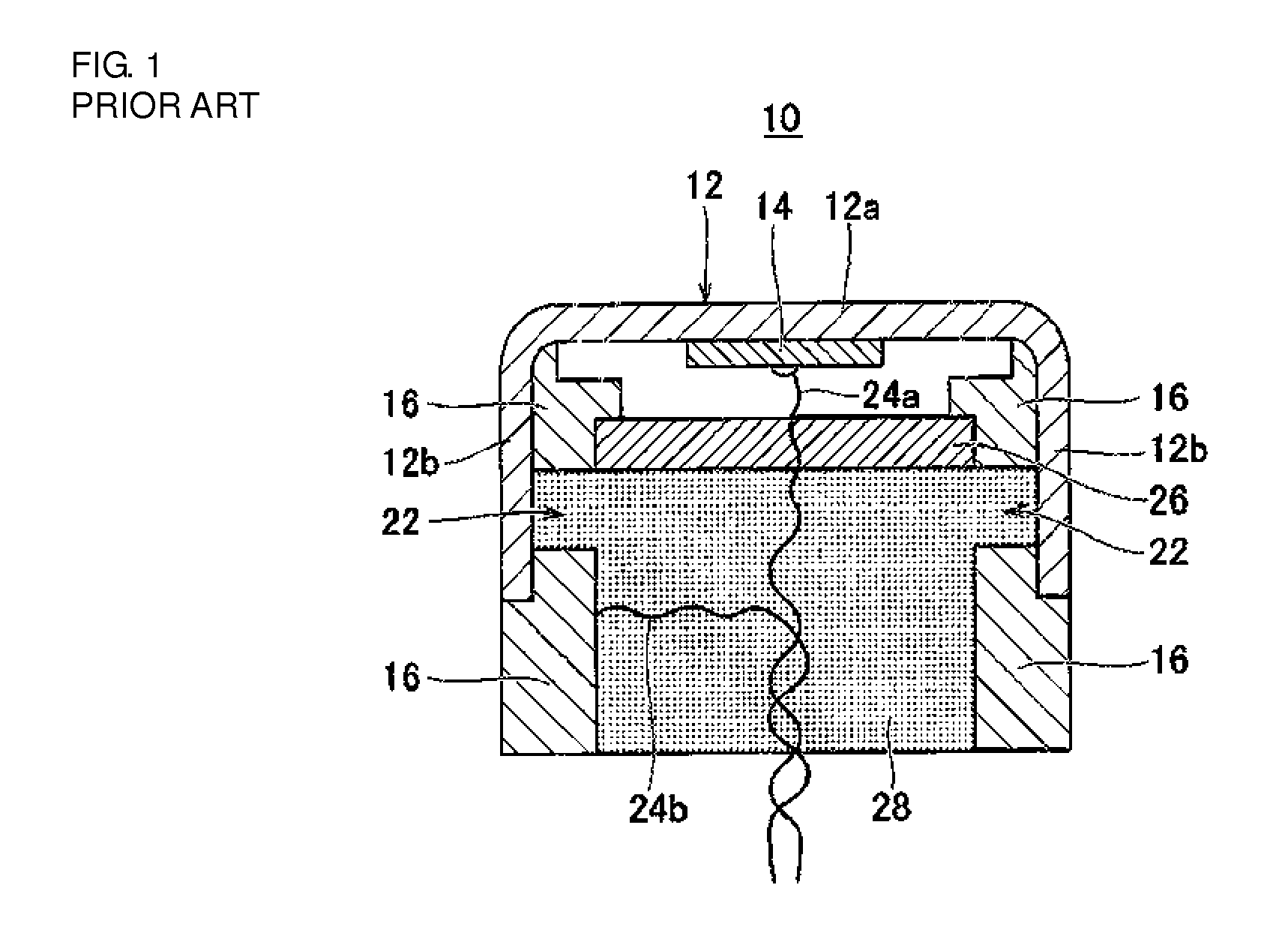

Electrical energy storage device

InactiveUS20110317333A1Difference in thicknessIncrease rangeLiquid electrolytic capacitorsCurrent conducting connectionsHigh rateElectrical polarity

Provided is an electrical energy storage device including an electrode winding body, which includes a positive electrode generating electrons by oxidation and reduction, a negative electrode for absorbing the generated electrons, and separation layers for physically separating the negative electrode from the positive electrode, which are sequentially wound around a winding core, and an electrolyte provided between the positive electrode and the negative electrode, the electrical energy storage device including: a terminal plate for externally connecting the electrode winding body to an external electrode connecting member such as an external resistor; a cylindrical can for accommodating the electrode winding body connected to the terminal plate; and a conductive interconnecting member for connection between the terminal plate and polarity-leads on one side of the electrode winding body by a method selected from the group consisting of plasma-spraying, welding, soldering and adhesion using a conductive adhesive material. According to the present invention, in which an interconnecting member for reducing a difference in thickness between objects to be welded is employed, it is possible to prevent welding failure between the polarity-leads of the electrode winding body and the terminal plate, thereby improving high-rate discharge (large current discharge) efficiency.

Owner:MAXWELL TECH KOREA CO LTD

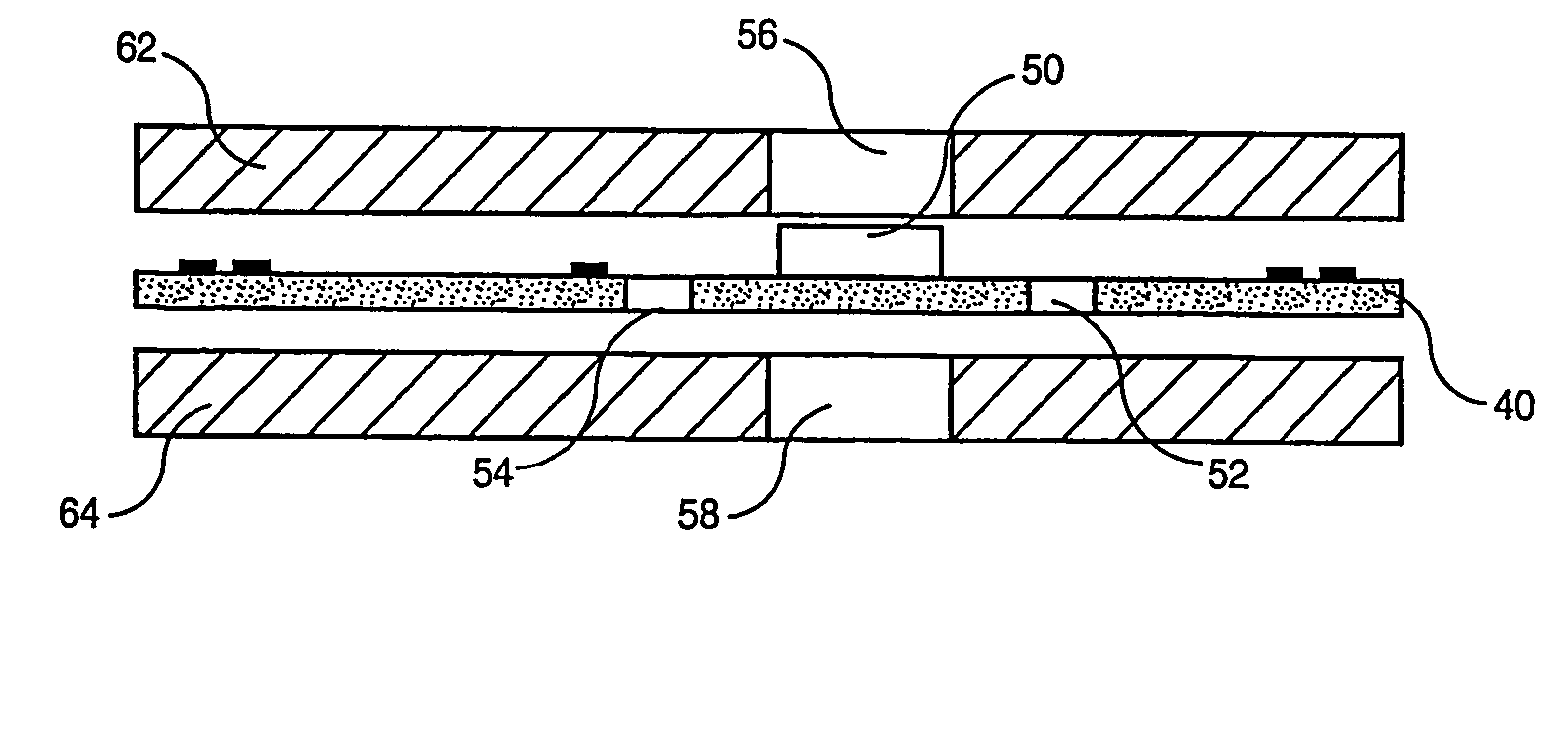

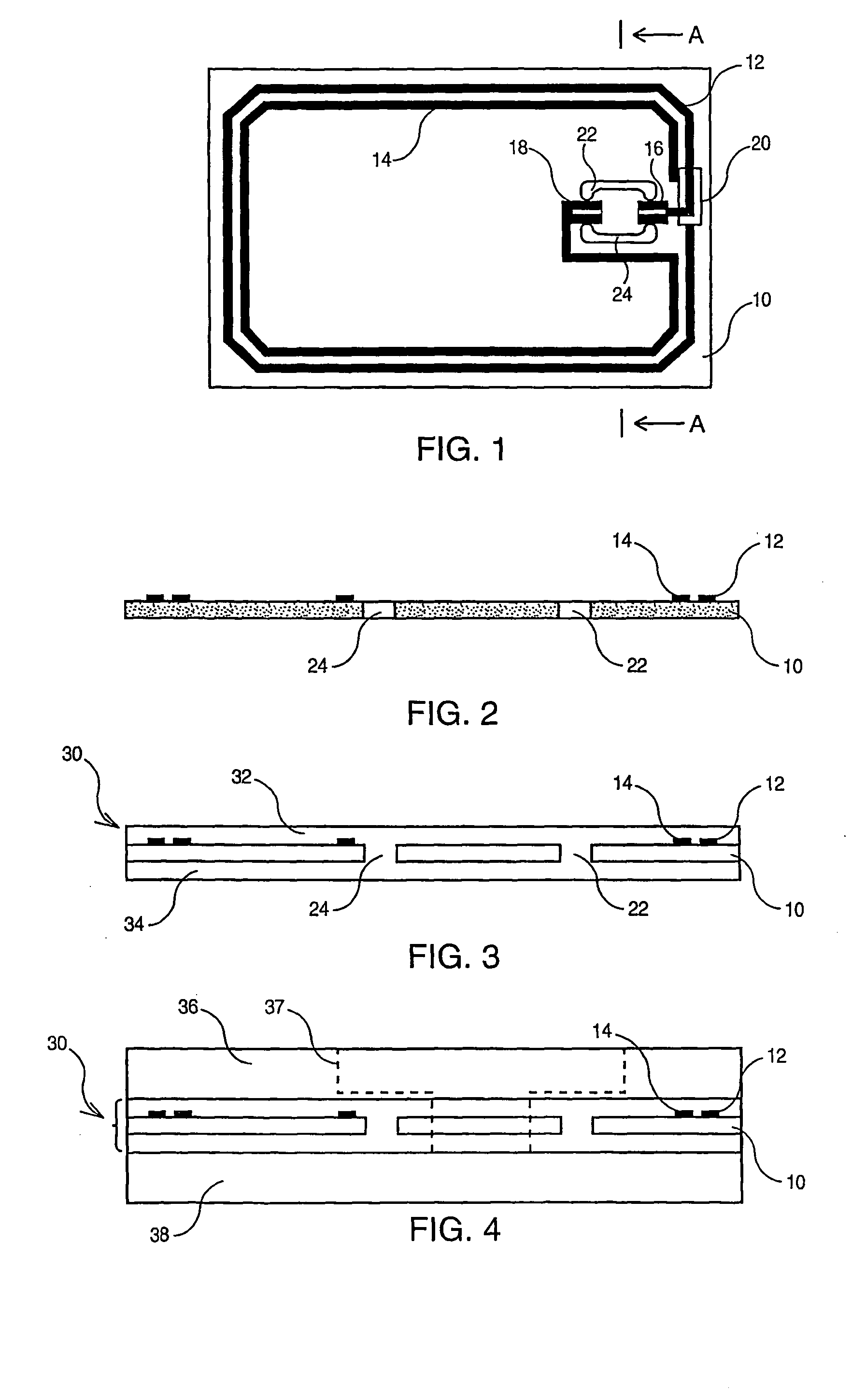

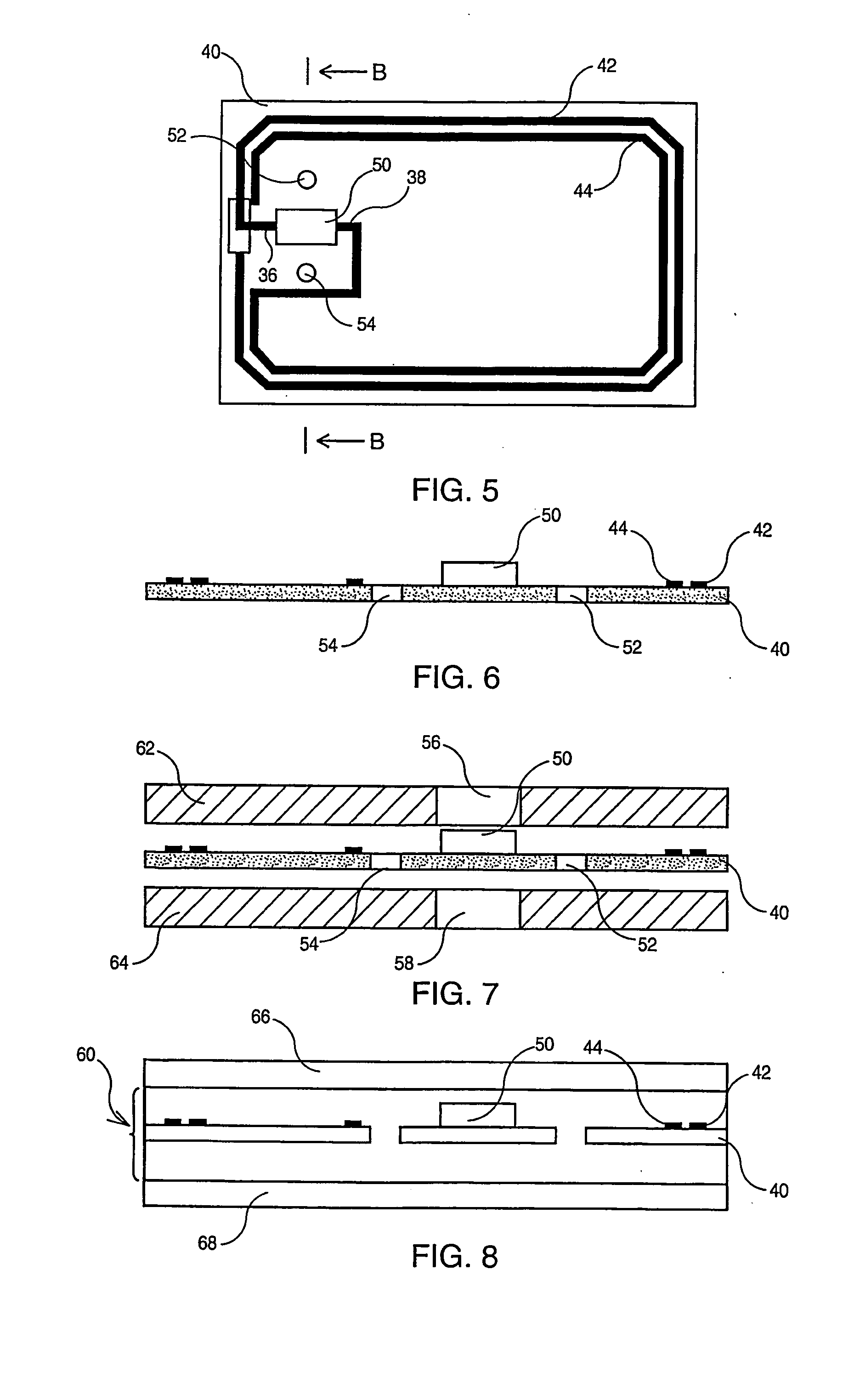

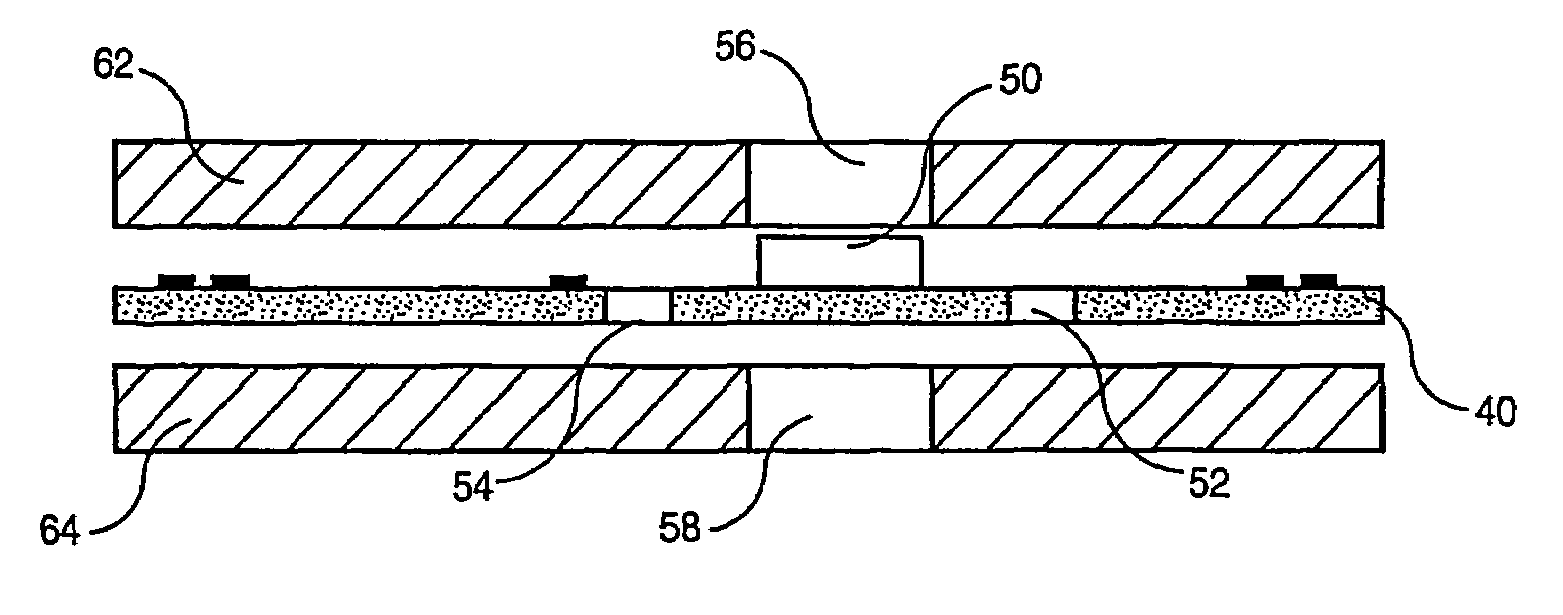

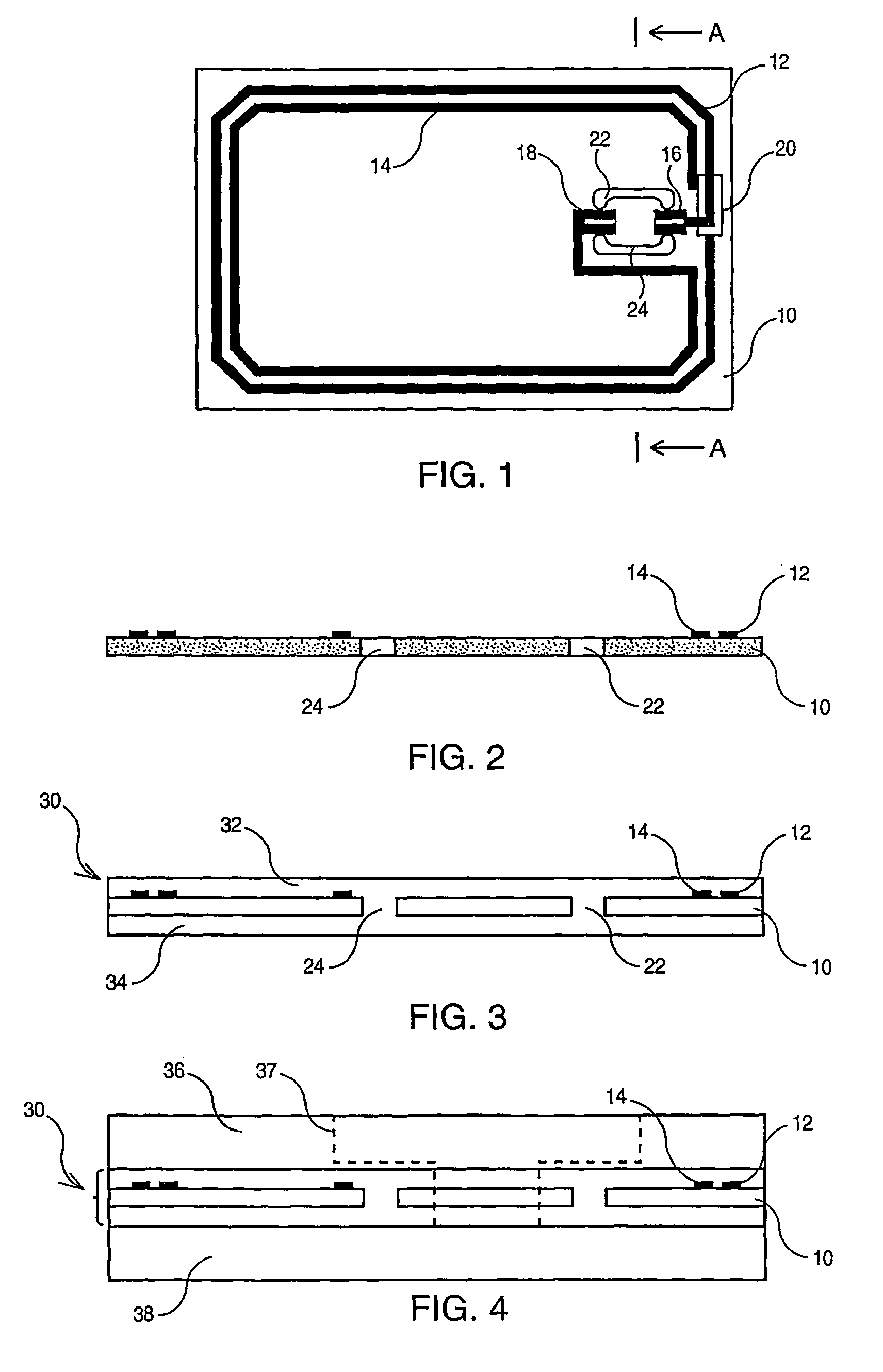

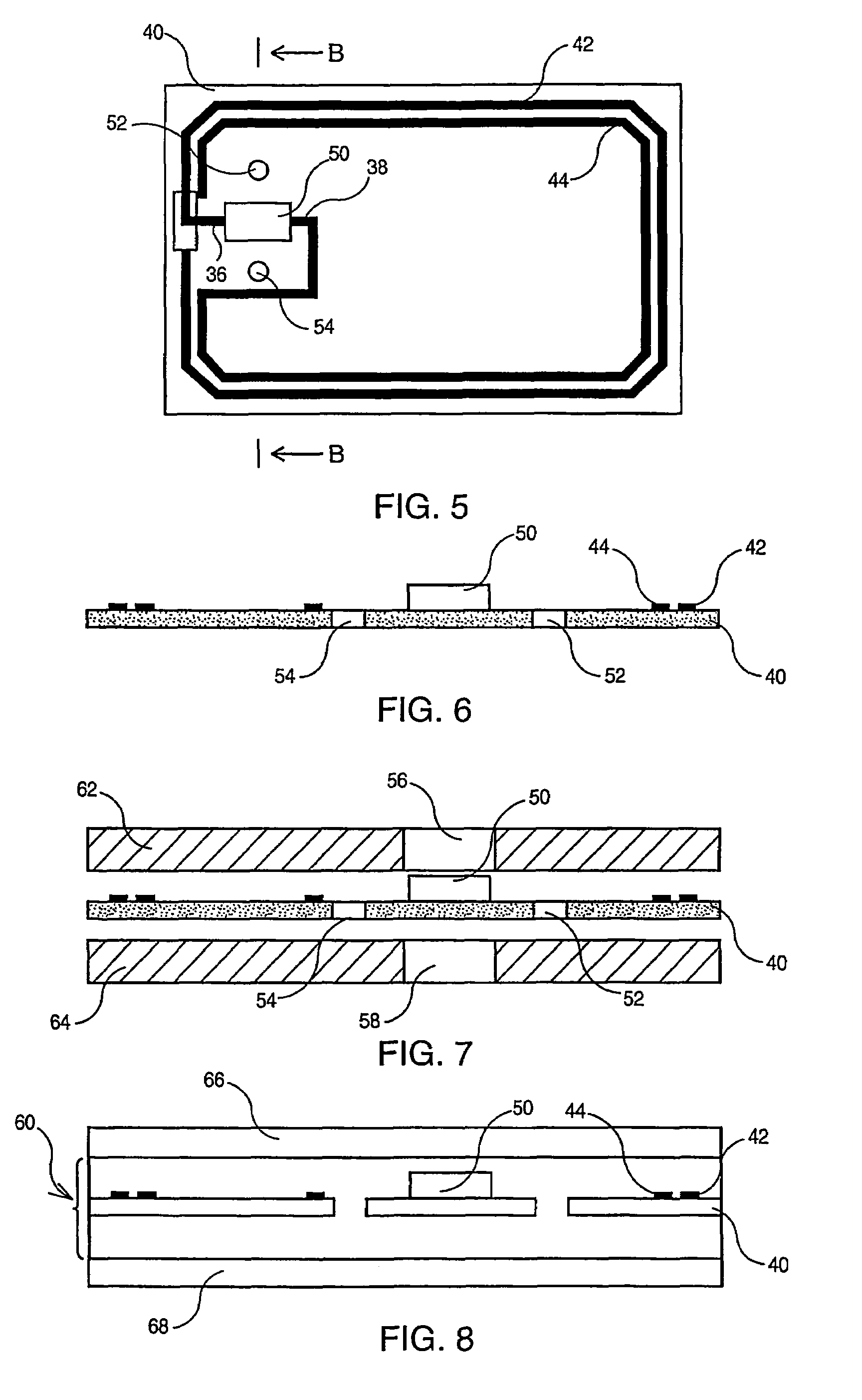

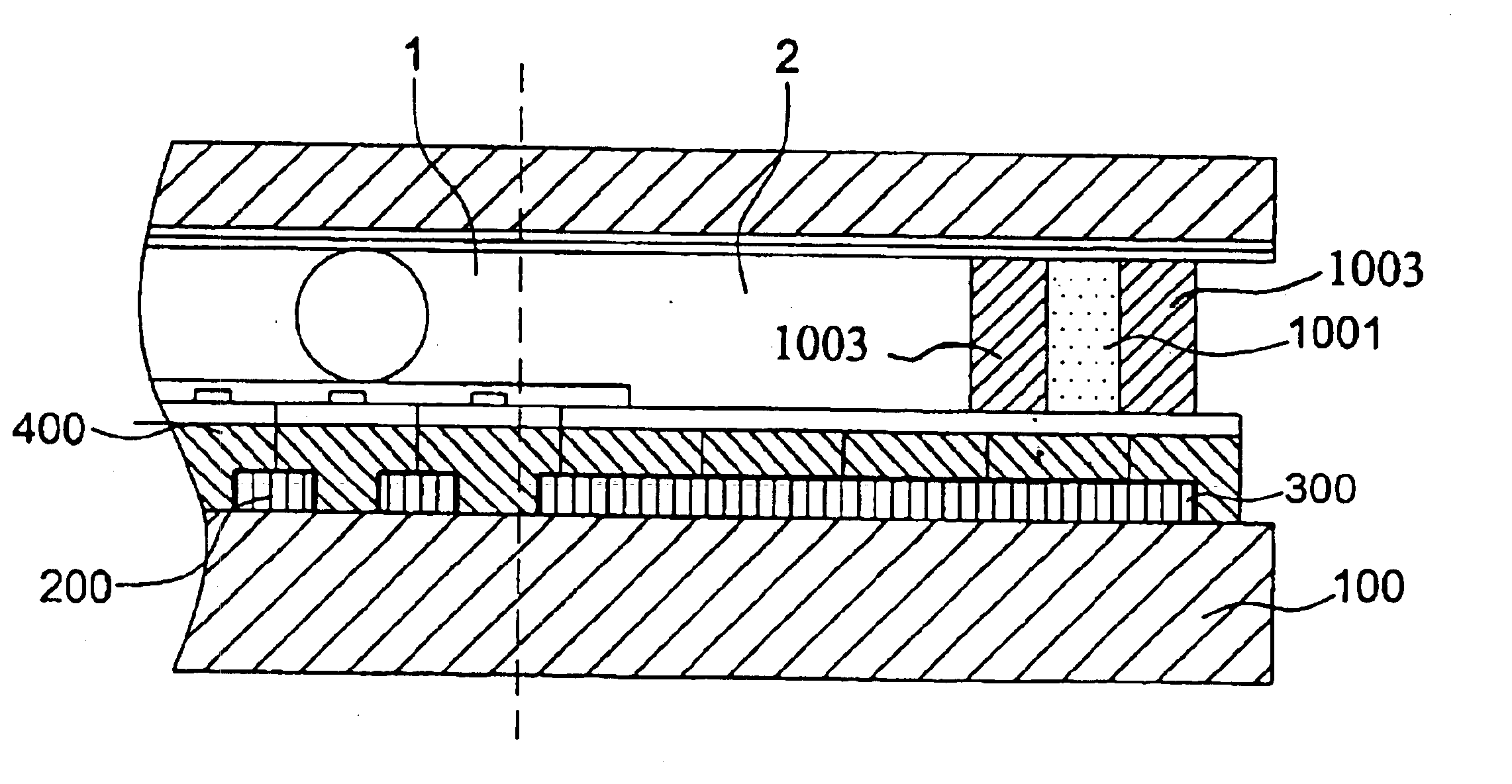

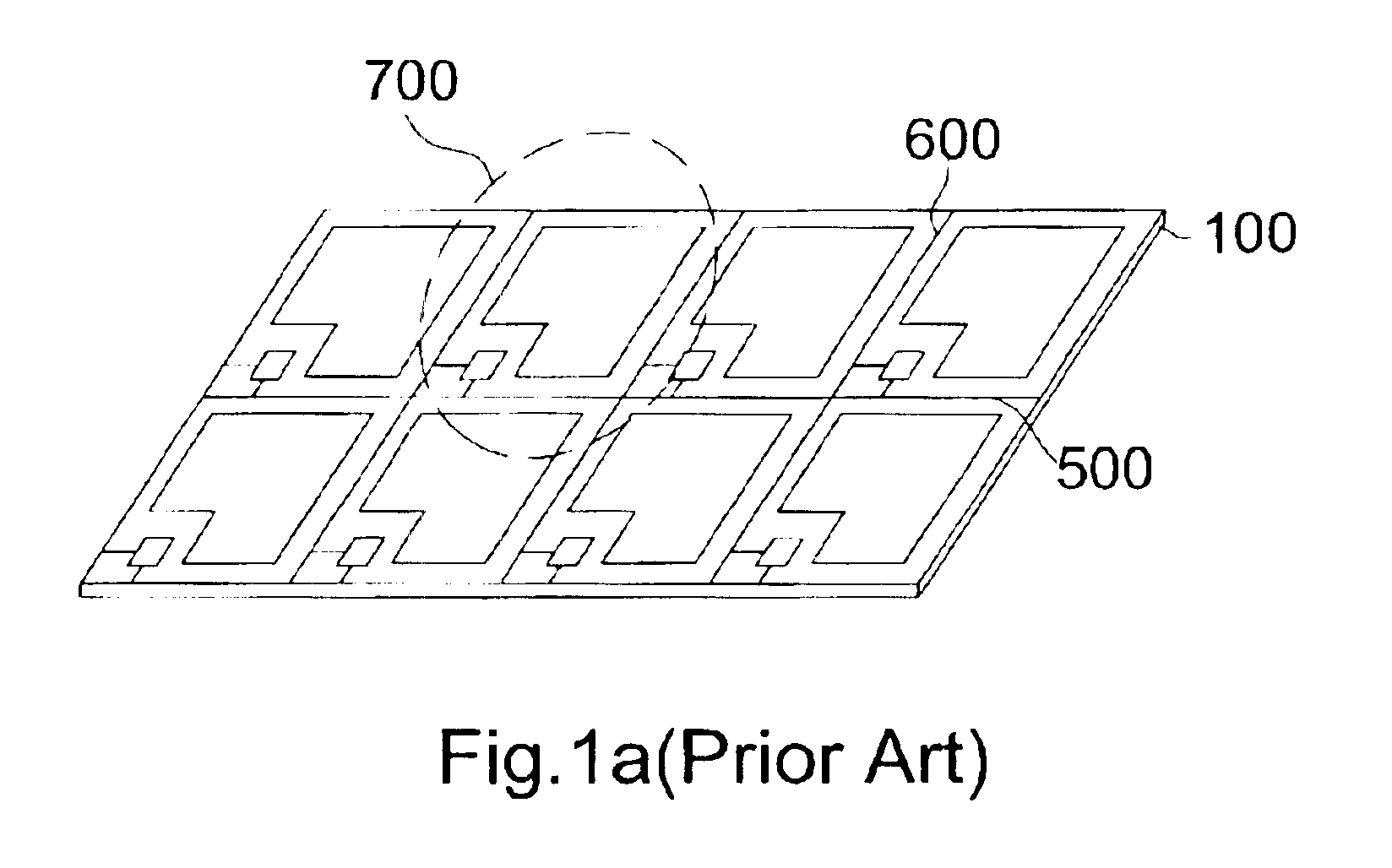

Method of producing a contactless chip card or a contact/contactless hybrid chip card with improved flatness

InactiveUS20050066513A1Difference in thicknessOther printing matterWave amplification devicesEngineeringElectron

Method of manufacturing a chip card having an antenna support, two card bodies and an electronic module or a chip linked to the antenna. This method has a first lamination step which includes fusing two thermoplastic sheets (32, 34 or 62, 64) on each side of antenna support (10 or 40) at a temperature sufficient for the thermoplastic sheet material to soften and to flow wholly so as to eliminate any differences in thickness from the support, and a second lamination step carried out after a period of time necessary for the thermoplastic sheets (32, 34 or 62, 64) to be solidified, the second step including fusing by hot pressing two plastic layers (36, 38 or 66, 68) making up the card bodies onto the plasticised and even faces of uniformly thick antenna support (30 or 60) plasticised by the thermoplastic sheets.

Owner:ASK SA (FR)

Method of producing a contactless chip card or a contact/contactless hybrid chip card with improved flatness

InactiveUS7116231B2Difference in thicknessOther printing matterLayered product treatmentThermoplasticComputer module

Owner:ASK SA (FR)

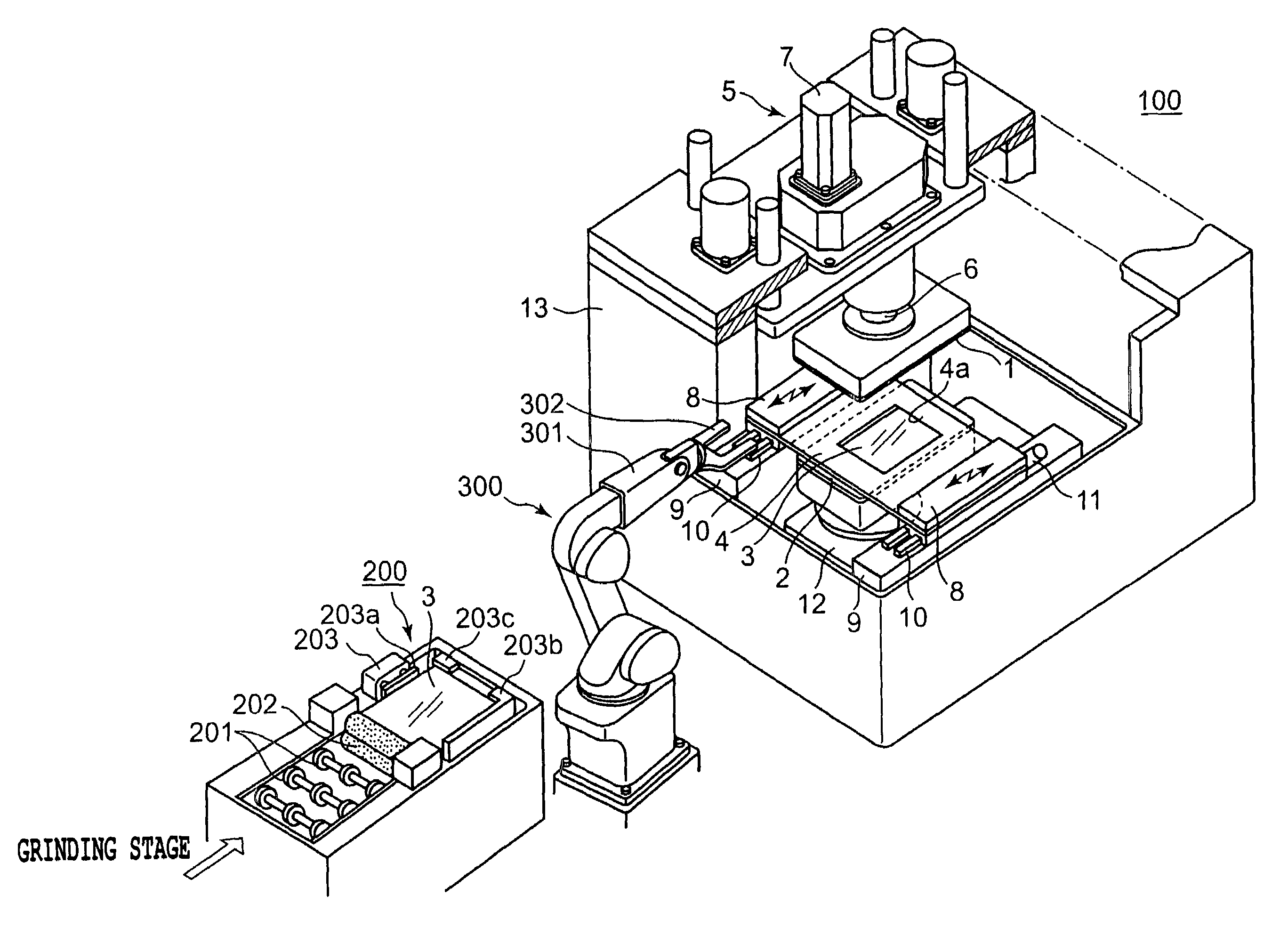

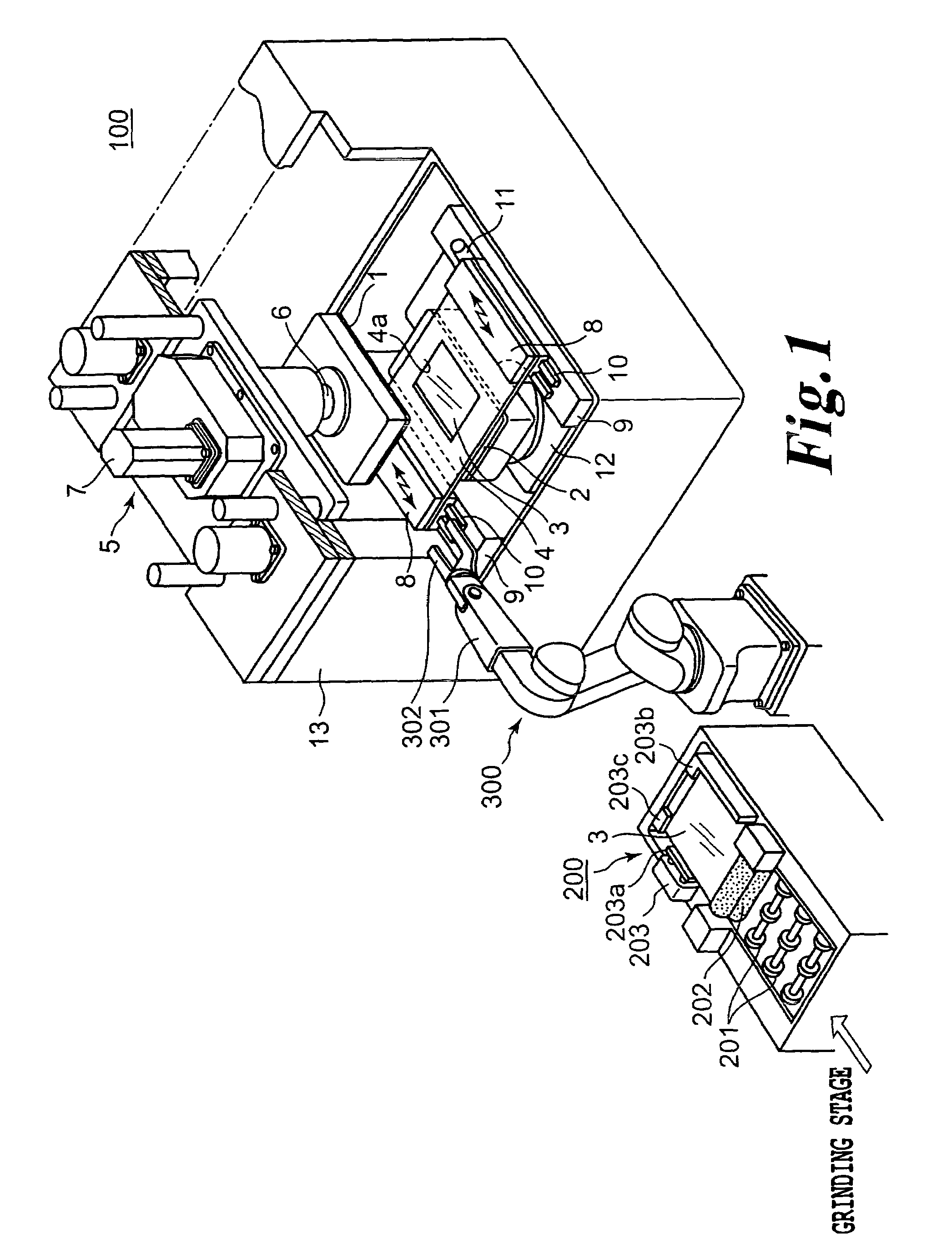

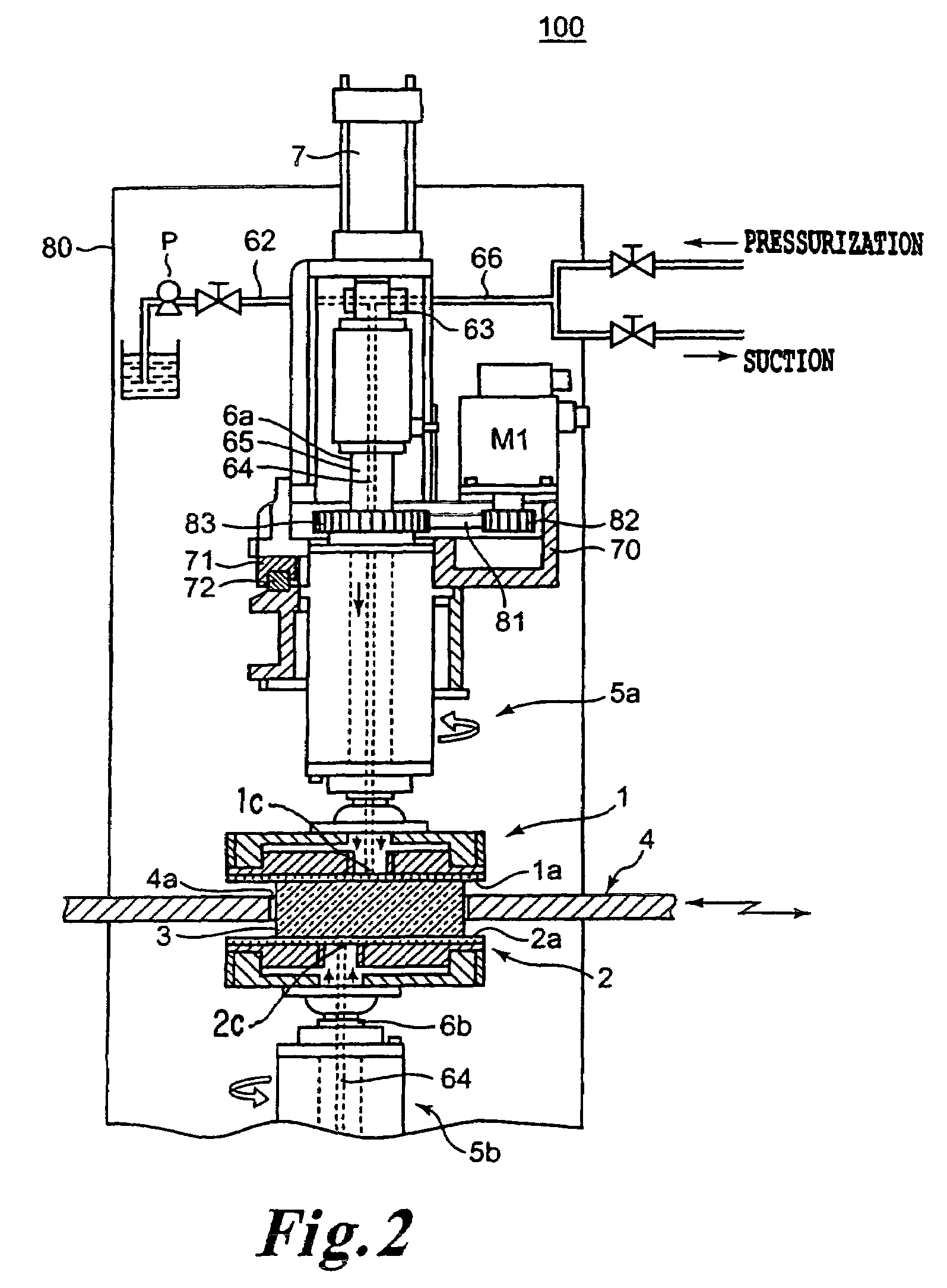

Equipment and method for polishing both sides of a rectangular substrate

InactiveUS7214124B2Good thickness consistencyDifference in thicknessEdge grinding machinesRevolution surface grinding machinesRotational axisElectrical and Electronics engineering

Double-sided polishing equipment configured to polish a rectangular substrate, comprising a carrier having a pocket configured to accommodate a rectangular substrate, a lateral linear moving mechanism configured to move the carrier, first and second polishing pads with first and second rotational axes, respectively, offset from centers of the pads, the polishing surfaces of the first and second polishing pads being parallel. The equipment further includes at least one elevating mechanism coupled to at least one of the polishing pads, first and second rotary drive mechanisms coupled to each of the first and second polishing pads, respectively; and configured to rotate the first and second pads about the first and second rotational axes. A polishing-agent supplying device is present and configured to supply polishing agent to a plane where a substrate that is accommodated in the pocket to accommodate the substrate comes into contact with the polishing pads.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

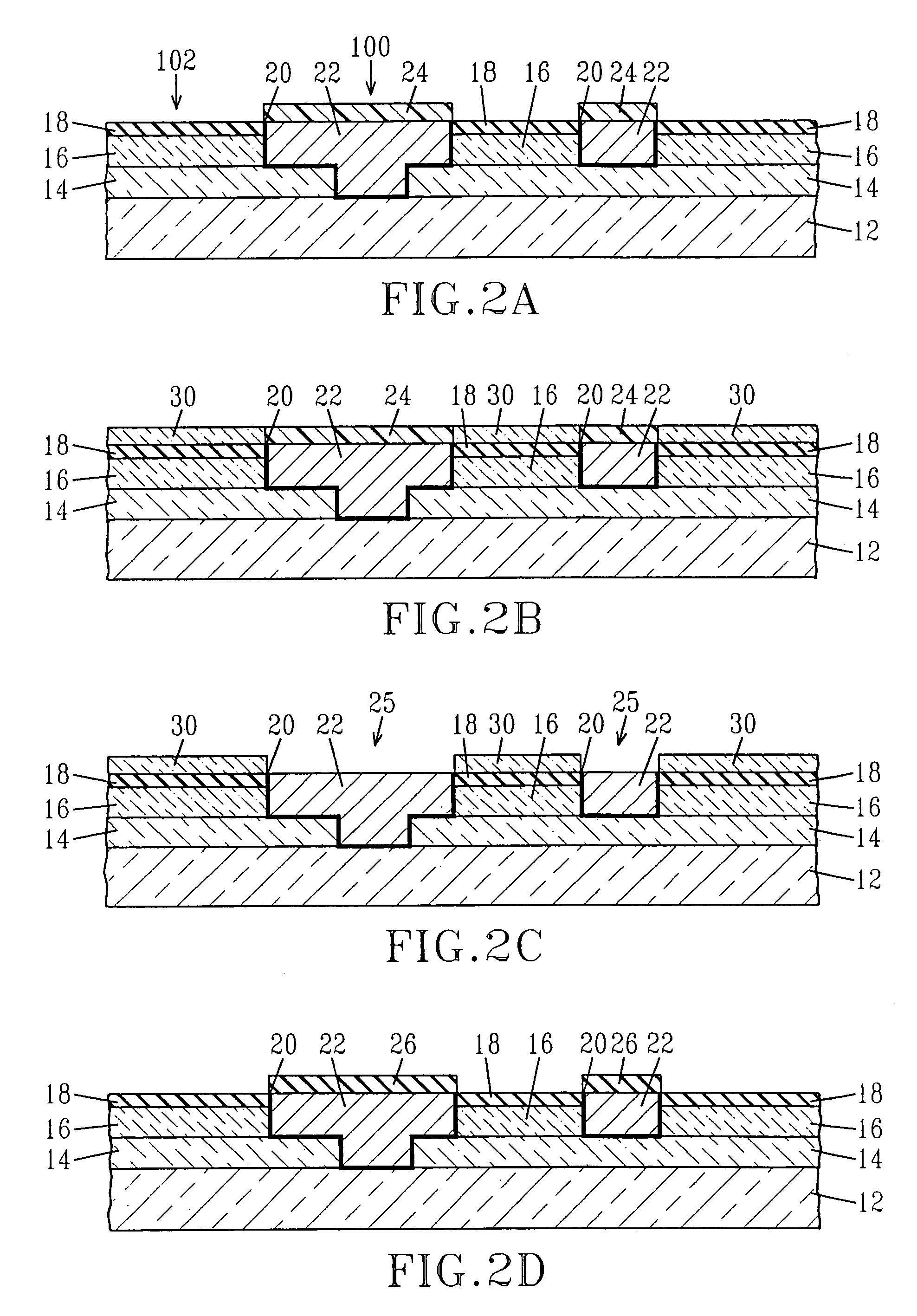

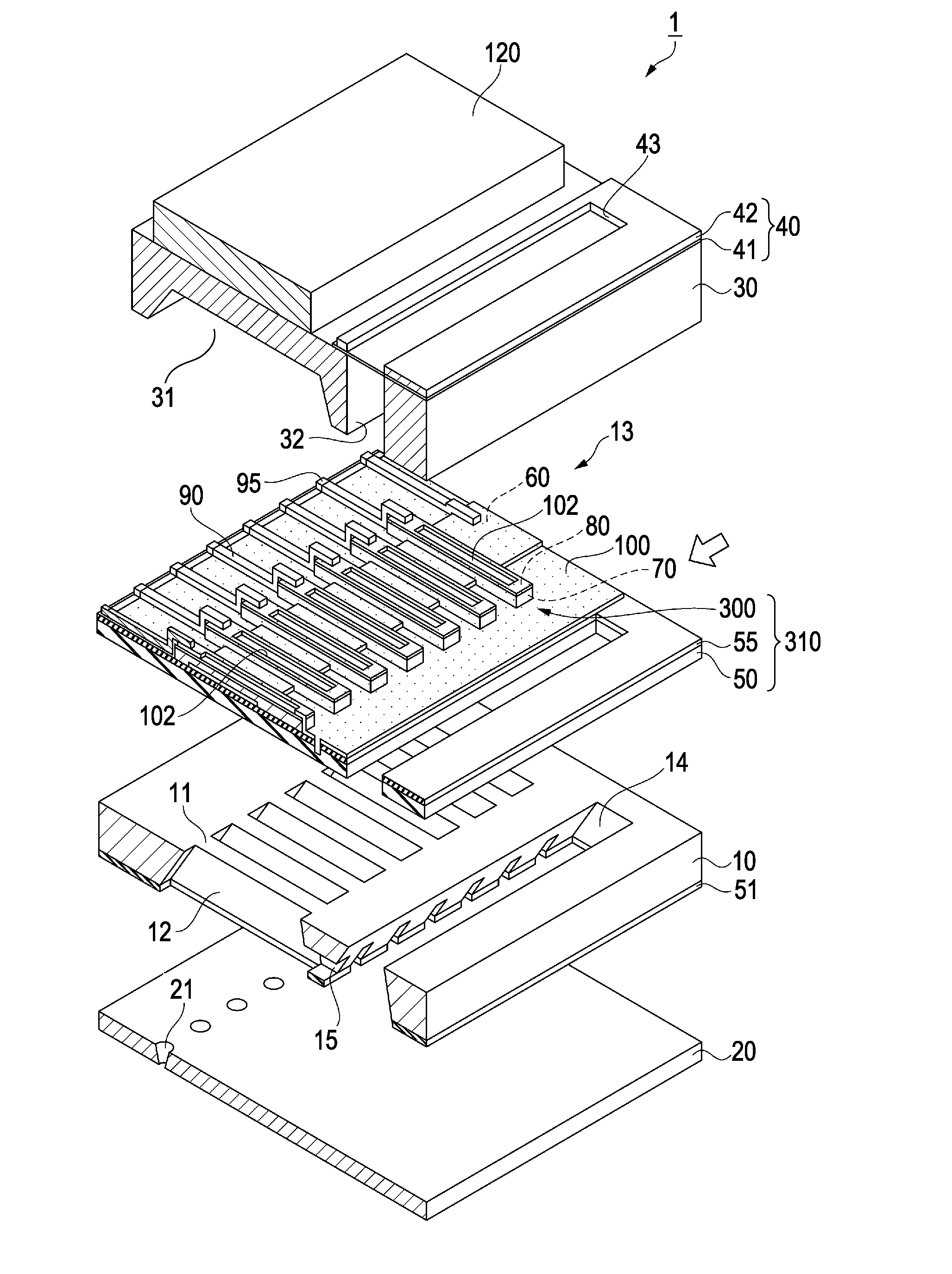

Method for producing self-aligned mask, articles produced by same and composition for same

InactiveUS20050045997A1Effective dielectric constant of be reduceMaximize propagation speedRadiation applicationsSemiconductor/solid-state device detailsReflectivityDielectric

A method for forming a self-aligned pattern on an existing pattern on a substrate comprising applying a coating of a solution containing a masking material in a carrier, the masking material being either photo or thermally sensitive; performing a blanket exposure of the substrate; and allowing at least a portion of the masking material to preferential develop in a fashion that is replicates the existing pattern of the substrate. The existing pattern may be comprised of a first set of regions of the substrate having a first reflectivity and a second set of regions of the substrate having a second reflectivity different from the first composition. The first set of regions may include one or more metal elements and the second set of regions may include a dielectric. Structures made in accordance with the method.

Owner:TAIWAN SEMICON MFG CO LTD

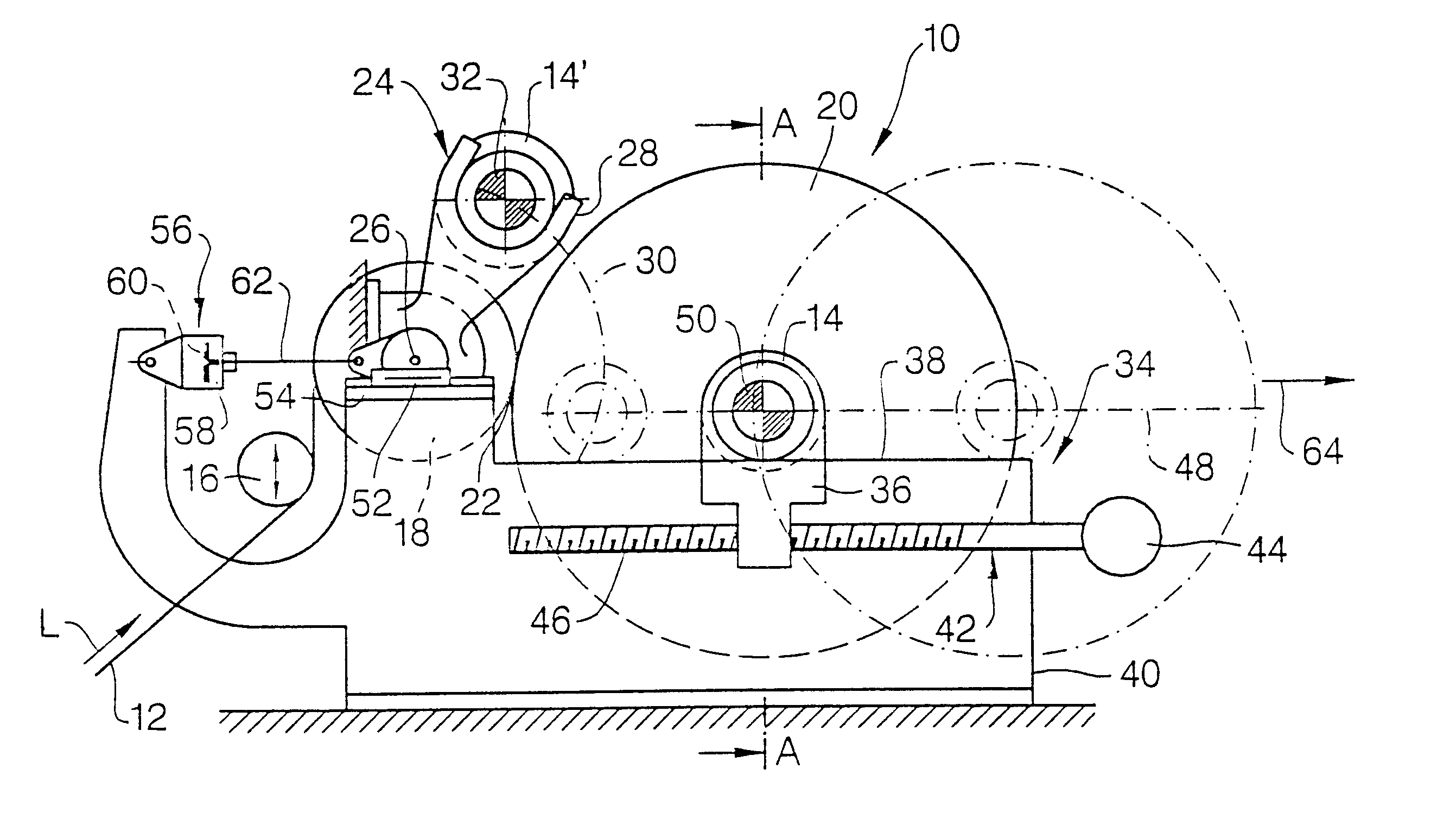

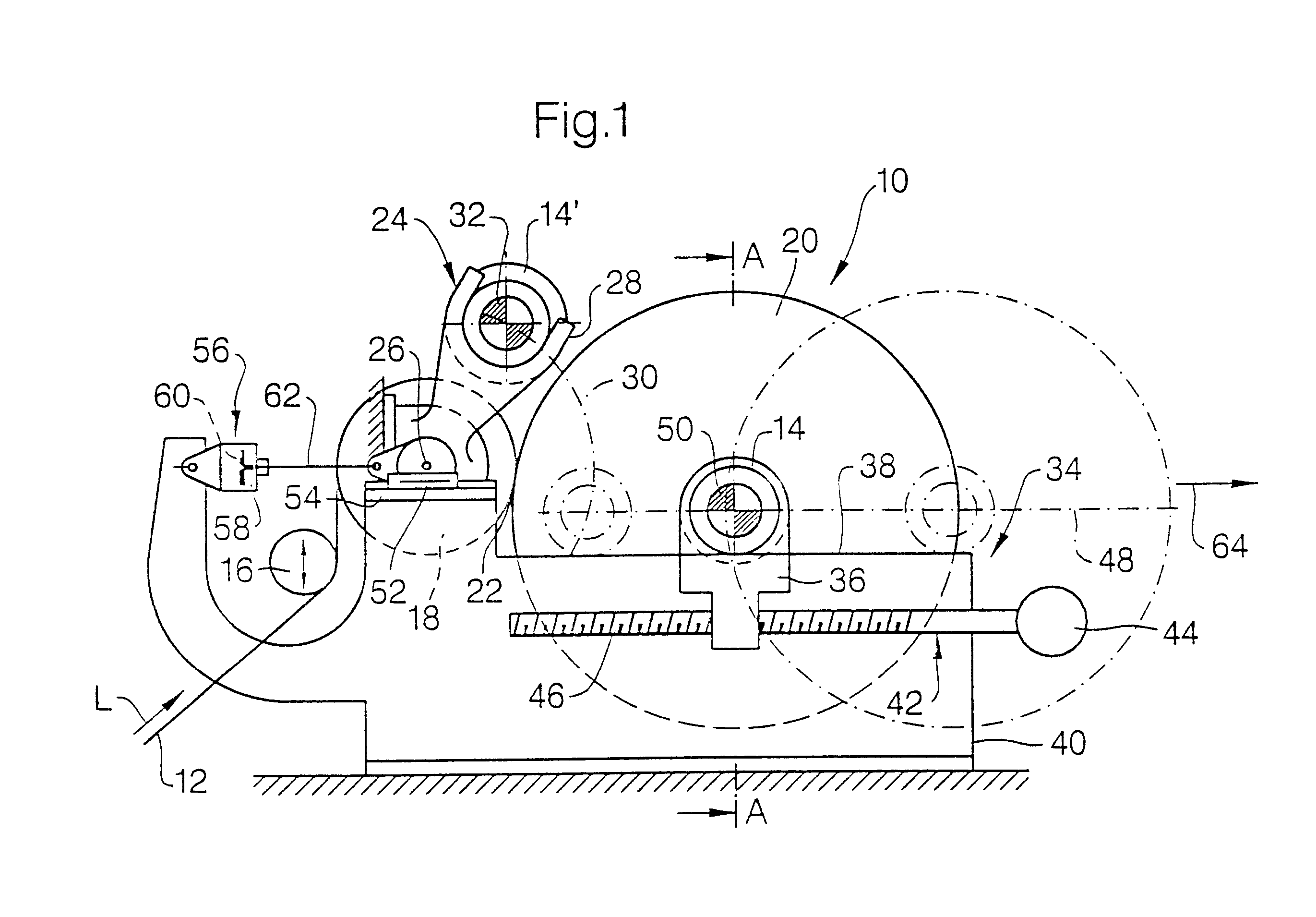

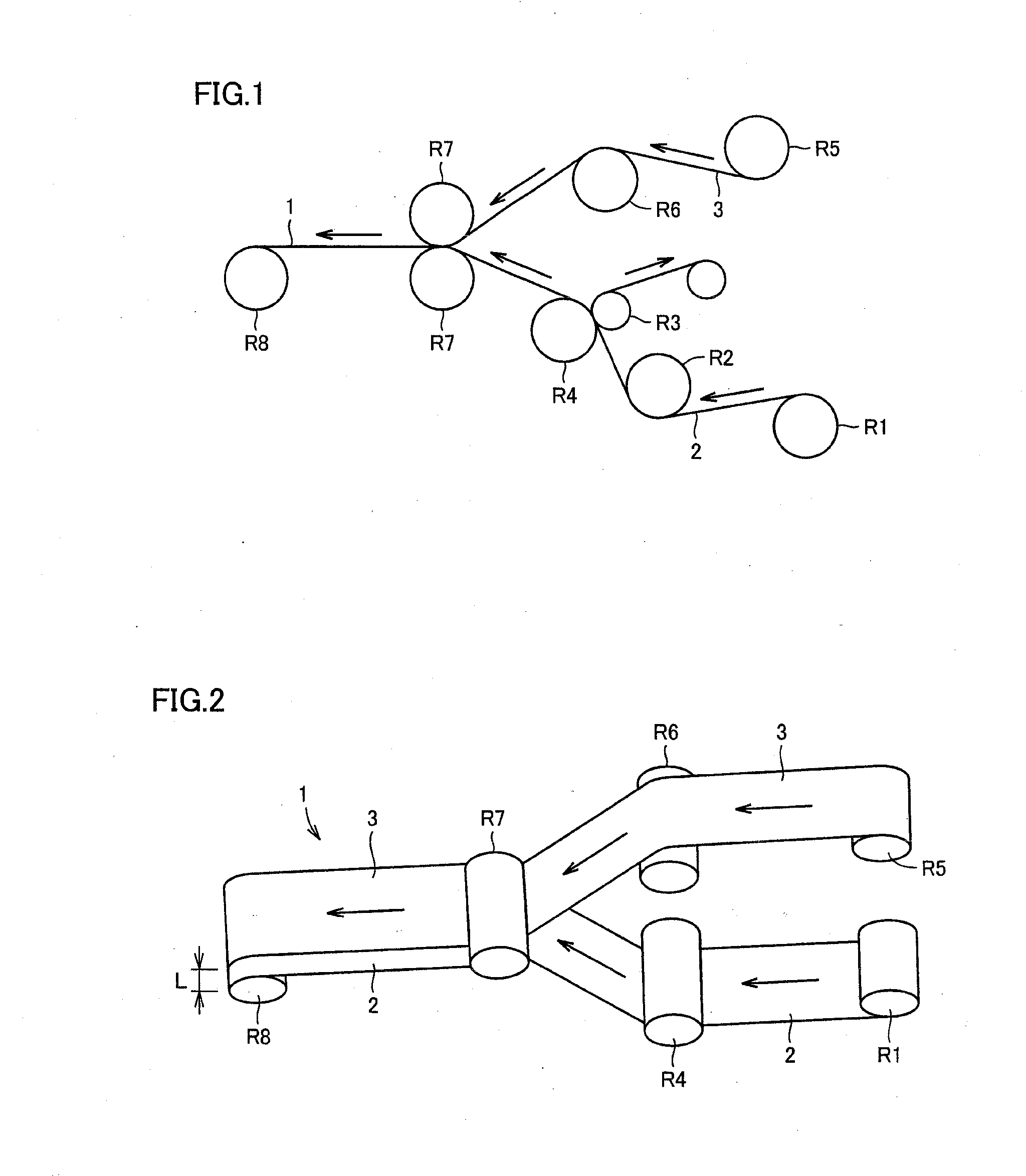

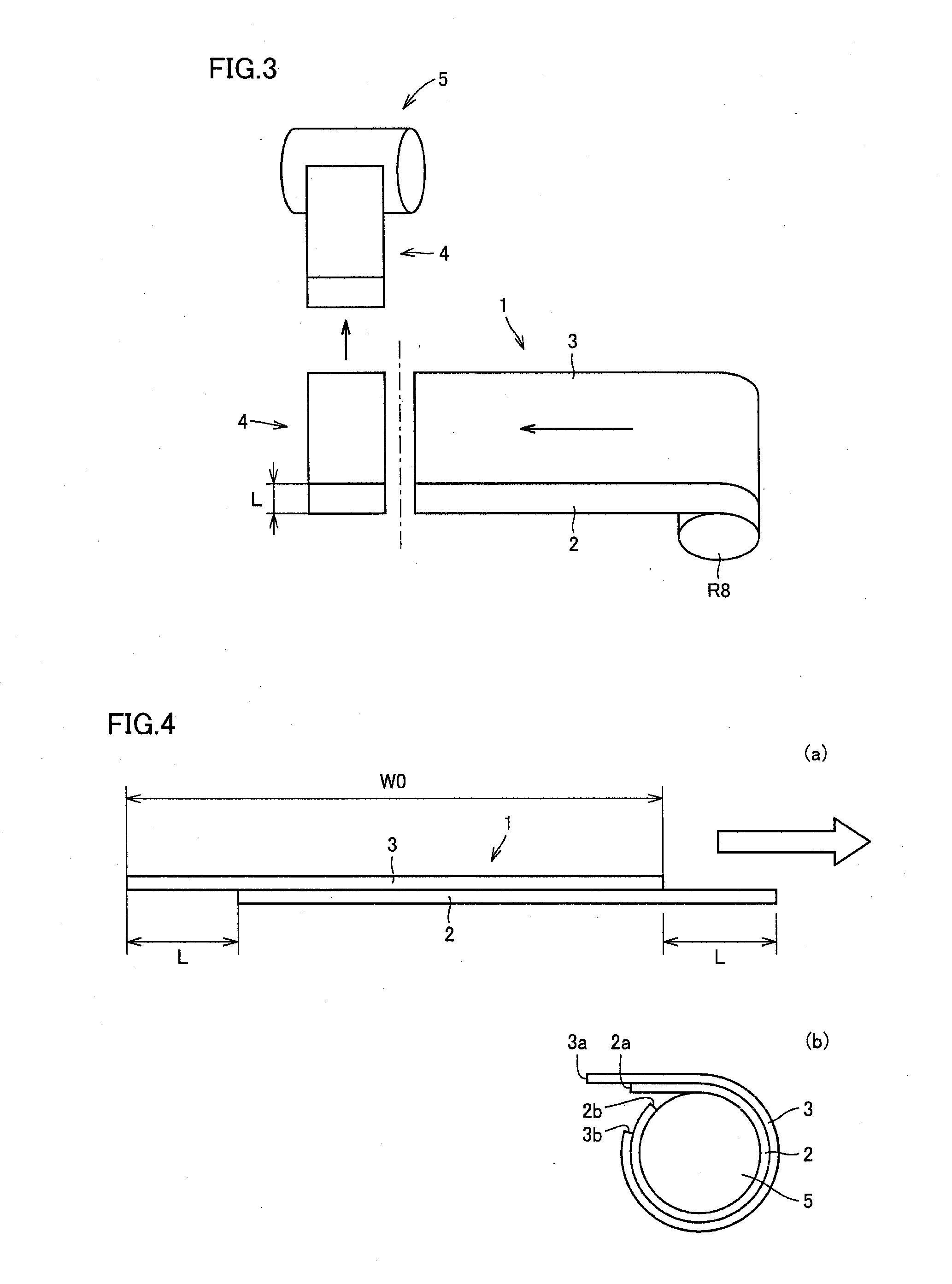

Winding machine and process for winding a material web

InactiveUS6402082B1Rapid increase in diameterEliminate dangerWebs handlingWinding machineMeasurement device

Apparatus and process for winding a material web into a wound roll on a winding core. The apparatus includes a press roll, movable press roll bearings coupled to the press roll, and a pressing device positioned to press the press roll against the wound roll. In this manner, the press roll and the wound roll form a winding nip, and the material web is guided the press roll and through the winding nip. The pressing device is adapted to set a line load in the winding nip, and movable winding core bearings are couplable to the winding core of the wound roll and are adapted to move the winding core to compensate for an increasing wound roll diameter. The winding nip one of remains in an at least approximately same position and is displaced by a small amount during winding. A driving device is positioned to move each of the movable winding core bearings, and a control device is arranged to control the driving device as a function of movement of the press roll from a desired position. A position measurement device, coupled to at least one of the movable press roll bearings, is adapted to produce an instantaneous position value of the press roll in accordance with a current position of the press roll, a regulator is adapted to compare the instantaneous position value with a desired position value of the press roll and to transmit an actuating variable that corresponds to a deviation of the instantaneous value from the desired value, and a wire is adapted to transmit the actuating variable from the regulator to the control device.

Owner:VOITH PATENT GMBH

Semiconductor memory device and method of manufacturing the same

ActiveUS8735967B2Well formedDifference in thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor memory device includes a lower select transistor formed within a semiconductor substrate, memory cells stacked over the lower select transistors, and an upper select transistor formed over the memory cells.

Owner:SK HYNIX INC

Method for producing self-aligned mask, articles produced by same and composition for same

InactiveUS7378738B2Reduce electromigrationEffective dielectric constantRadiation applicationsSemiconductor/solid-state device detailsDielectricMetal

A method for forming a self-aligned pattern on an existing pattern on a substrate comprising applying a coating of a solution containing a masking material in a carrier, the masking material being either photo or thermally sensitive; performing a blanket exposure of the substrate; and allowing at least a portion of the masking material to preferential develop in a fashion that is replicates the existing pattern of the substrate. The existing pattern may be comprised of a first set of regions of the substrate having a first reflectivity and a second set of regions of the substrate having a second reflectivity different from the first composition. The first set of regions may include one or more metal elements and the second set of regions may include a dielectric. Structures made in accordance with the method.

Owner:TAIWAN SEMICON MFG CO LTD

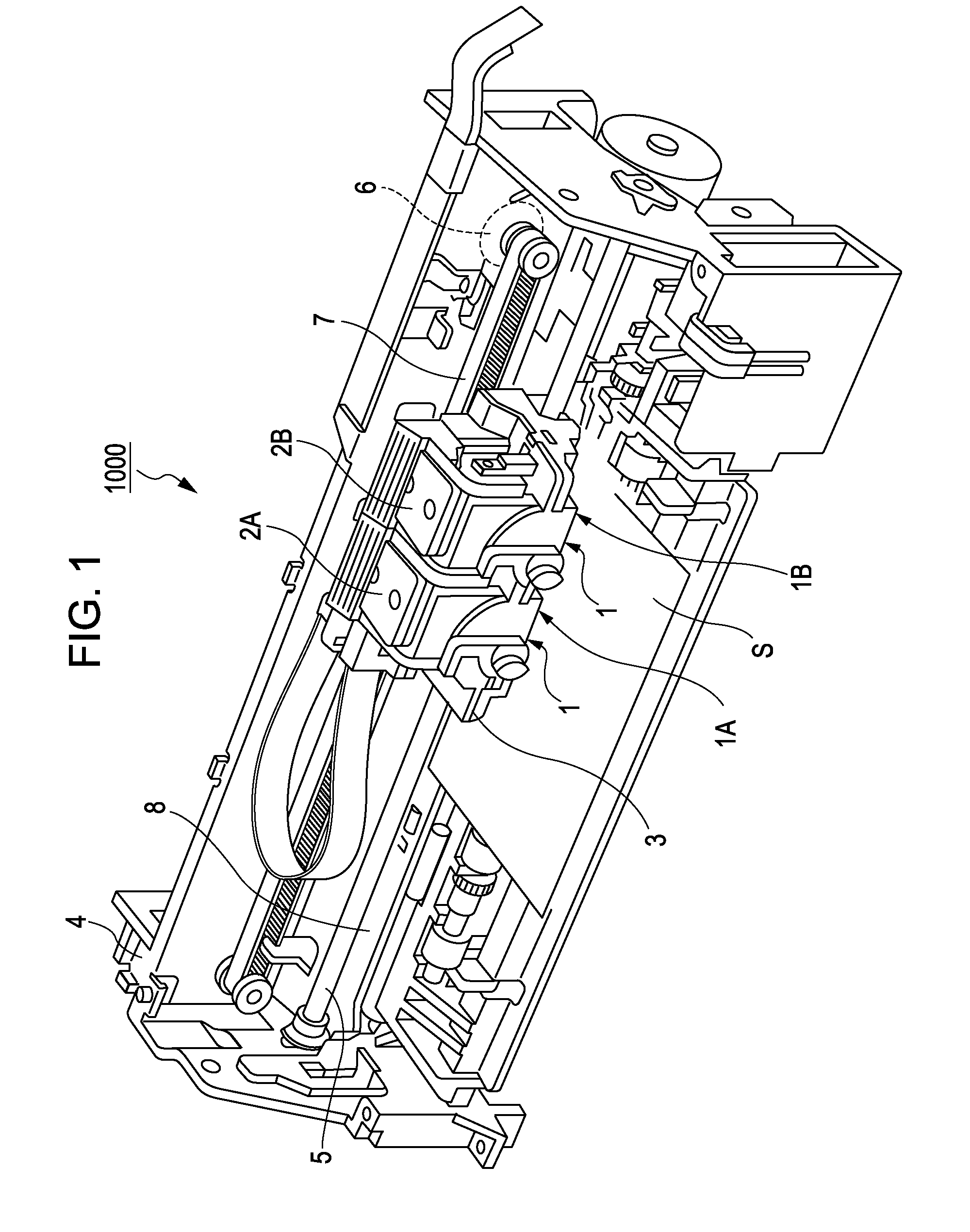

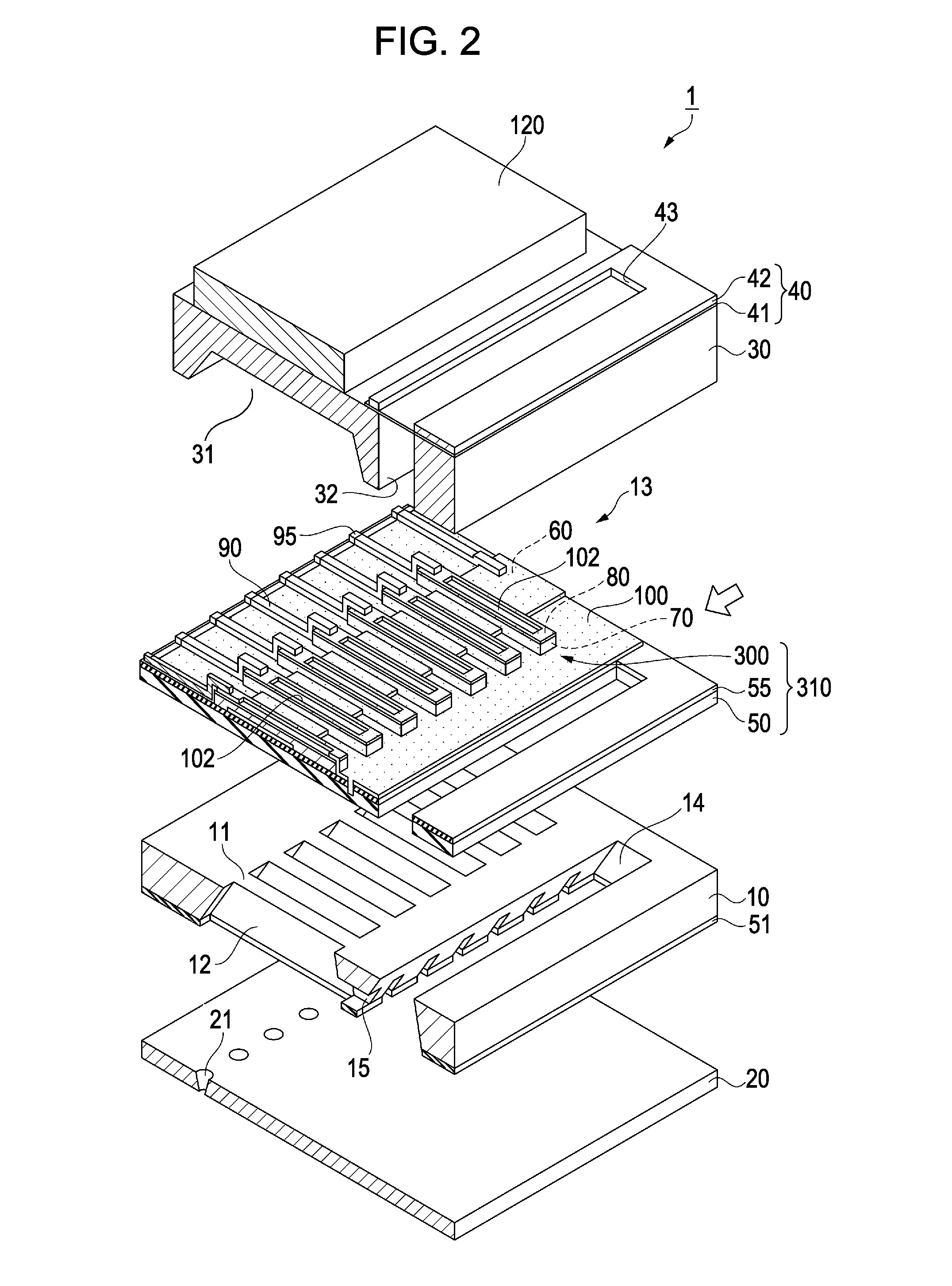

Piezoelectric actuator, method for manufacturing piezoelectric actuator, liquid-ejecting head, and liquid-ejecting apparatus

InactiveUS20110043573A1More resistant to sputteringSmall differencePiezoelectric/electrostrictive device manufacture/assemblyLiquid surface applicatorsTectorial membranePiezoelectric actuators

A piezoelectric actuator includes a substrate; a diaphragm overlying the substrate; a lower electrode overlying the diaphragm; a piezoelectric body overlying the lower electrode; an upper electrode that includes a first upper sub-electrode which overlies the piezoelectric body and which has a first sputtering rate and also includes a second upper sub-electrode which overlies the first upper sub-electrode, which has a second sputtering rate less than the first sputtering rate, and which is the uppermost layer; and a protective film extending over side surfaces of the piezoelectric body and the second upper sub-electrode, a portion of the protective film that overlies the second upper sub-electrode being removed by sputtering.

Owner:SEIKO EPSON CORP

Imaging lens unit

A compact low-cost imaging lens unit for a solid-state image sensor which corrects various aberrations adequately and produces a high-resolution high-definition image. The components of the unit are arranged from an object side to an image side in the following order: an aperture stop, a first lens with positive refractive power having a convex surface facing the object side, a second lens with negative refractive power having a convex surface facing the object side near an optical axis, a third lens with negative refractive power having a convex surface facing the object side near the optical axis, a fourth lens as a meniscus lens with positive refractive power having a convex surface facing the image side near the optical axis; and a fifth lens with negative refractive power having a concave surface facing the image side near the optical axis.

Owner:TOKYO VISIONARY OPTICS CO LTD

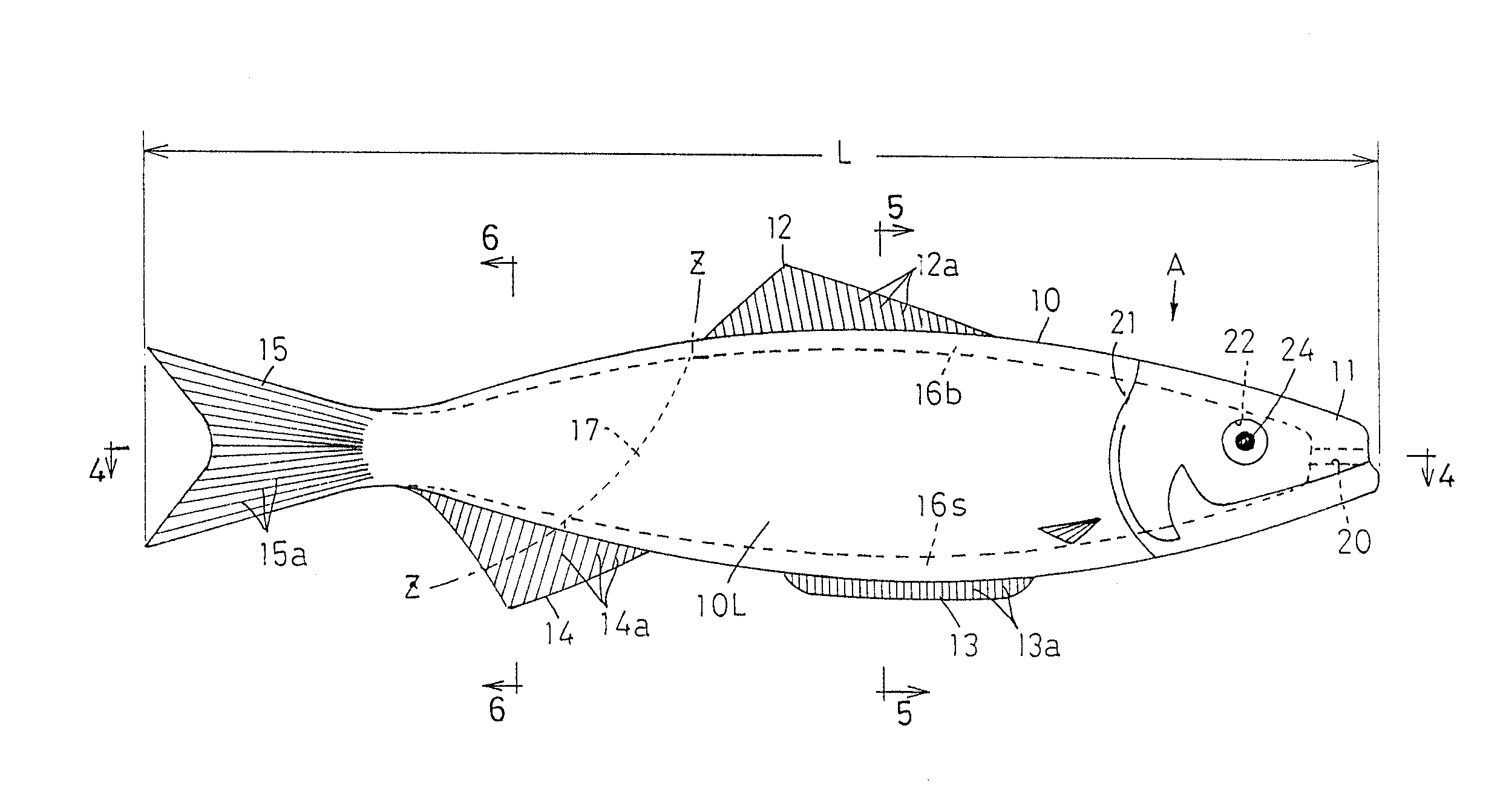

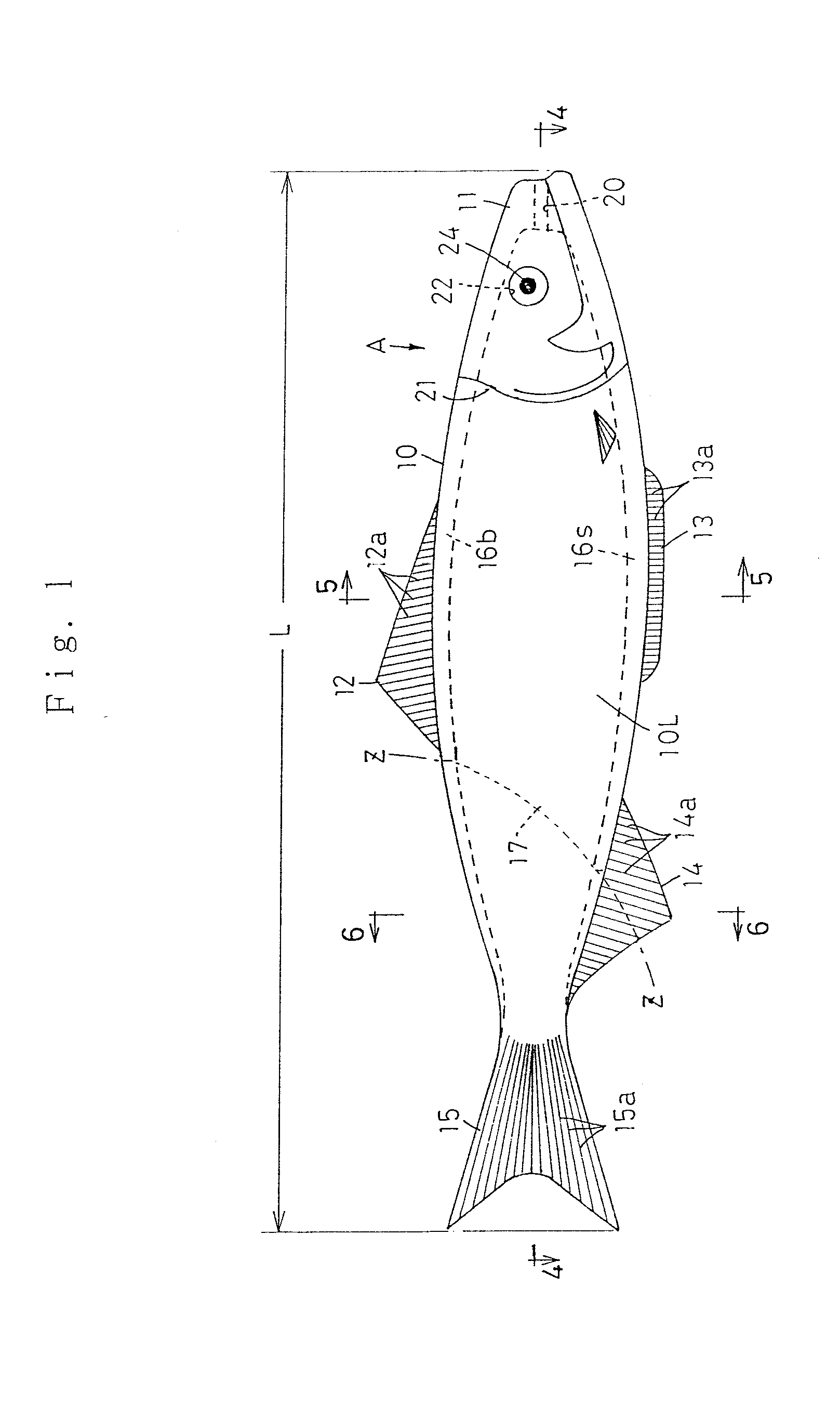

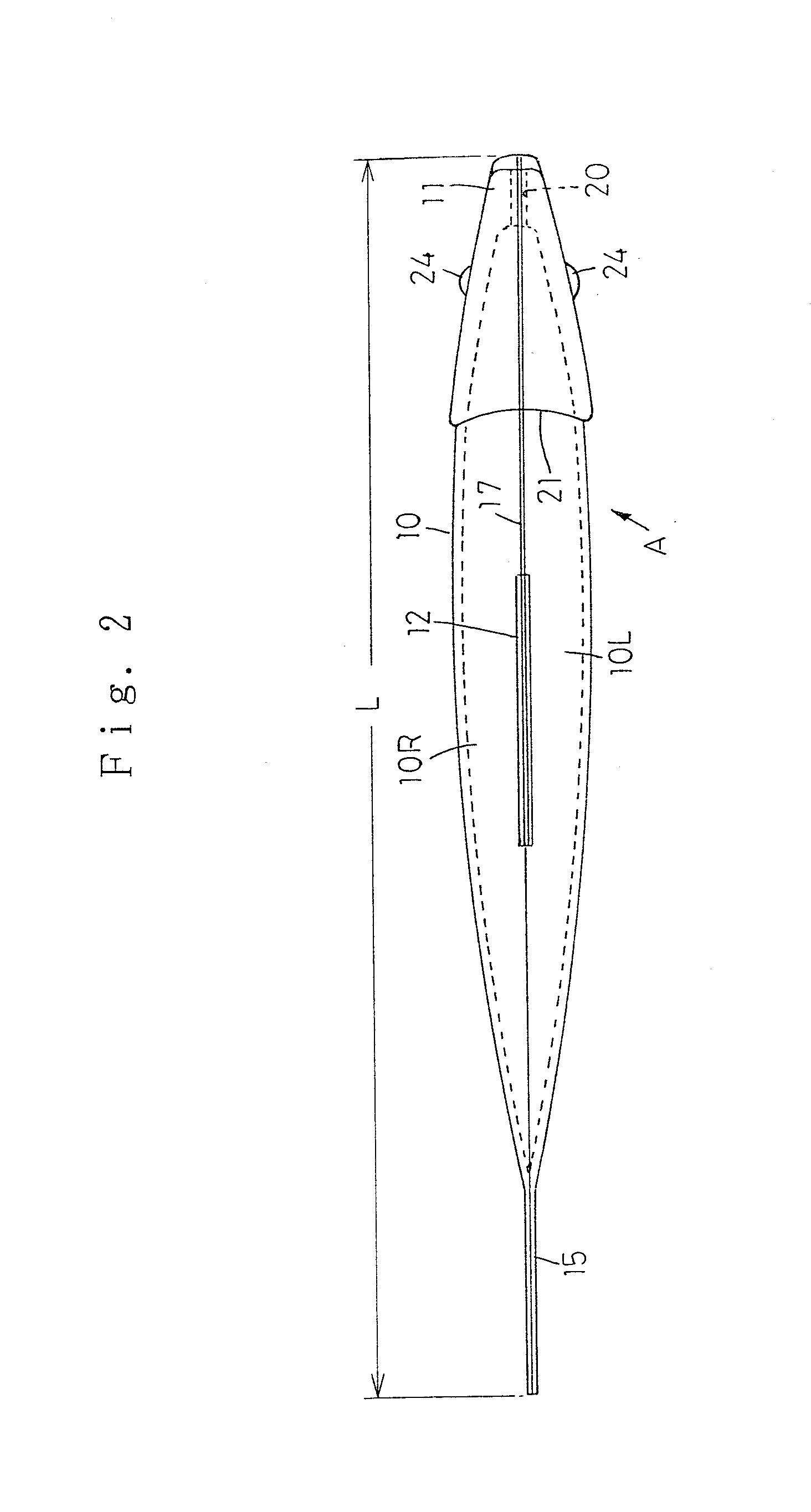

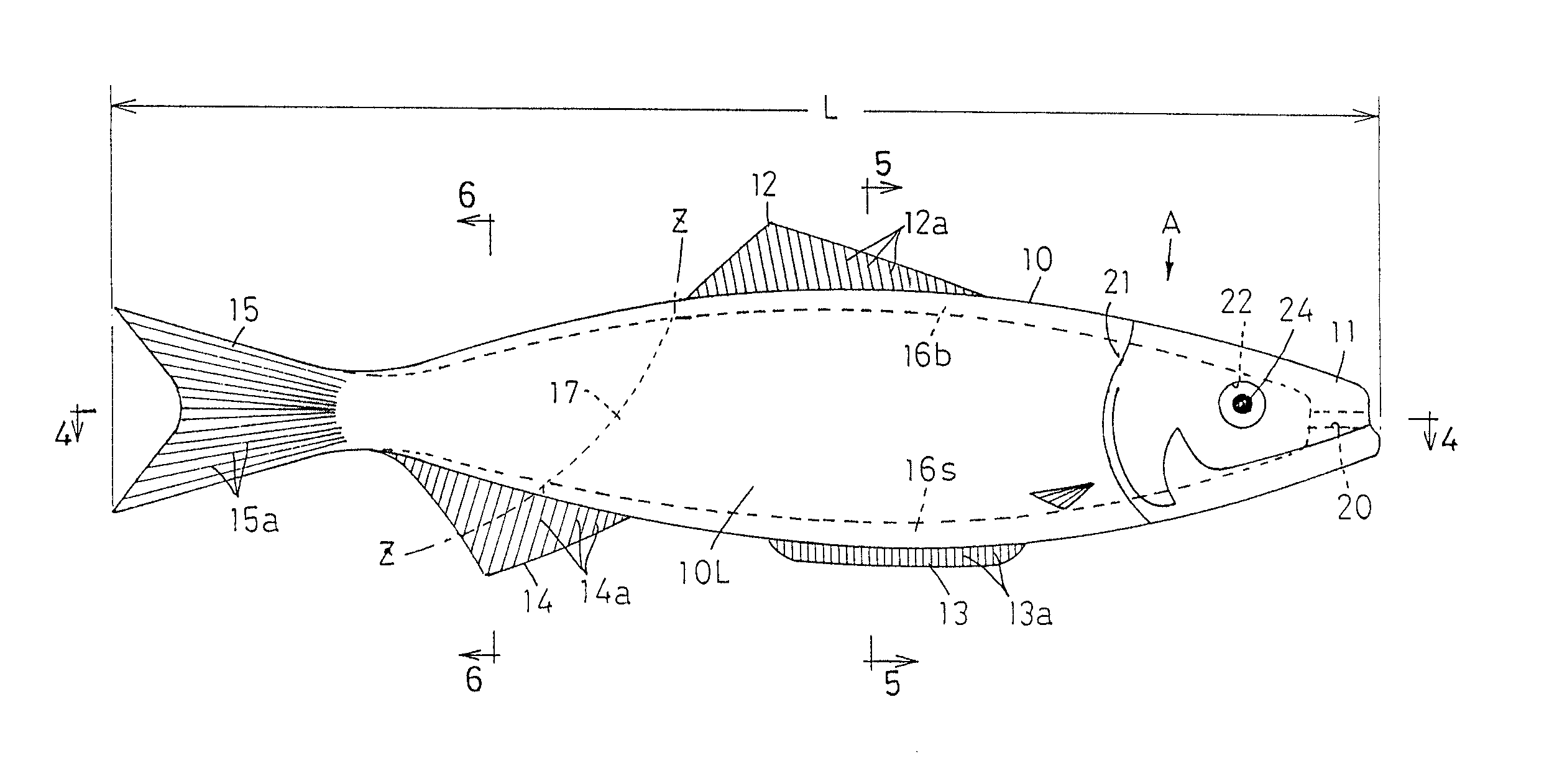

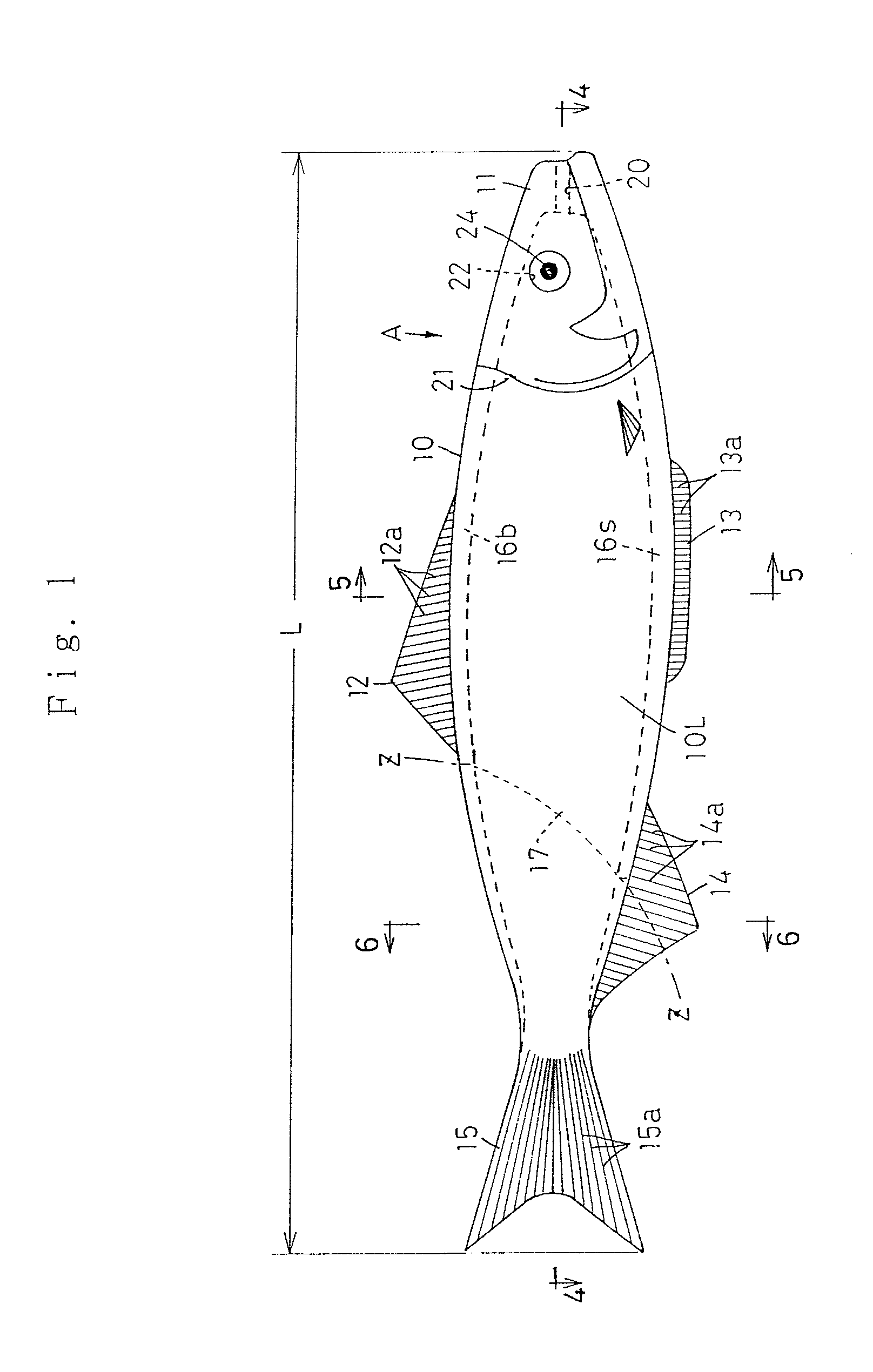

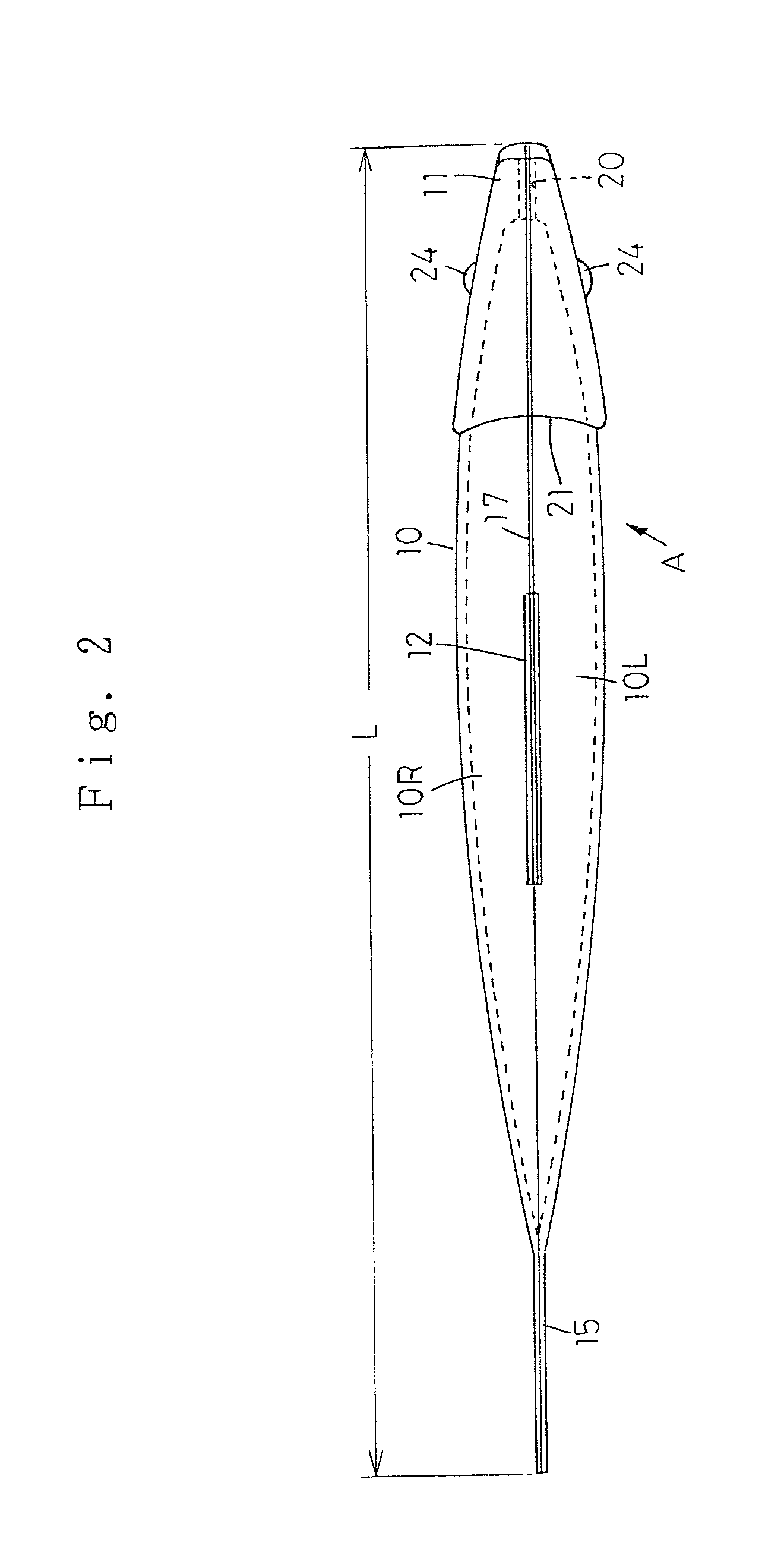

Fish shaped lure for trolling

Transfer sheets on which an image quite closely resembling an external appearance of a bait fish is color printed on the surface of a hologram sheet are adhered to back sides of bilaterally symmetrical body-half segments made of a flexible transparent thermoplastic resin in a state that the image can be viewed perspectively from the surface side. Only front head sides which occupy at least half in both the body-half segments are adhered and remaining rear end sides are kept open, by which a line equipped with a hook is guided out and wired to the front from the rear end sides via an interior hollow of a lure body.

Owner:HOPEC

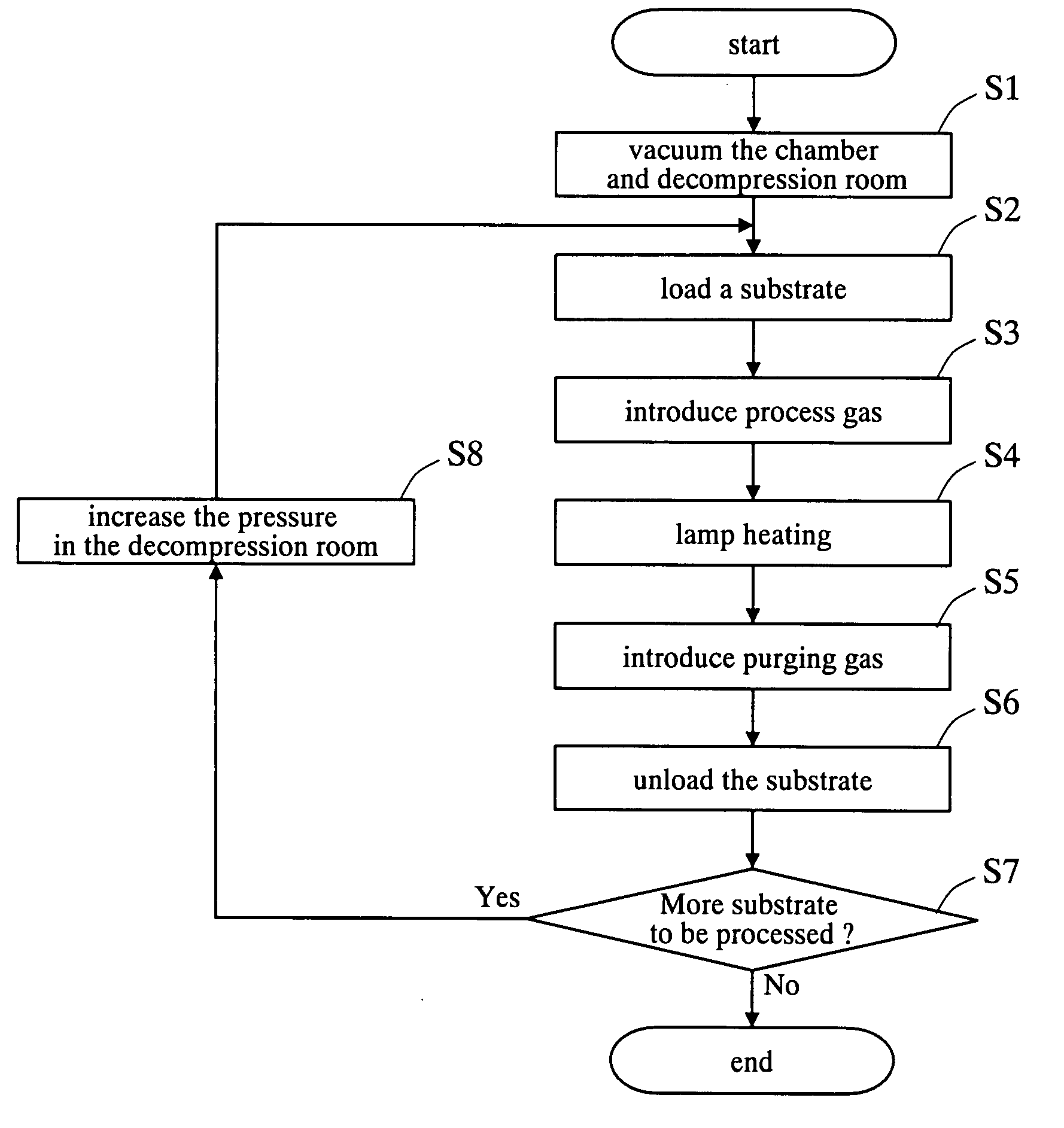

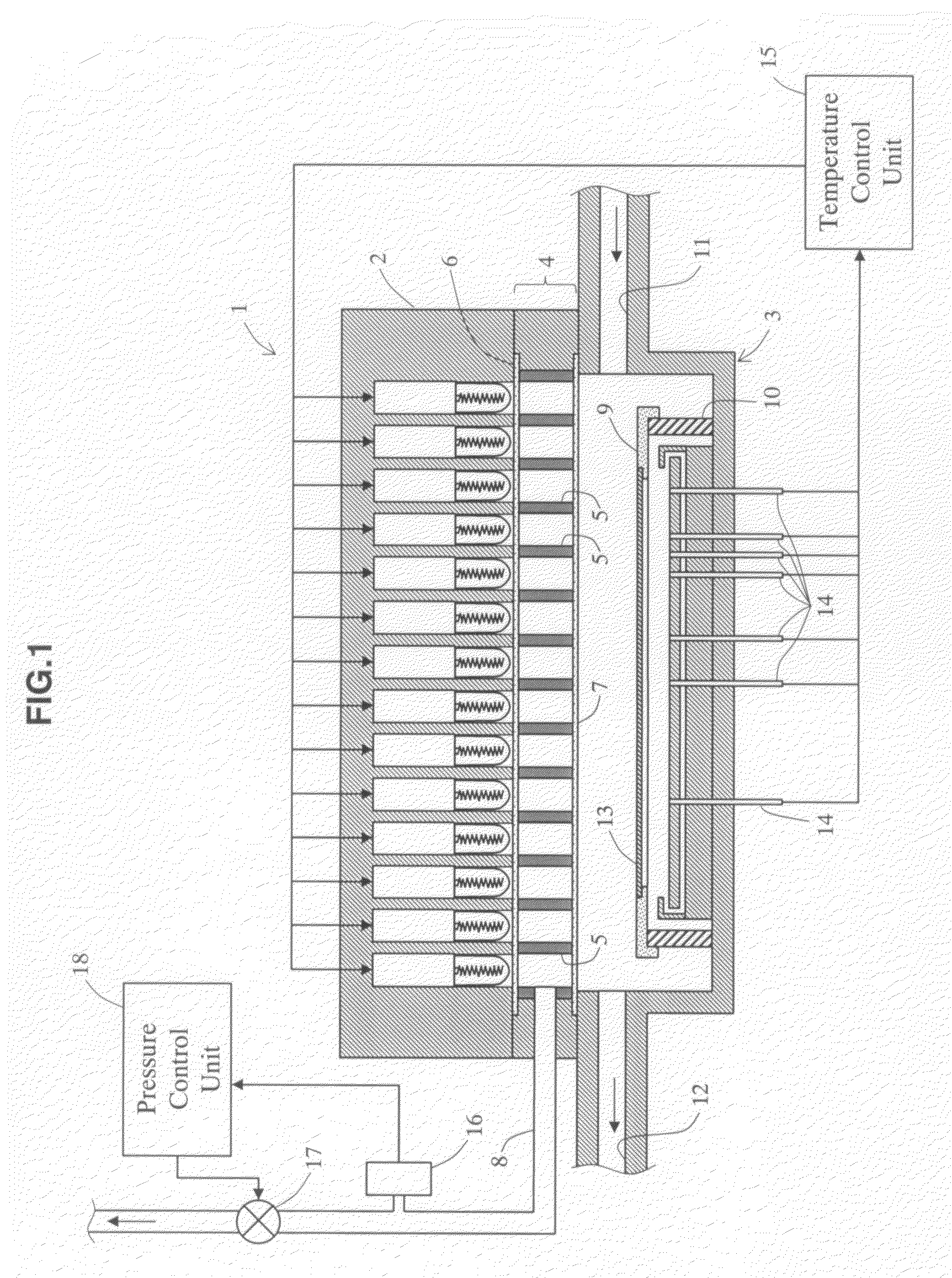

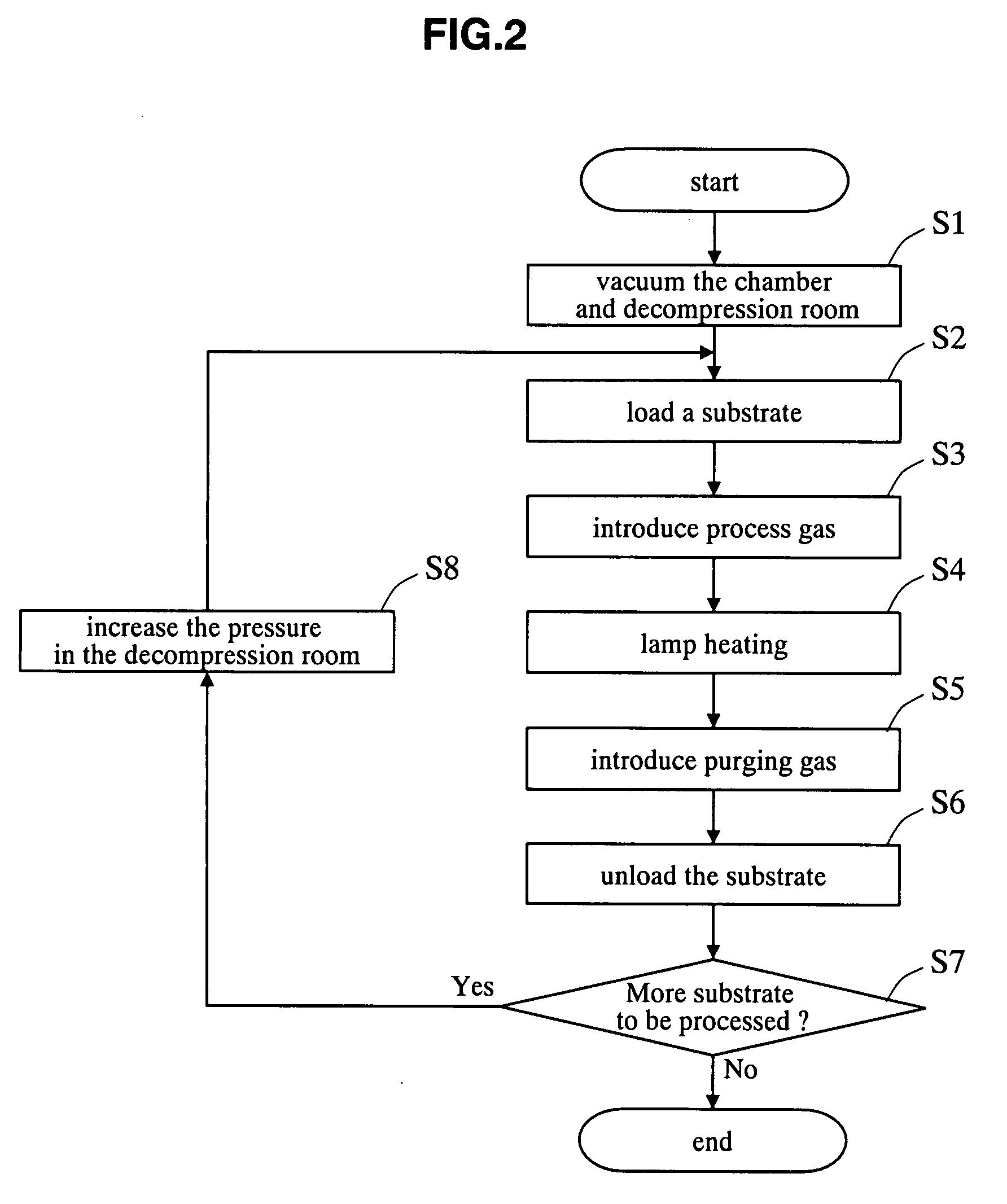

Apparatus and method for processing a substrate

InactiveUS20080038479A1Difference in film thicknessDifference in thicknessRadiation applicationsVacuum evaporation coatingInternal pressurePressure control

An apparatus for processing a substrate according to the present invention comprises a lamp unit heating the substrate placed in the chamber at a position facing the substrate. A transmission window constituting the top wall of the chamber and transmitting light emitted from the lamp unit is provided between the chamber and the lamp unit. A window assembly having a wall constituted by the transmission window is provided at the lamp unit side of the transmission window. An evacuation unit is connected to the window assembly. A pressure control unit controls the evacuation unit to maintain the internal pressure of the window assembly at a specific pressure. In this way, multiple substrates are subject to a significantly uniform substrate processing when they are processed in succession.

Owner:PANASONIC CORP

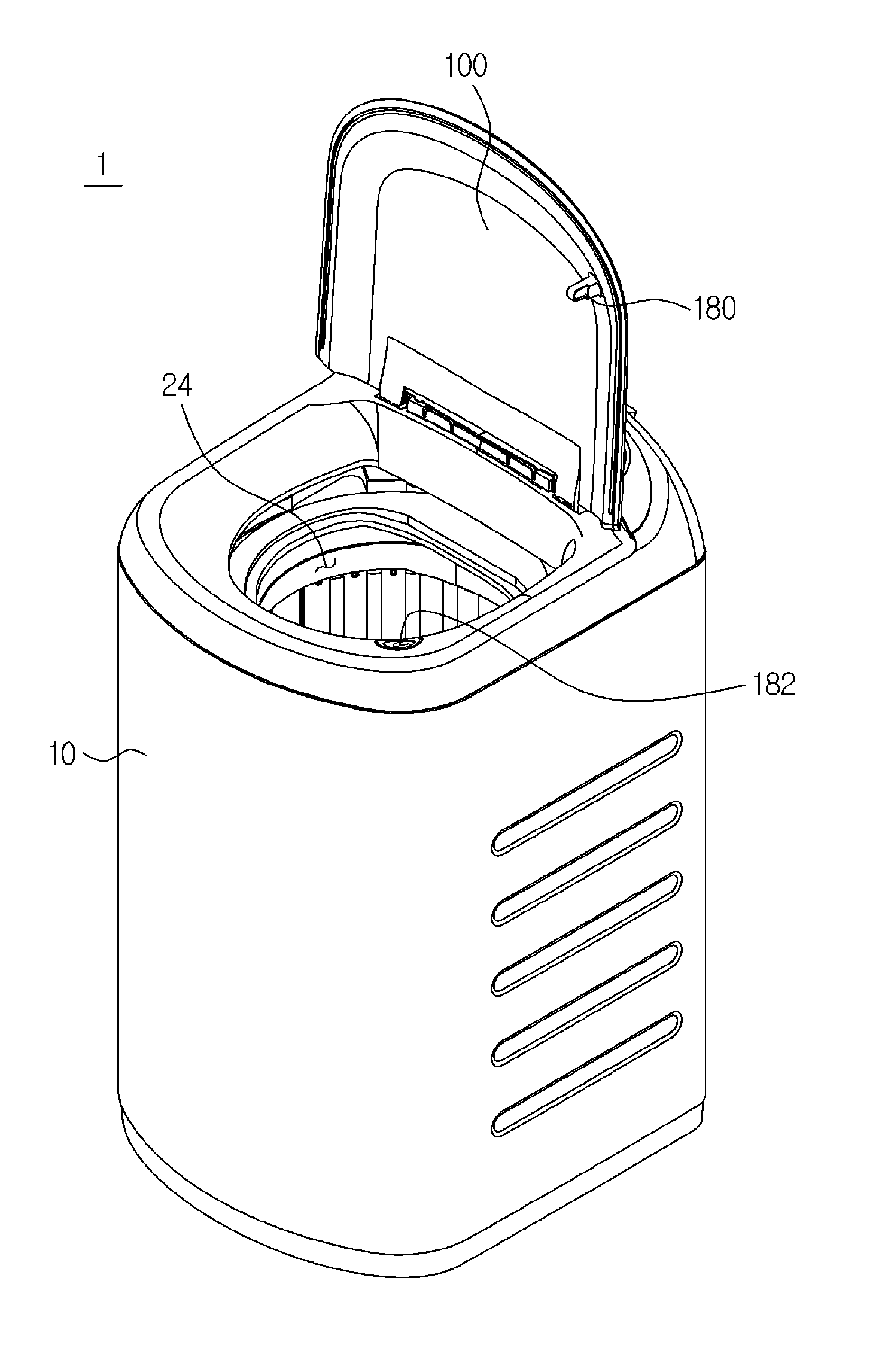

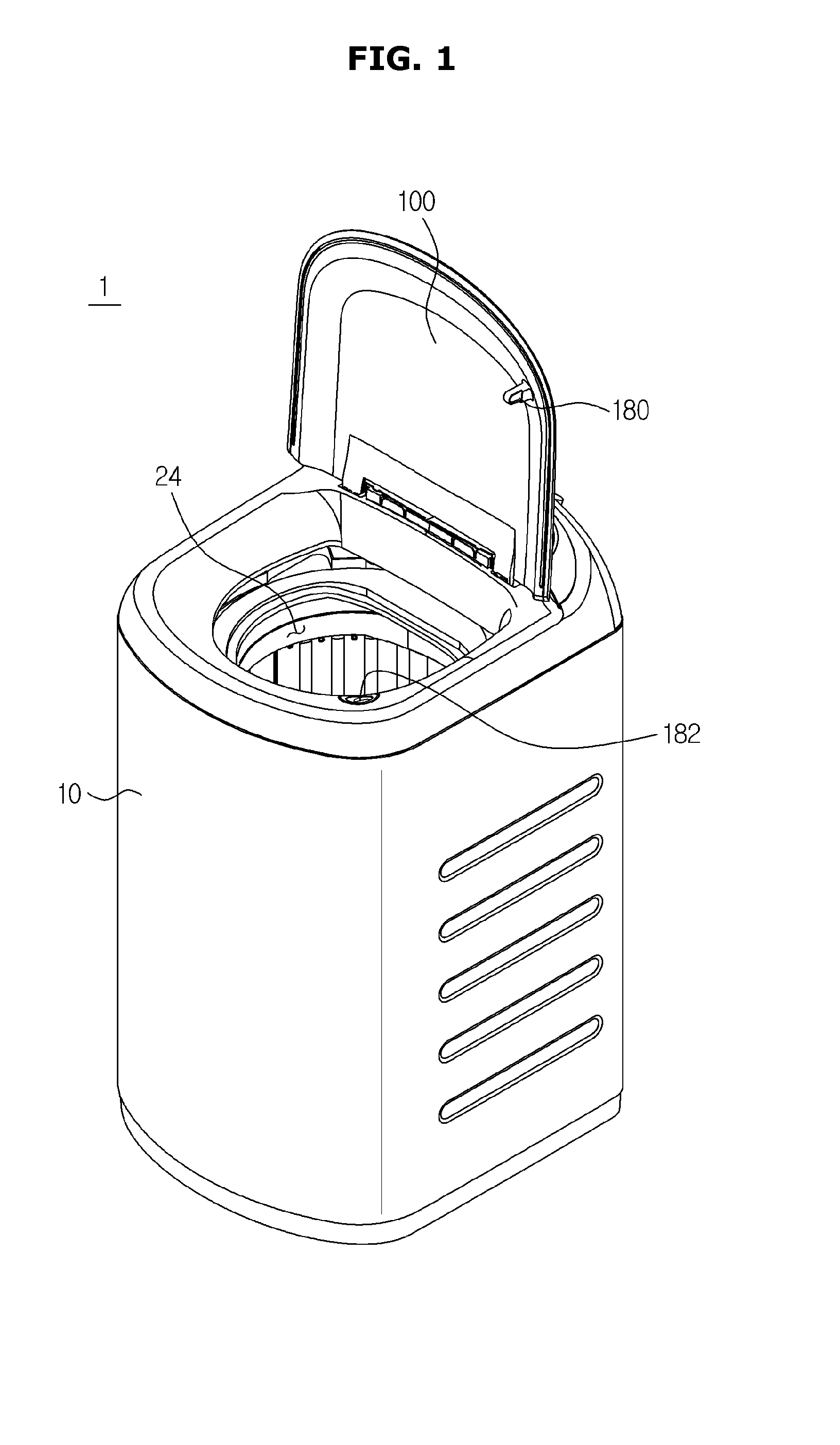

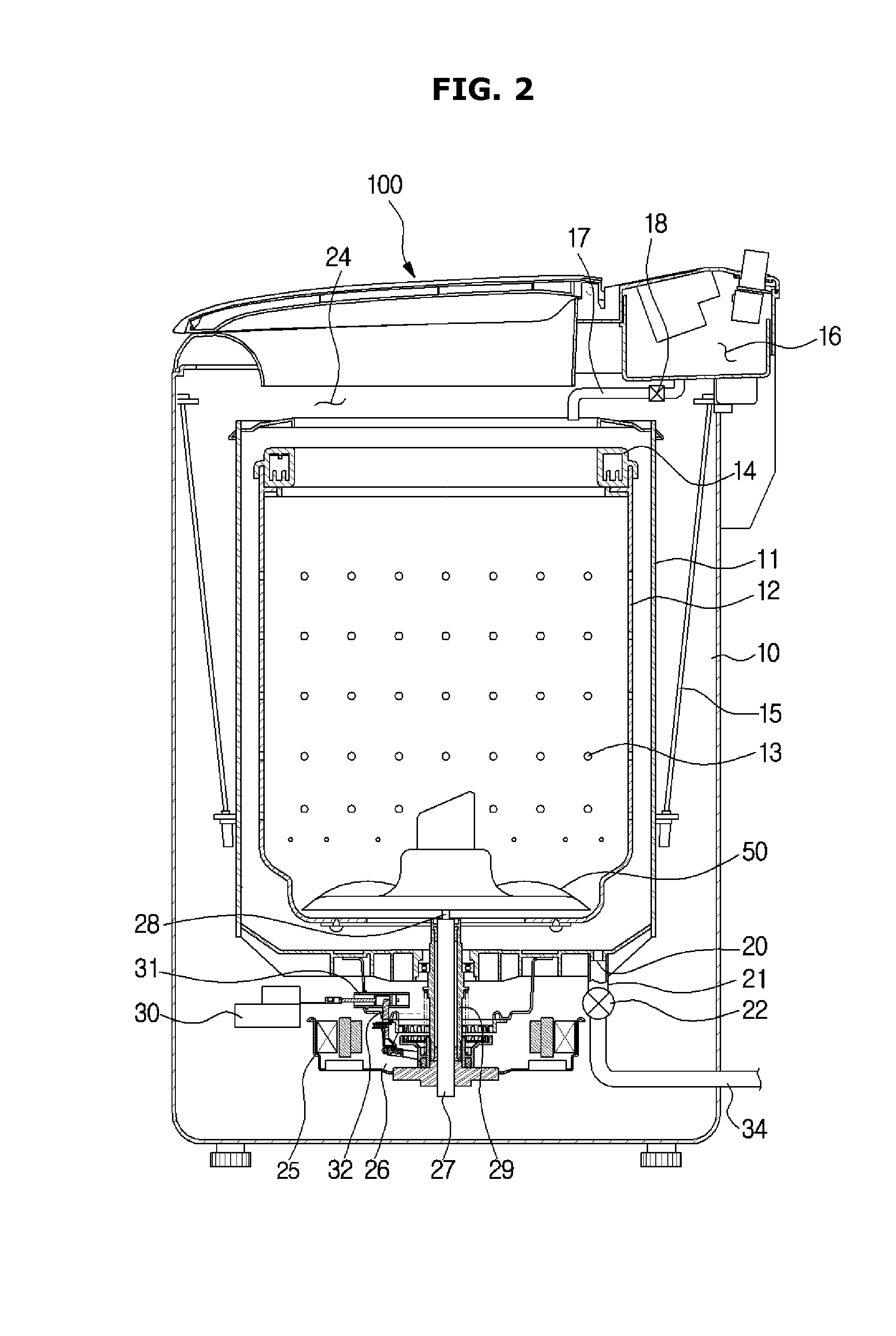

Washing machine and manufacturing method of door

ActiveUS20150069889A1Inhibition of contractionDifference in thicknessTableware washing/rinsing machine detailsWing accessoriesEngineeringMechanical engineering

A washing machine including a door to open and close an opening for laundry. The door includes a first upper door, a second upper door disposed to allow at least one portion of the first upper door to be seen therethrough, and a lower door. The lower door includes a contraction preventing part to prevent the lower door from contracting when molded.

Owner:SAMSUNG ELECTRONICS CO LTD

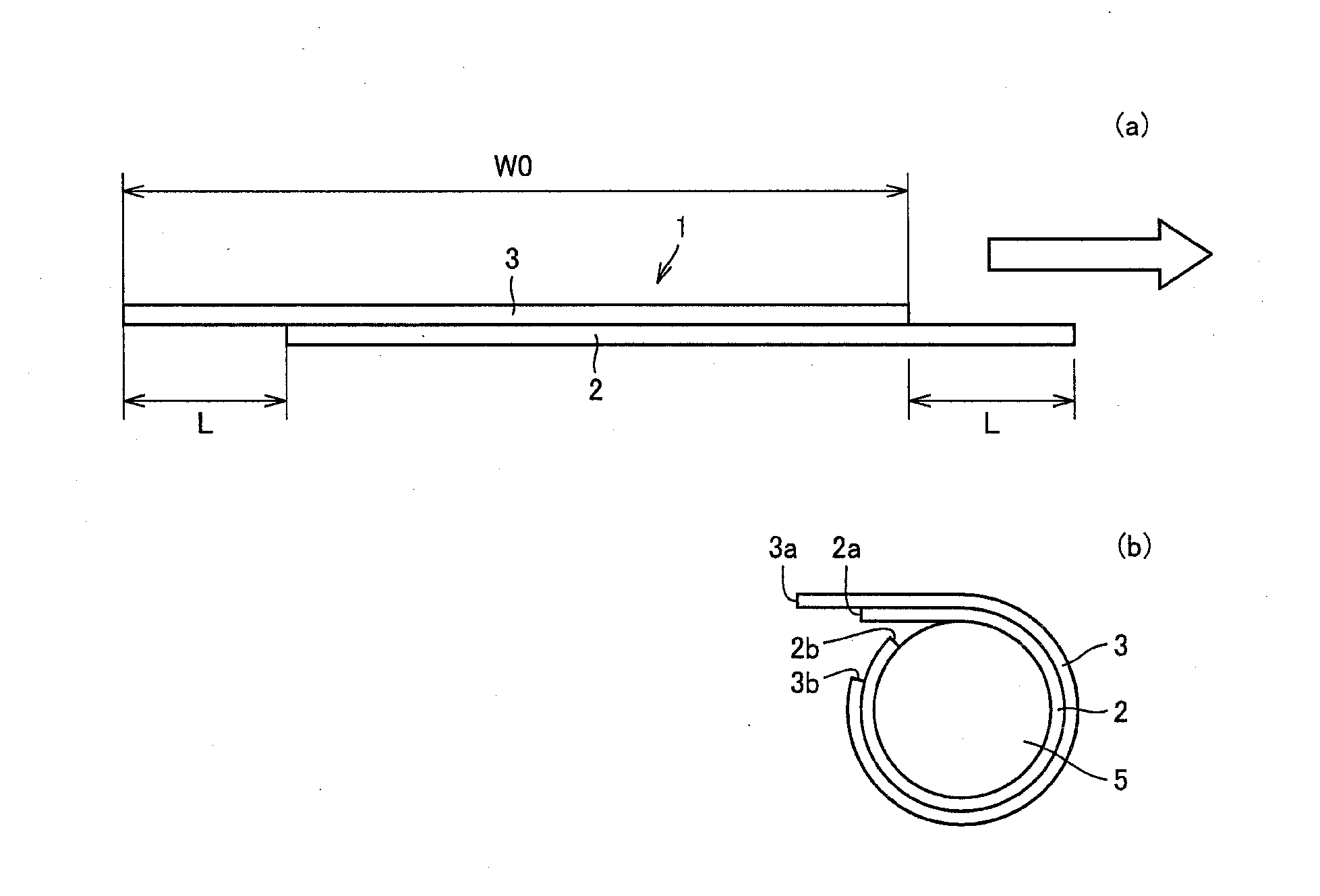

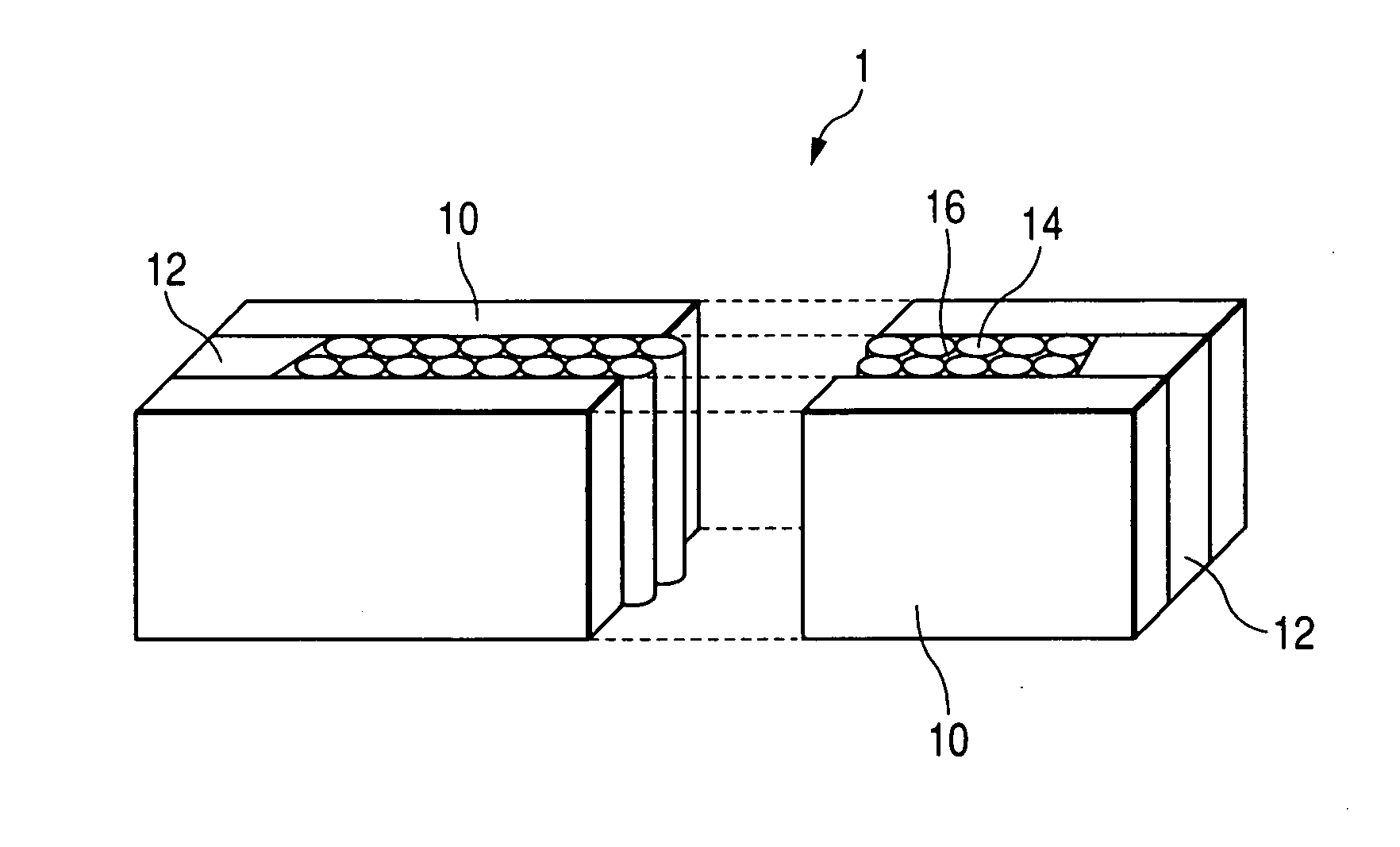

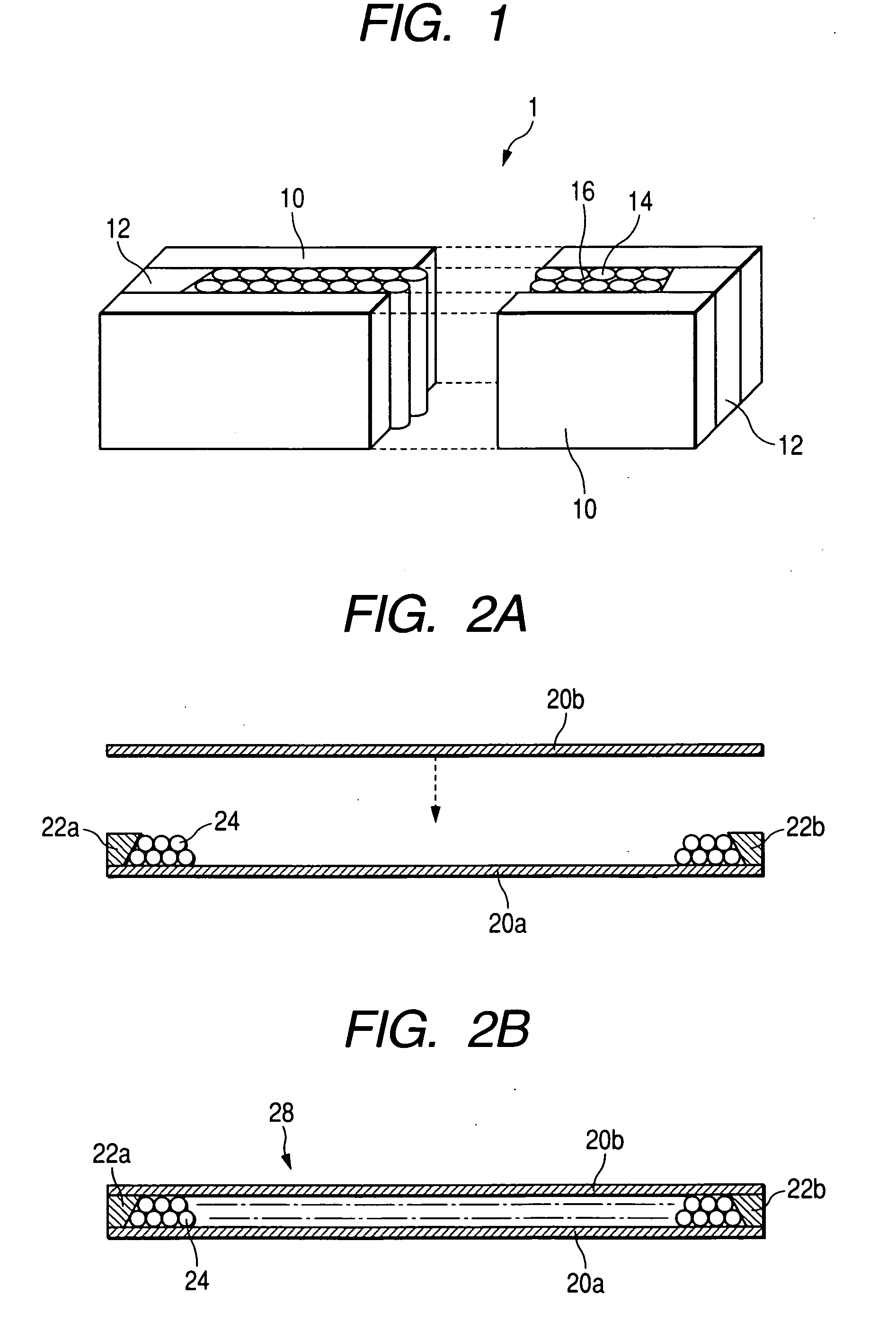

Method for manufacturing pneumatic tire

InactiveUS20130220519A1Difference in thicknessReduce damage and breakageWithout separate inflatable insertsWith separate inflatable insertsEngineeringRubber sheet

A method for manufacturing a pneumatic tire including: (a) an assembly step of bonding the inner liner and an unvulcanized rubber sheet with end portions thereof in a width direction being displaced from each other in the range of 50 mm to 500 mm in the width direction to manufacture a laminate; (b) a cutting step of cutting the laminate to have a constant length corresponding to a width of a drum to manufacture a cut sheet; and (c) a joining step of winding the cut sheet on entire circumference of the drum such that a cut surface thereof extends in a circumferential direction of the drum and the inner liner is disposed on an inner surface side, and joining the end portions of the inner liner and joining the end portions of the unvulcanized rubber sheet.

Owner:SUMITOMO RUBBER IND LTD

Rod lens array and method of manufacturing the same

In a rod lens array having a structure in which a plurality of rod lens elements are arranged between two side panels and a resin is filled and cured in spaces between the rod lens elements to be integrally formed, the side panels are made of a glass fiber reinforced epoxy resin and a phenol-based curing agent is used as a curing agent of the epoxy resin. In detail, the curing agent is exemplified by a phenol-based curing agent including a tris-hydroxyphenyl-methane skeleton.

Owner:NIPPON SHEET GLASS CO LTD

Thin film magnetic head and method of manufacturing same

InactiveUS7002776B2Reduce the differenceReduce areaConstruction of head windingsHeads using thin filmsMagnetic tension forceMagnetomotive force

Owner:TDK CORPARATION

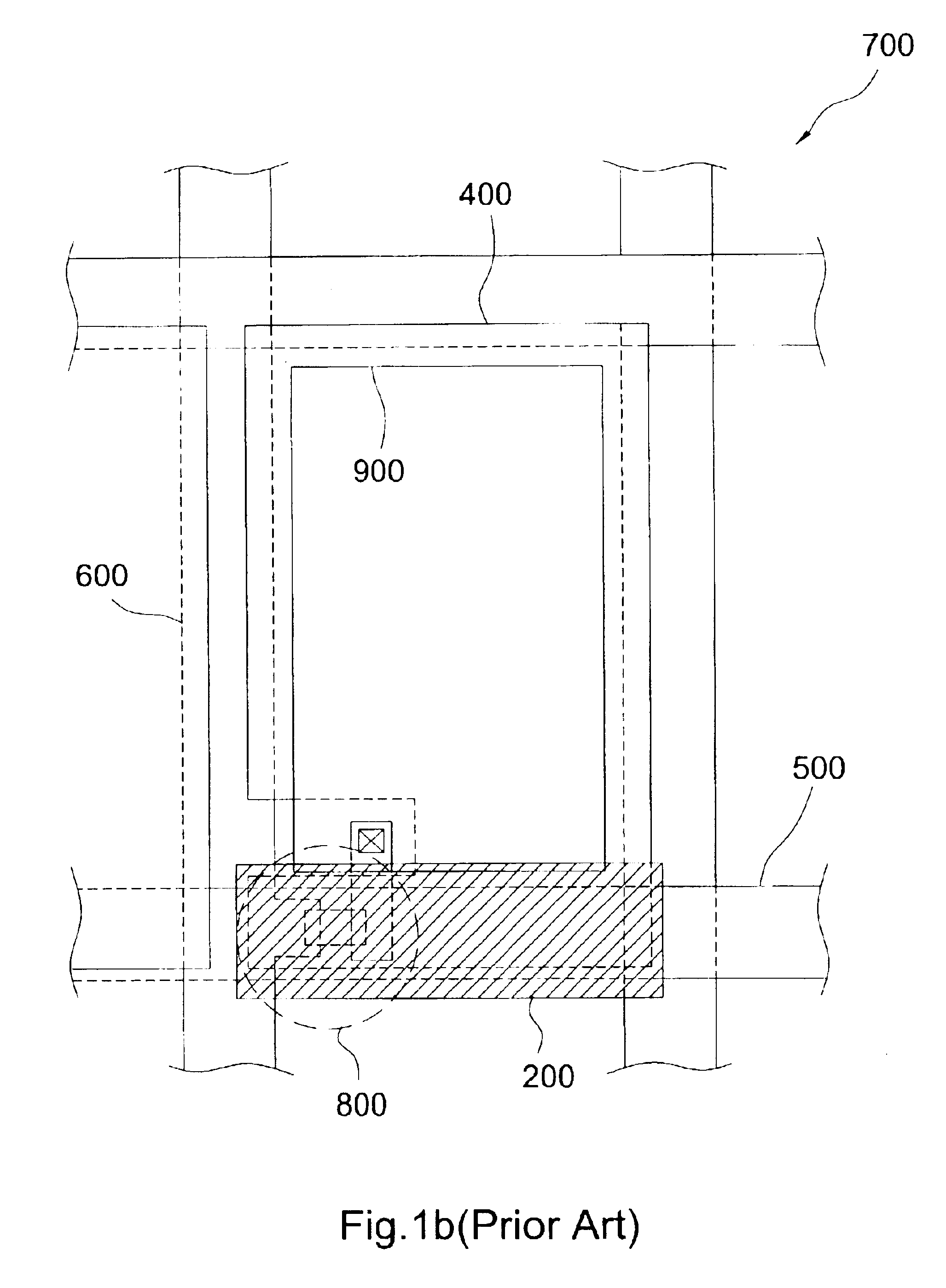

Method of forming a color filter layer on an array substrate and device thereof

InactiveUS6933993B2Decrease thicknessSimplify produce processOriginals for photomechanical treatmentNon-linear opticsLiquid-crystal displayScan line

The present invention provides a color liquid crystal display device in which a color filter layer is formed on an array substrate. The array substrate includes a scan line and a data line forming a pixel, on which a thin film transistor is formed, and a pixel electrode is connected to the thin film transistor. A black matrix layer is formed on the array substrate. A black matrix frame is formed around the periphery of the black matrix layer. A color filter layer is formed on the array substrate and the black matrix layer, and extends to cover the black matrix frame.

Owner:INNOLUX CORP

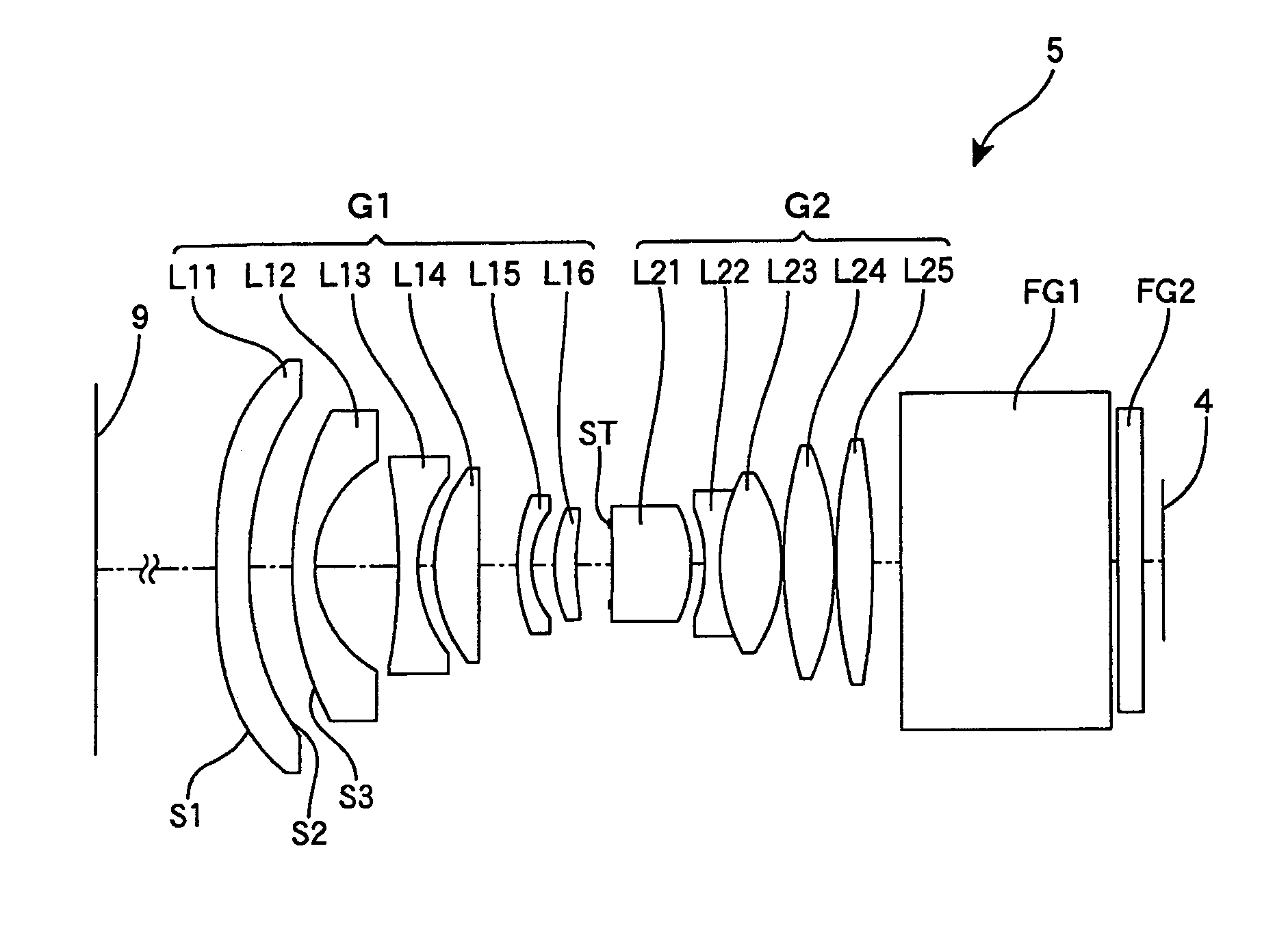

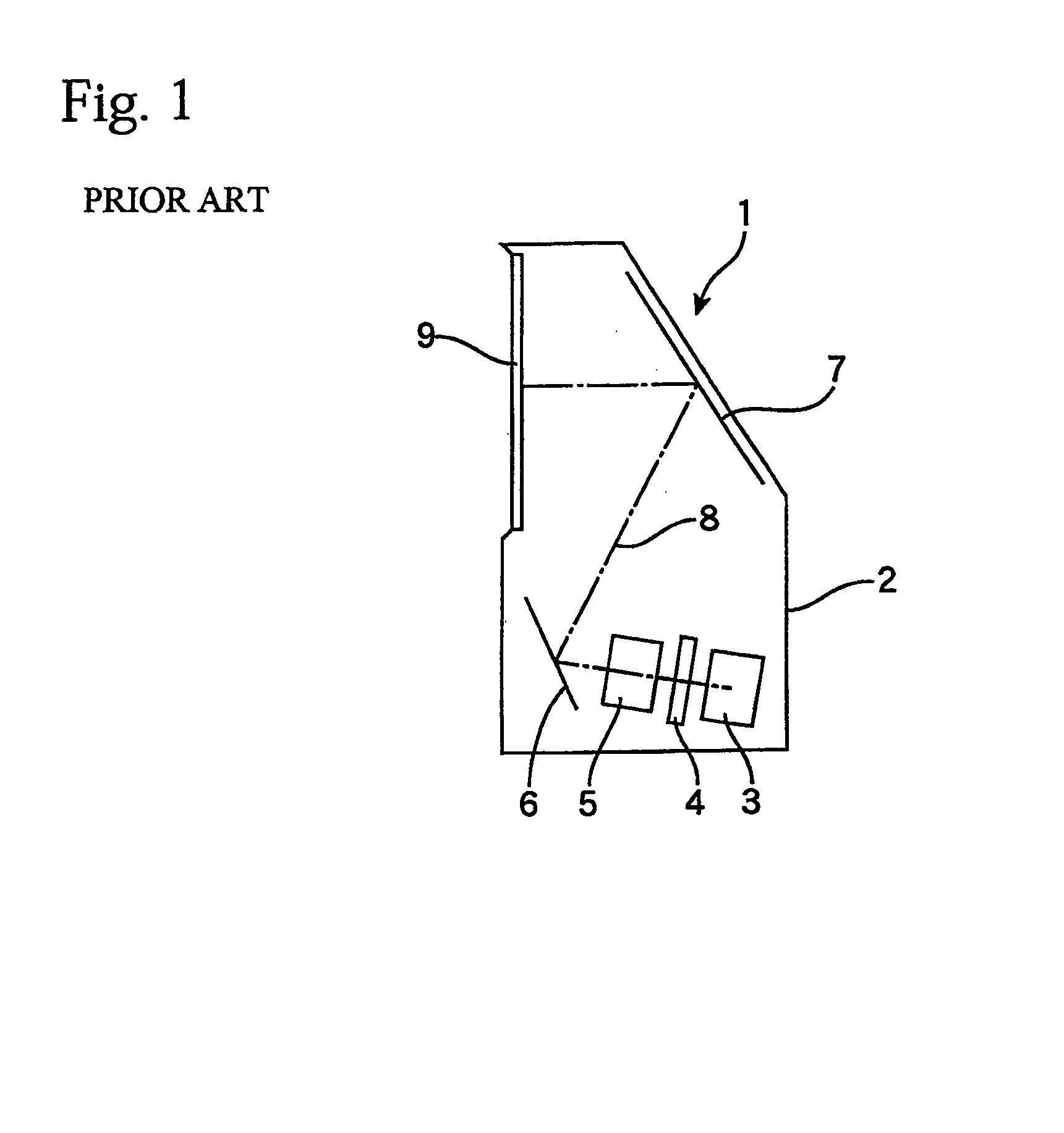

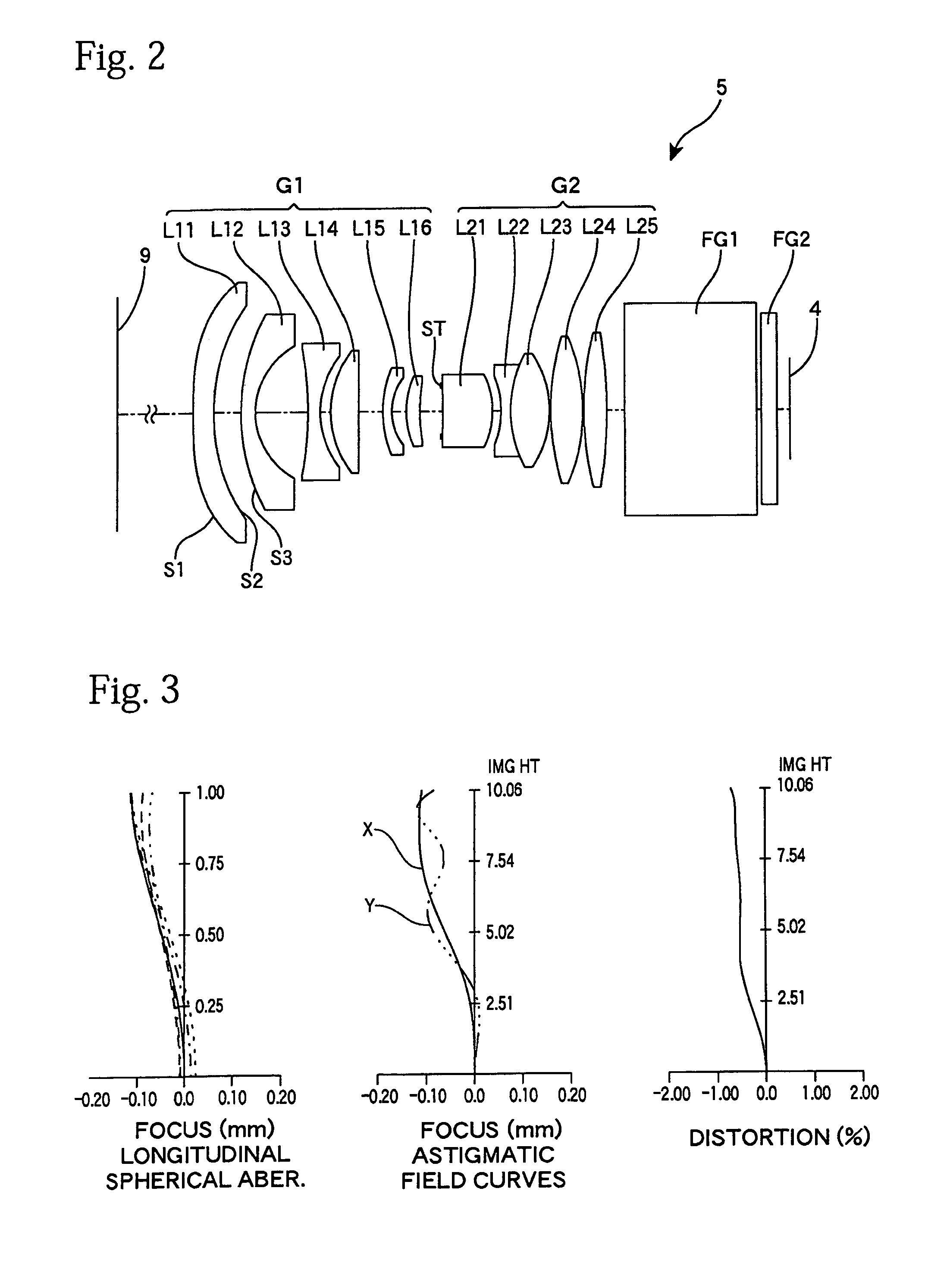

Projection lens system and projector

InactiveUS20050219706A1Ensure correct executionReduce the overall diameterProjectorsLensCamera lensThermal deformation

A projection lens system that projects projection light from a light modulator onto a screen and which is telecentric on an input side is provided. The projection lens system comprises a first meniscus lens that is disposed closest to the screen, is convex on a screen side, and has negative refractive power; and a second meniscus lens that is disposed next closest to the screen, is convex on a screen side, and has negative refractive power. The first meniscus lens is made of plastic and at least one out of two curved surfaces thereof is aspherical, and a refractive power of the first meniscus lens is lower than a refractive power of the second meniscus lens. In the projection lens system, far superior aberration-correcting performance can be achieved and a drop in aberration-correcting performance due to thermal deformation can be prevented.

Owner:NITTO OPTICAL CO LTD

Semiconductor device and its manufacturing method

InactiveUS20090072286A1Highly accurate shapeFavorable coverage propertySolid-state devicesSemiconductor/solid-state device manufacturingDielectricHydrogen

A semiconductor device includes: a ferroelectric capacitor that is provided above a base substrate and includes a first electrode, a ferroelectric film provided on the first electrode and a second electrode provided on the ferroelectric film; a stopper film that covers a top surface of the second electrode of the ferroelectric capacitor; a hydrogen barrier film that covers a top surface and a side surface of the stopper film and a side surface of the ferroelectric capacitor; an interlayer dielectric film that covers the hydrogen barrier film and the base substrate; a contact hole that penetrates the interlayer dielectric film, the hydrogen barrier film and the stopper film and exposes the second electrode; a barrier metal that covers the second electrode exposed in the contact hole and an inner wall surface of the contact hole and is composed of a conductive material having hydrogen barrier property; and a plug conductive section that is embedded in the contact hole and conductively connects to the barrier metal, wherein the stopper film is formed from a dielectric material having a smaller etching rate than an etching rate of the interlayer dielectric film.

Owner:SEIKO EPSON CORP

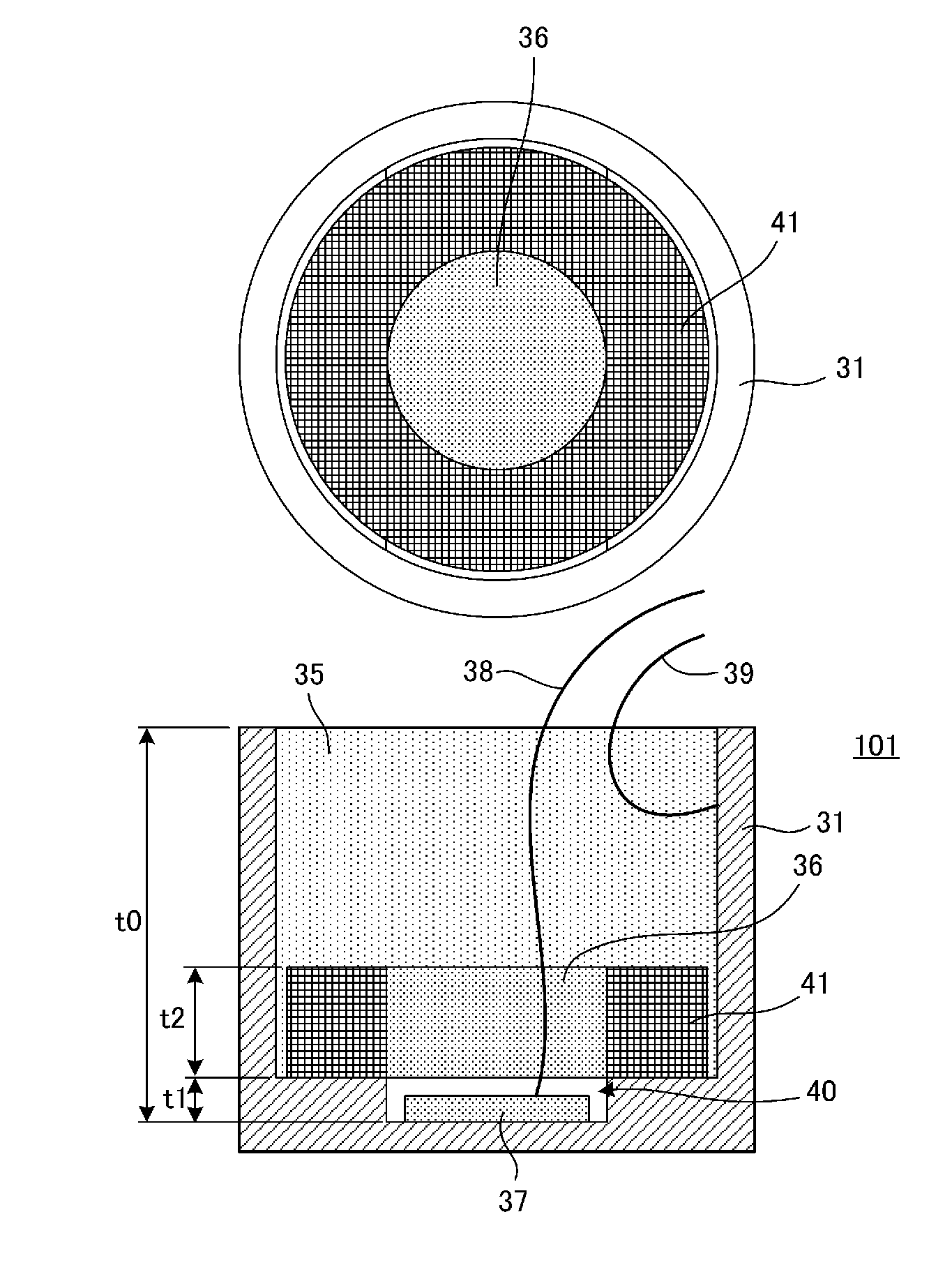

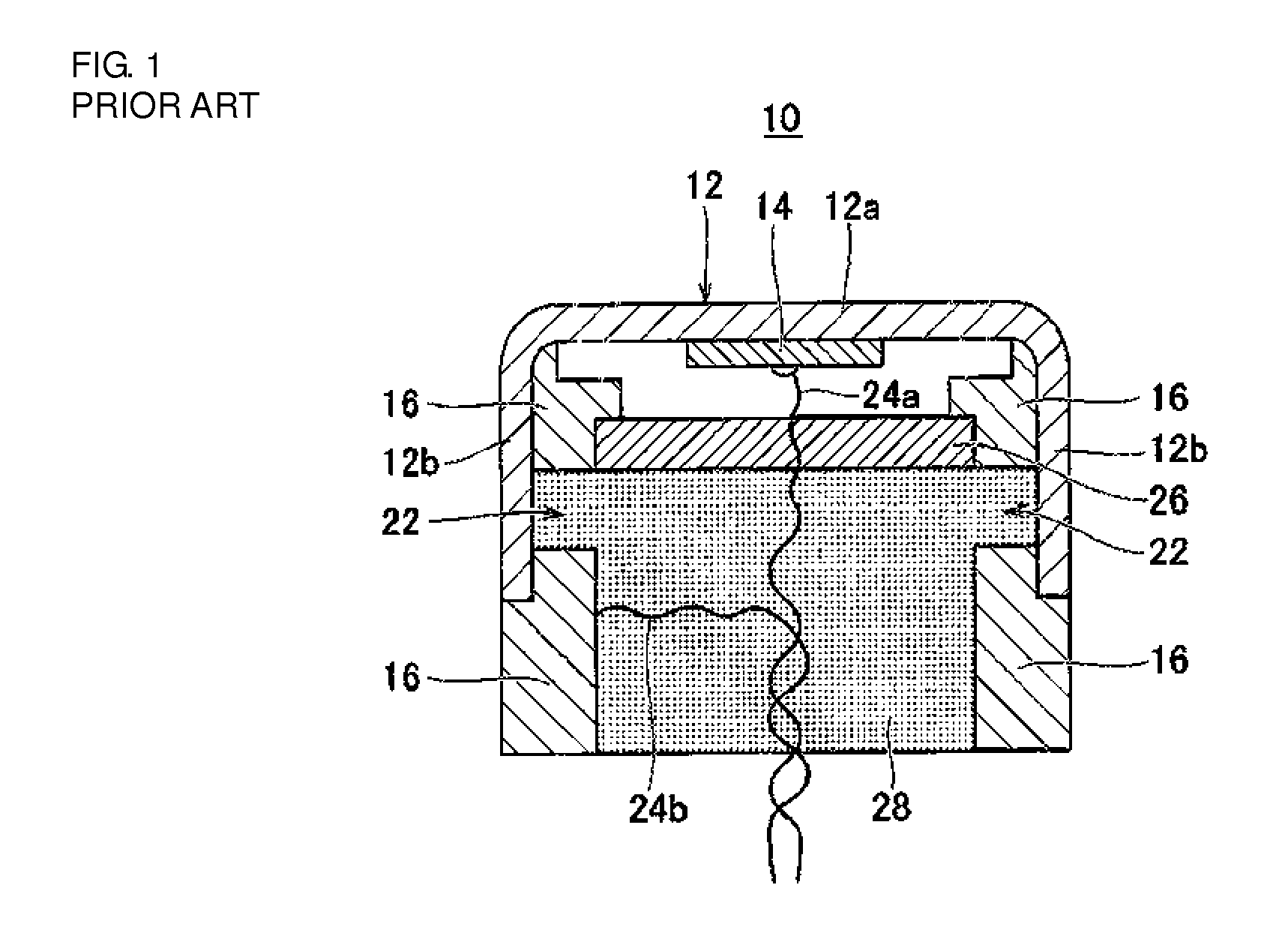

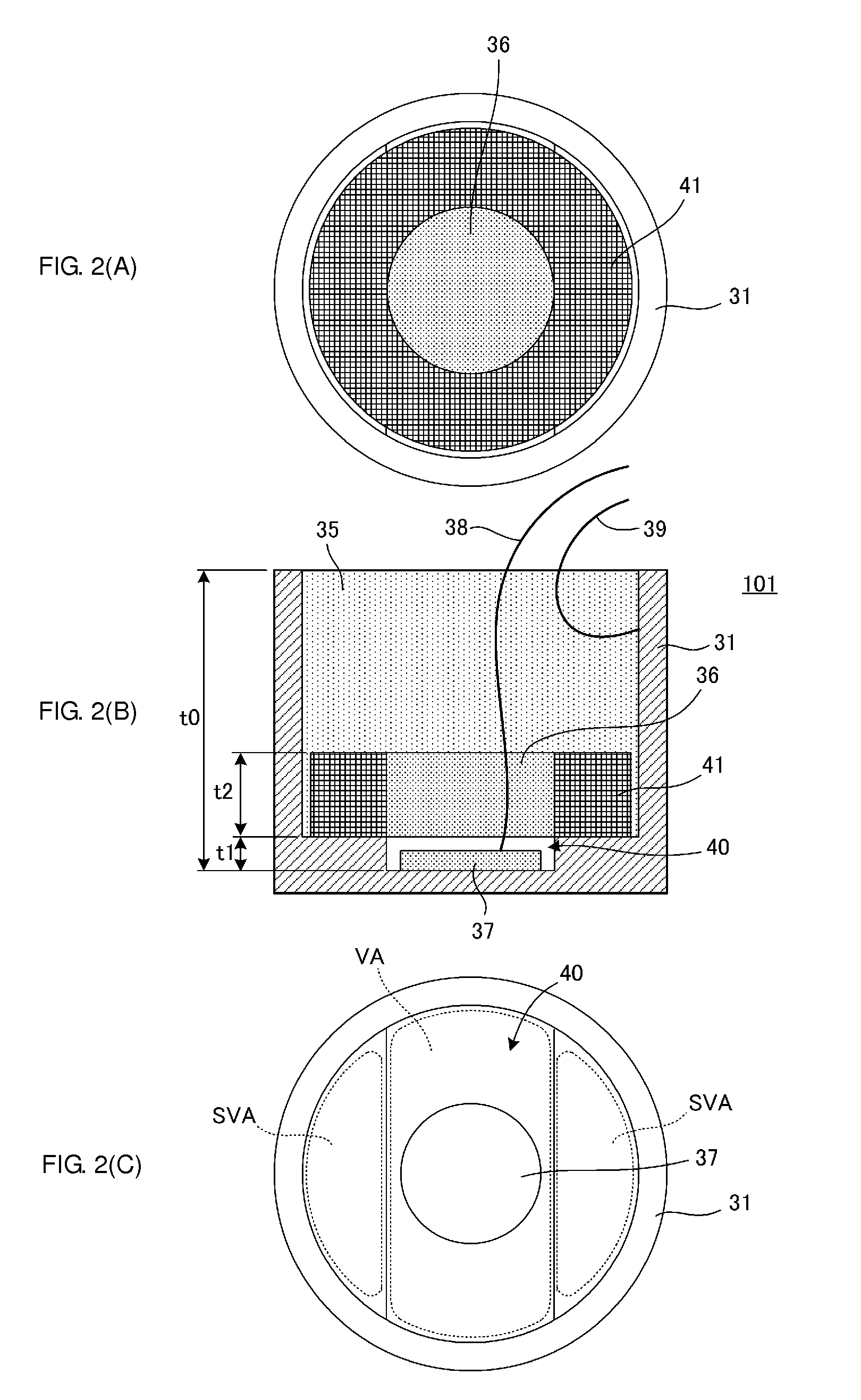

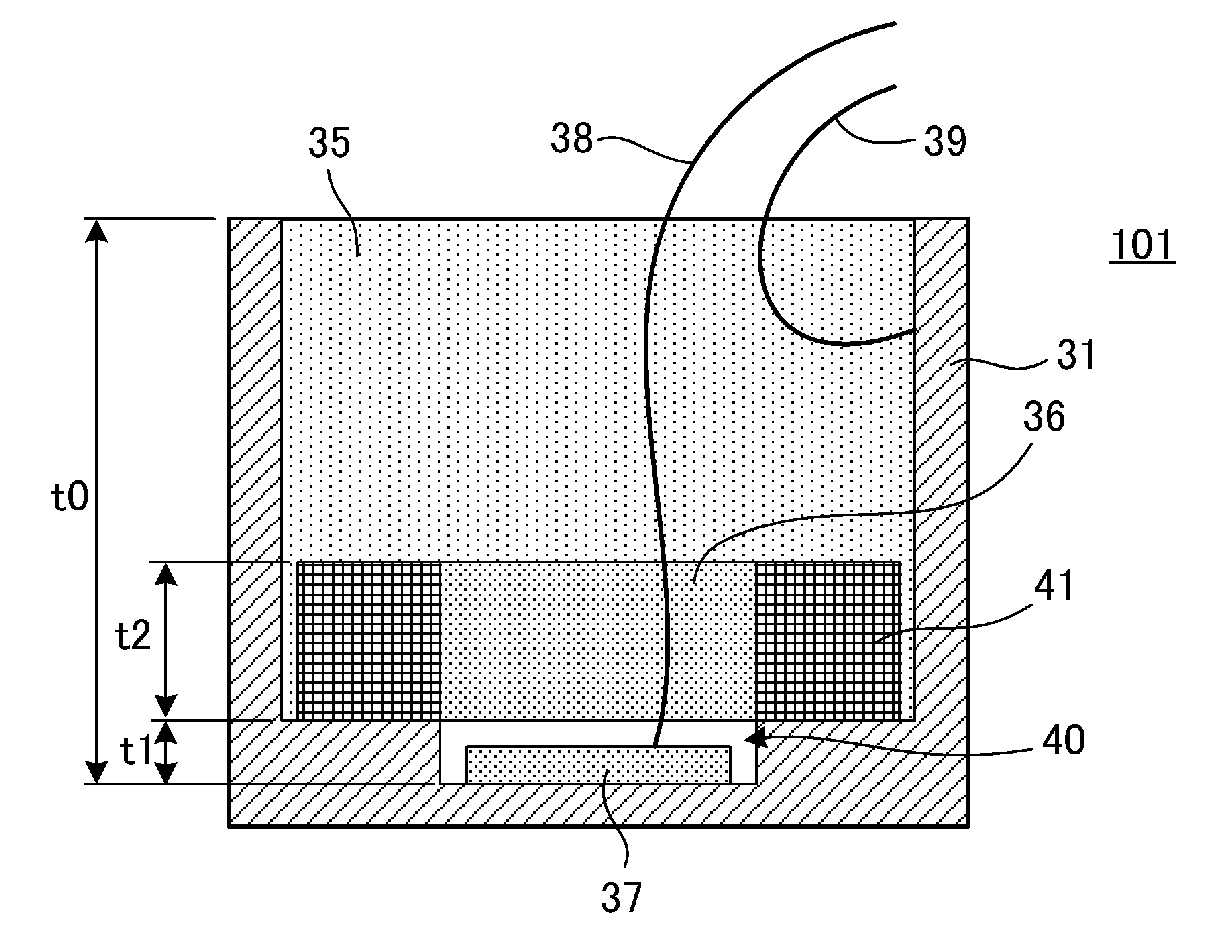

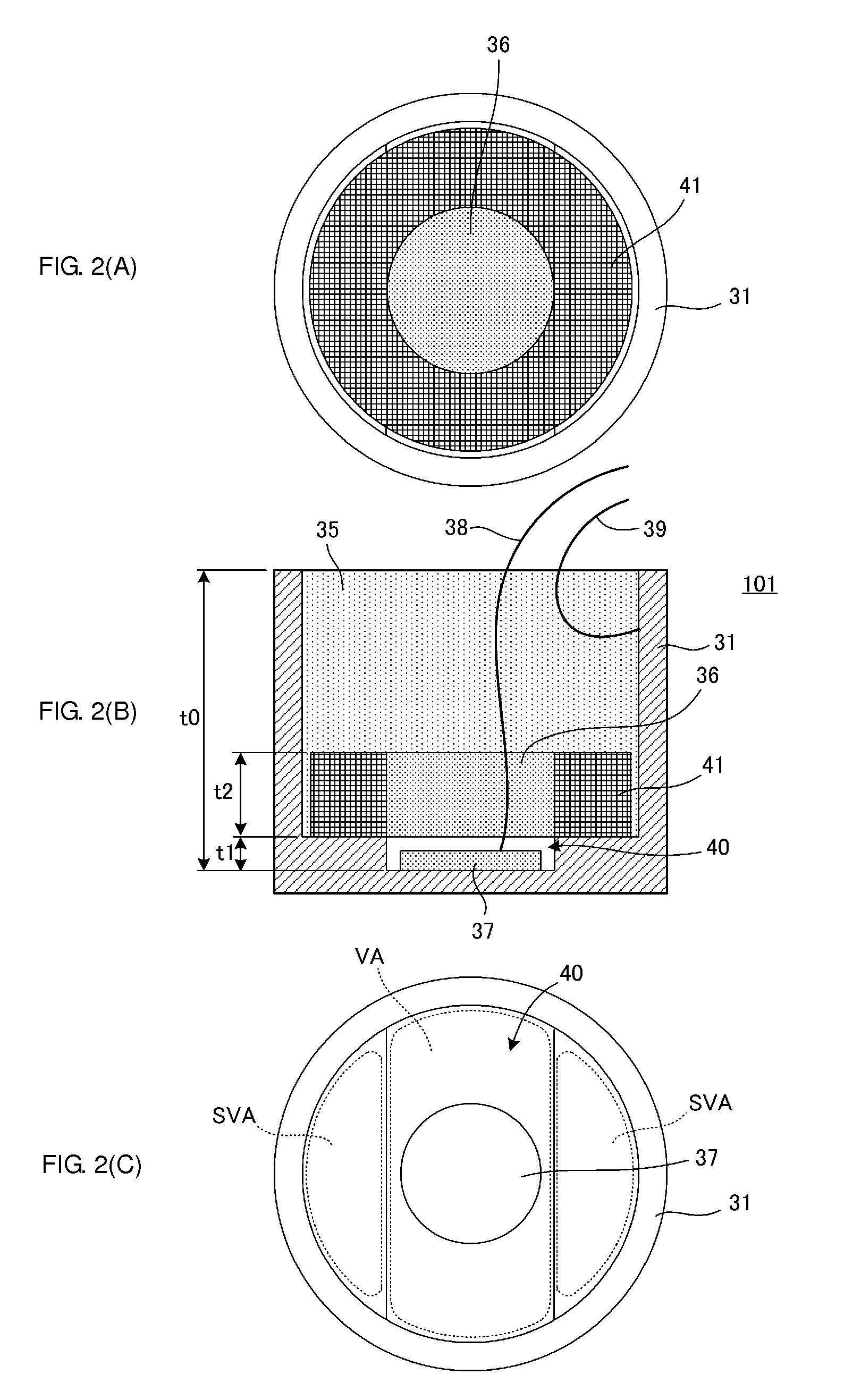

Ultrasonic Vibration Device

ActiveUS20120286626A1Suppress propagationIncrease rigidityWave based measurement systemsPiezoelectric/electrostriction/magnetostriction machinesEngineeringUltrasound

In an inner bottom surface of a case, a substantially oblong recess having a long axis and a short axis forms a vibration area. A piezoelectric element is bonded to the center of the recess. On the opposite sides of the vibration area, vibration suppression areas thicker than the vibration area are disposed. A side portion of the case is formed to be thin over the entire circumference thereof. A reinforcing member higher in rigidity than the case is bonded to upper portions of the vibration suppression areas. The reinforcing member has a bottom surface substantially equal to the shape of the vibration suppression areas, and has a predetermined height. A gap between the reinforcing member and an inner side surface of the case is also filled with a filling member.

Owner:MURATA MFG CO LTD

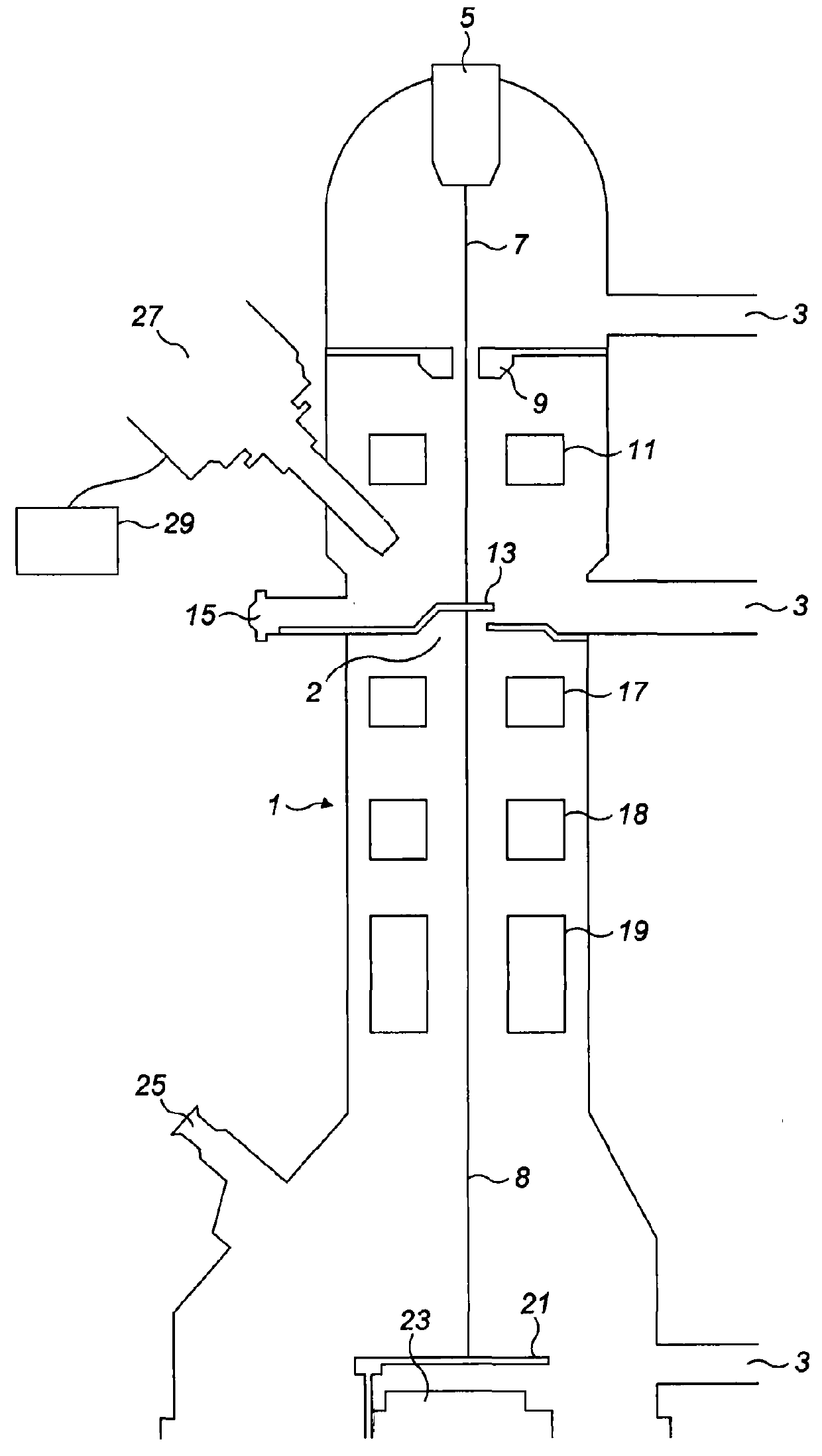

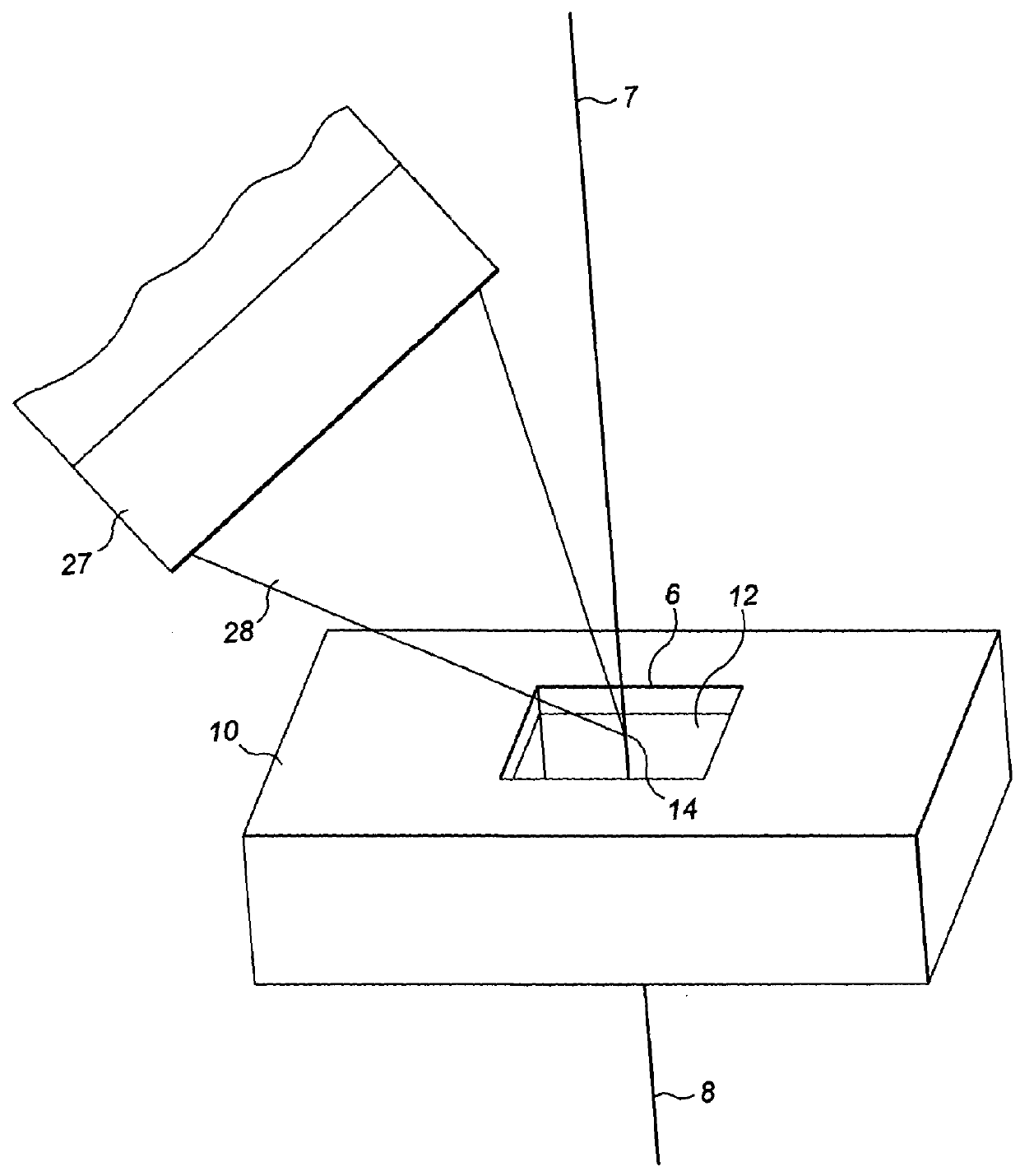

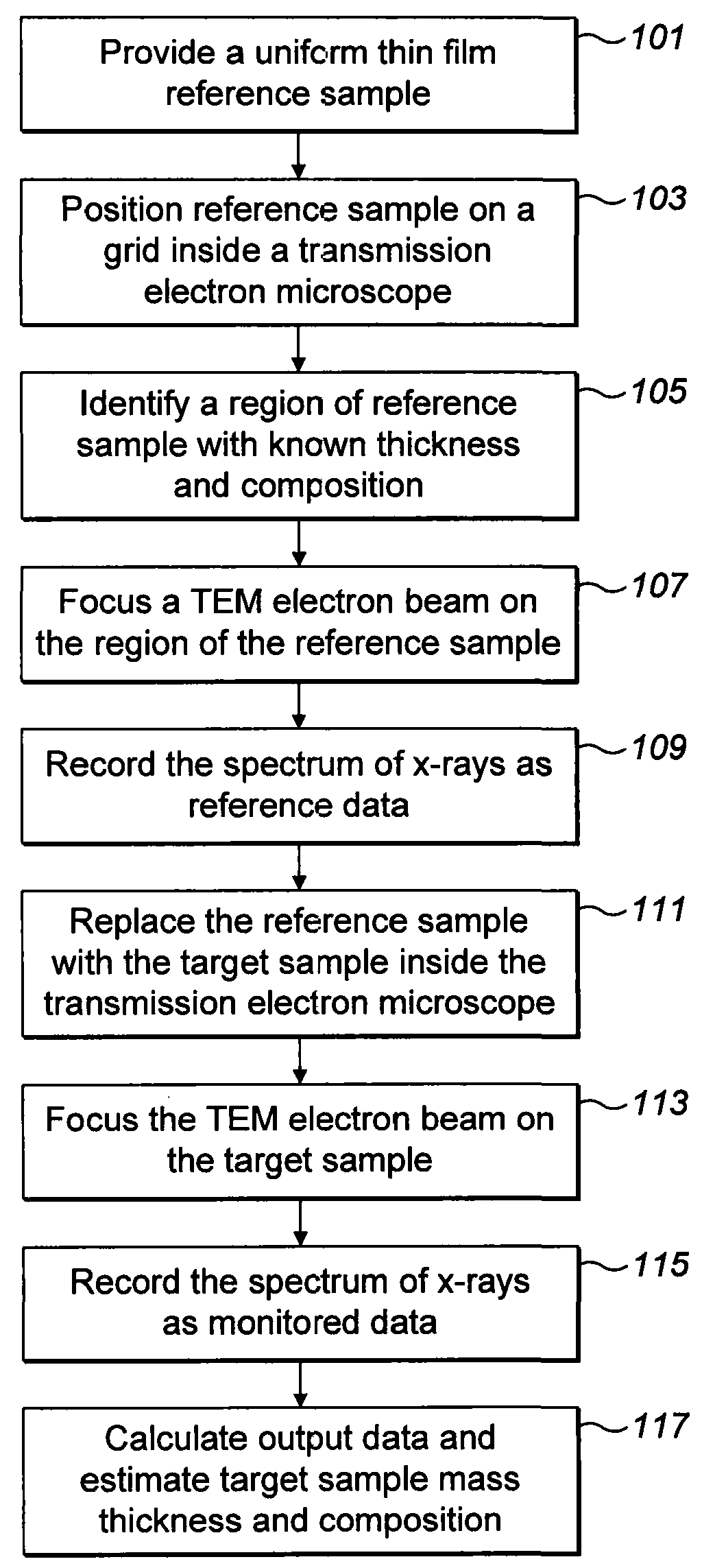

A method for measuring the mass thickness of a target sample for electron microscopy

ActiveUS20170269011A1Avoid the needGood repeatabilityMaterial analysis using wave/particle radiationElectric discharge tubesReference sampleParticle beam

A method is provided of measuring the mass thickness of a target sample for use in electron microscopy. Reference data are obtained which is representative of the X-rays (28) generated within a reference sample (12) when a particle beam (7) is caused to impinge upon a region (14) of the reference sample (12). The region (14) is of a predetermined thickness of less than 300 nm and has a predetermined composition. The particle beam (7) is caused to impinge upon a region (18) of the target sample (16). The resulting X-rays (29) generated within the target sample (16) are monitored (27) so as to produce monitored data. Output data are then calculated based upon the monitored data and the reference data, the output data including the mass thickness of the region (18) of the target sample (16).

Owner:OXFORD INSTR NANOTECH TOOLS

Projection lens system and projector

InactiveUS7119966B2Ensure correct executionReduce the overall diameterProjectorsLensCamera lensThermal deformation

A projection lens system that projects projection light from a light modulator onto a screen and which is telecentric on an input side is provided. The projection lens system comprises a first meniscus lens that is disposed closest to the screen, is convex on a screen side, and has negative refractive power; and a second meniscus lens that is disposed next closest to the screen, is convex on a screen side, and has negative refractive power. The first meniscus lens is made of plastic and at least one out of two curved surfaces thereof is aspherical, and a refractive power of the first meniscus lens is lower than a refractive power of the second meniscus lens. In the projection lens system, far superior aberration-correcting performance can be achieved and a drop in aberration-correcting performance due to thermal deformation can be prevented.

Owner:NITTO OPTICAL CO LTD

Ultrasonic vibration device

ActiveUS8896183B2Shorten the timeHigh sensitivityWave based measurement systemsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic vibrationEngineering

In an inner bottom surface of a case, a substantially oblong recess having a long axis and a short axis forms a vibration area. A piezoelectric element is bonded to the center of the recess. On the opposite sides of the vibration area, vibration suppression areas thicker than the vibration area are disposed. A side portion of the case is formed to be thin over the entire circumference thereof. A reinforcing member higher in rigidity than the case is bonded to upper portions of the vibration suppression areas. The reinforcing member has a bottom surface substantially equal to the shape of the vibration suppression areas, and has a predetermined height. A gap between the reinforcing member and an inner side surface of the case is also filled with a filling member.

Owner:MURATA MFG CO LTD

Fish shaped lure for trolling

ActiveUS9271482B2Difference in thicknessIncreasing the thicknessBaitLinesDecoyBiomedical engineering

Transfer sheets on which an image quite closely resembling an external appearance of a bait fish is color printed on the surface of a hologram sheet are adhered to back sides of bilaterally symmetrical body-half segments made of a flexible transparent thermoplastic resin in a state that the image can be viewed perspectively from the surface side. Only front head sides which occupy at least half in both the body-half segments are adhered and remaining rear end sides are kept open, by which a line equipped with a hook is guided out and wired to the front from the rear end sides via an interior hollow of a lure body.

Owner:HOPEC

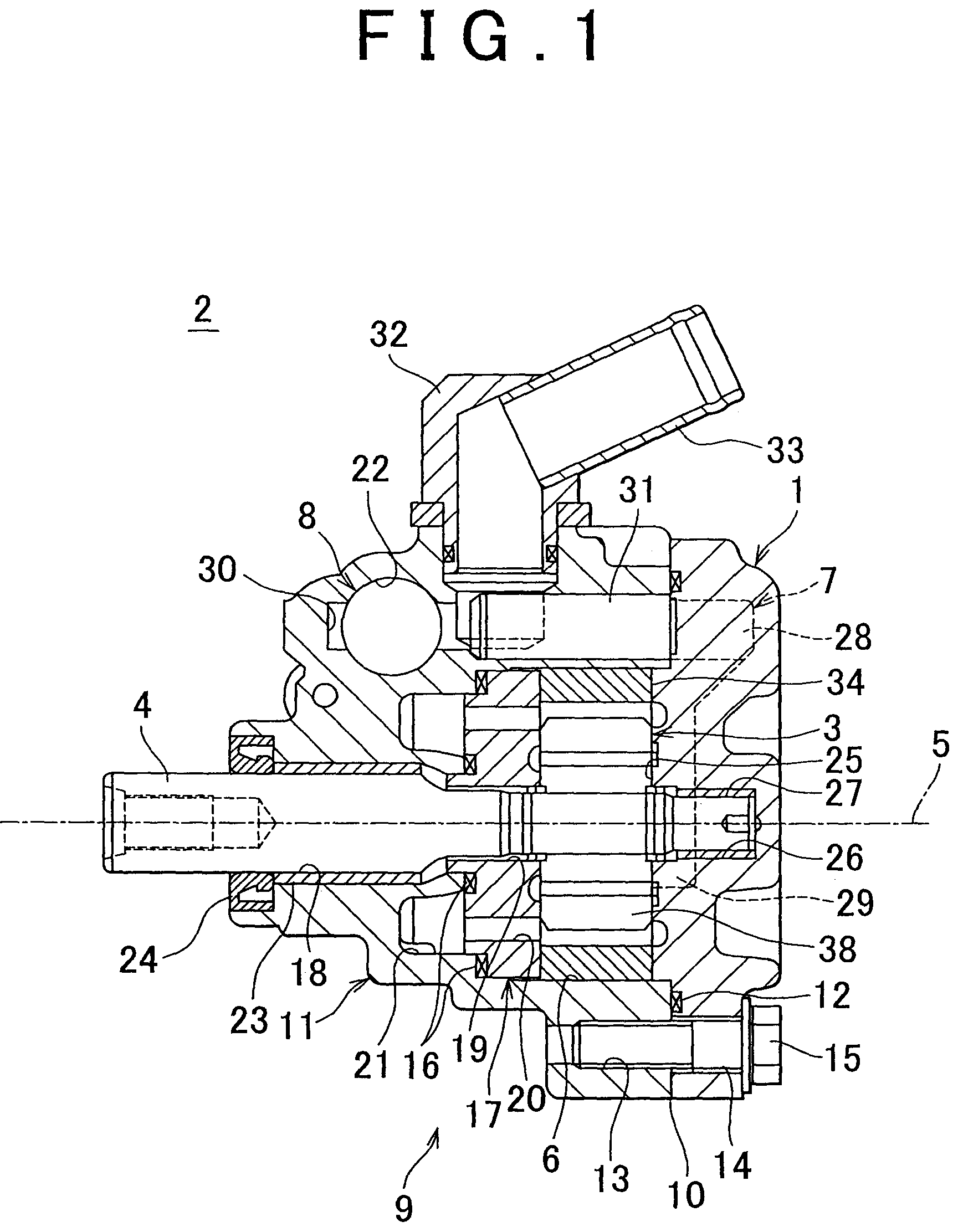

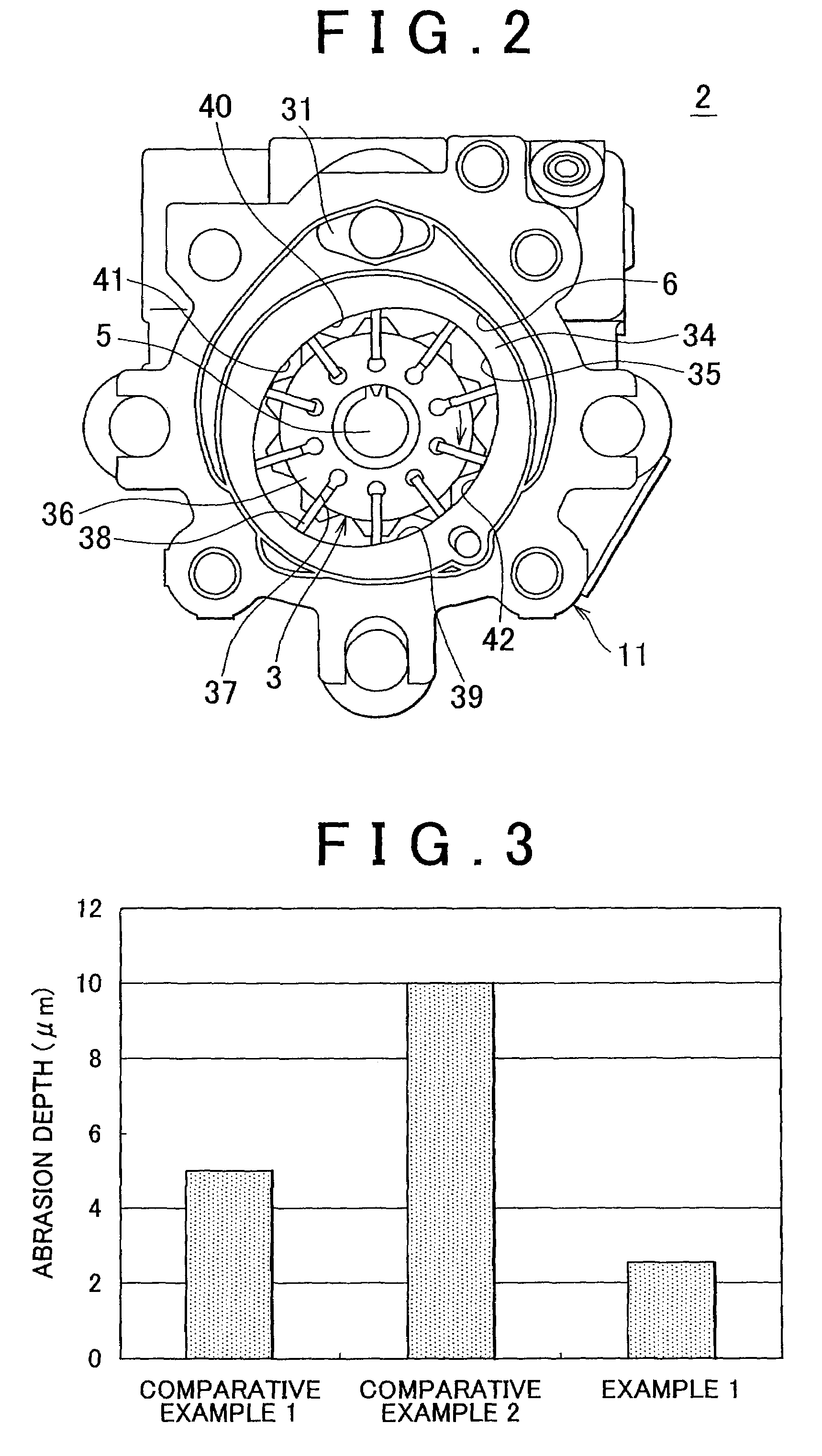

Metal part and method of manufacturing metal part

ActiveUS8172561B2Improve surface smoothnessHigh strengthAnodisationOscillating piston enginesSiliconMetal

A metal part in which a base material of silicon-aluminum alloy having 1 to 25% by mass of silicon as an anode is immersed in an electrolyte together with a cathode, and at least a portion of a surface of the base material is anodized and coated with an anodic oxide film. A current density provided to both the anode and the cathode is increased from an initial current density of 0 A / dm2 at a rate between 0.15 and 0.35 A / dm2 per minute, wherein once the current density reaches a prescribed current density of between 0.8 A / dm2 and 1.2 A / dm2, the current density provided to the anode and the cathode is maintained at the prescribed current density.

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com