Patents

Literature

31results about How to "Non-uniformity can be corrected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

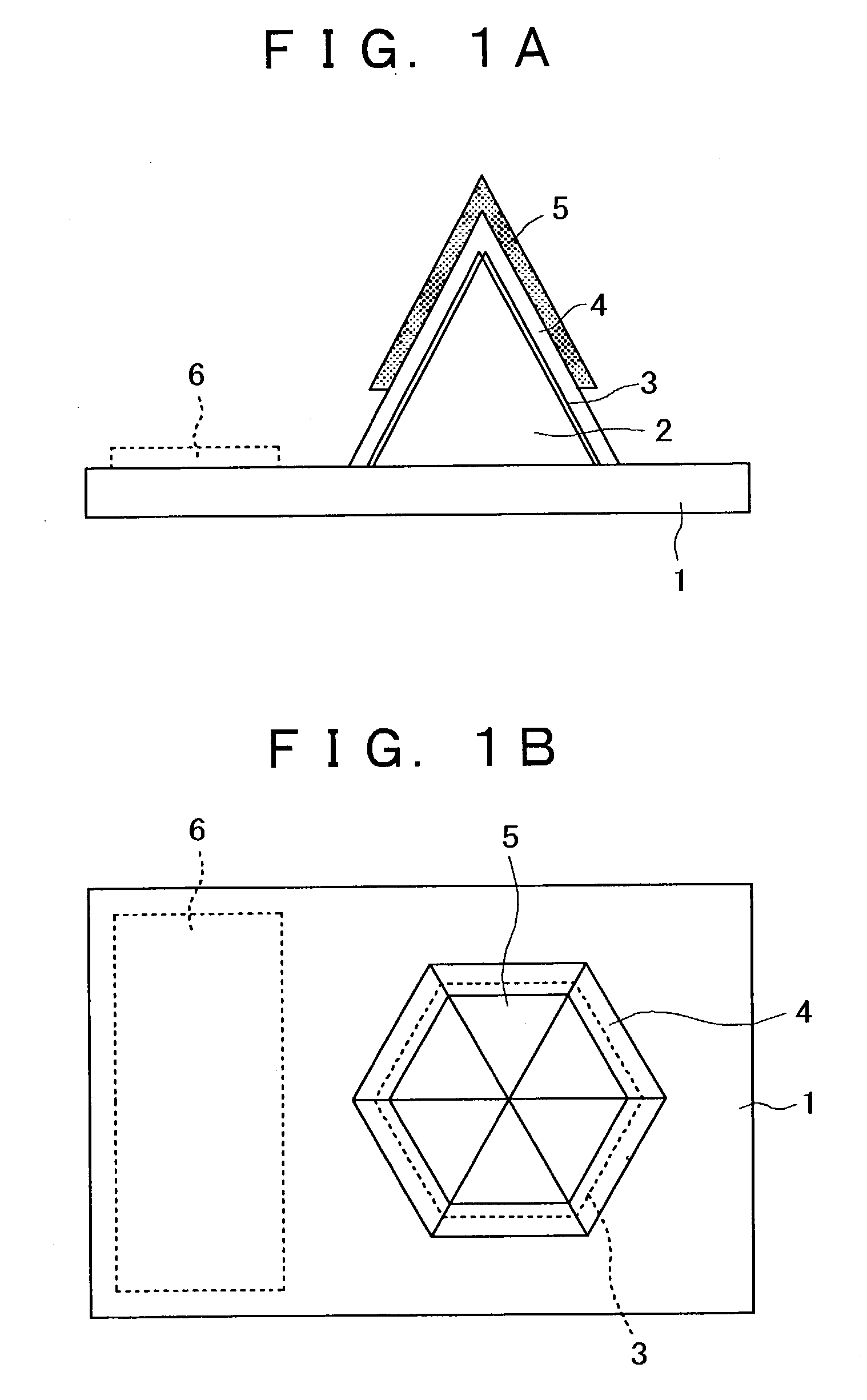

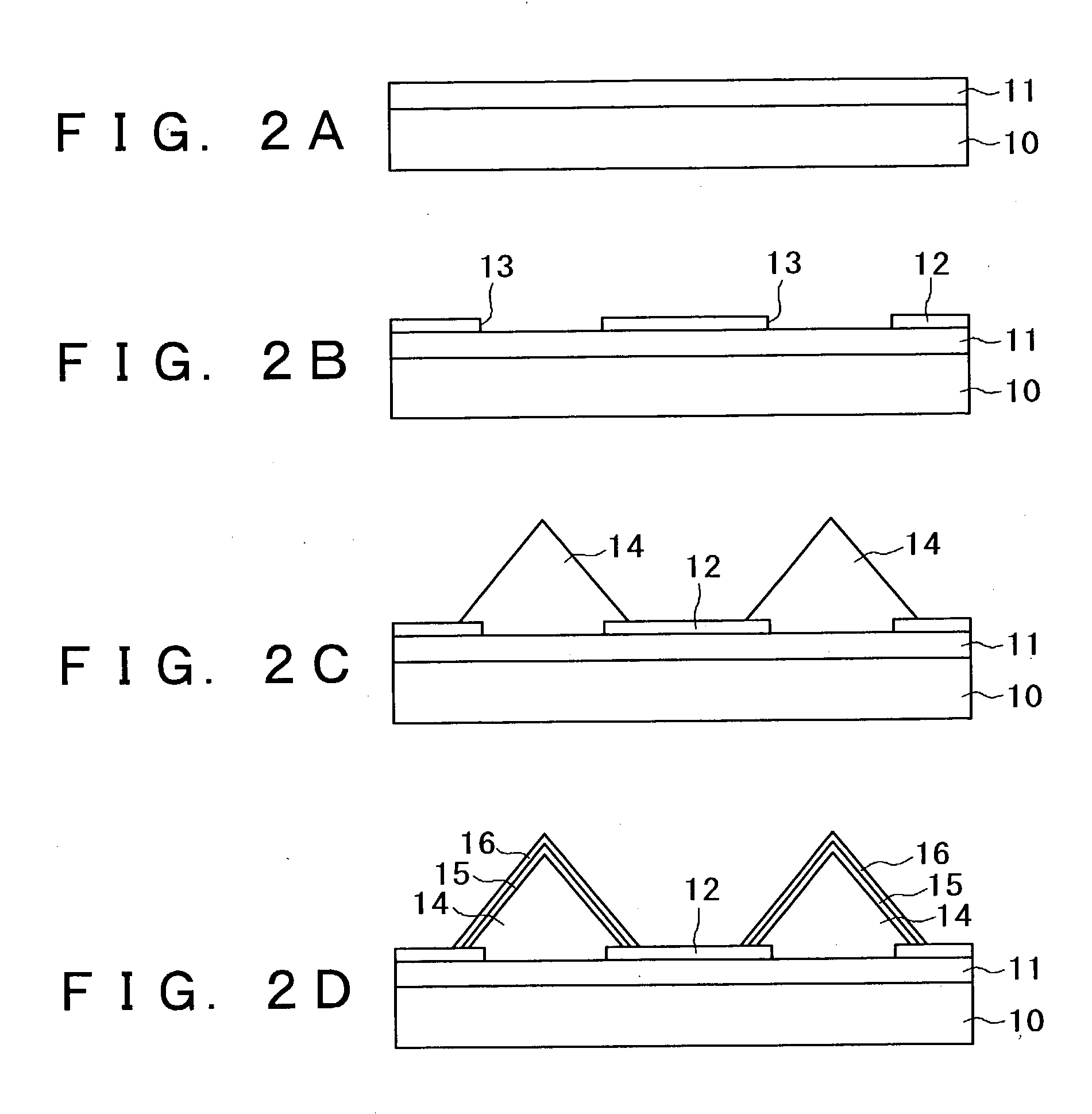

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS6858081B2Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

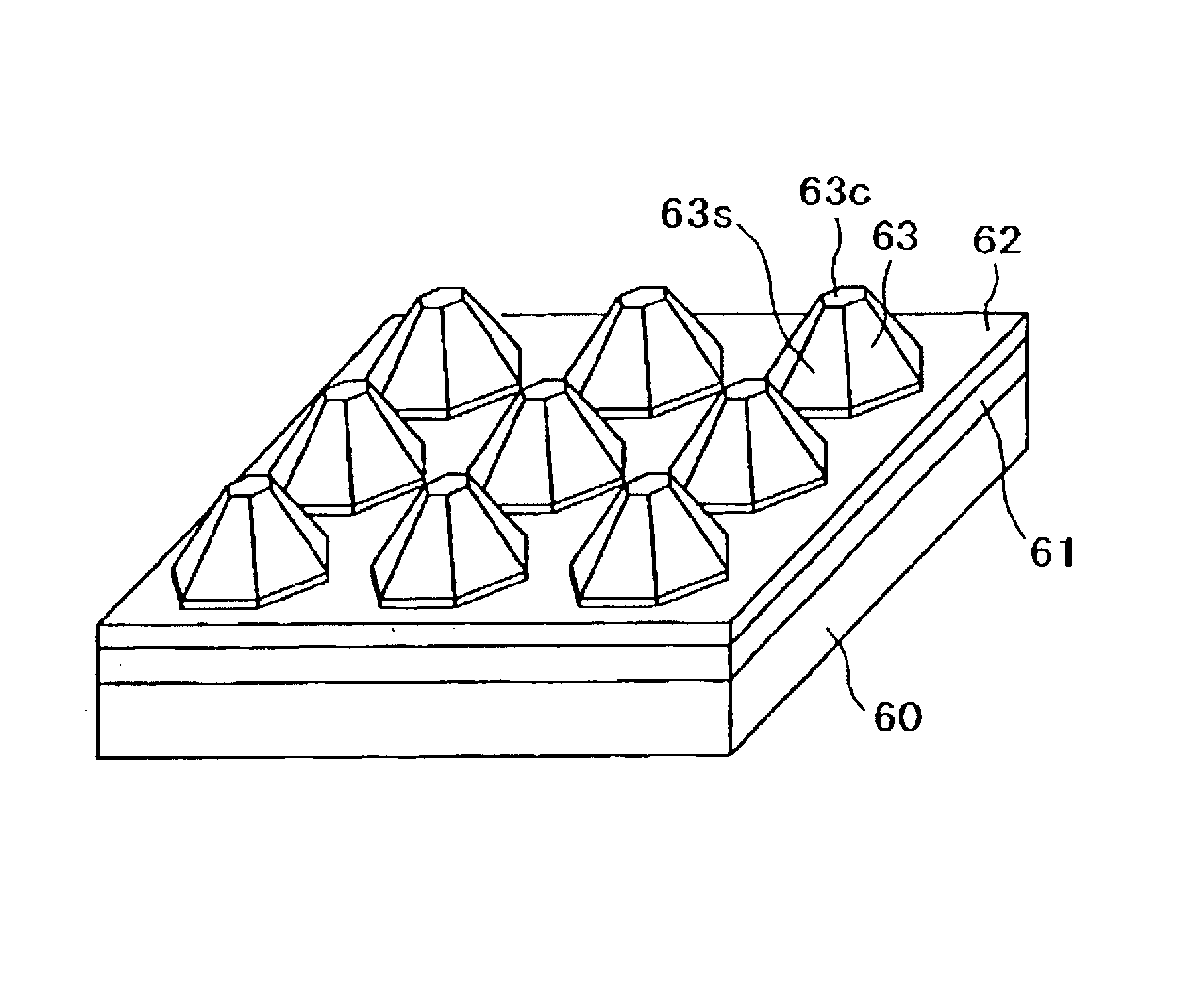

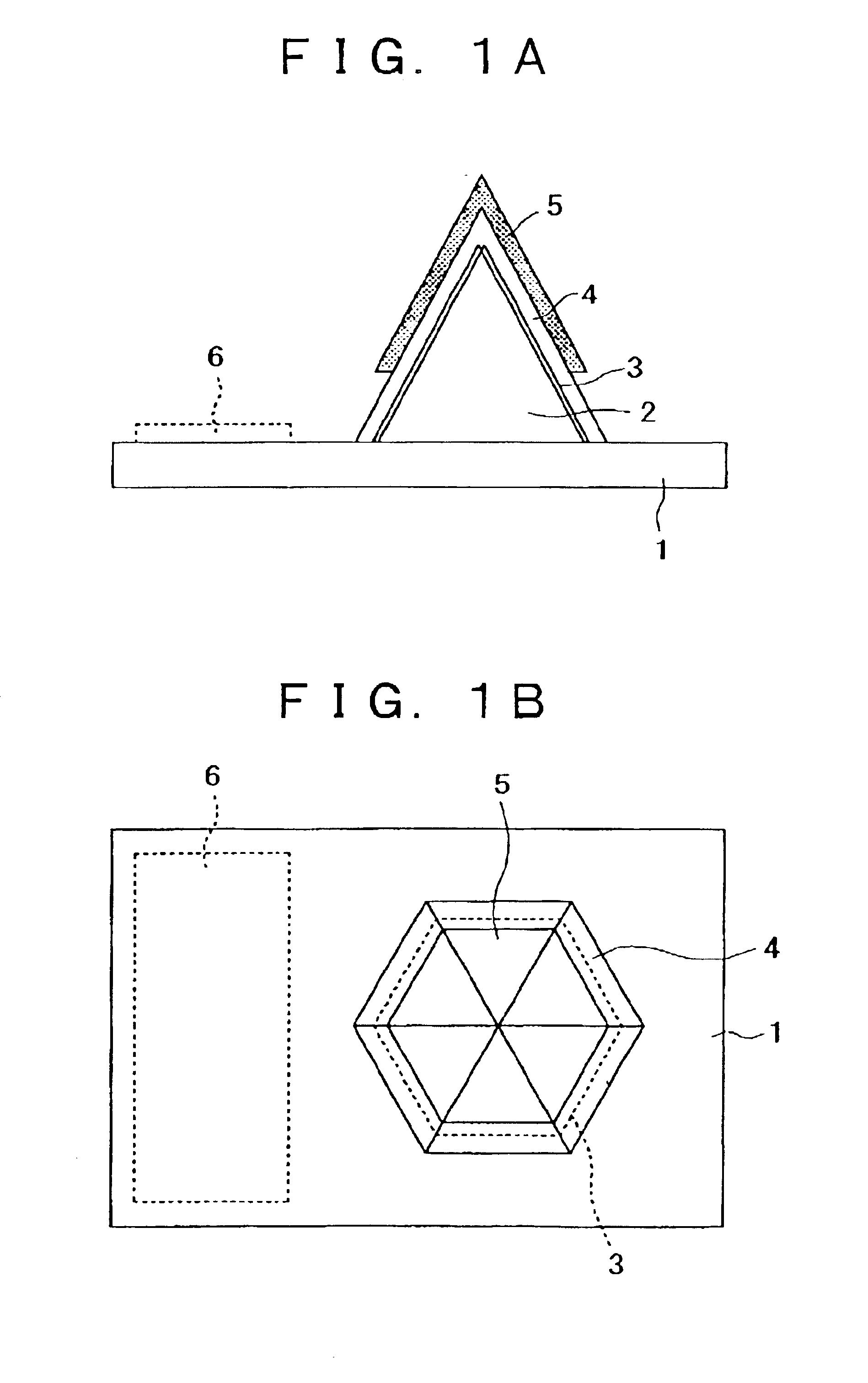

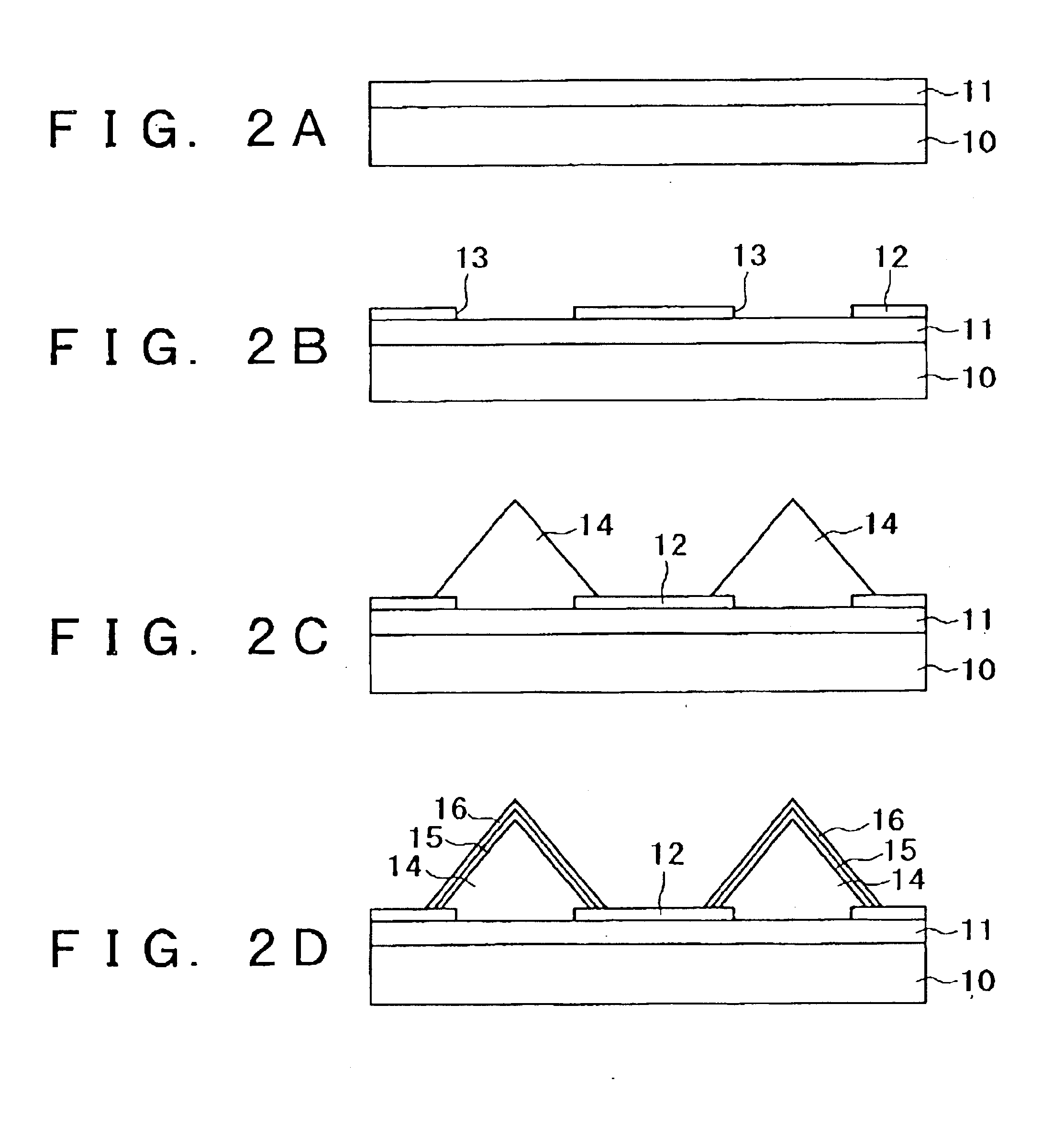

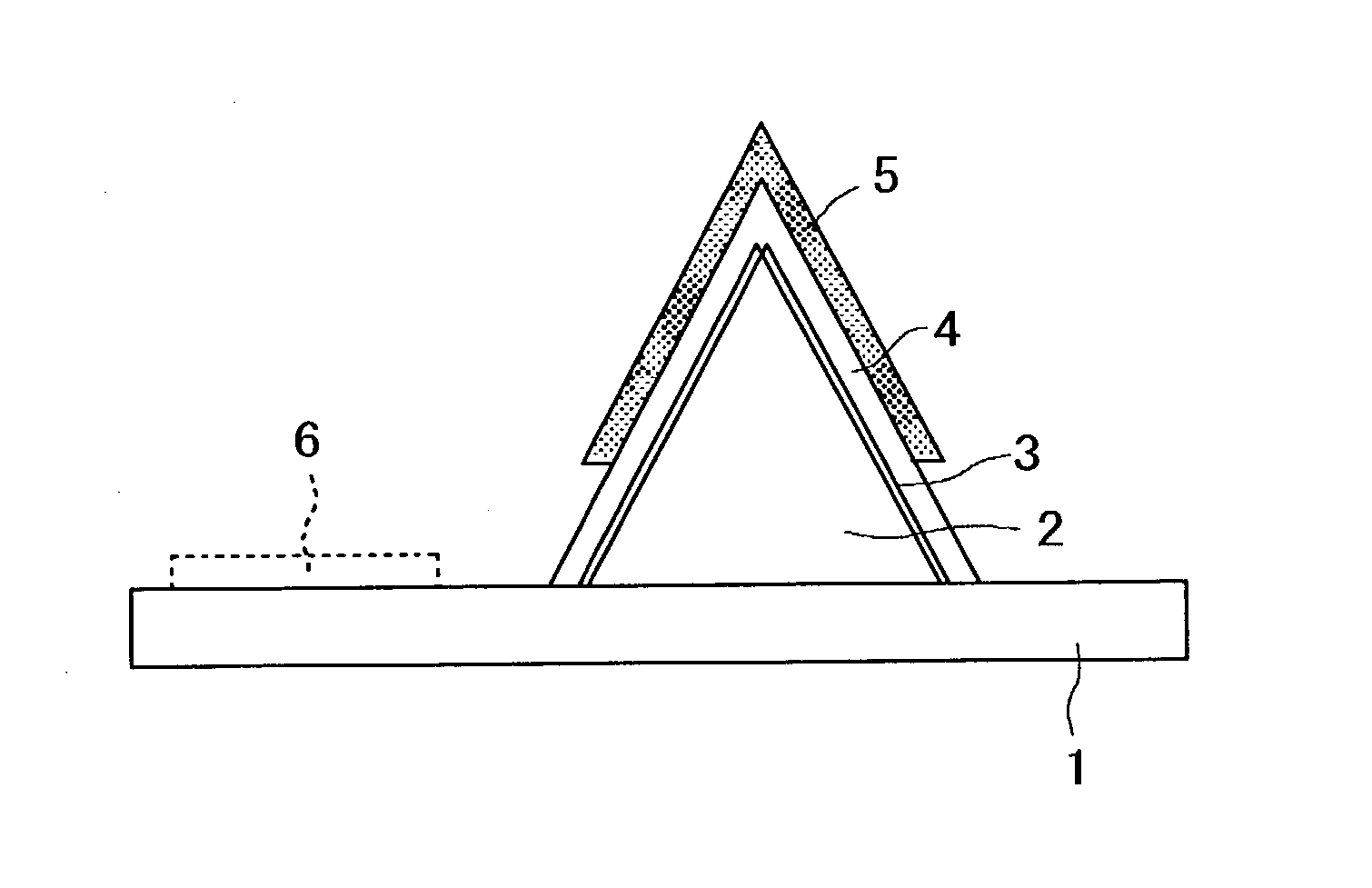

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

Selective growth method, and semiconductor light emitting device and fabrication method thereof

InactiveUS20030140846A1Improve featuresReduce widthPolycrystalline material growthSemiconductor/solid-state device manufacturingThree dimensional shapeActive layer

In a selective growth method, growth interruption is performed at the time of selective growth of a crystal layer on a substrate. Even if the thickness distribution of the crystal layer becomes non-uniform at the time of growth of the crystal layer, the non-uniformity of the thickness distribution of the crystal layer can be corrected by inserting the growth interruption. As a result of growth interruption, an etching rate at a thick portion becomes higher than that at a thin portion, to eliminate the difference in thickness between the thick portion and the thin portion, thereby solving the problem associated with degradation of characteristics due to a variation in thickness of the crystal layer, for example, an active layer. The selective growth method is applied to fabrication of a semiconductor light emitting device including an active layer as a crystal layer formed on a crystal layer having a three-dimensional shape by selective growth.

Owner:SAMSUNG ELECTRONICS CO LTD

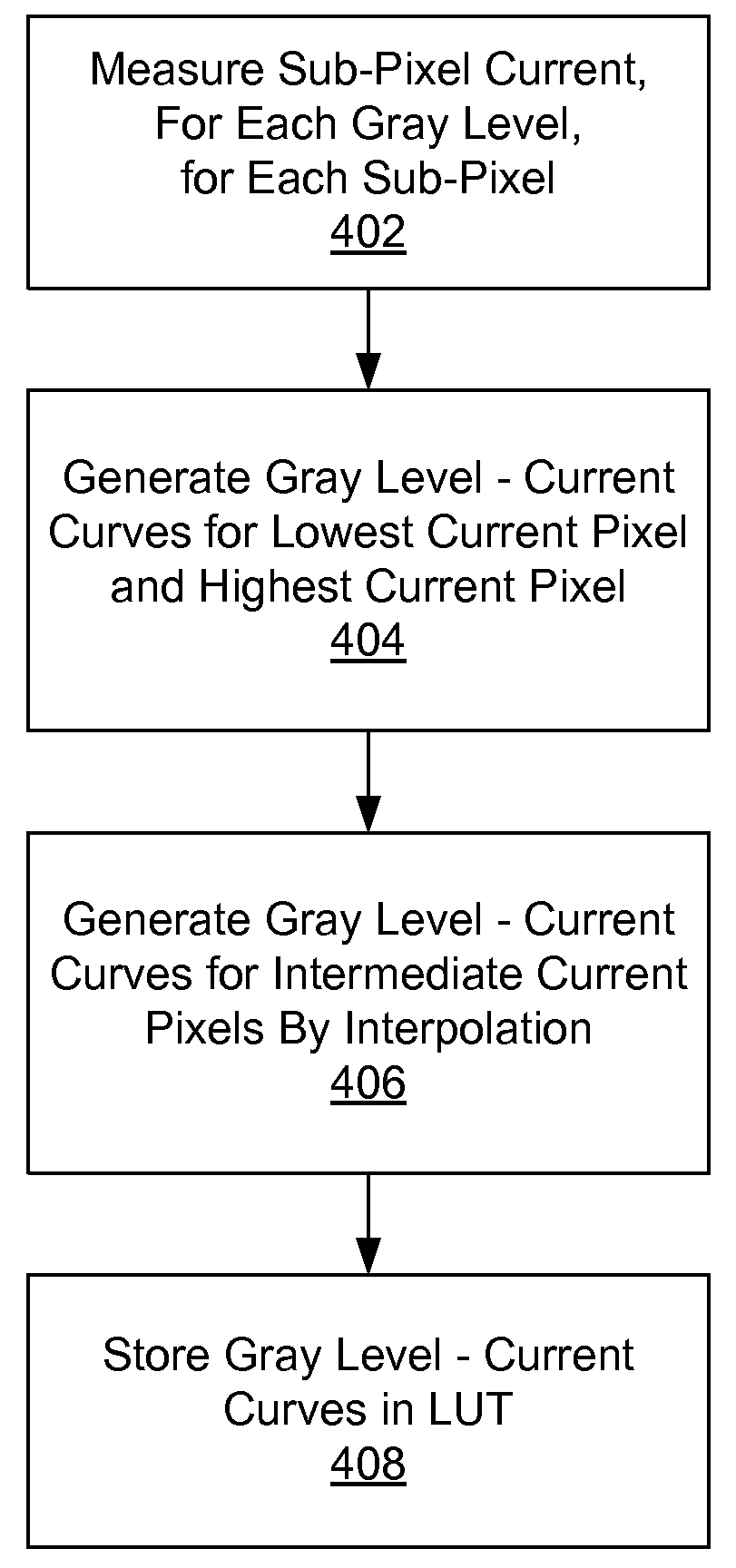

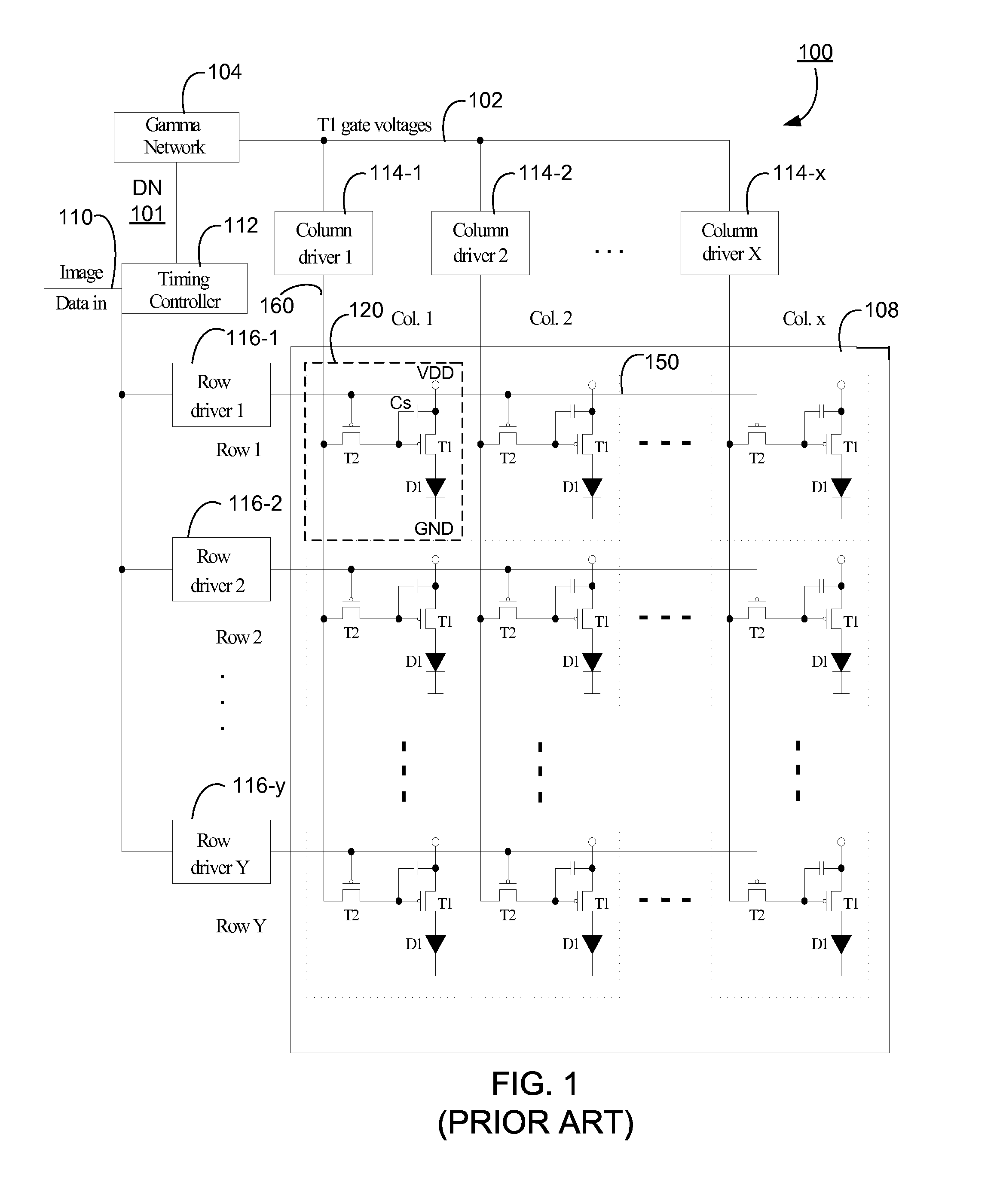

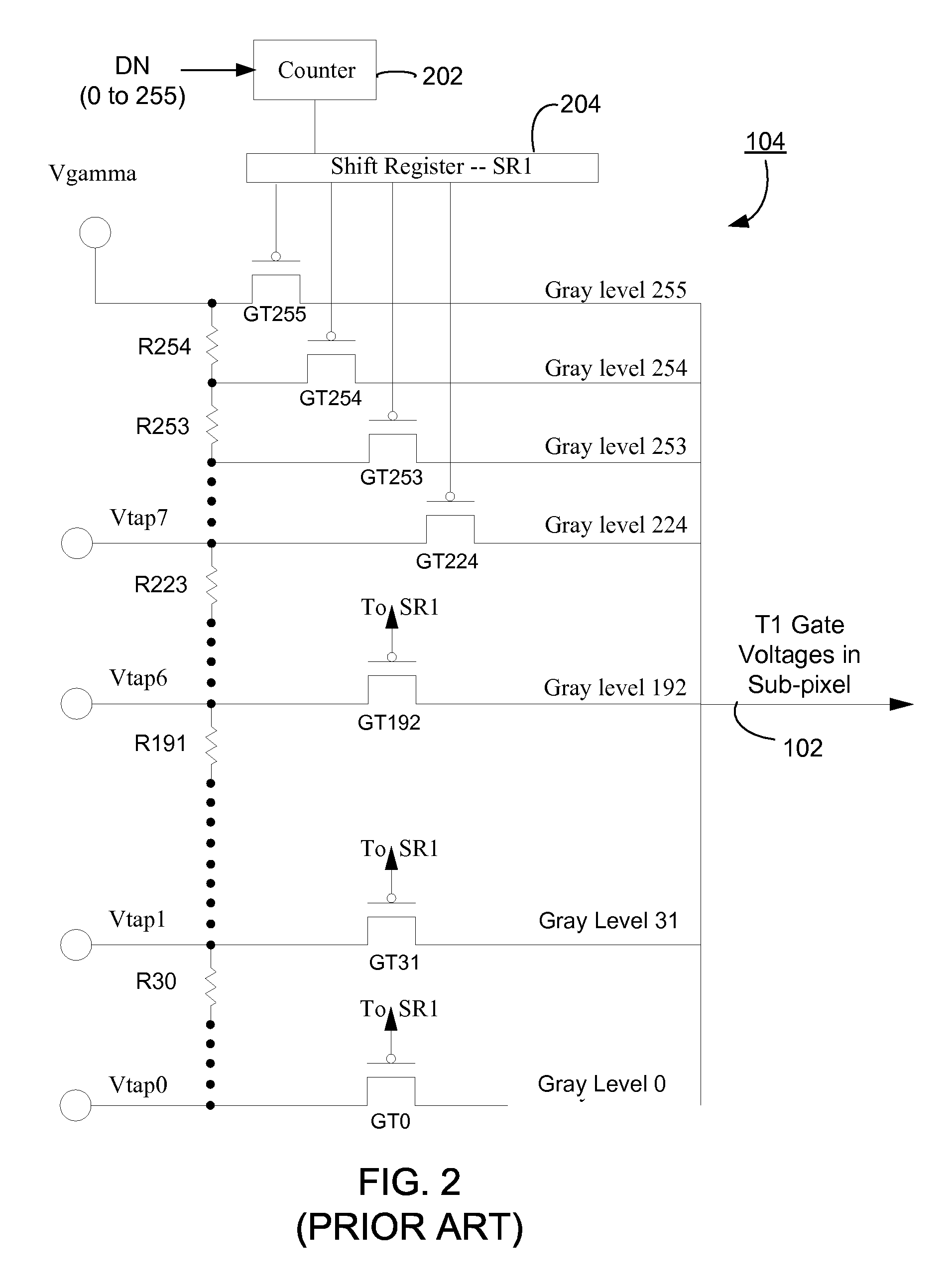

Using standard current curves to correct non-uniformity in active matrix emissive displays

InactiveUS20090195483A1Shorten timeEfficient calibrationStatic indicating devicesGray levelEngineering

A plurality of gray level versus OLED current curves are generated by measuring many OLED panels from a stable manufacturing process, and those curves are stored as standard gray level versus OLED current curves. When a new OLED display is manufactured from the process, each of its sub-pixels is characterized as having the characteristics of one of the pre-generated standard gray level versus OLED current curves, based on a gray level versus OLED current measurement at a single gray level. This drastically reduces the time it takes to determine the TFT gate voltage versus OLED current characteristics of the sub-pixels in the OLED display. The OLED display can use the selected one of the pre-generated standard gray level versus OLED current curves to correct non-uniformities of the sub-pixels in the OLED display caused by non-uniform TFTs in the active matrix.

Owner:LEADIS TECH

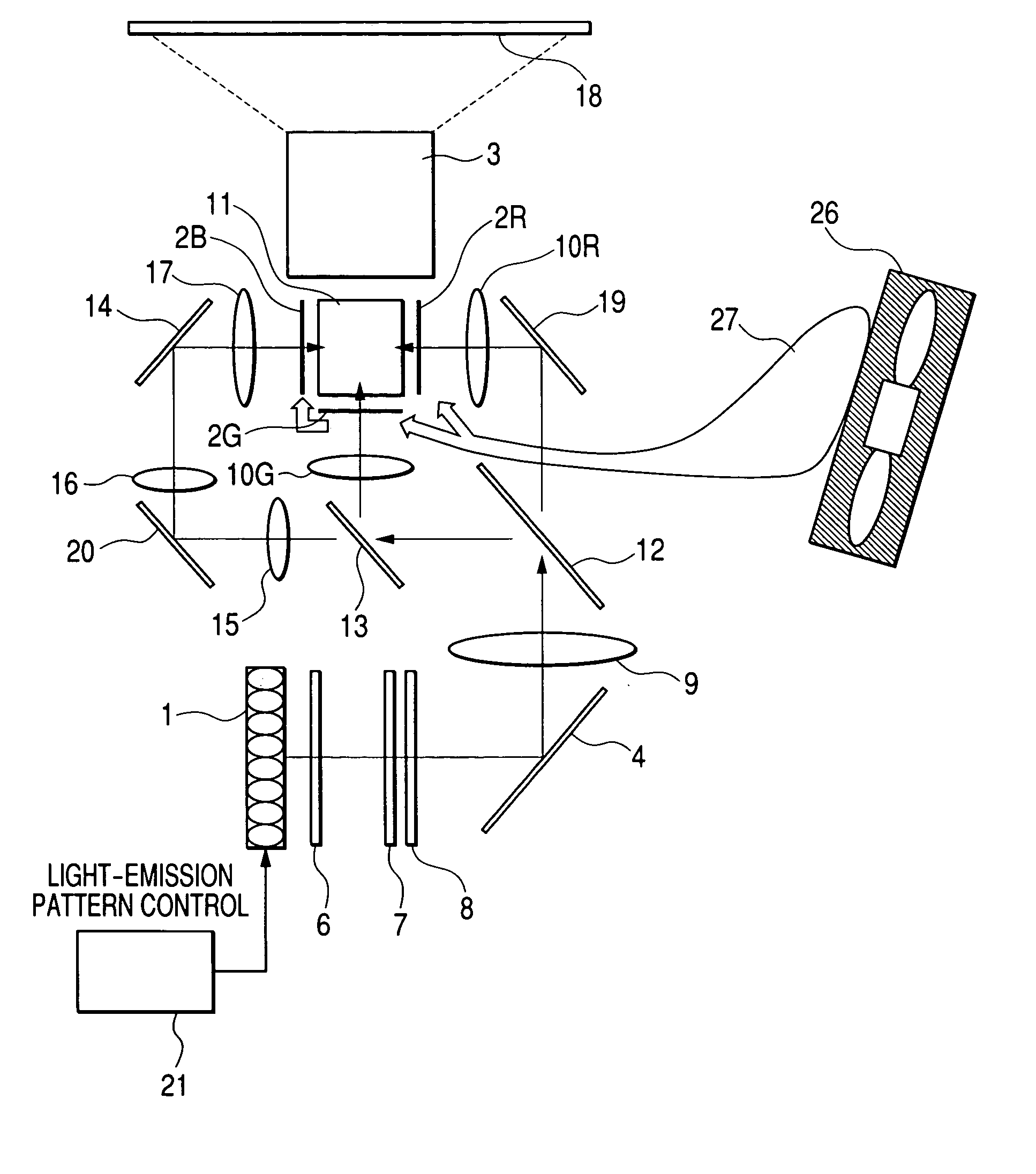

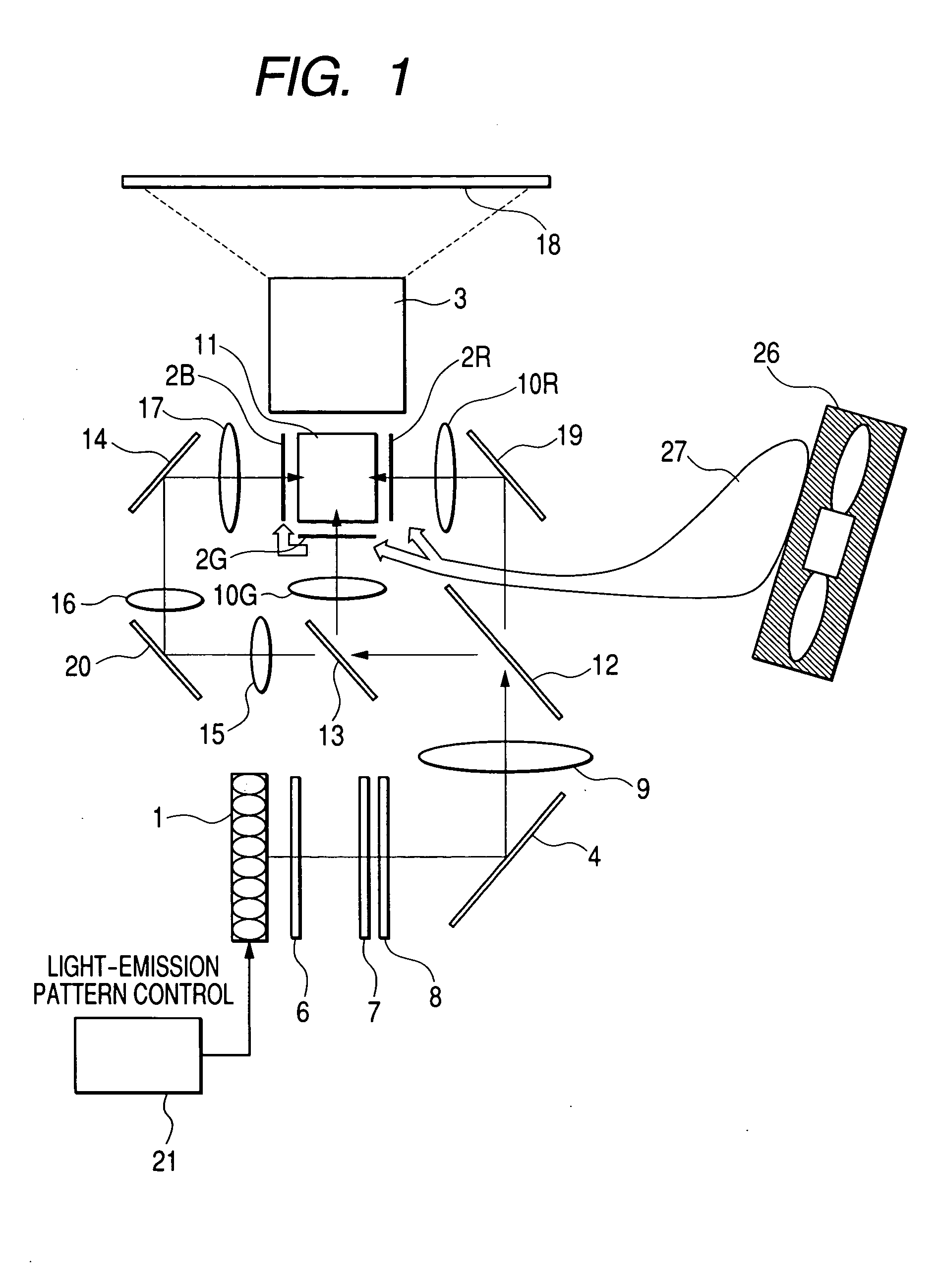

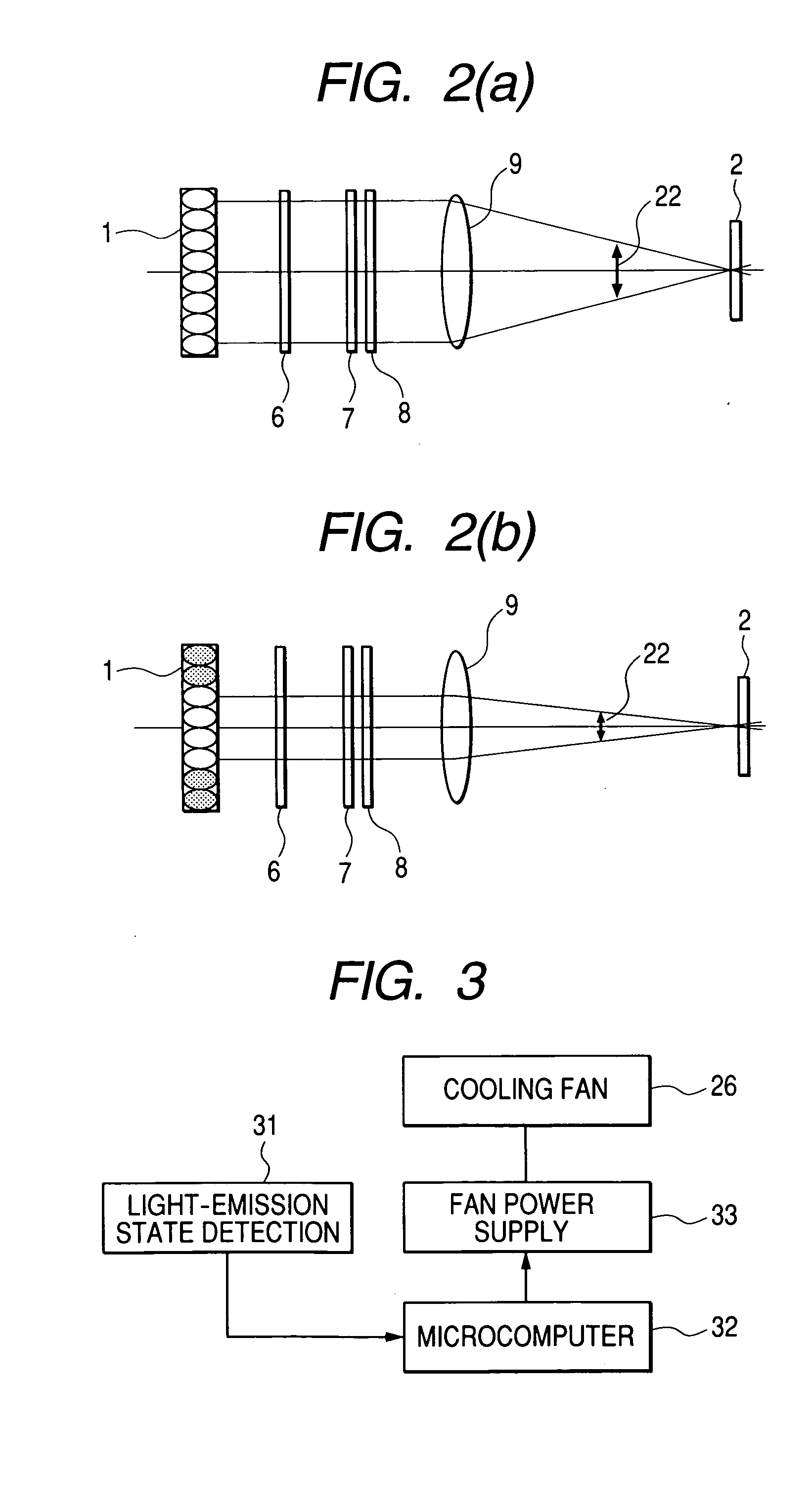

Projection-type image display apparatus

InactiveUS20050122481A1True colorCorrecting nonuniformity of luminanceTelevision system detailsStatic indicating devicesComputer graphics (images)Contrast ratio

An object of the present invention is to provide a projection-type image display apparatus improved in contrast. In order to achieve the above object, the present invention includes multiple LED elements, a controller for conducting control so that part of the multiple LED elements emit light, an image display element for forming a desired optical image from the light emitted from part of the LED elements, and a projector for projecting the optical image formed by the image display element.

Owner:HITACHI LTD

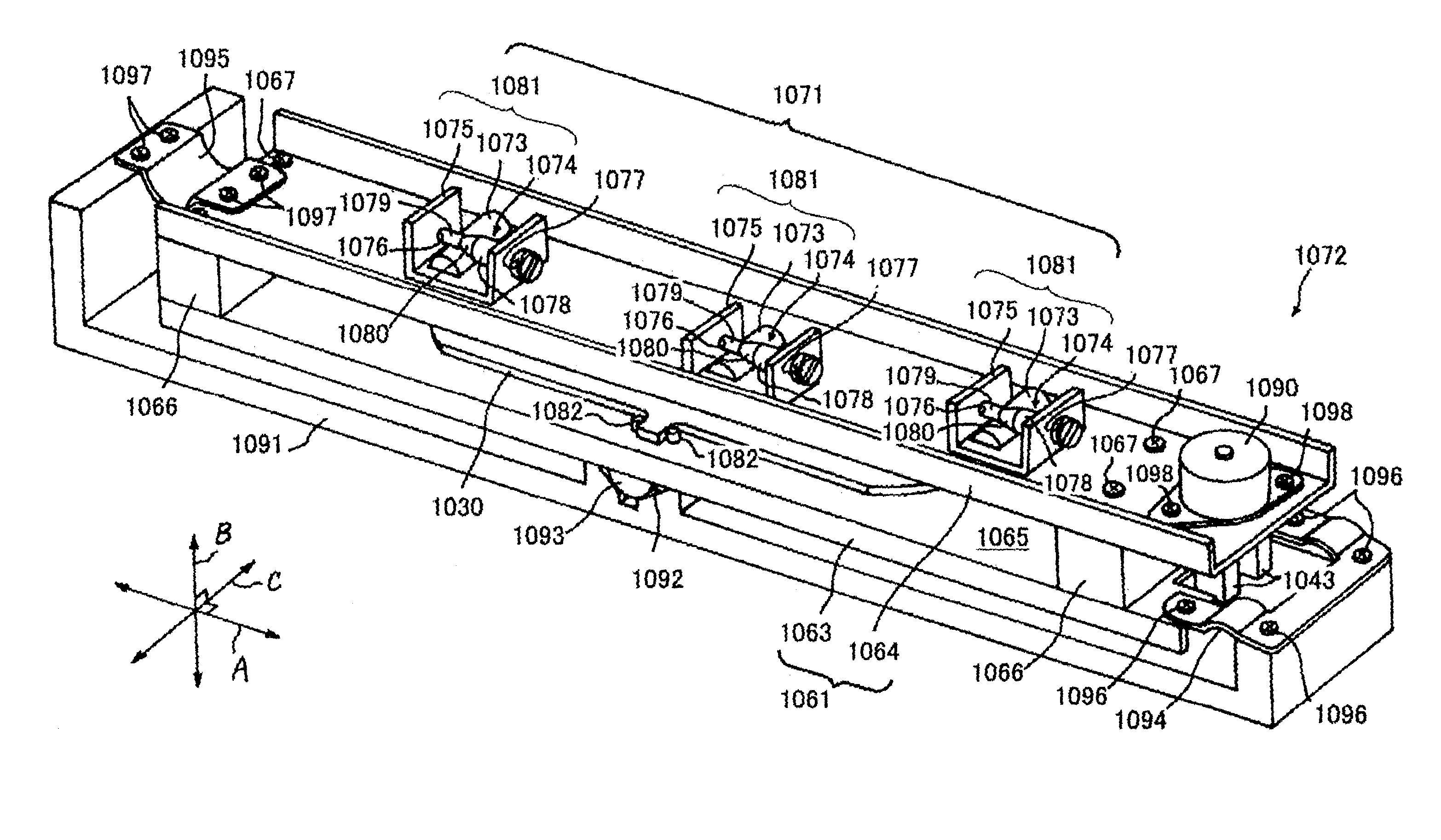

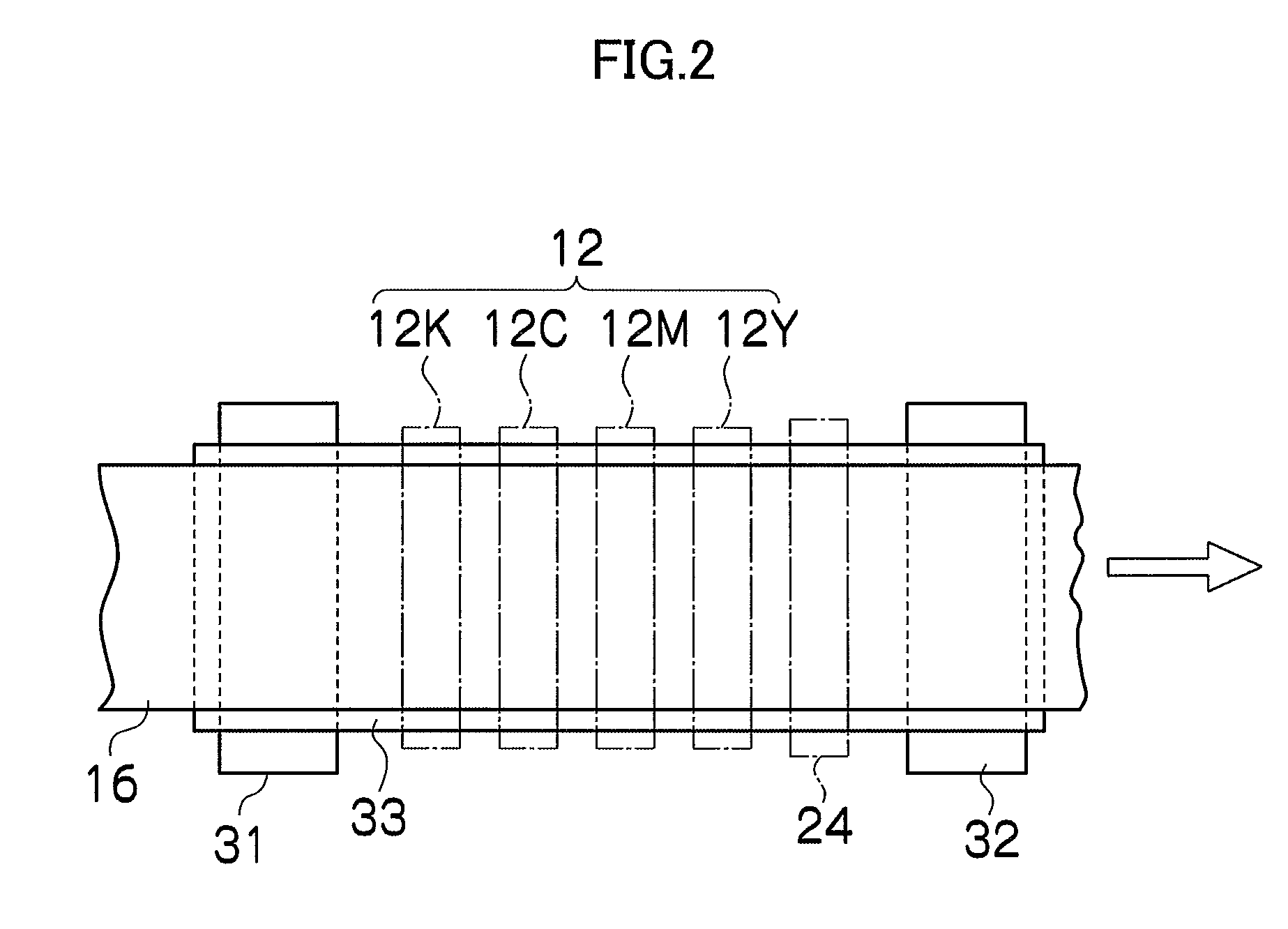

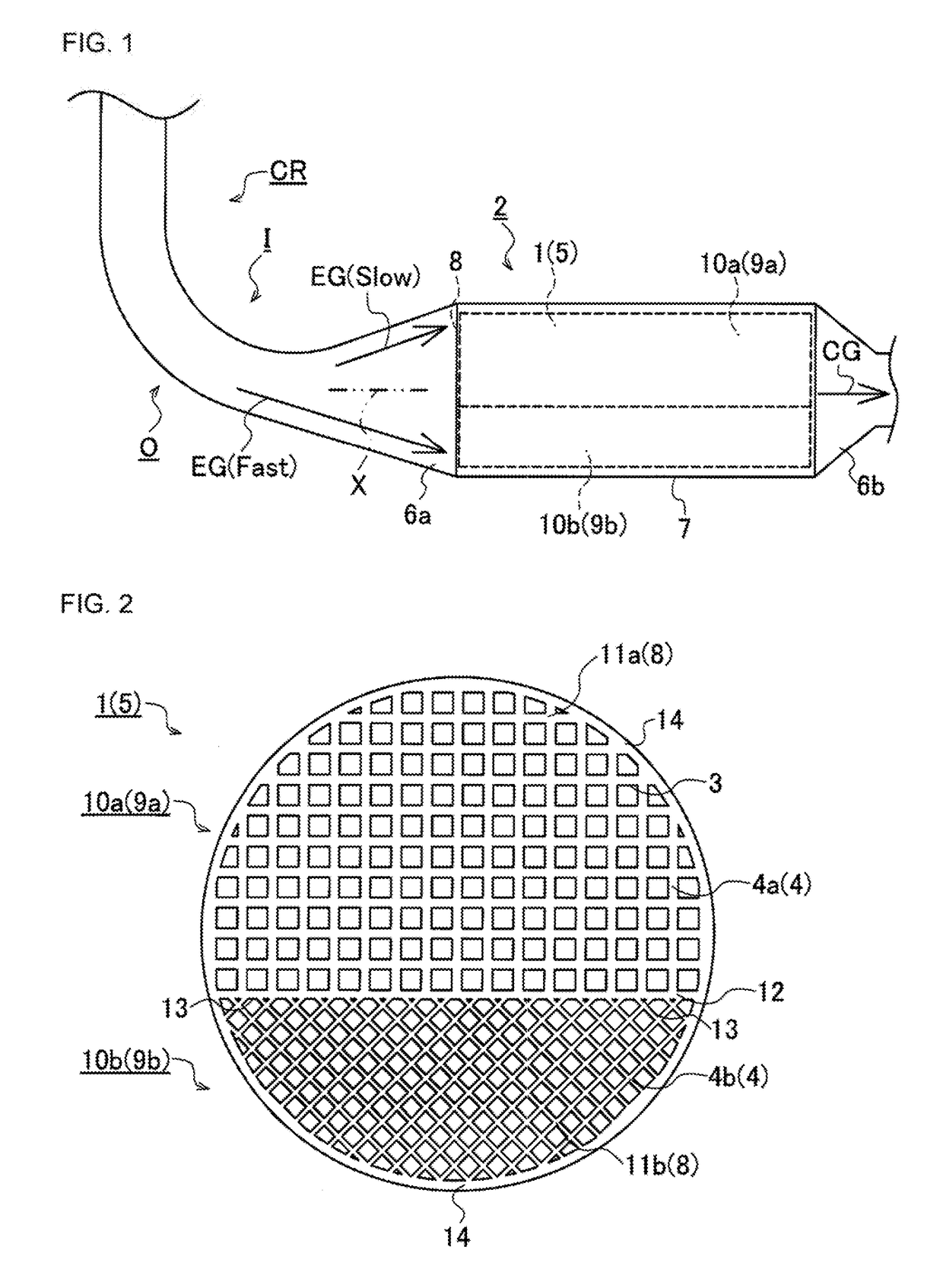

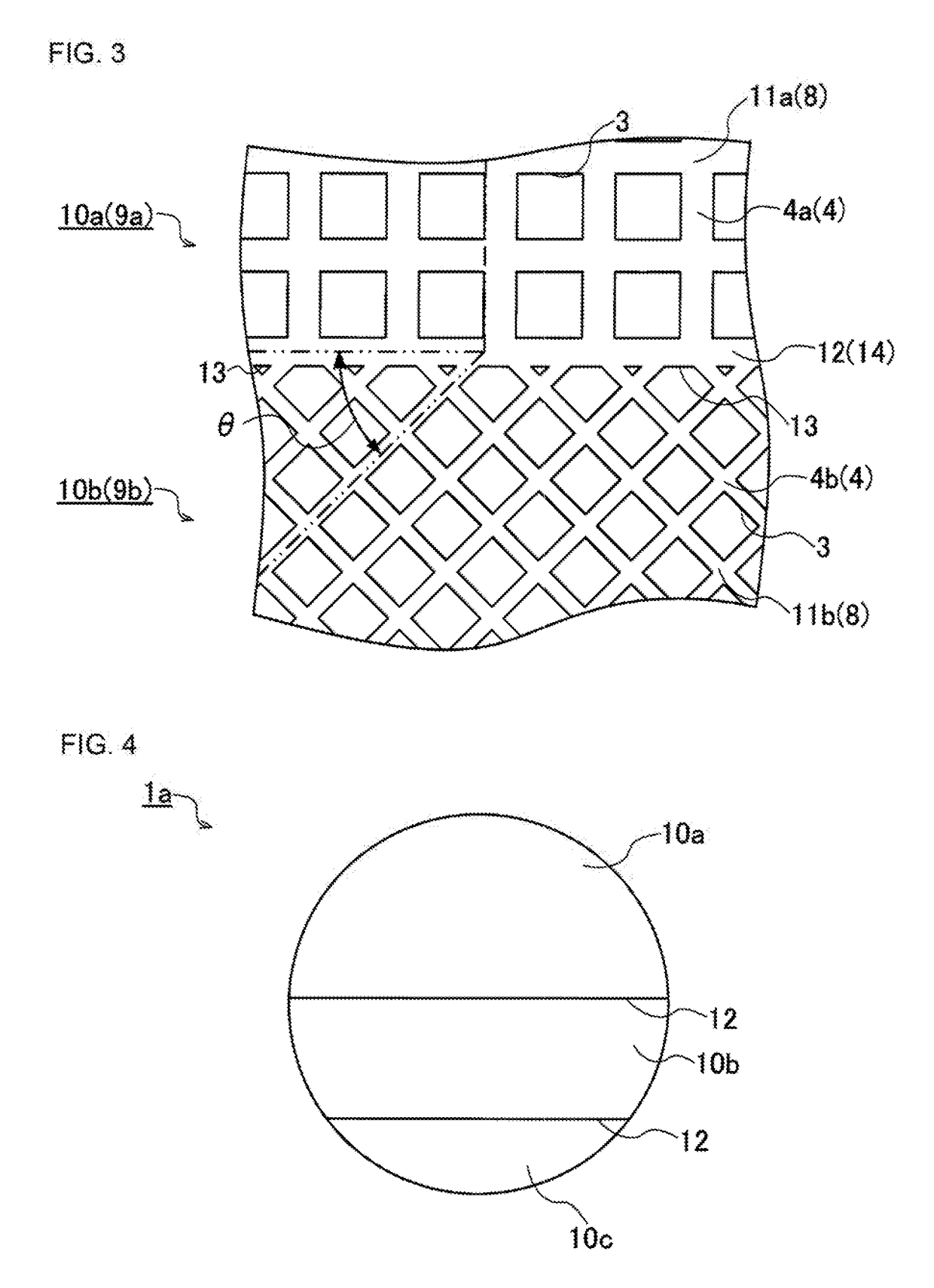

Light scanning device, scanning line adjusting method, scanning line adjusting control method, image forming apparatus, and image forming method

InactiveUS7301554B2Suppress deformationEasily and accuratelyRecording apparatusInking apparatusComputational physicsLight beam

A light scanning device includes an optical element that images, on an image holding body, a light beam emitted from a light source. The light scanning device further includes a holding member that holds the optical element, and scanning line curve correcting mechanism for correcting the optical element in a sub scanning direction to correct a scanning line formed by the light beam in the sub scanning direction. The light scanning device further includes a scanning line inclination correcting mechanism for entirely tilting the optical element to correct an inclination of the scanning line. At least one part of the scanning line curve correcting mechanism, and at least one part of the scanning line inclination correcting mechanism are provided integrally with the holding member.

Owner:RICOH KK

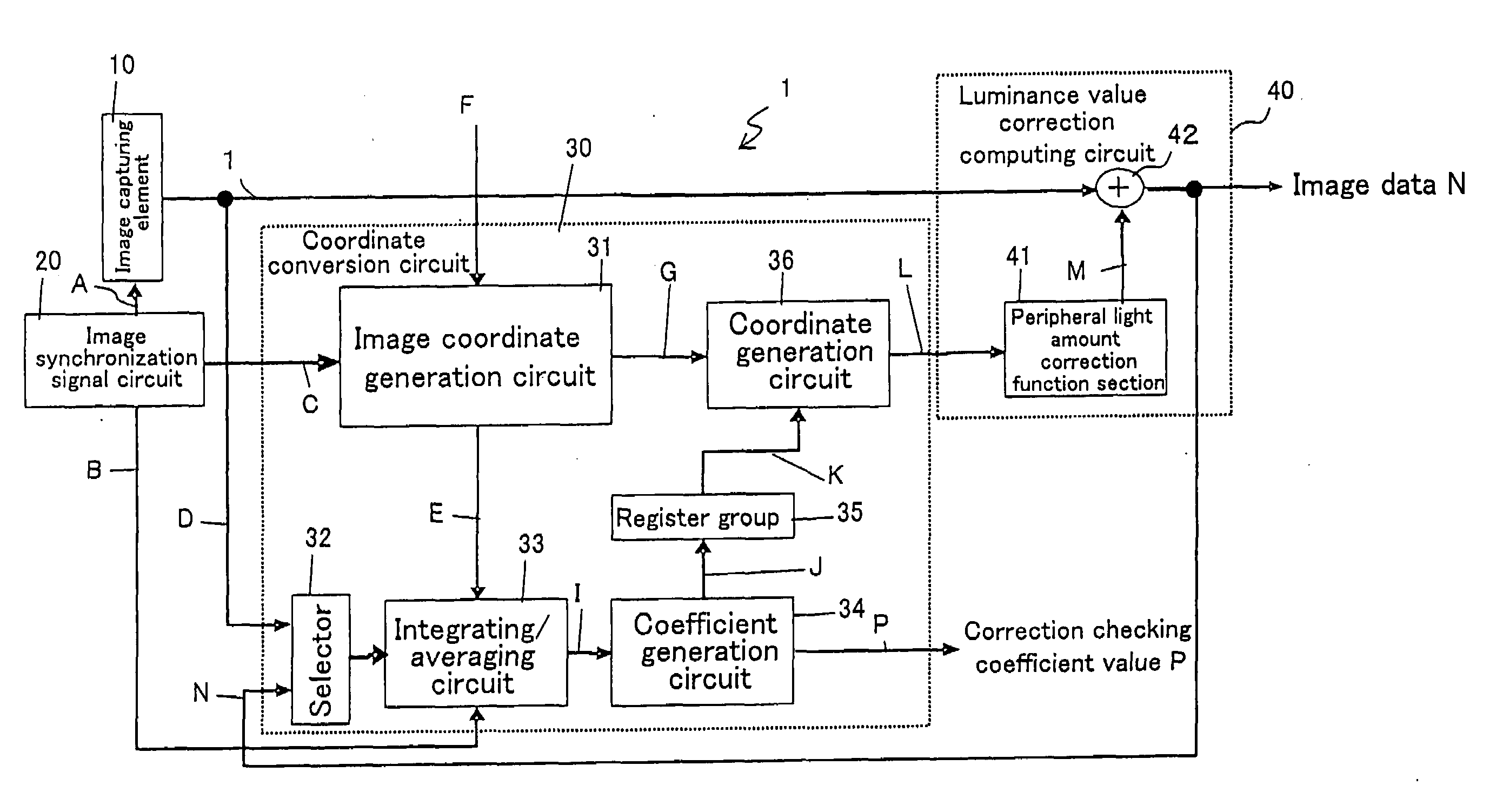

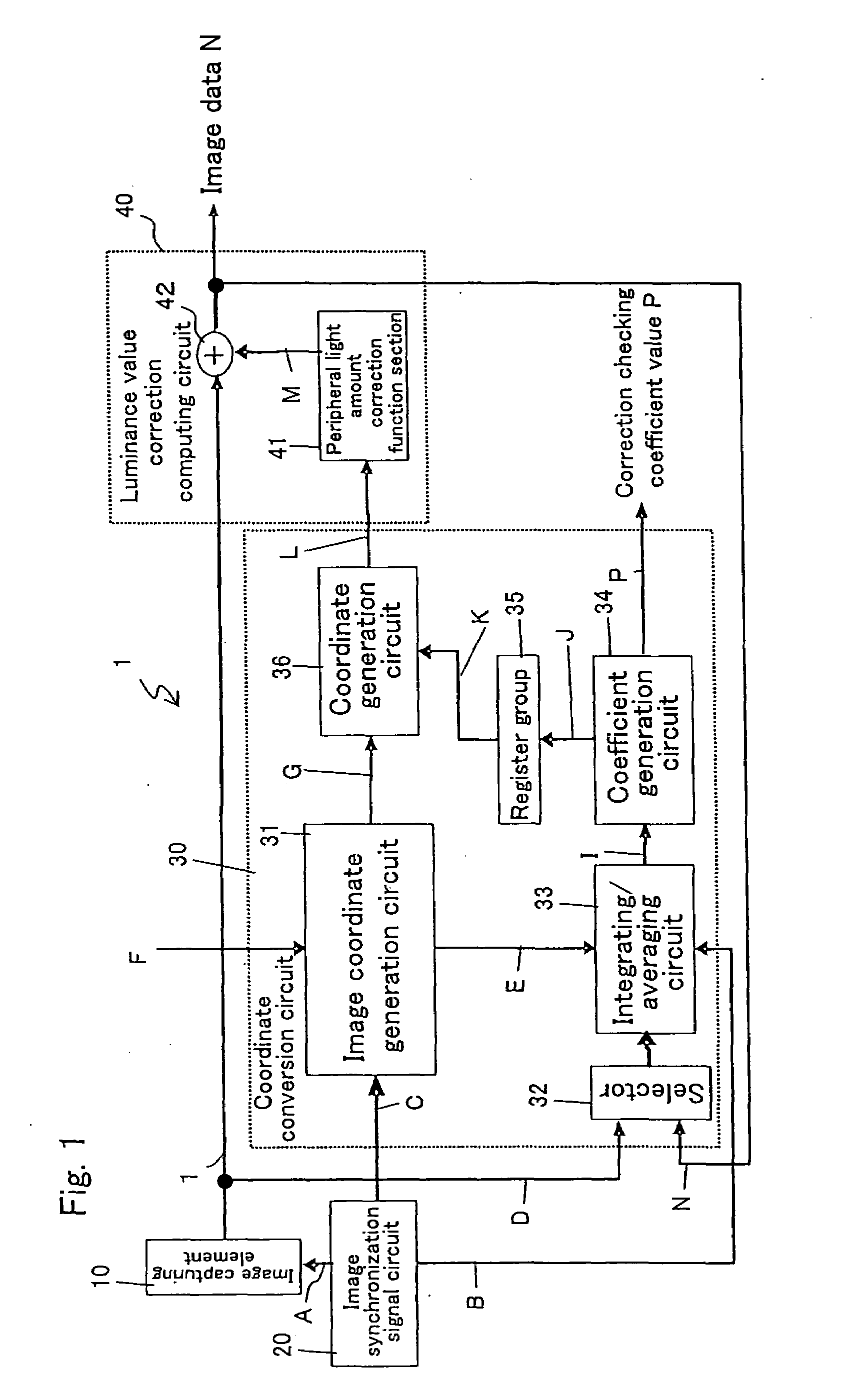

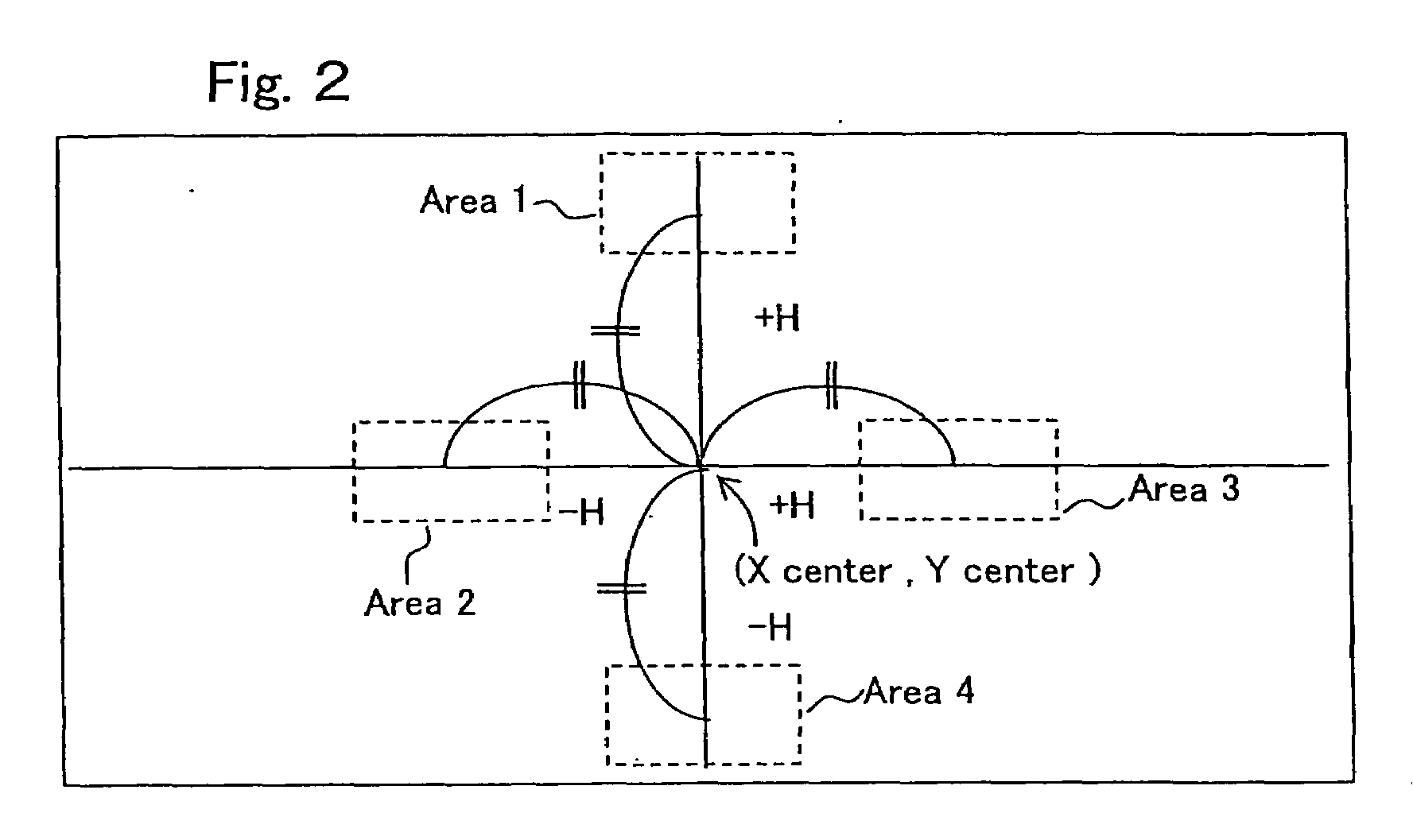

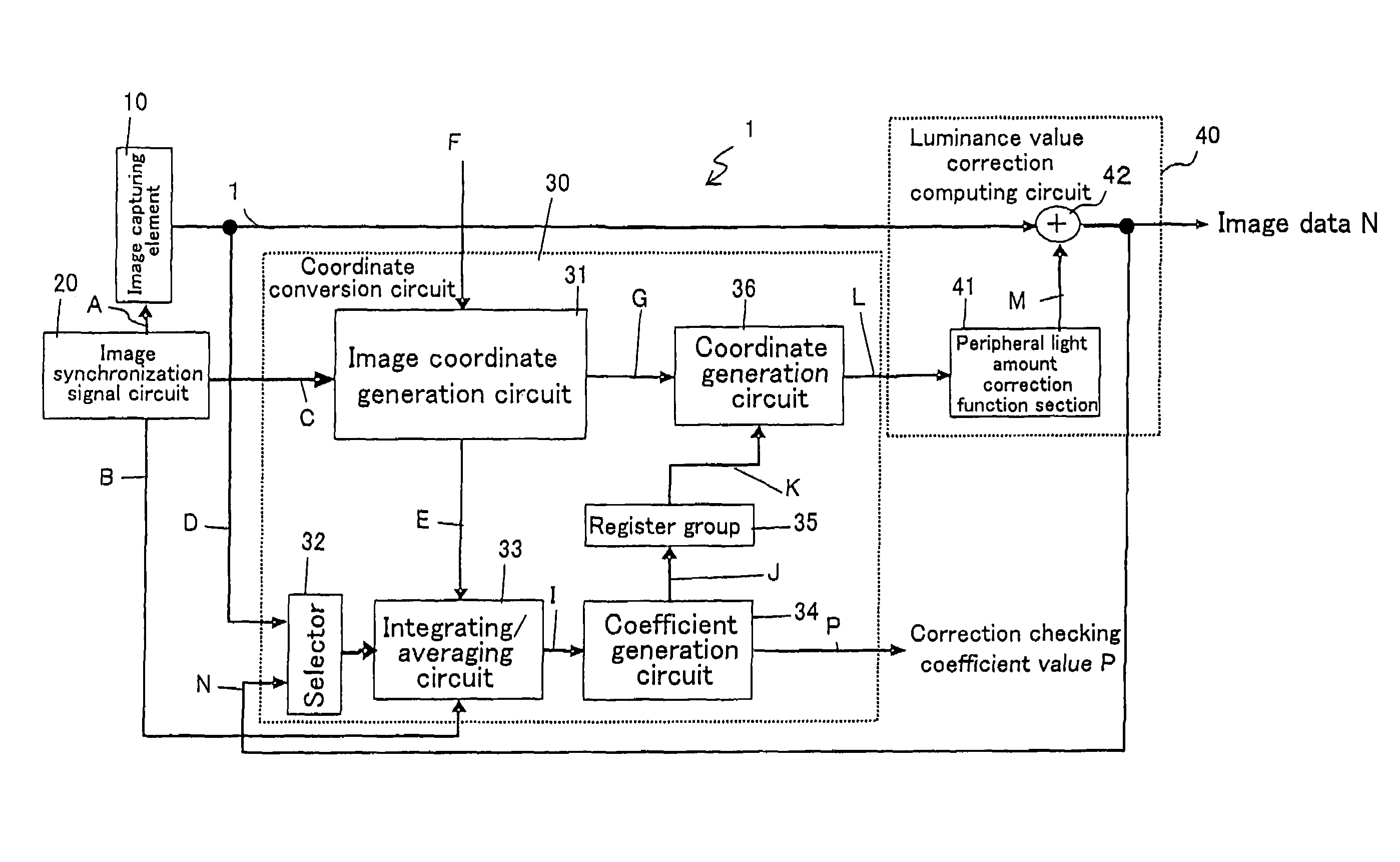

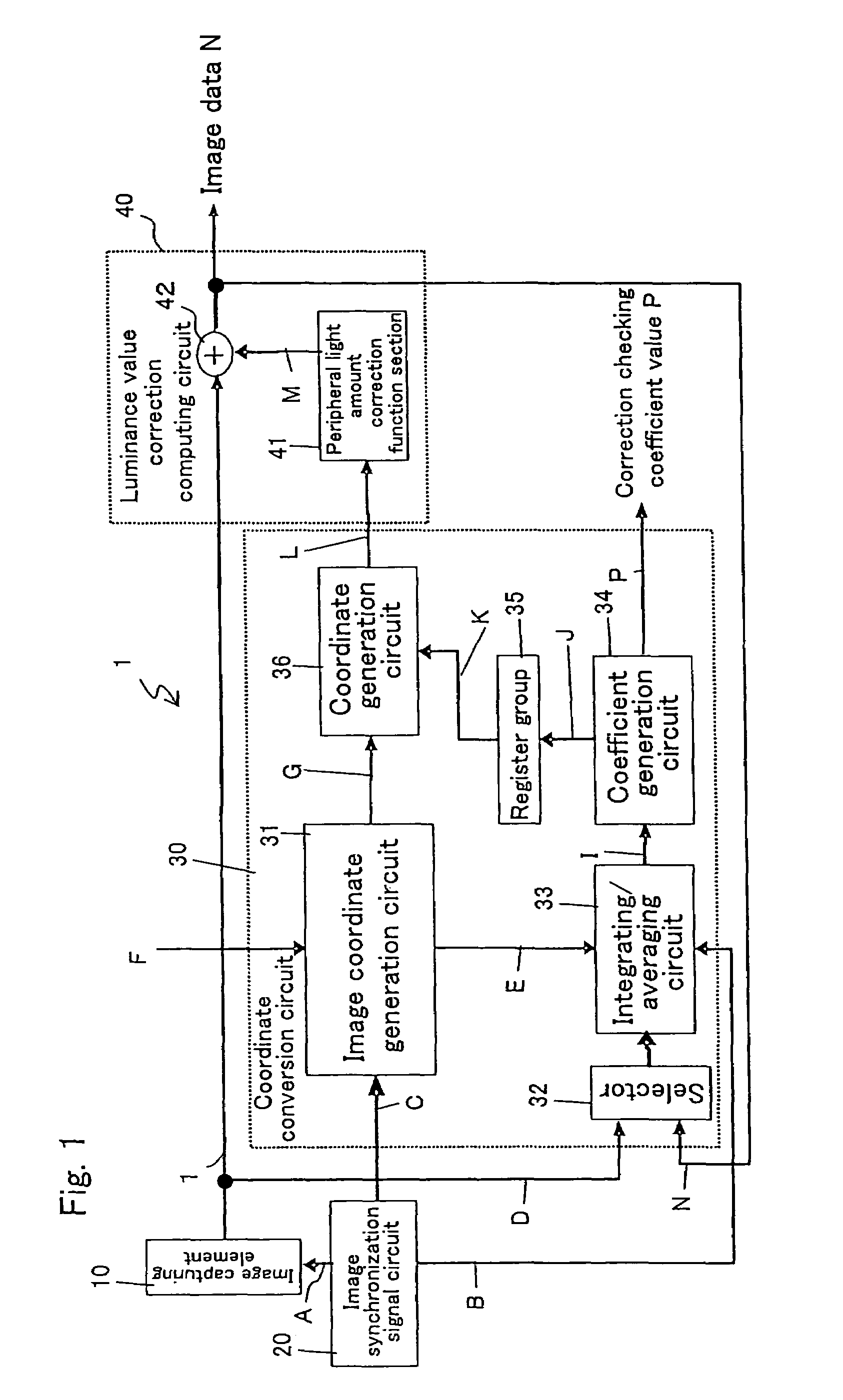

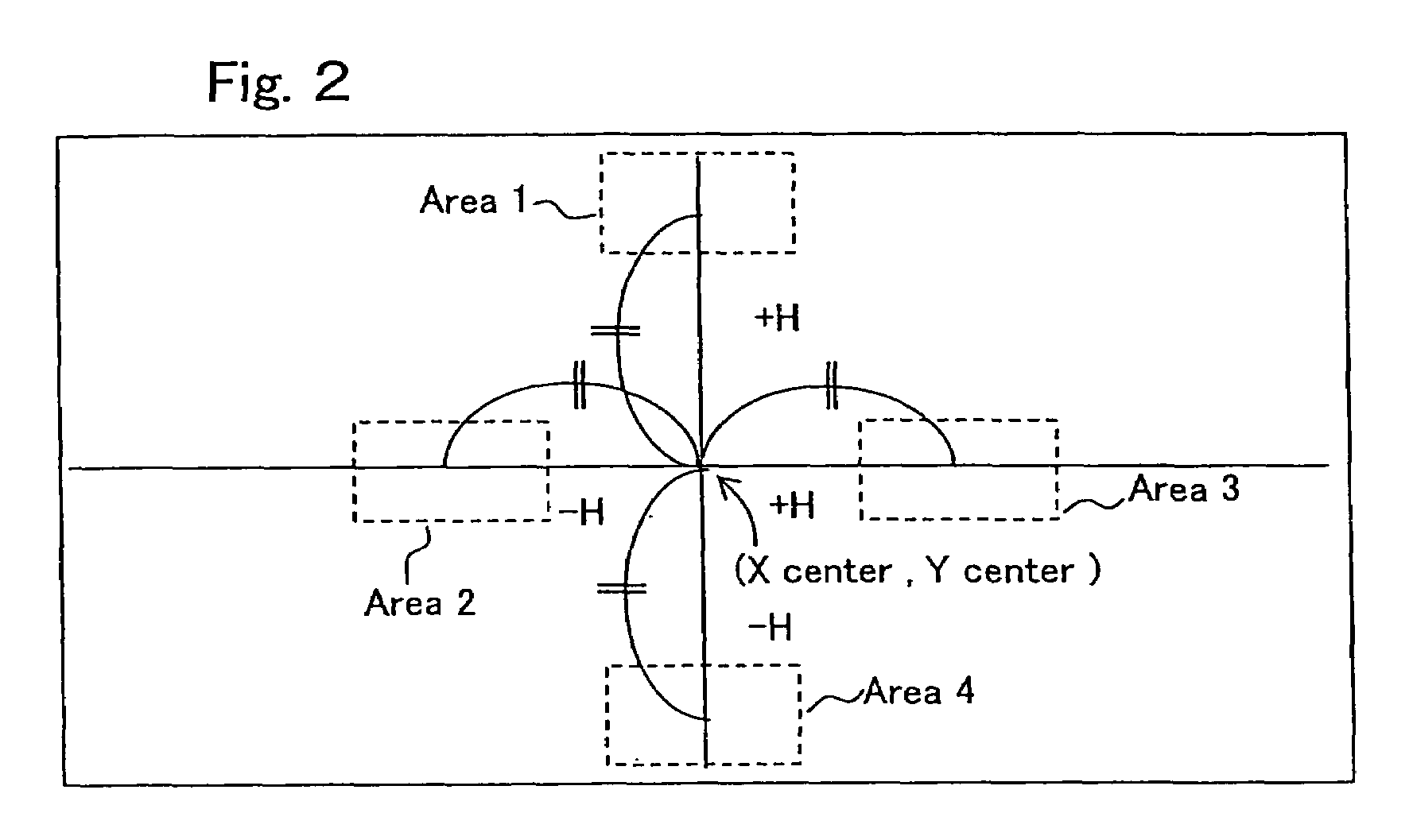

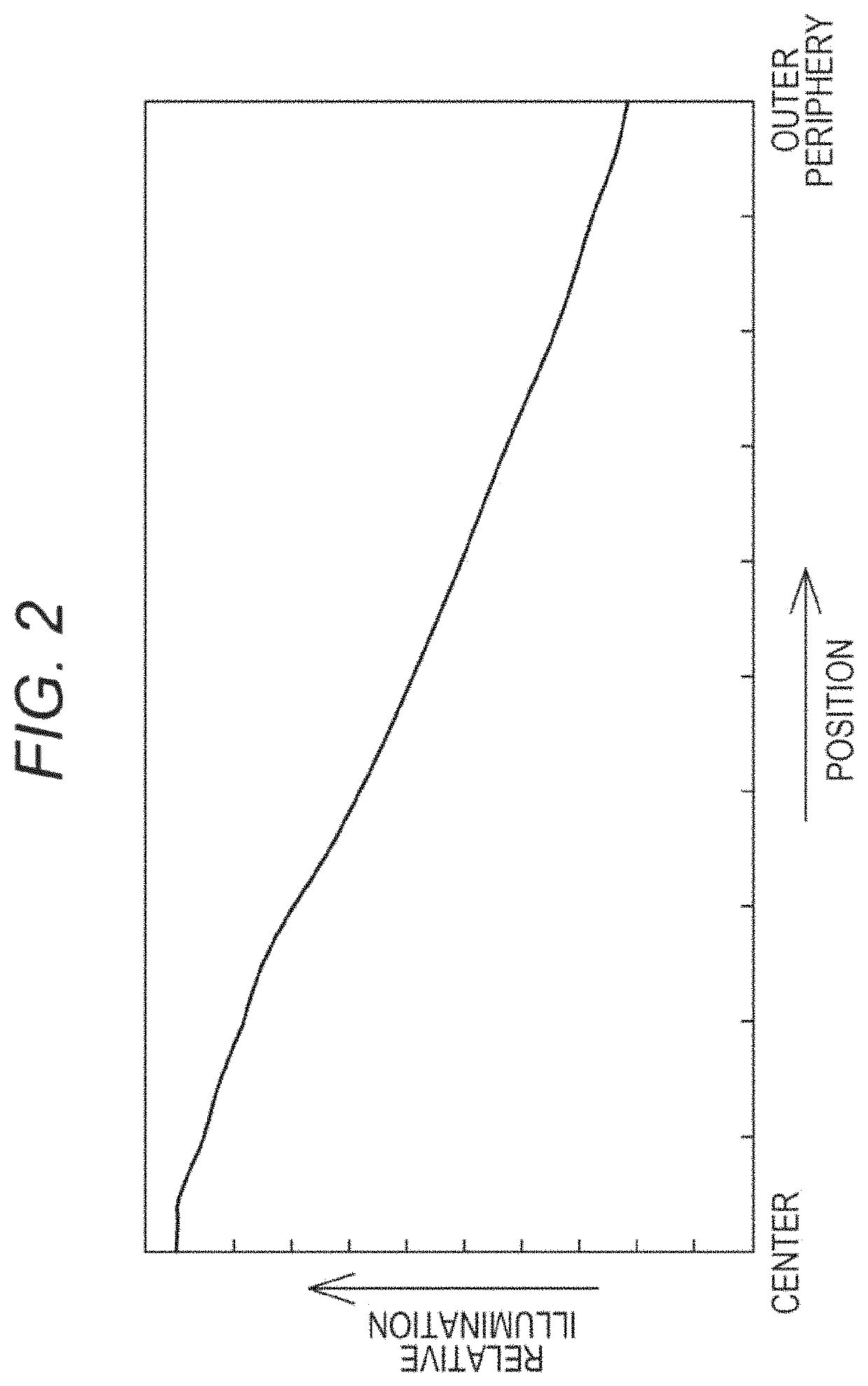

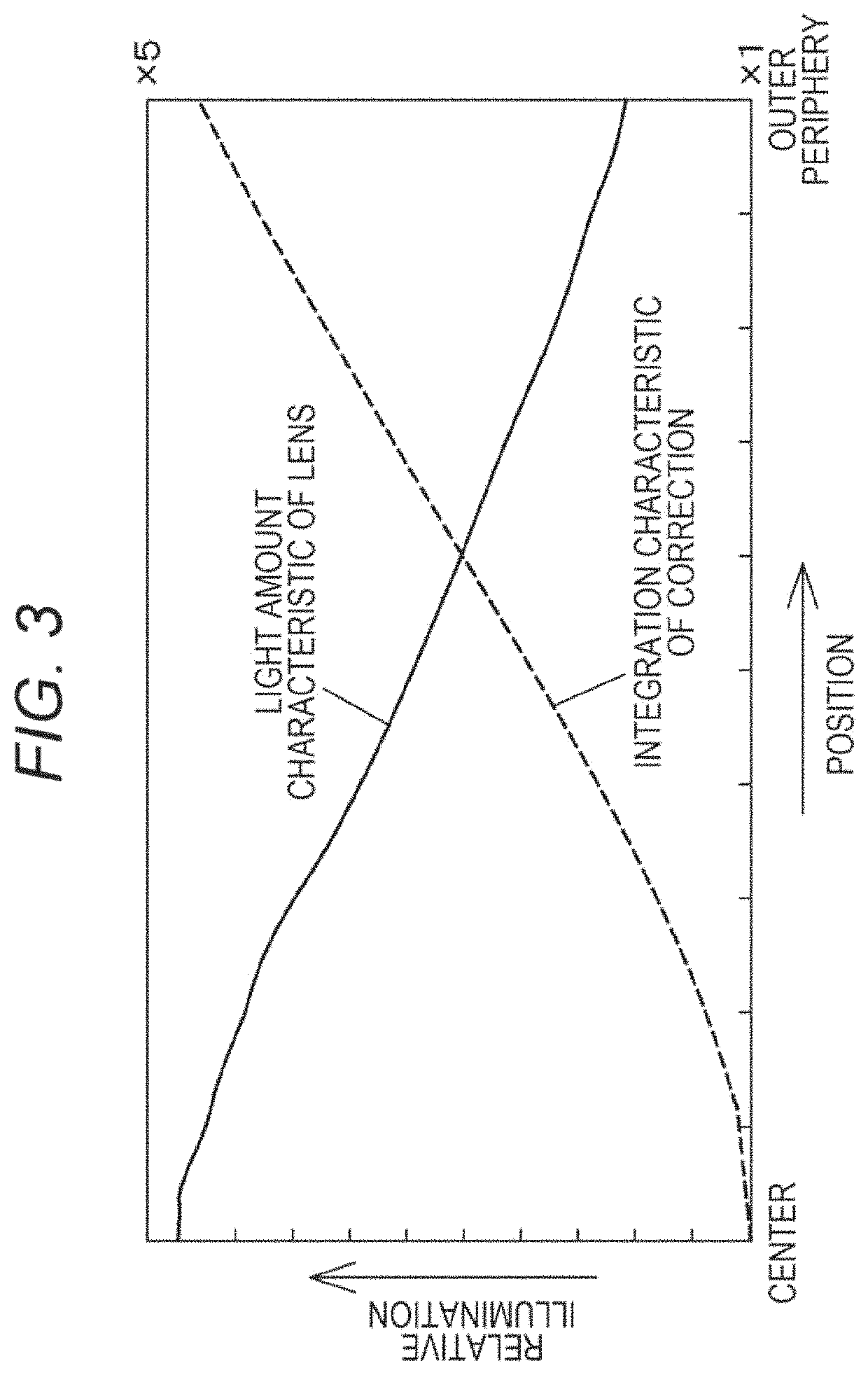

Peripheral Light Amount Correction Apparatus, Peripheral Light Amount Correction Method, Electronic Information Device, Control Program and Readable Recording Medium

InactiveUS20090219419A1Poor precisionUniform resolutionImage enhancementTelevision system detailsElectricityElectronic information

The present invention corrects the insufficient peripheral light amount due to the lens shading and correcting the non-uniformity of light amount at the periphery due to a distortion resulting from a precision of the lens or a poor mounting precision of the lens. A peripheral light amount correction circuit is structured by an image synchronization signal generation circuit, a coordinate conversion circuit and a luminance value correction computing circuit. An integrated value of luminance values is calculated at the coordinate conversion circuit to extract light amount information. Coordinate values to be input to the luminance value correction computing circuit are generated based on an integrated / averaged value of the light amount information. In the luminance value correction computing circuit, peripheral light amount correction functions are converted based on the input coordinate values from the coordinate conversion circuit to perform appropriate correction on the input image.

Owner:SHARP KK

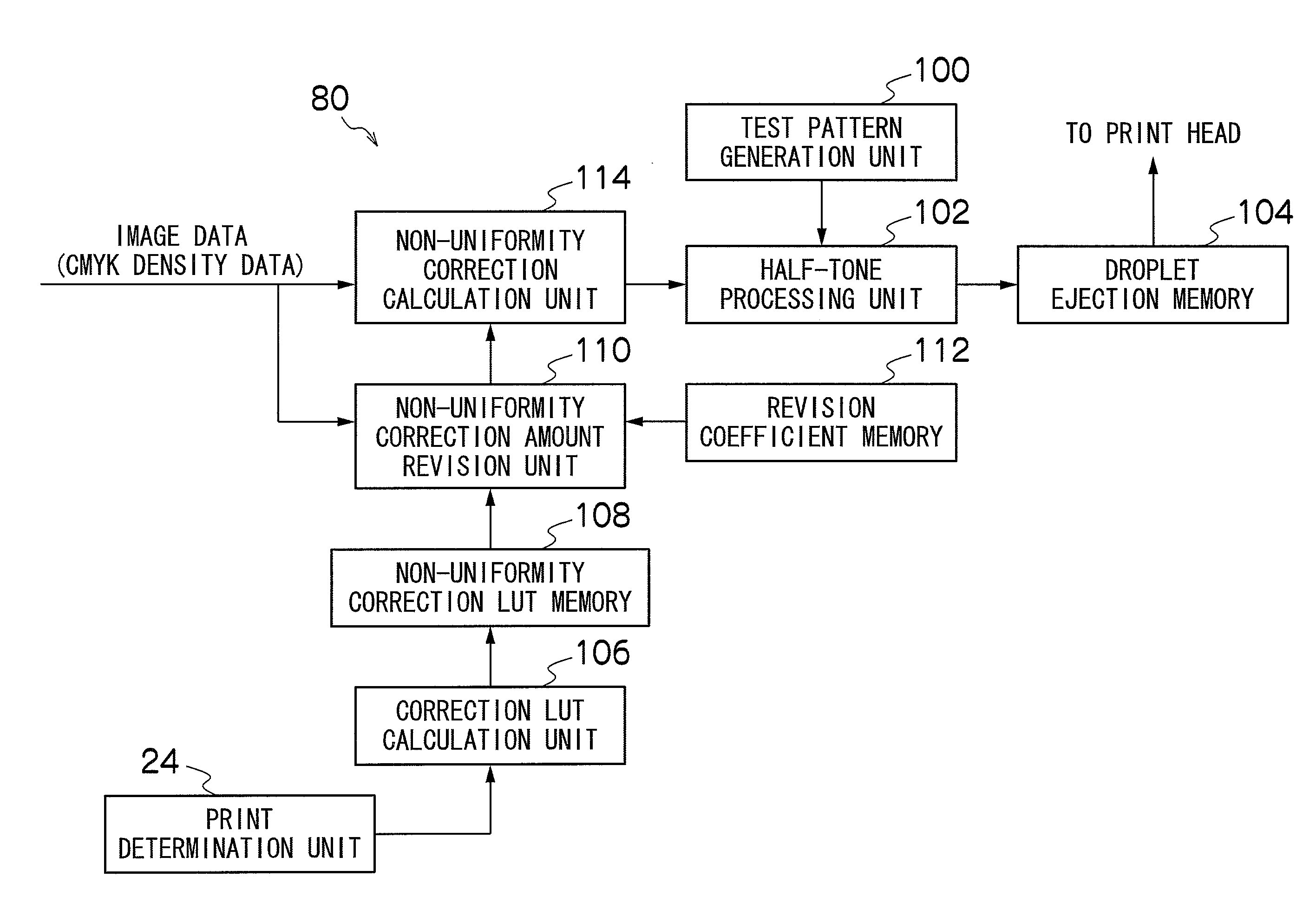

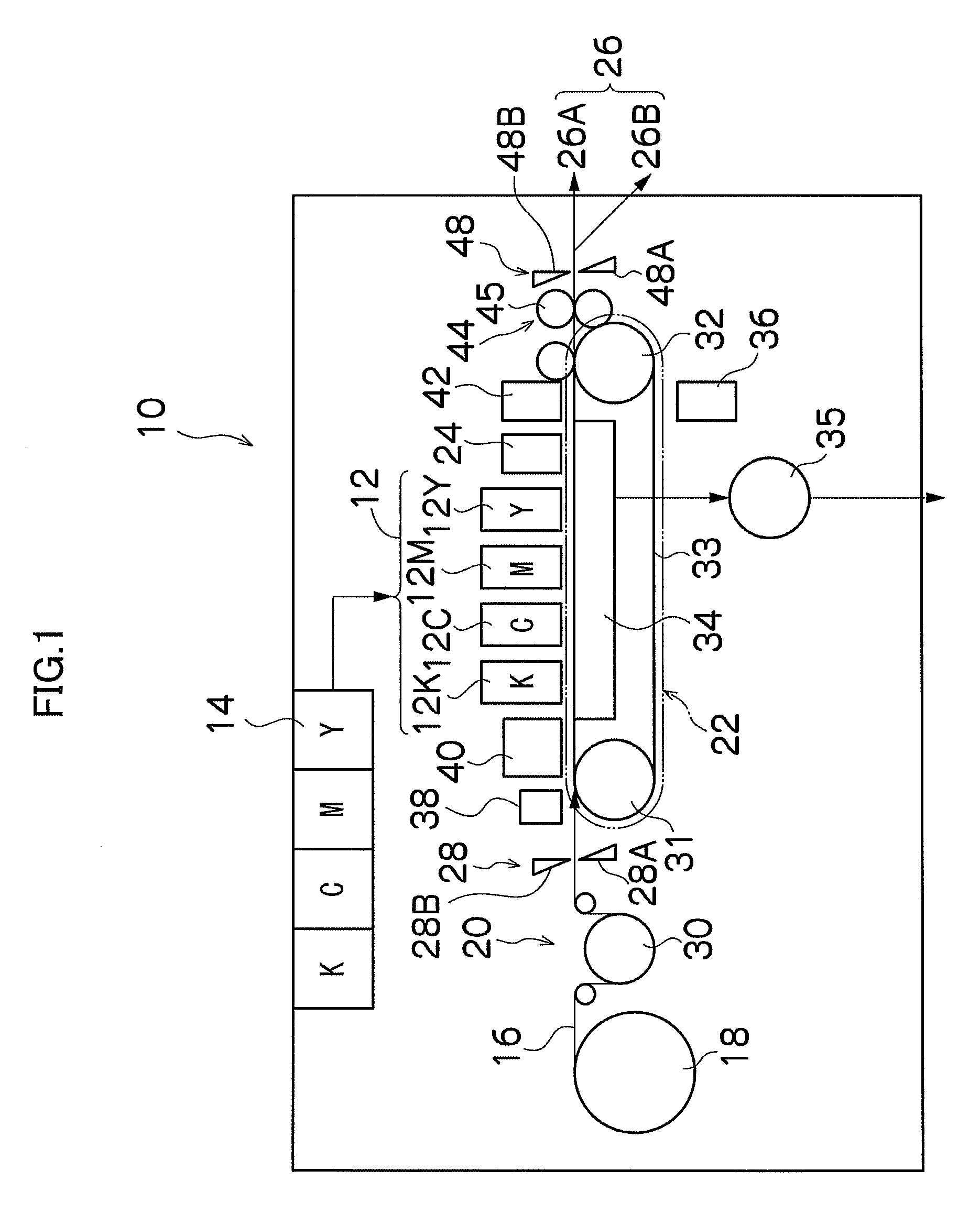

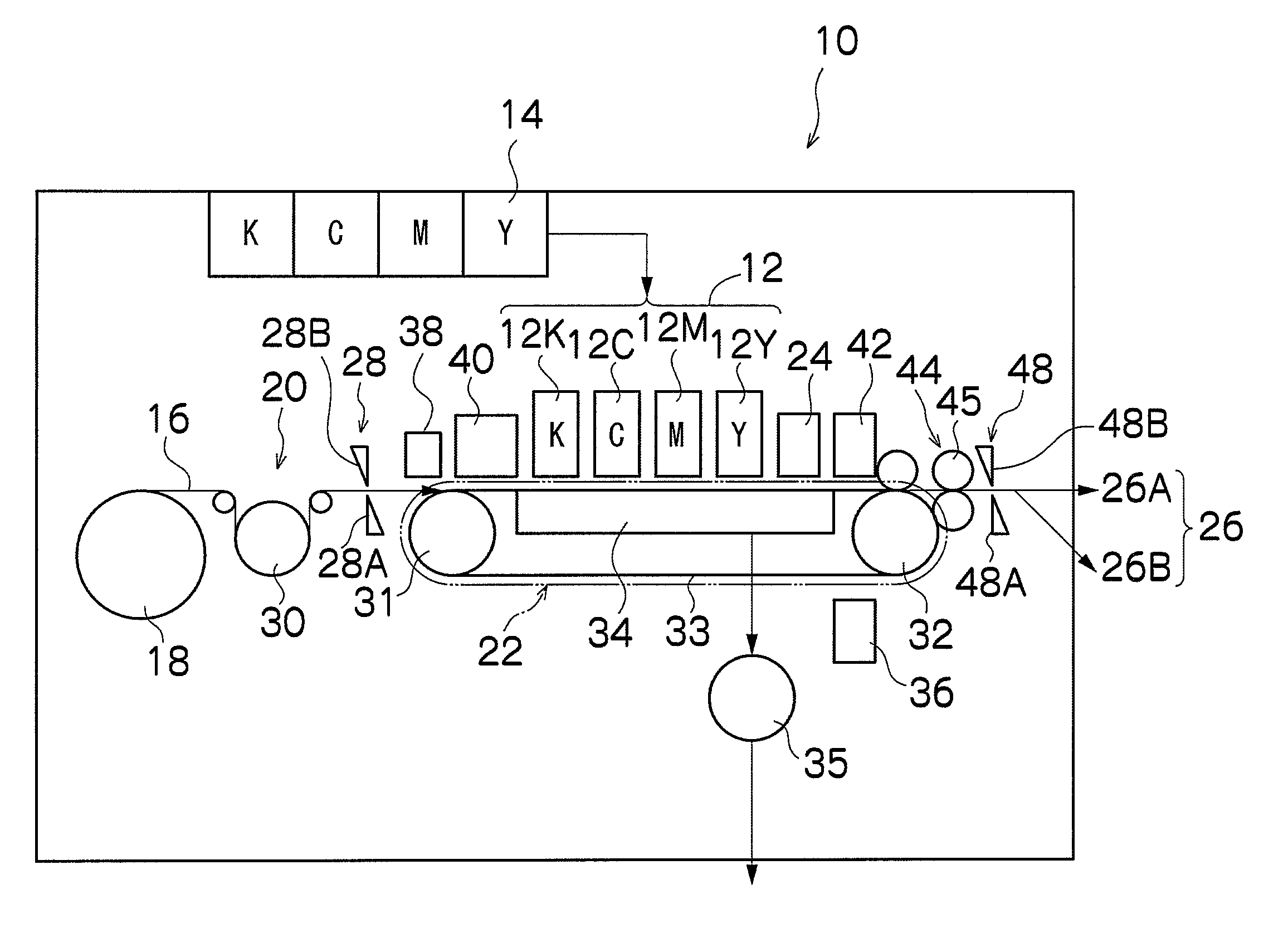

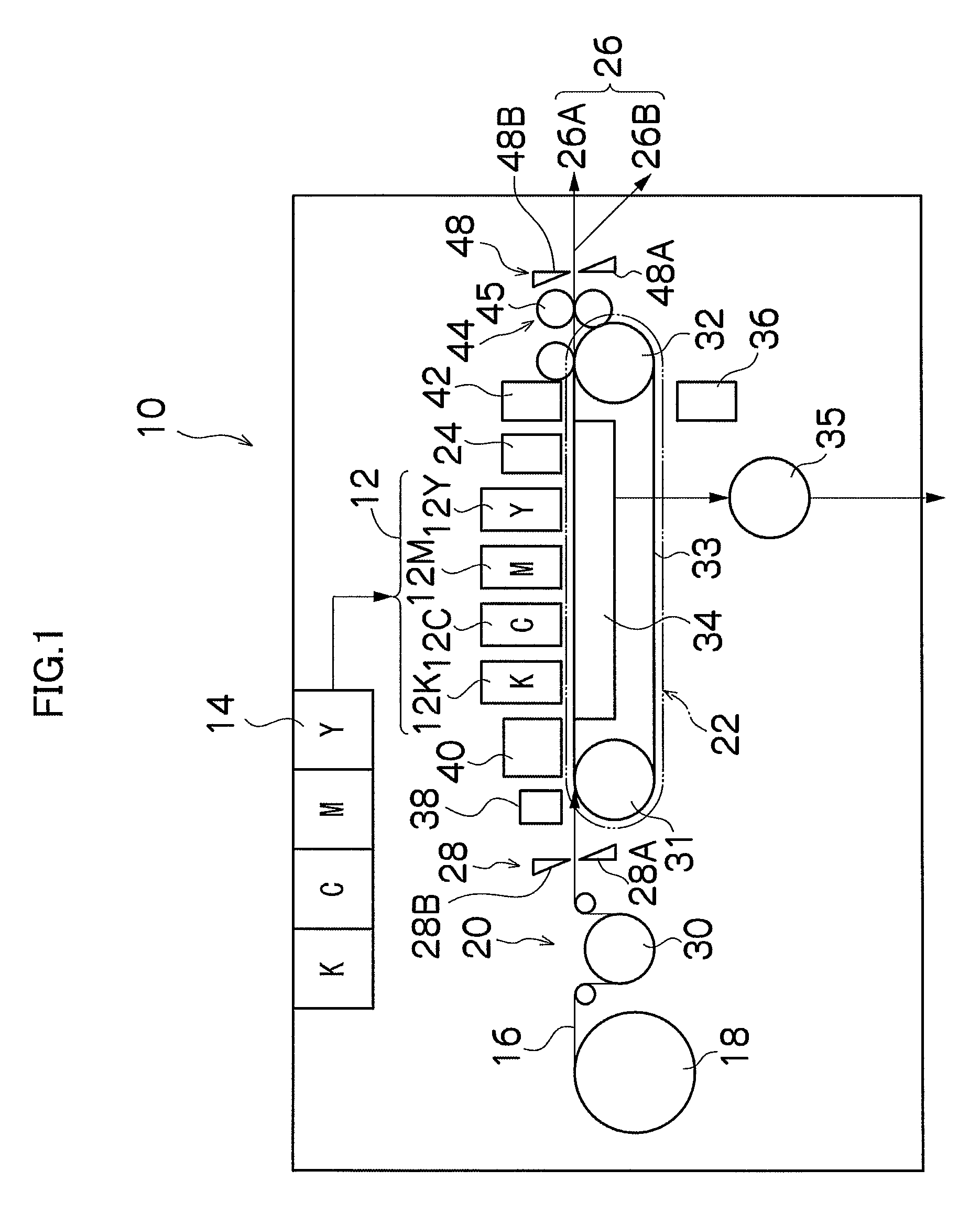

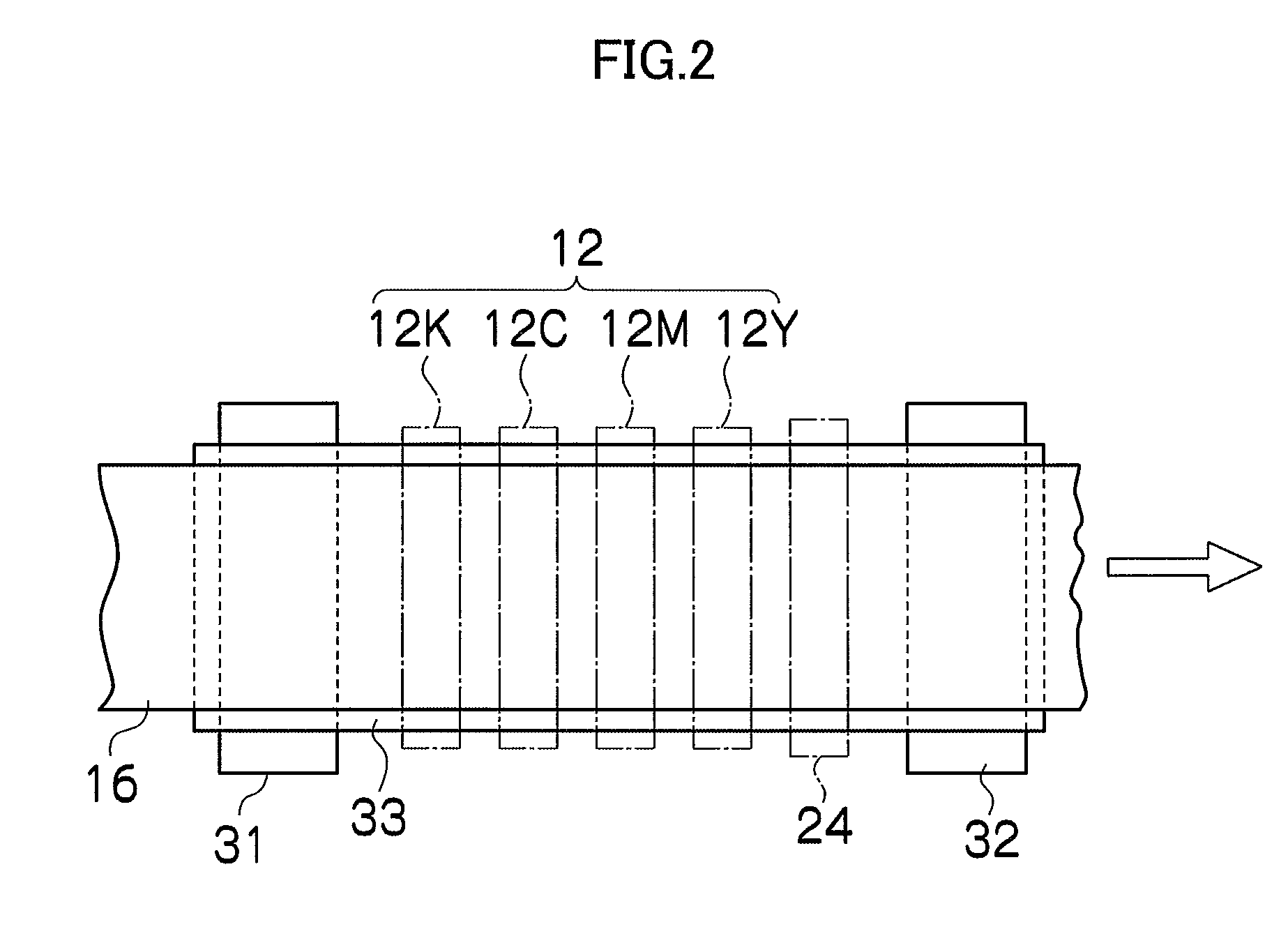

Inkjet recording apparatus and inkjet recording method

InactiveUS20090237430A1Accurate non-uniformity correctionReducing extent of non-uniformity correctionOther printing apparatusImage formationData acquisition

An inkjet recording apparatus includes: a treatment liquid deposition device which deposits on a recording medium a treatment liquid that insolubilizes or aggregates an ink; a recording head having nozzles which eject the ink; a non-uniformity correction amount storage device storing non-uniformity correction amount data which are prepared with respect to each of the plurality of nozzles and determined according to ejection characteristics of each of the plurality of nozzles; a data acquisition device which acquires density data of an image; a non-uniformity correction amount revision device which revises the non-uniformity correction amount data according to the density data related to another nozzle which ejects the ink that overlaps on the recording medium with the ink ejected by each of the plurality of nozzles, in such a manner that the non-uniformity correction amount data are determined; a non-uniformity correction device which corrects the density data according to the non-uniformity correction amount data; and an image forming device which controls the recording head according to the density data in such a manner that the image is formed on the recording medium.

Owner:FUJIFILM CORP

Peripheral light amount correction apparatus, peripheral light amount correction method, electronic information device, control program and readable recording medium

InactiveUS8106976B2Poor precisionUniform resolutionImage enhancementTelevision system detailsElectricityElectronic information

The present invention corrects the insufficient peripheral light amount due to the lens shading and correcting the non-uniformity of light amount at the periphery due to a distortion resulting from a precision of the lens or a poor mounting precision of the lens. A peripheral light amount correction circuit is structured by an image synchronization signal generation circuit, a coordinate conversion circuit and a luminance value correction computing circuit. An integrated value of luminance values is calculated at the coordinate conversion circuit to extract light amount information. Coordinate values to be input to the luminance value correction computing circuit are generated based on an integrated / averaged value of the light amount information. In the luminance value correction computing circuit, peripheral light amount correction functions are converted based on the input coordinate values from the coordinate conversion circuit to perform appropriate correction on the input image.

Owner:SHARP KK

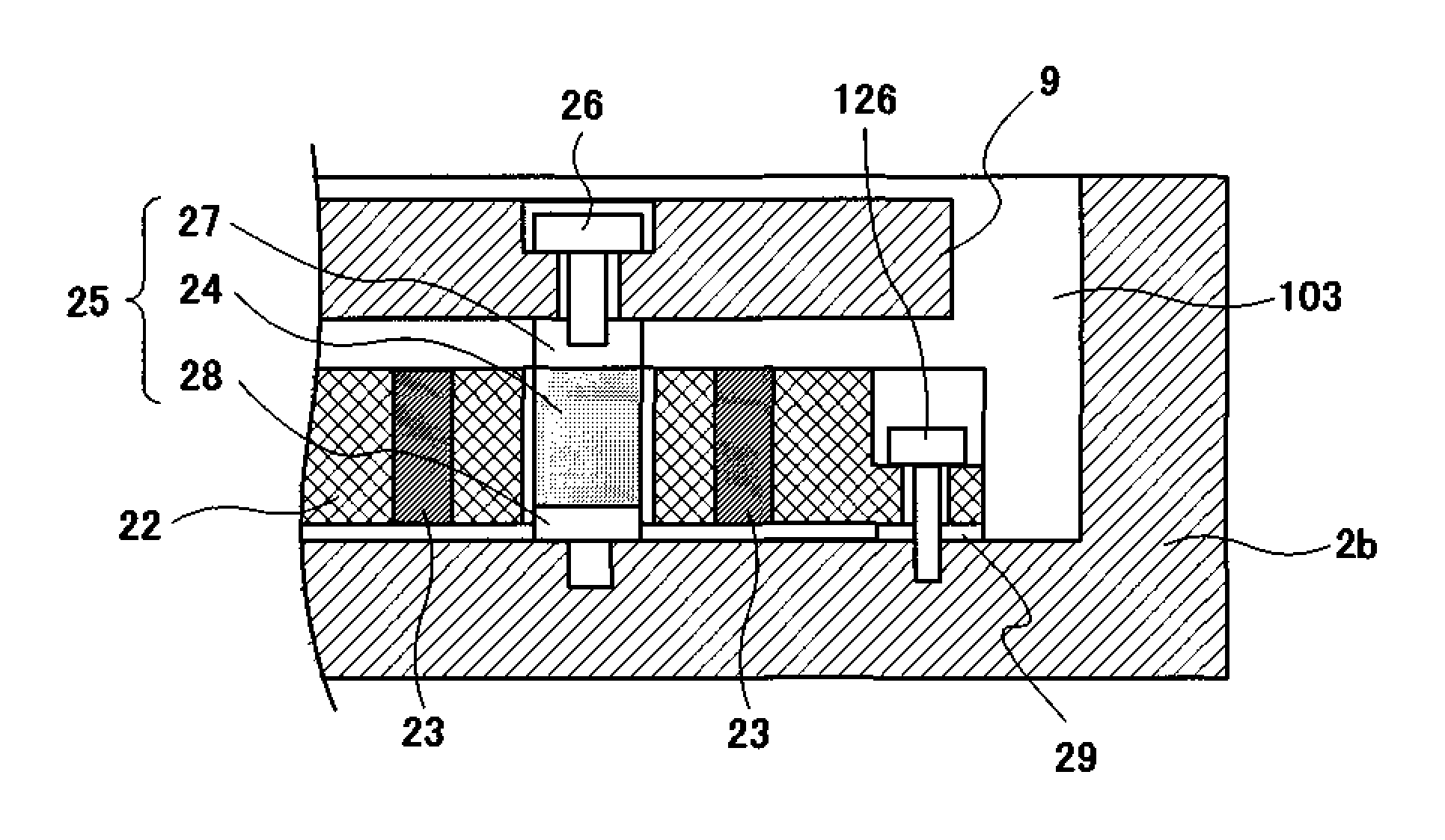

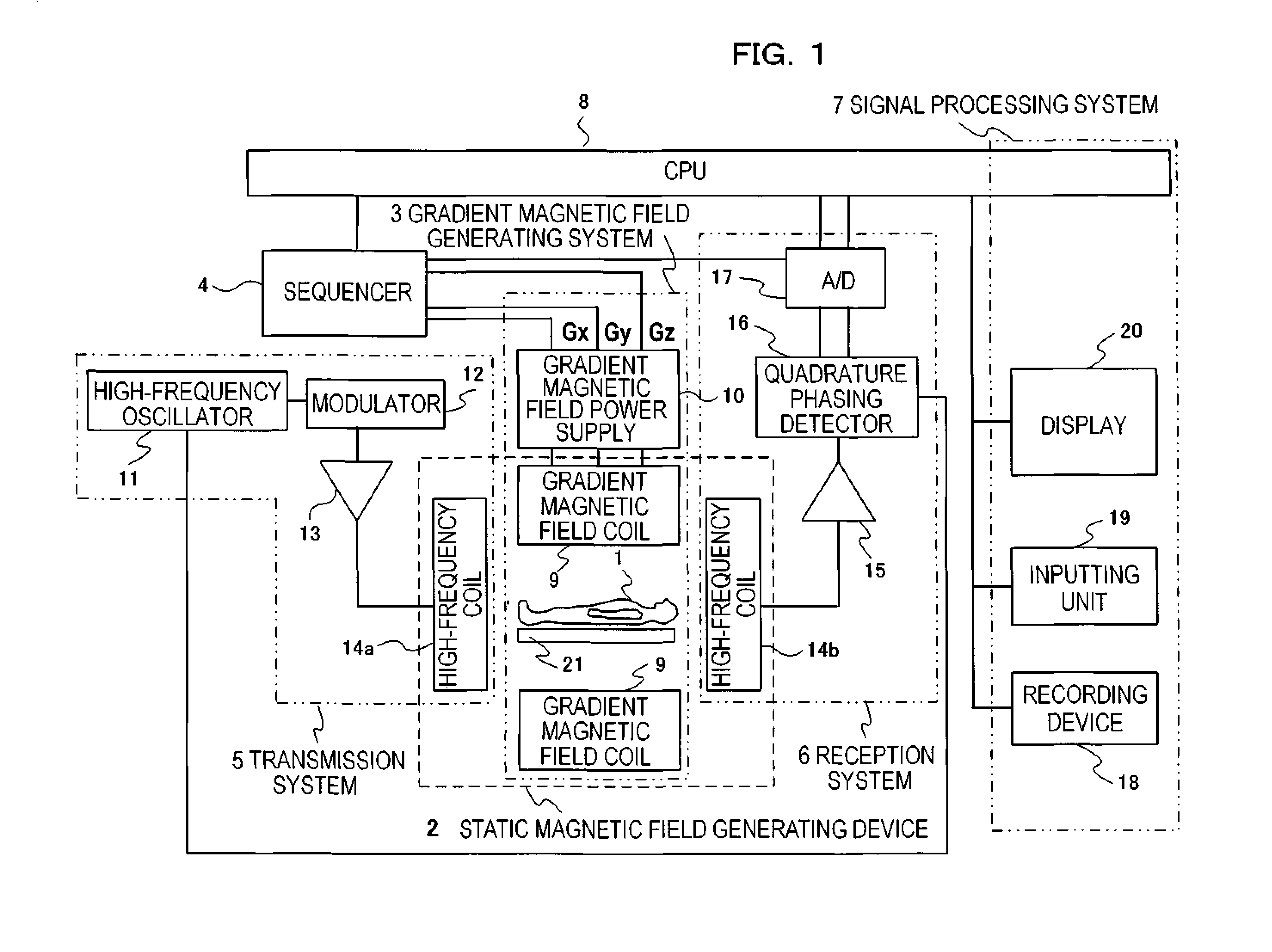

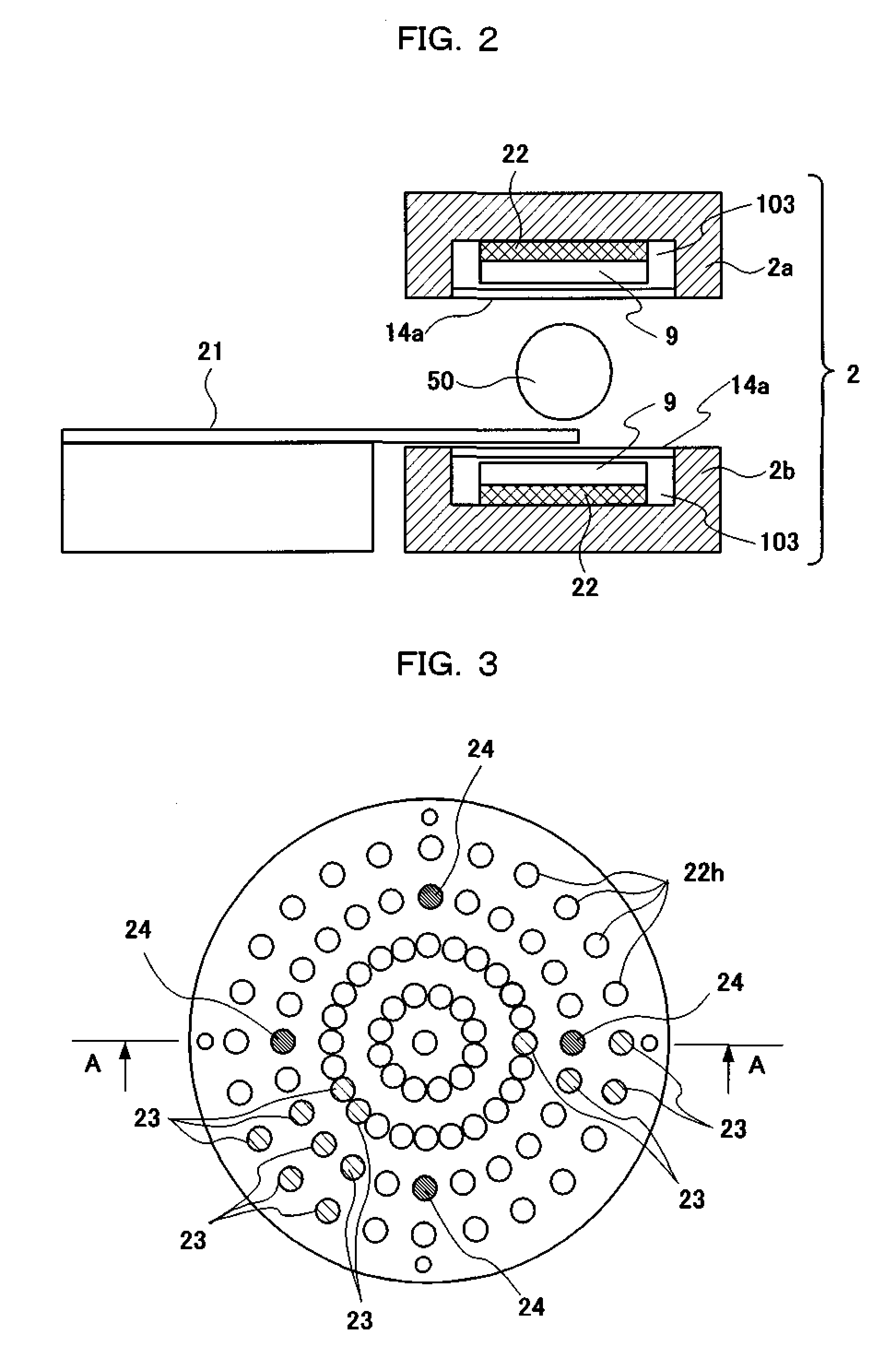

Structure for reducing noise in magnetic resonance imaging apparatus

ActiveUS7375518B2Save spaceAvoid vibrationMagnetic measurementsElectric/magnetic detectionField coilCondensed matter physics

A magnetic resonance imaging apparatus is provided in which vibration of a gradient magnetic field coil is reduced, the vibration is not transmitted to a static magnetic field correcting unit, and space can be saved.

Owner:FUJIFILM HEALTHCARE CORP

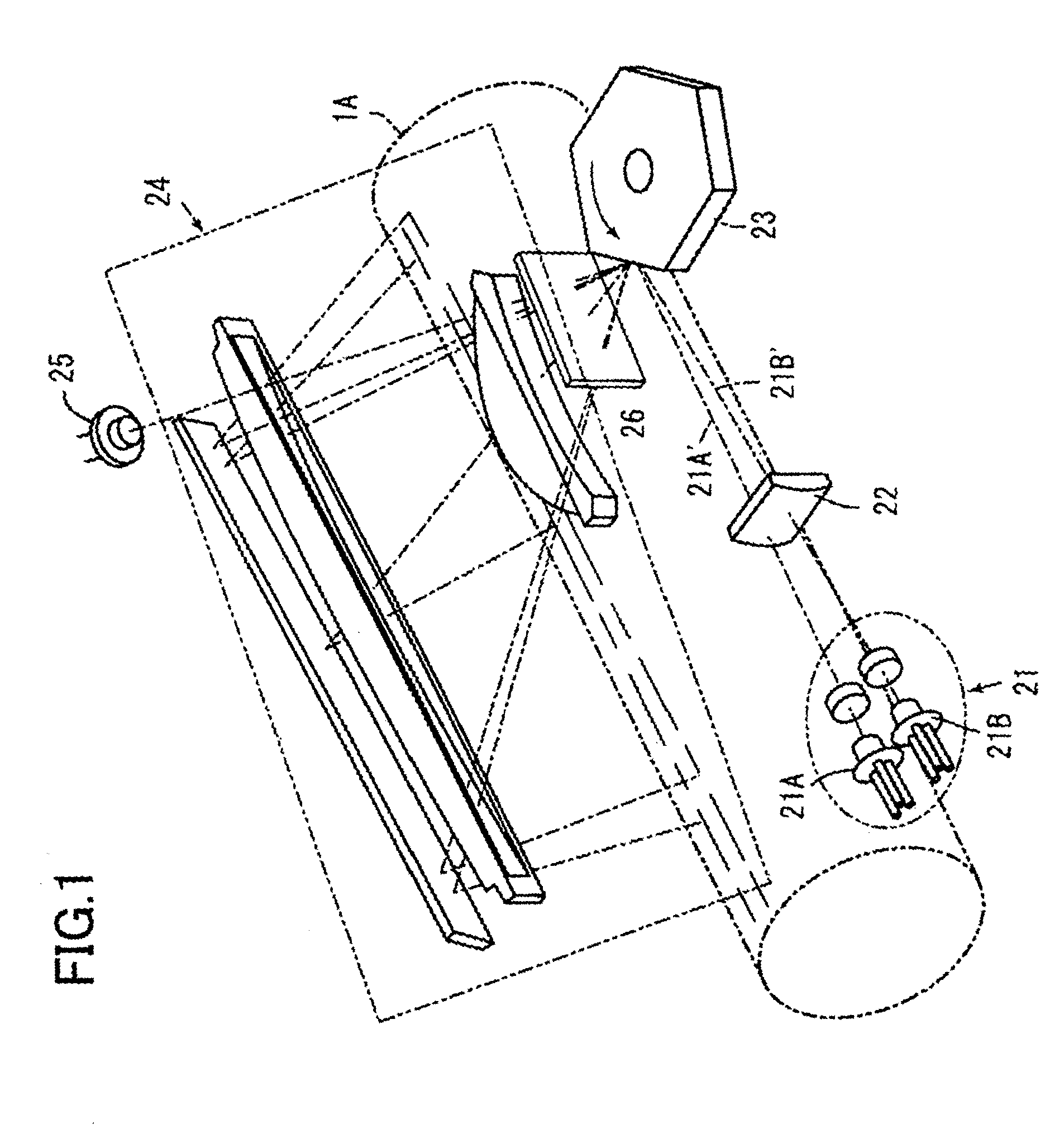

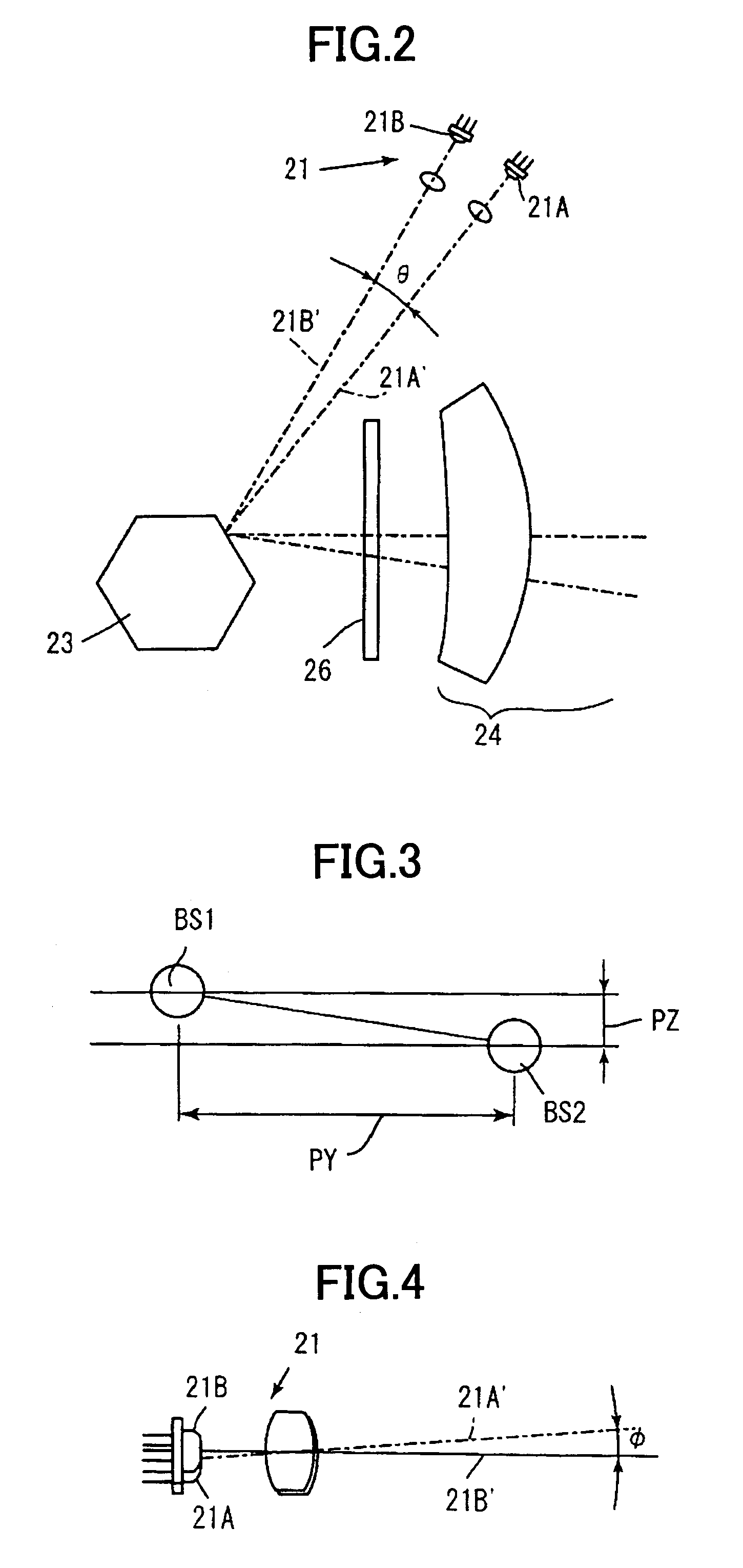

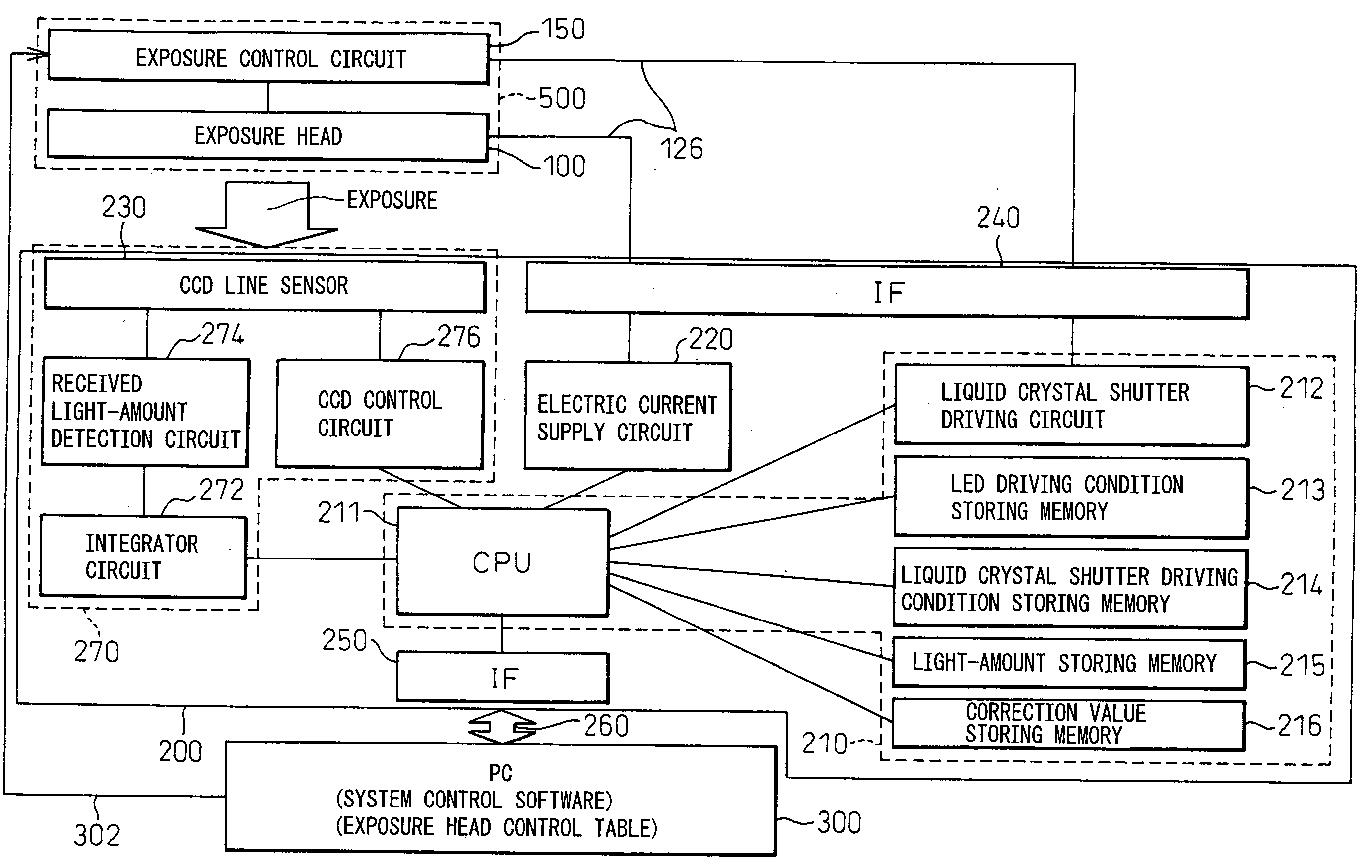

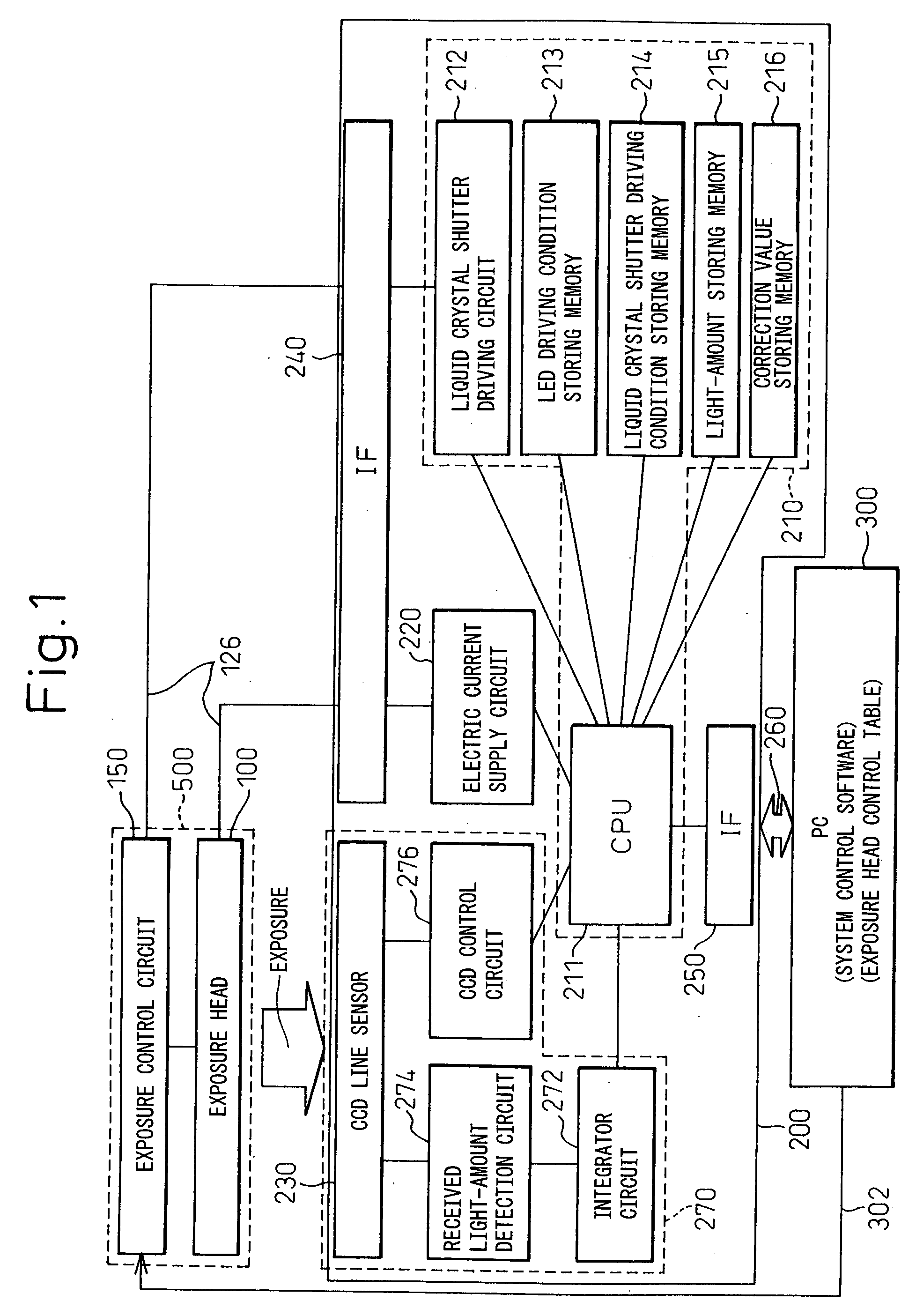

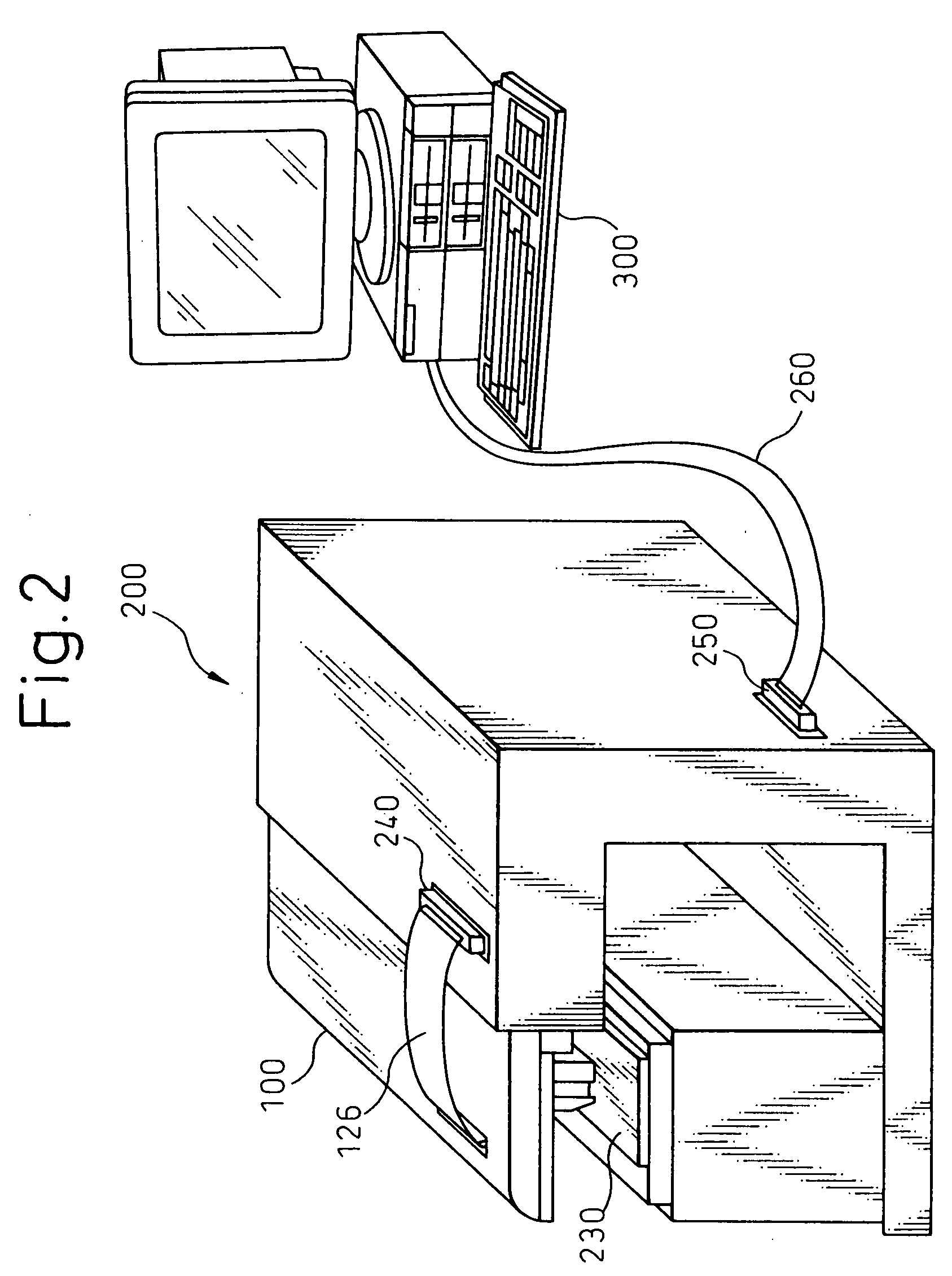

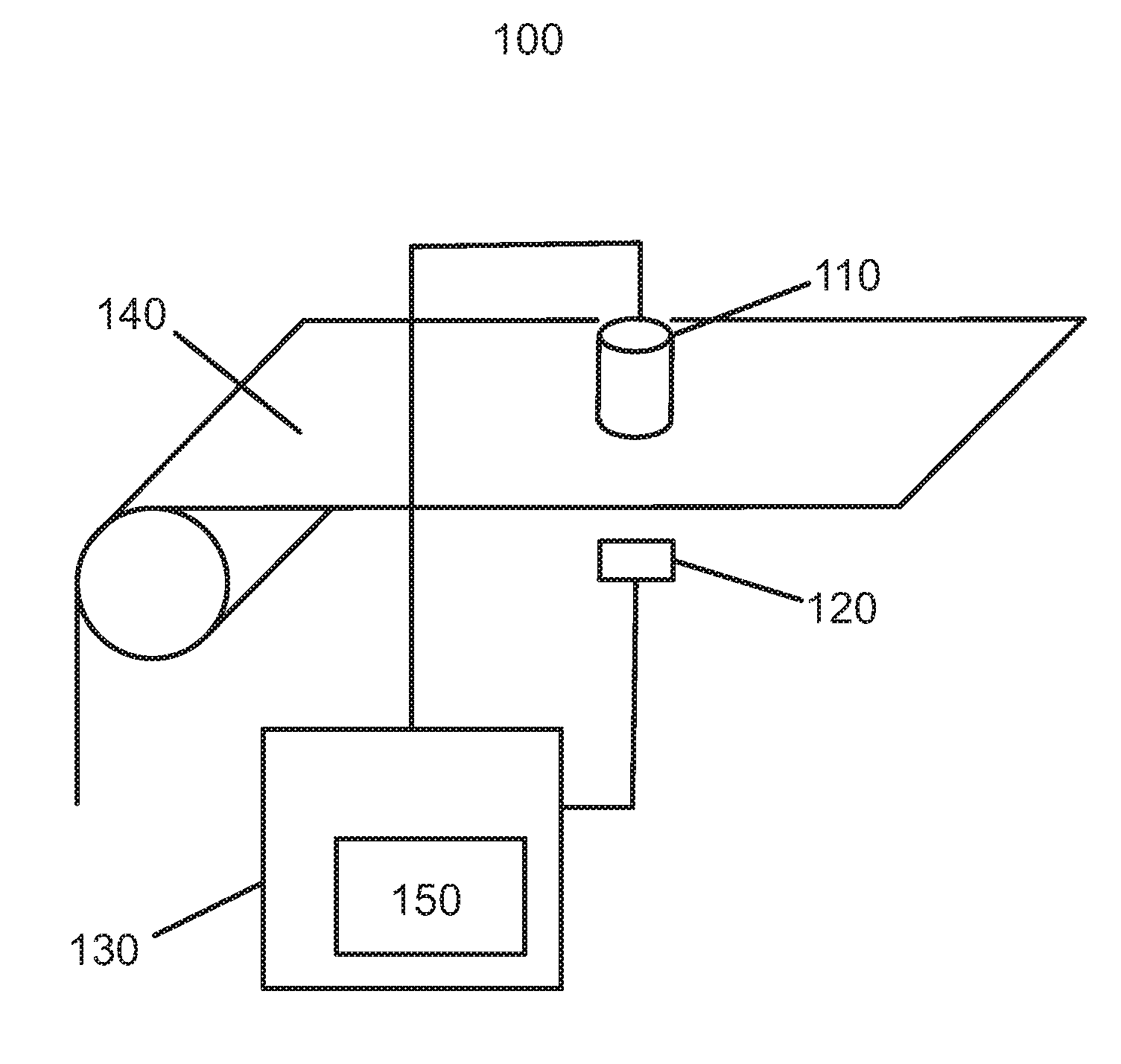

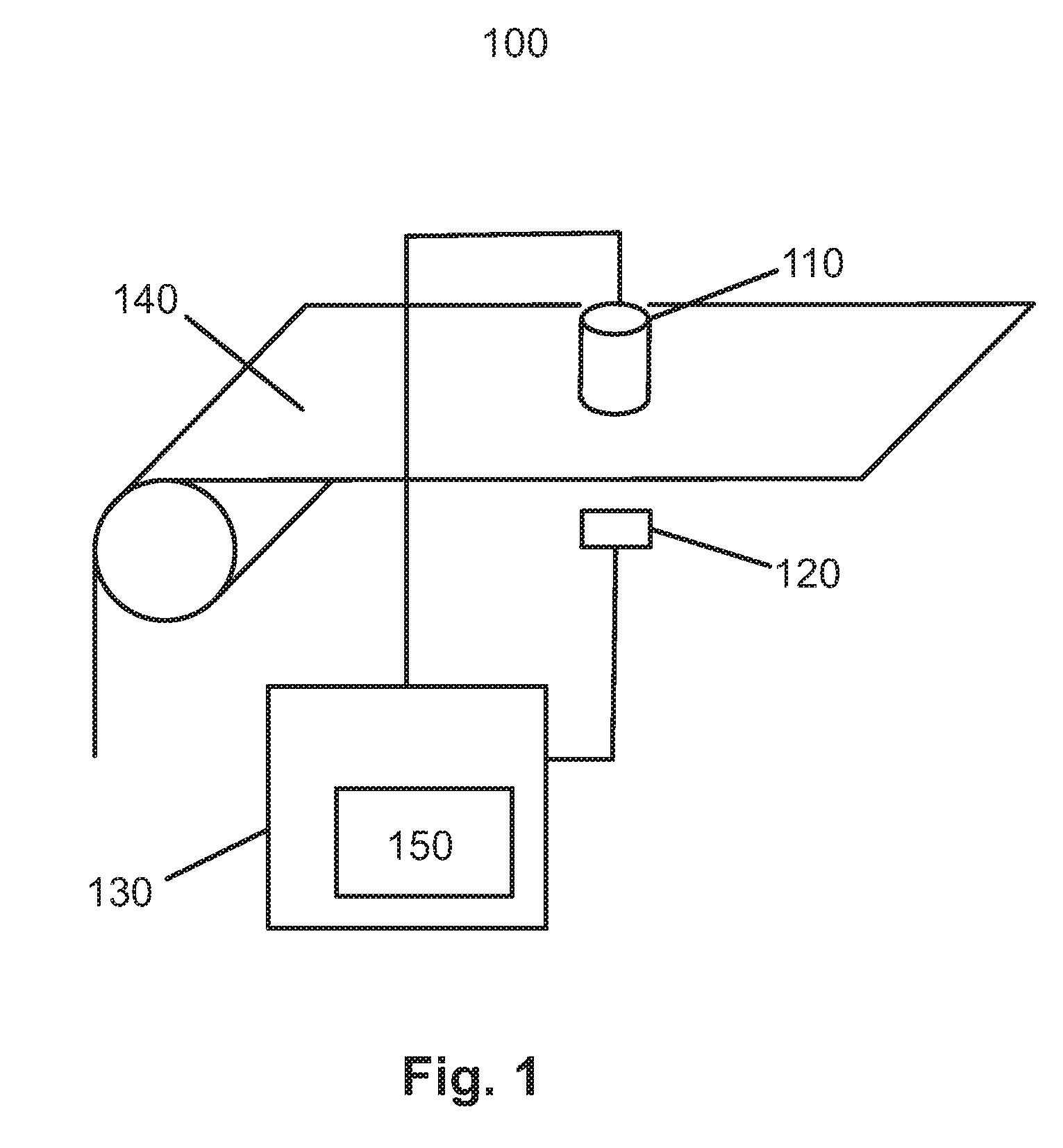

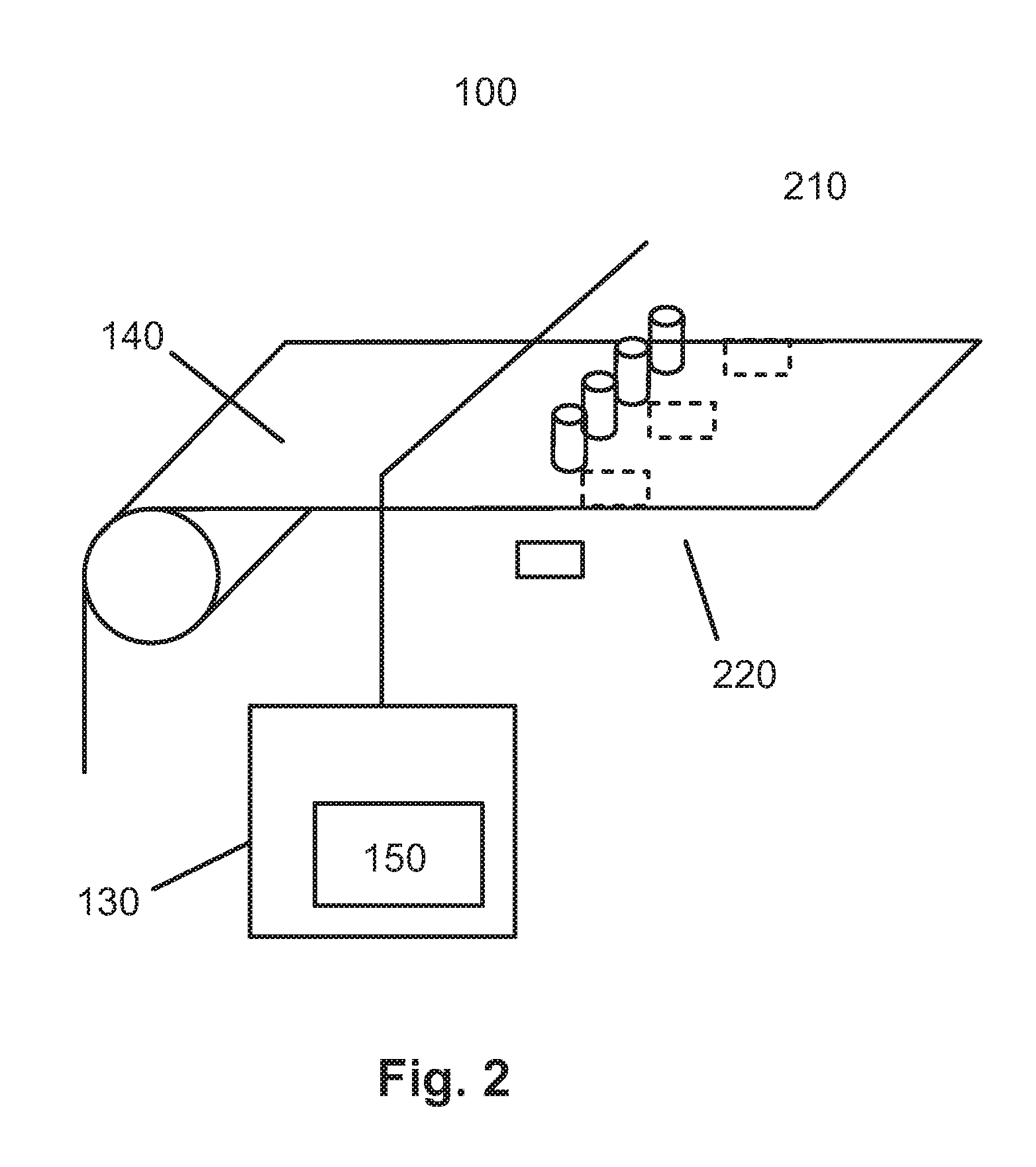

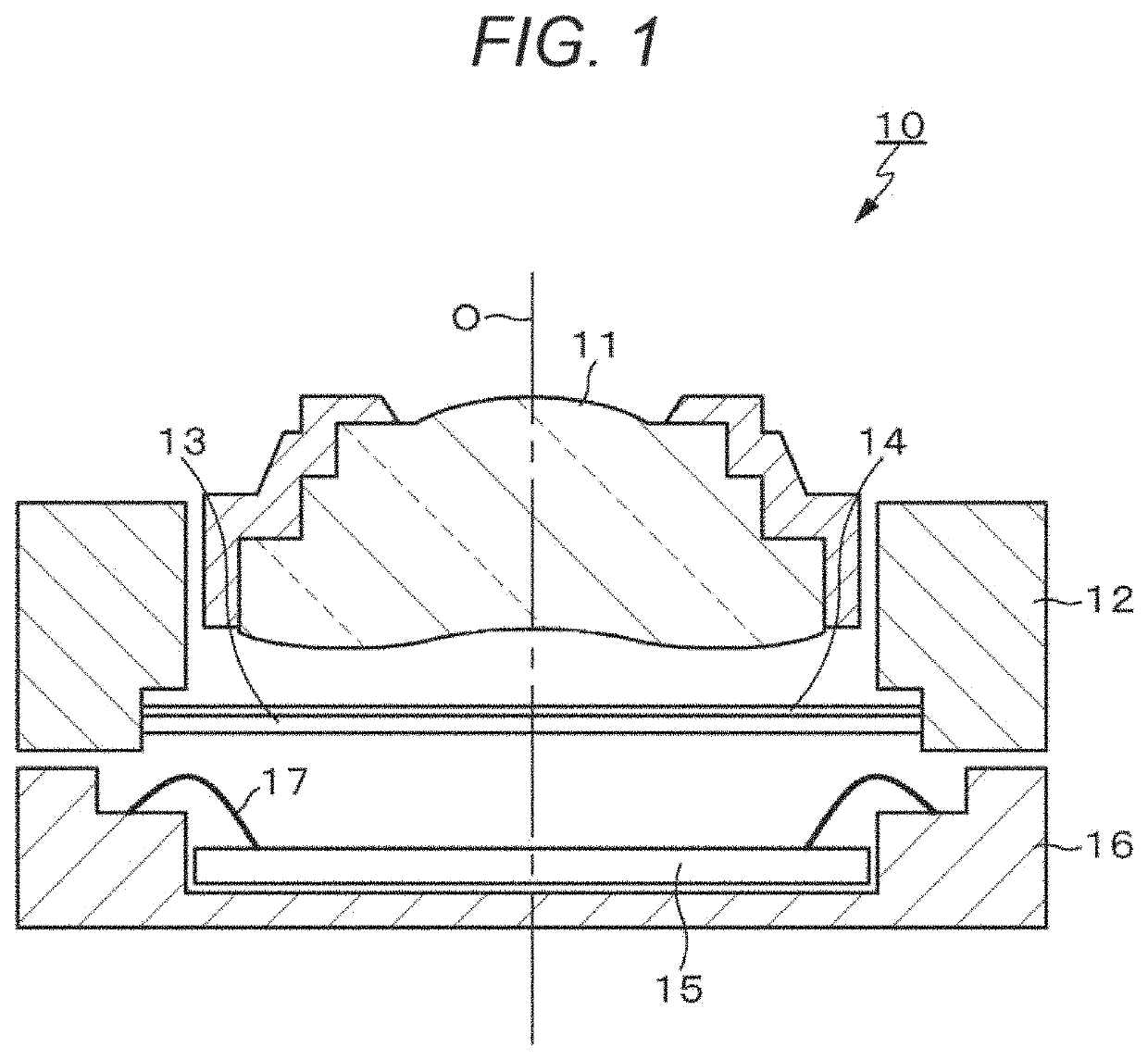

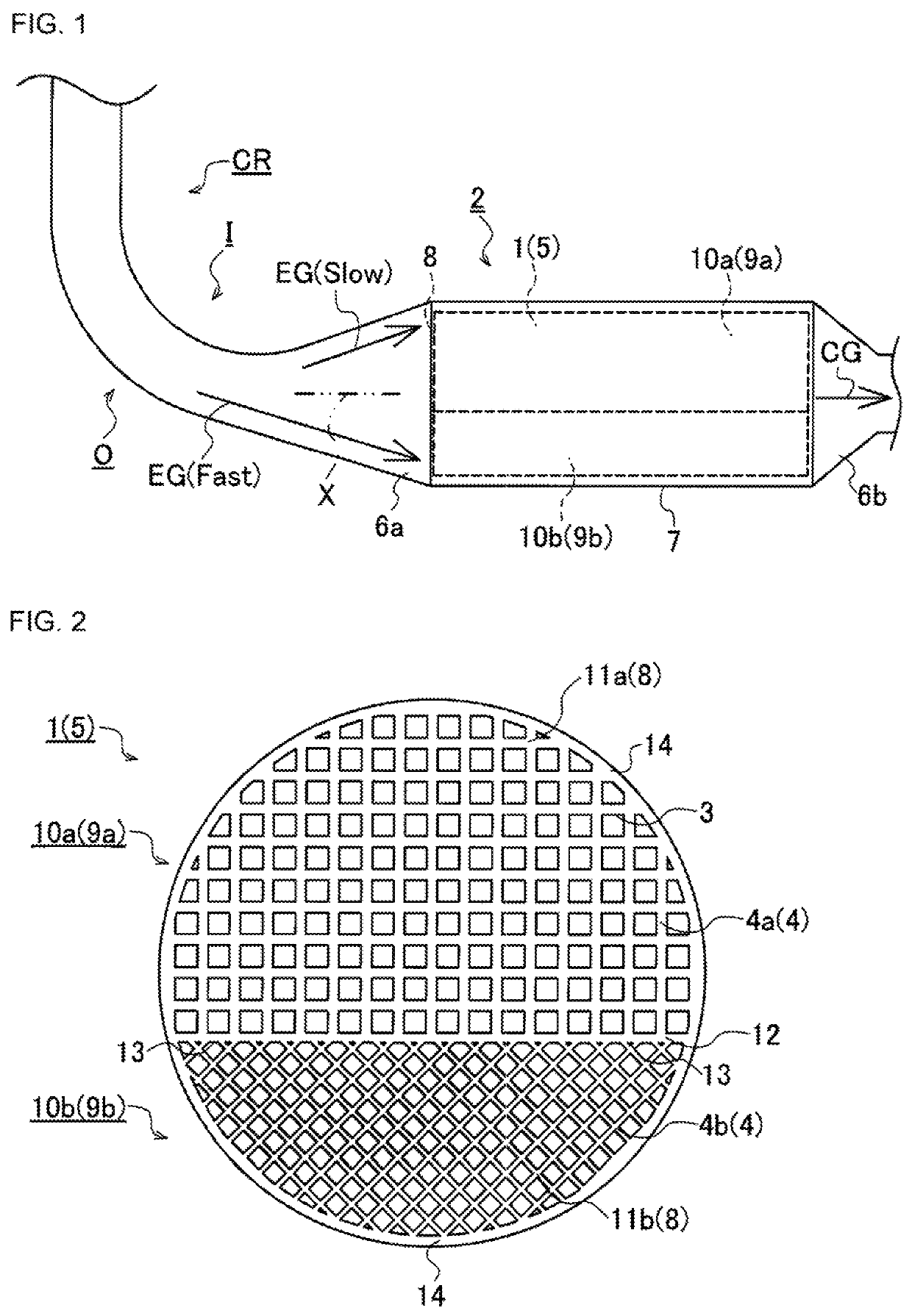

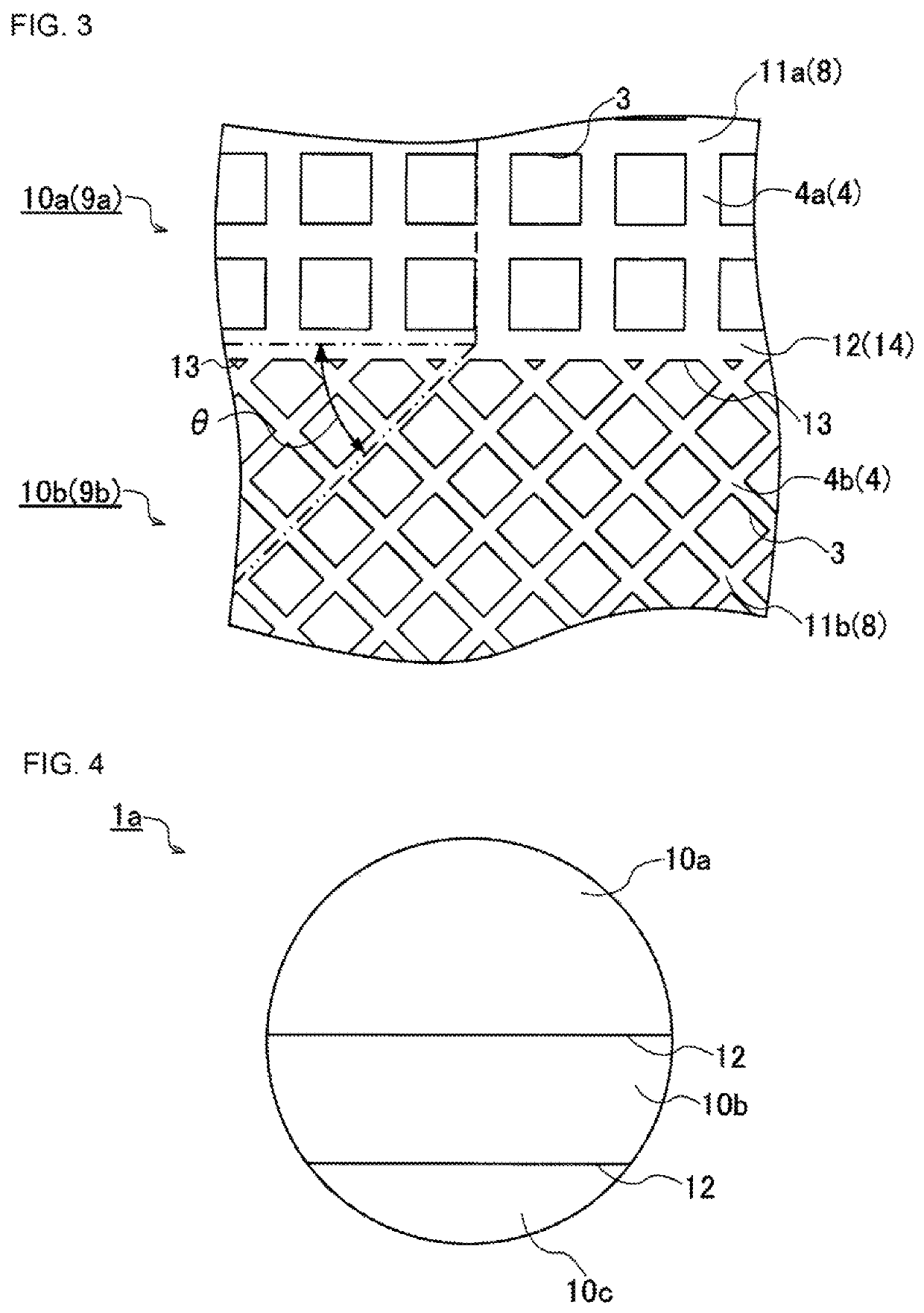

Exposure system and production method for exposure system

ActiveUS20050068590A1Accurate valueThe right amountInking apparatusVisual representatino by photographic printingOptoelectronics

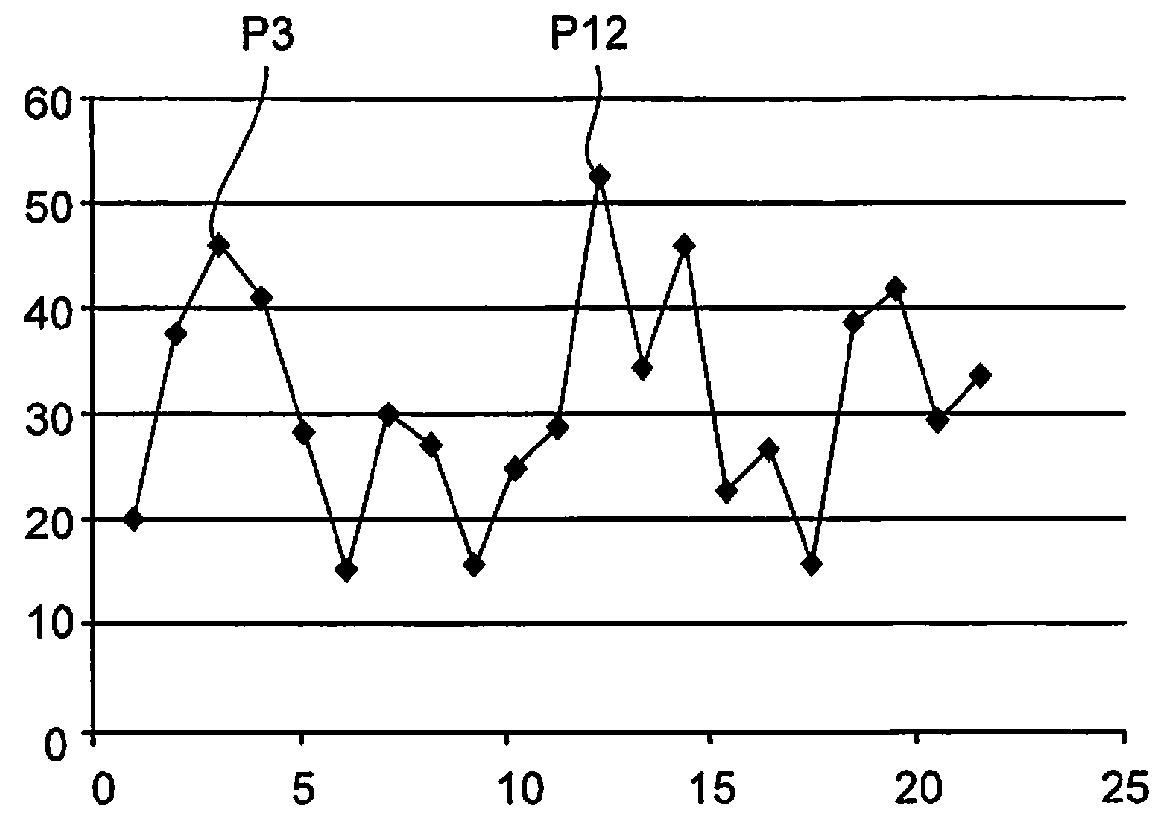

The invention is directed to the provision of an exposure apparatus that can determine a correction value for each individual light-emitting part by employing a method that detects the amount of light corresponding to one particular light-emitting part from composite light containing light rays from adjacent light-emitting parts, and also to the provision of a method for producing such an exposure apparatus. The production method according to the invention comprises the steps of lighting a plurality of light-emitting parts at the same time, detecting an output light-amount distribution across all of the plurality of light-emitting parts by making measurements using a line-like light-receiving device, detecting a peak position corresponding to each light-emitting part by using the output light-amount distribution; detecting the amount of light of each light-emitting part based on the peak position, and determining, based on the amount of light of each light-emitting part, the correction value for correcting nonuniformity in the amount of light of the light-emitting part.

Owner:CITIZEN WATCH CO LTD

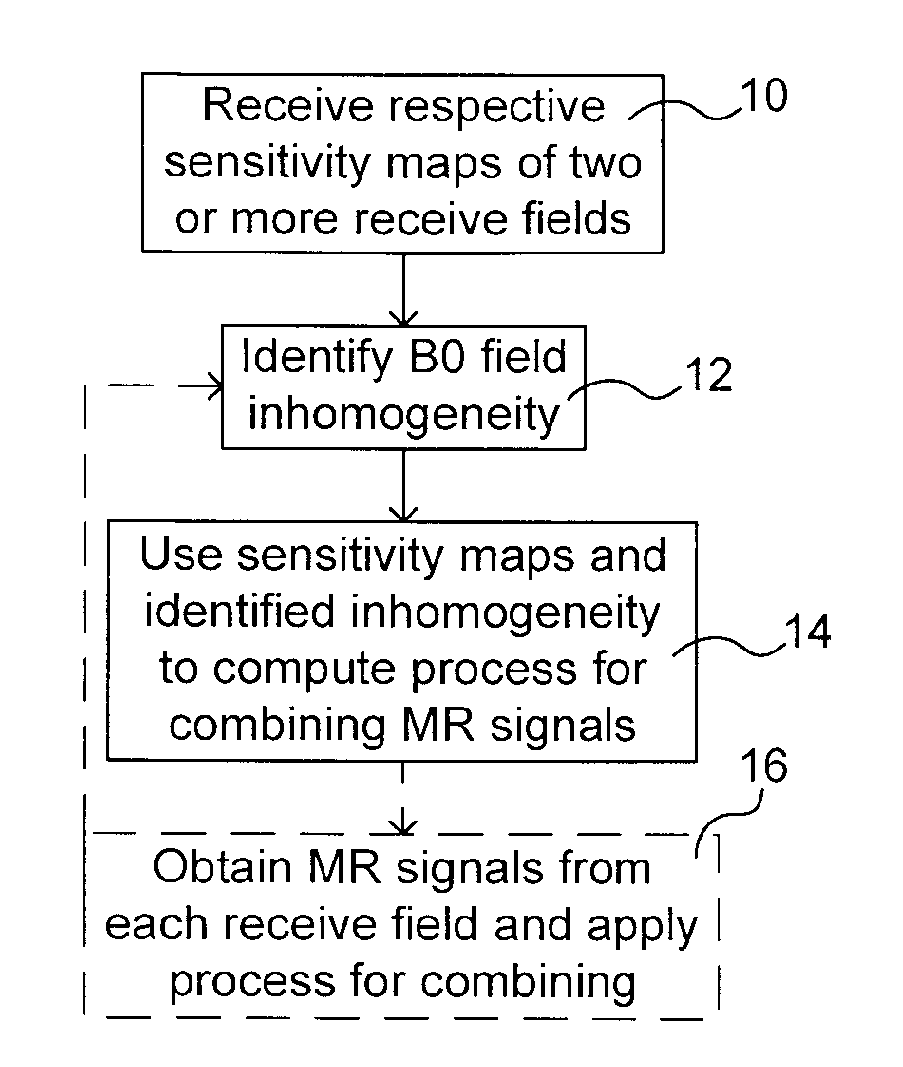

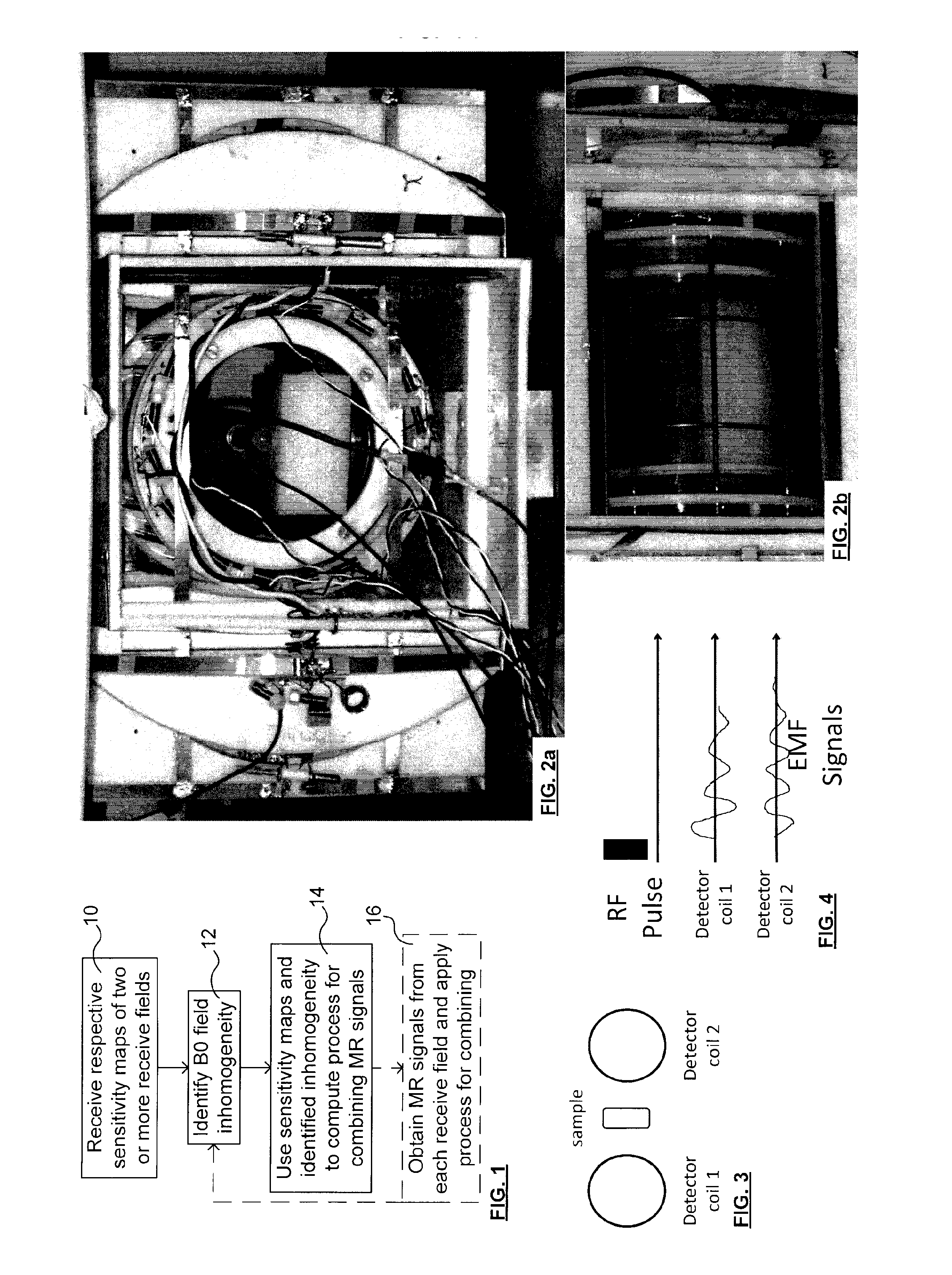

Method for B0 Field Correction in Magnetic Resonance

InactiveUS20150077107A1Reduce artifactsNon-uniformity can be correctedMeasurements using NMR spectroscopyElectric/magnetic detectionResonanceMR - Magnetic resonance

In a magnetic resonance (MR) experiment, a method for effectively improving B0 uniformity of a static magnet of a magnetic resonance (MR) apparatus, without shimming magnets or coils involves combining a plurality of RF receive fields, each having a different respective sensitivity map. This method can apply retrospectively to previously acquired data, as long as there is data from different receive fields.

Owner:NAT RES COUNCIL OF CANADA

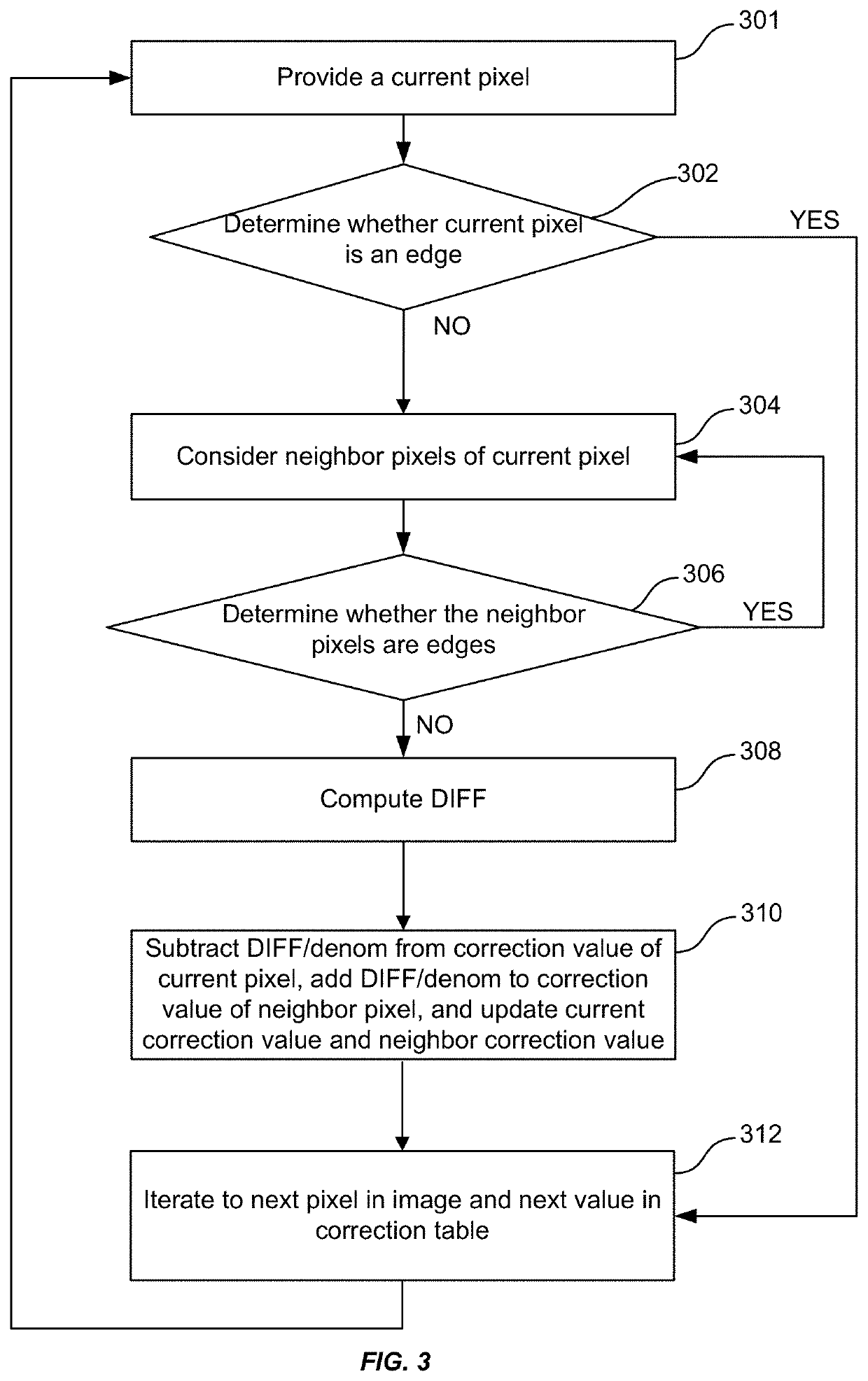

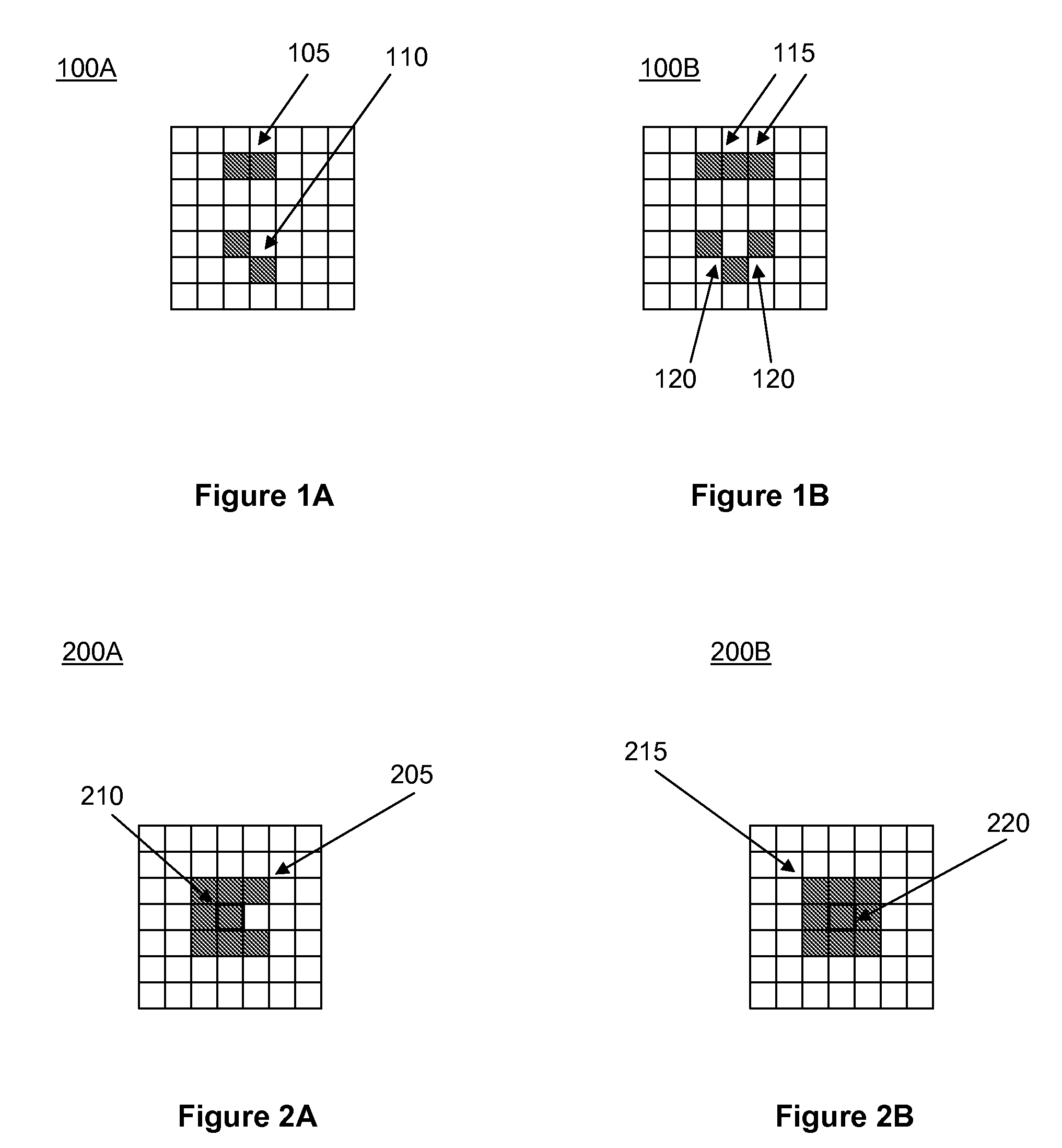

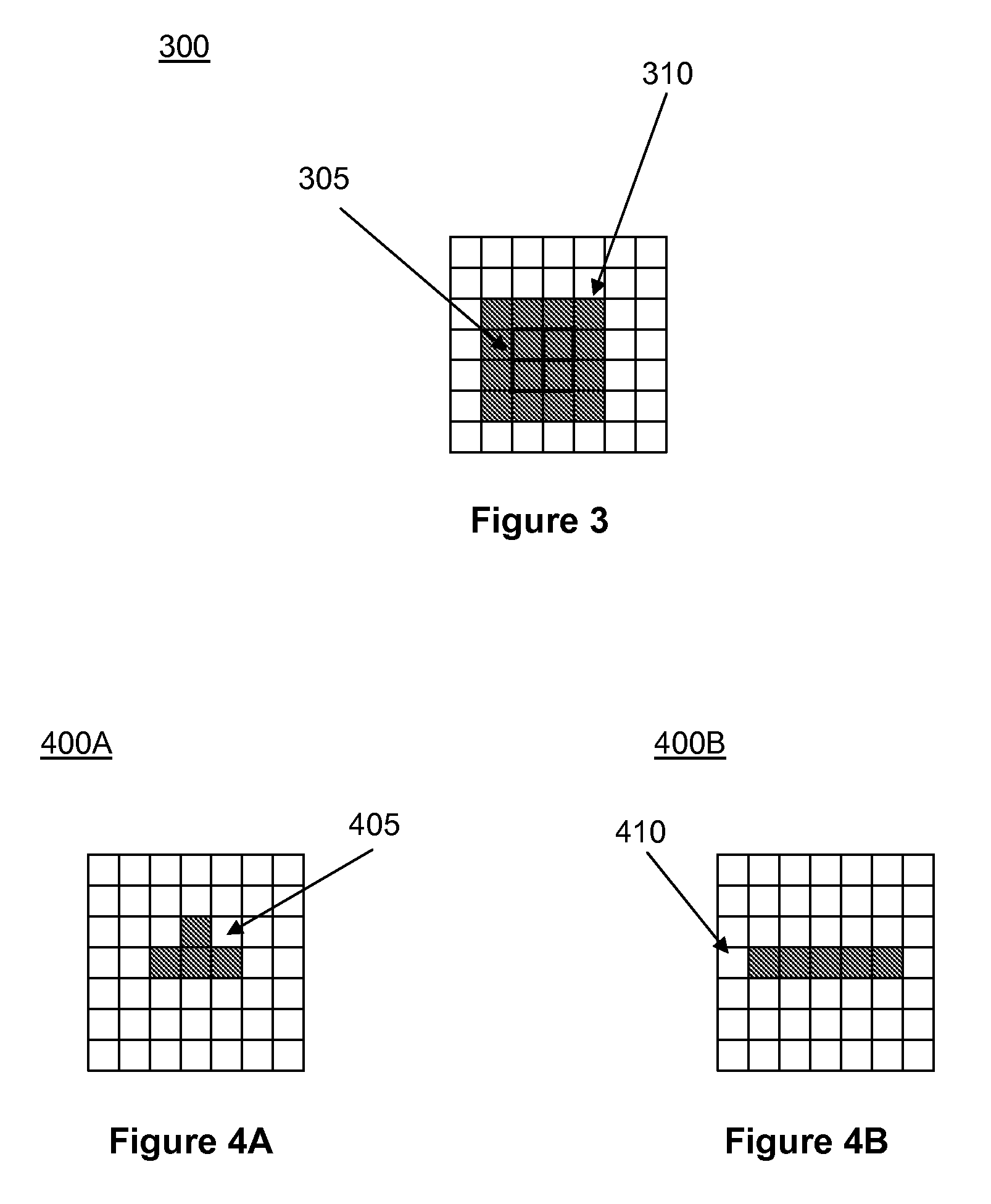

Error smoothing through global source non-uniformity correction

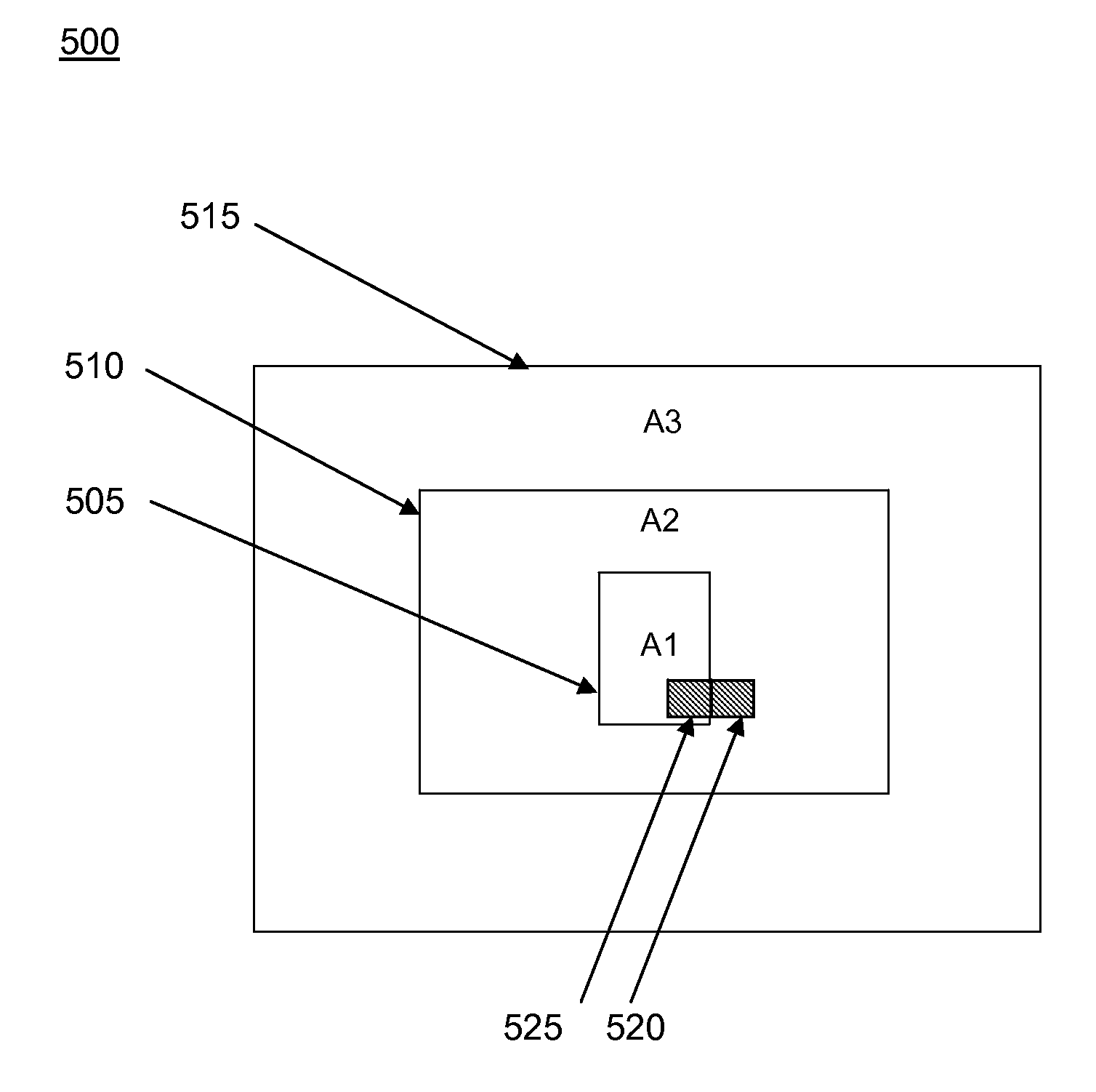

ActiveUS10542193B1Improve response timeImprove the correction effectTelevision system detailsImage enhancementReference frameComputer graphics (images)

A method of performing non-uniformity correction for an imaging system includes receiving image data from a detector. The method also includes retrieving stored correction coefficients from the memory. The method also includes retrieving a stored factory calibration reference frame. The method also includes acquiring an operational calibration reference frame. The method also includes computing updated correction coefficients based on the stored correction coefficients, the stored factory calibration reference frame, and the operational calibration reference frame. The method also includes computing the non-uniformity correction based on the updated correction coefficients. The method also includes forming a corrected image by applying the non-uniformity correction to the image data. The method further includes outputting the corrected image.

Owner:DRS NETWORK & IMAGING SYST

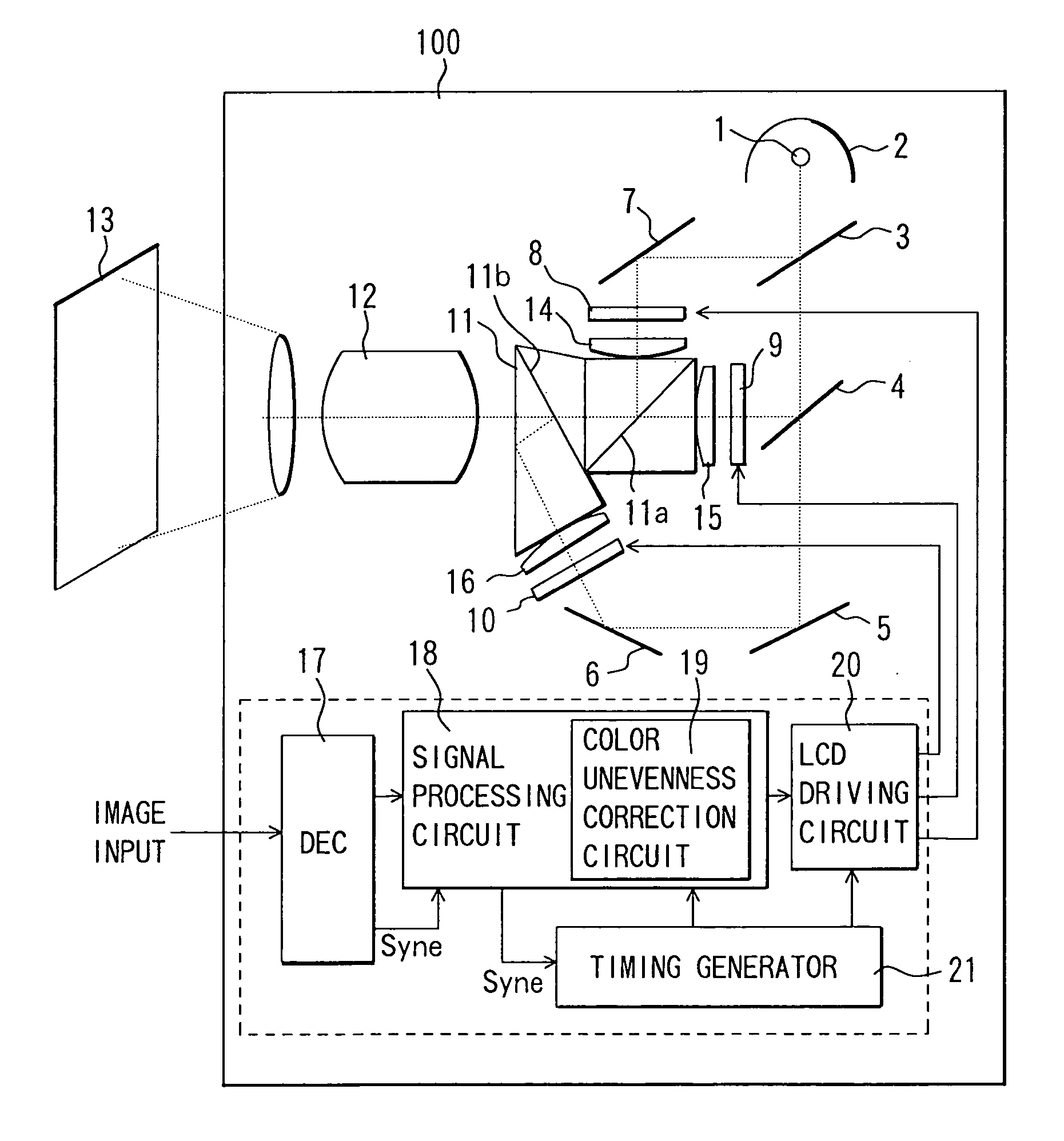

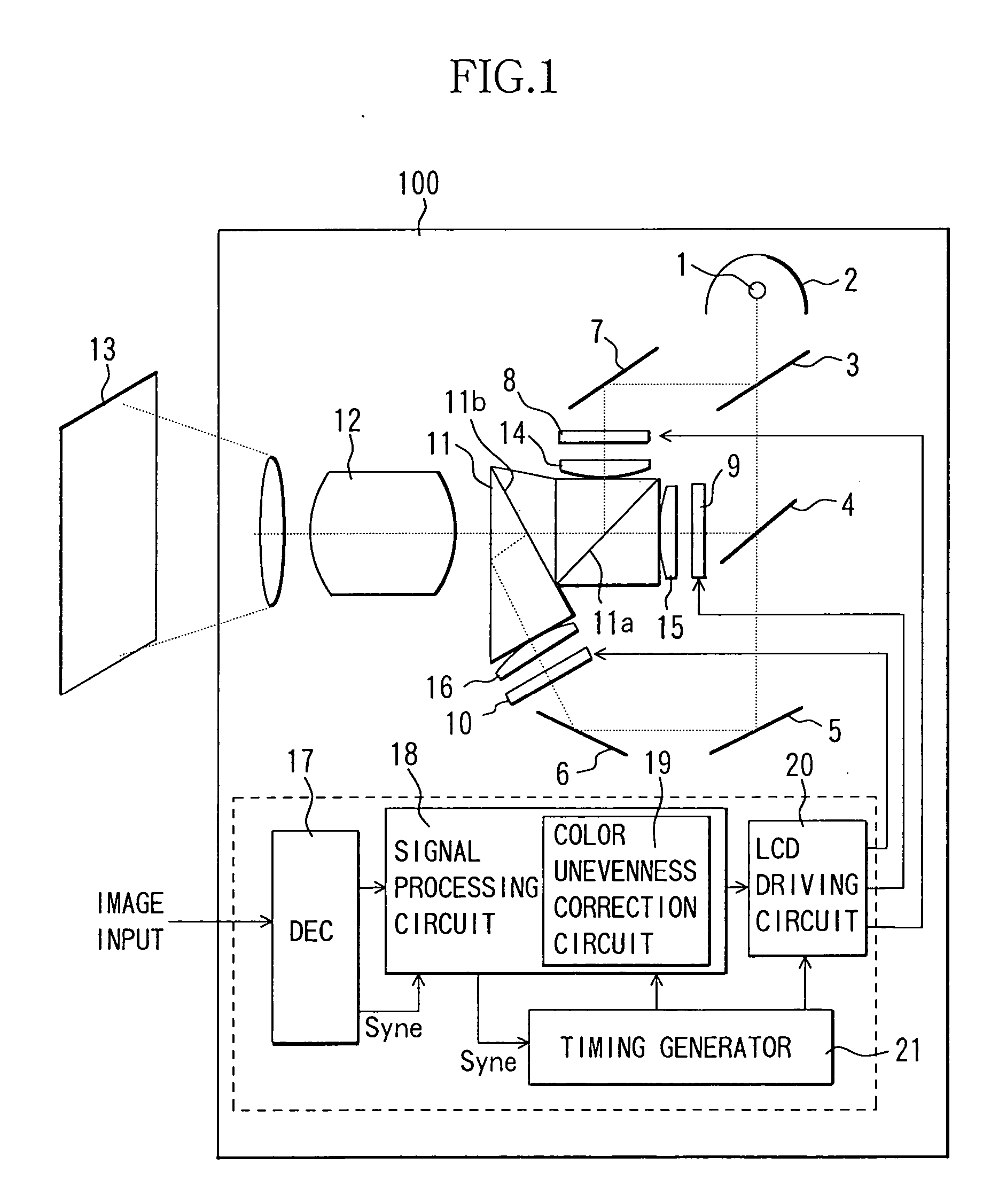

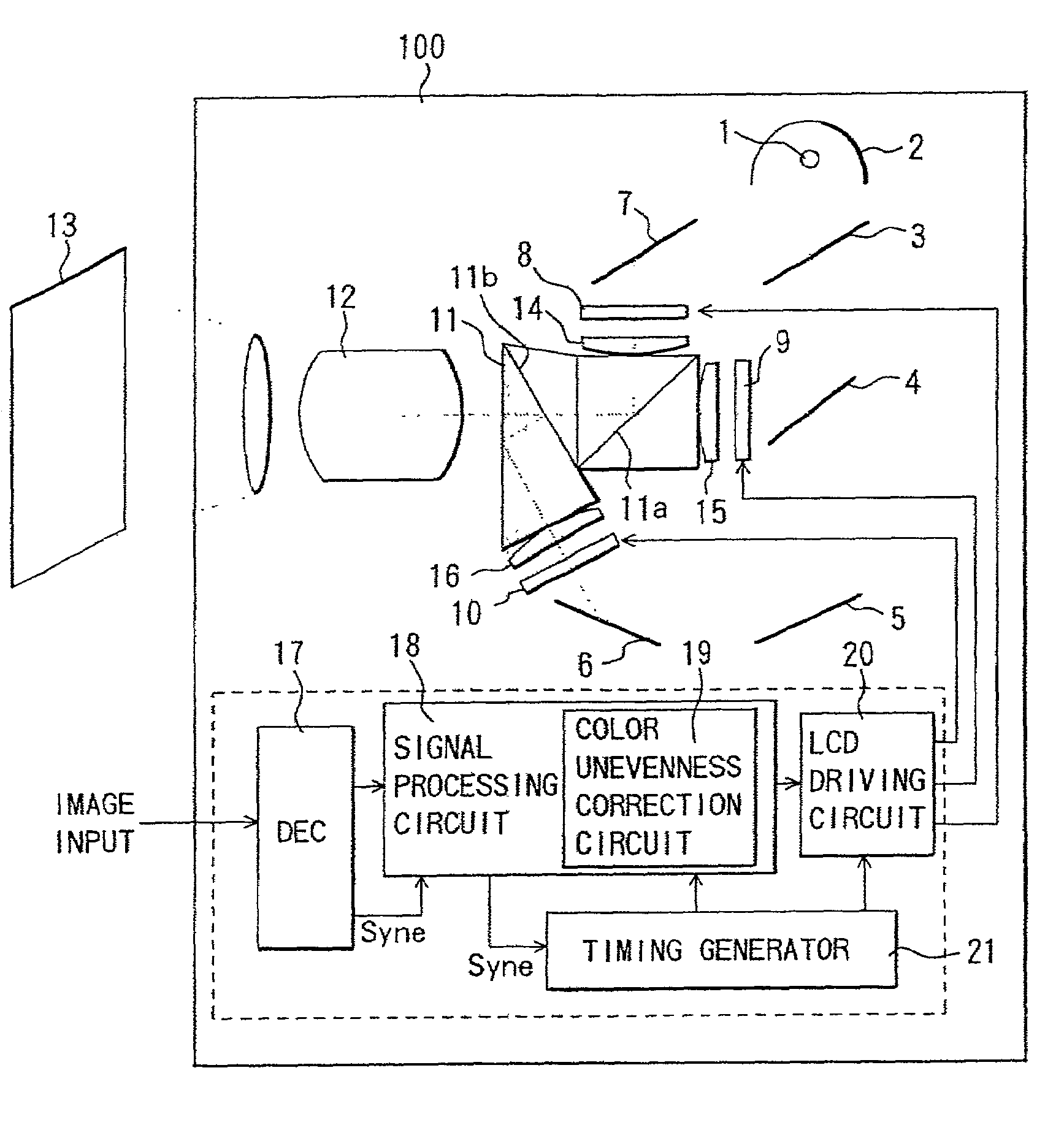

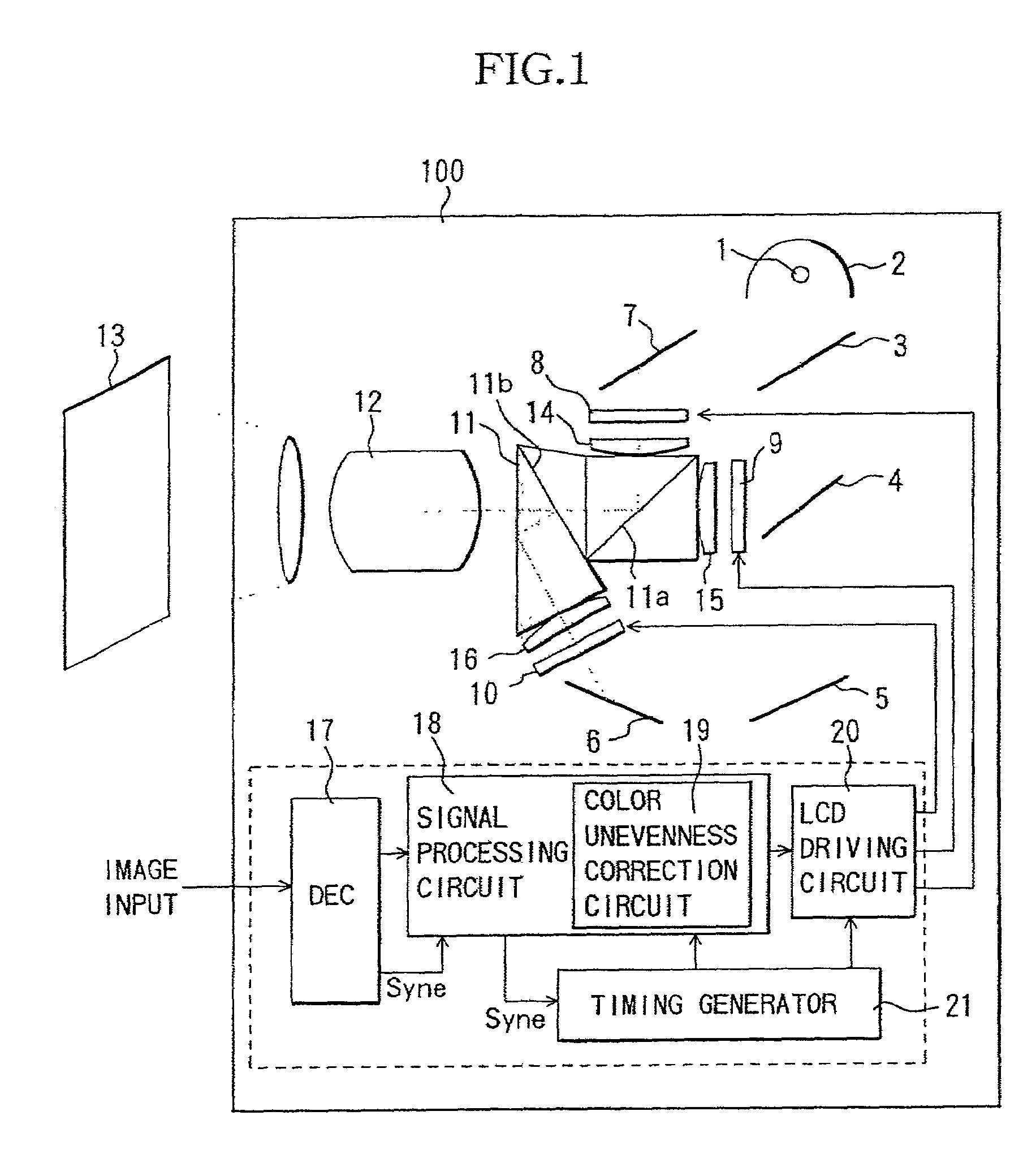

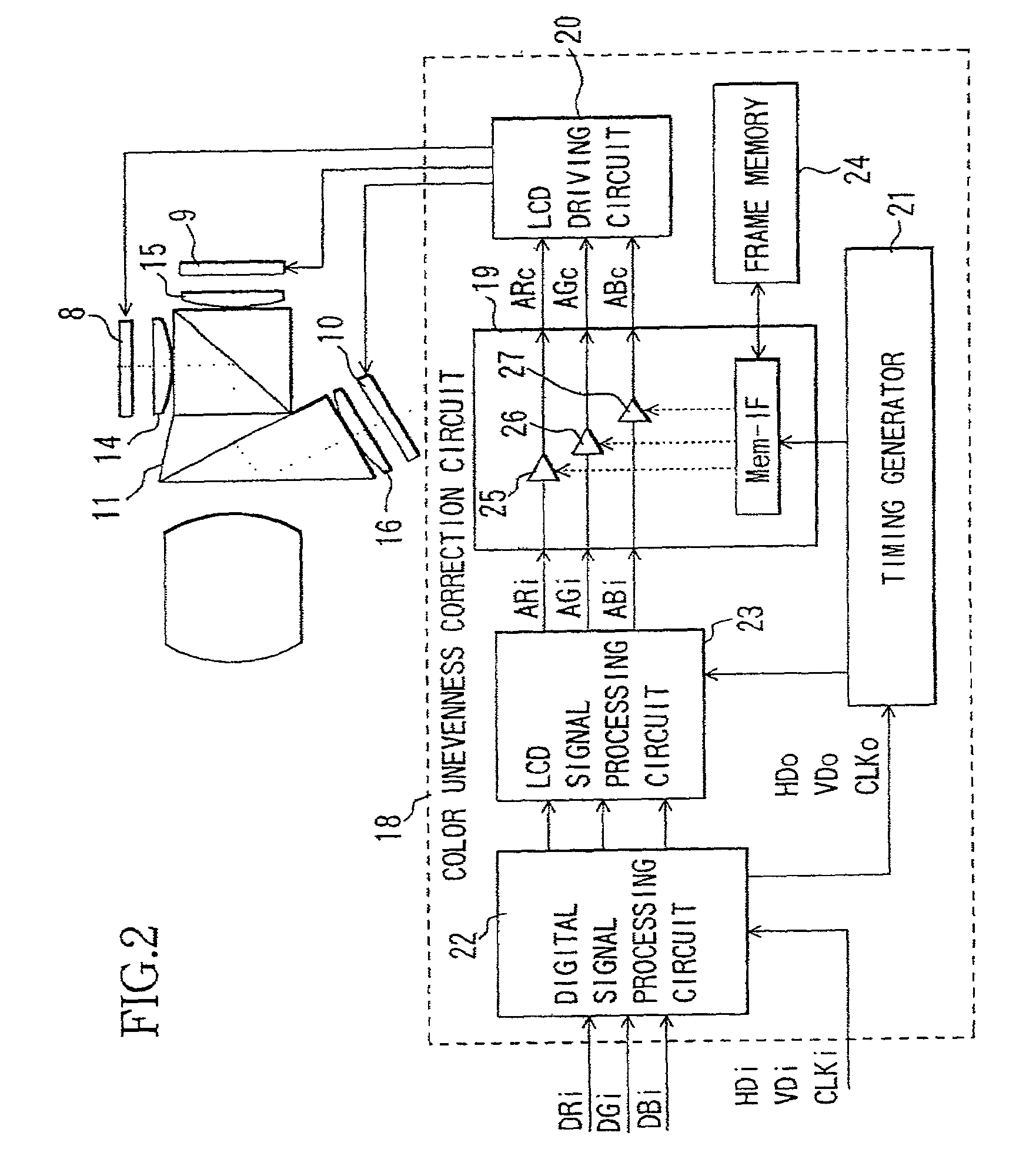

Projection type image display device

InactiveUS20050206851A1Correct color unevennessCorrecting color unevennessTelevision system detailsColor signal processing circuitsPhysicsProjection image

A projection type image display device includes a plurality of image display elements that perform modulation of light rays in accordance with an image signal, a color synthesizing optical element for synthesizing light rays having mutually different wavelength ranges that have been modulated by these image display elements by use of a dichroic membrane, lens groups having a positive refractive power as a whole that are disposed between the image display element and the color synthesizing optical element, and a projection optical system for projecting an image synthesized by the color synthesizing optical element. The projection type image display device further includes a storage circuit for storing data used to correct the brightness irregularity of a projected image, and a brightness irregularity correcting circuit for correcting brightness irregularity of a projected image on the basis of the data stored in the storage circuit.

Owner:CANON KK

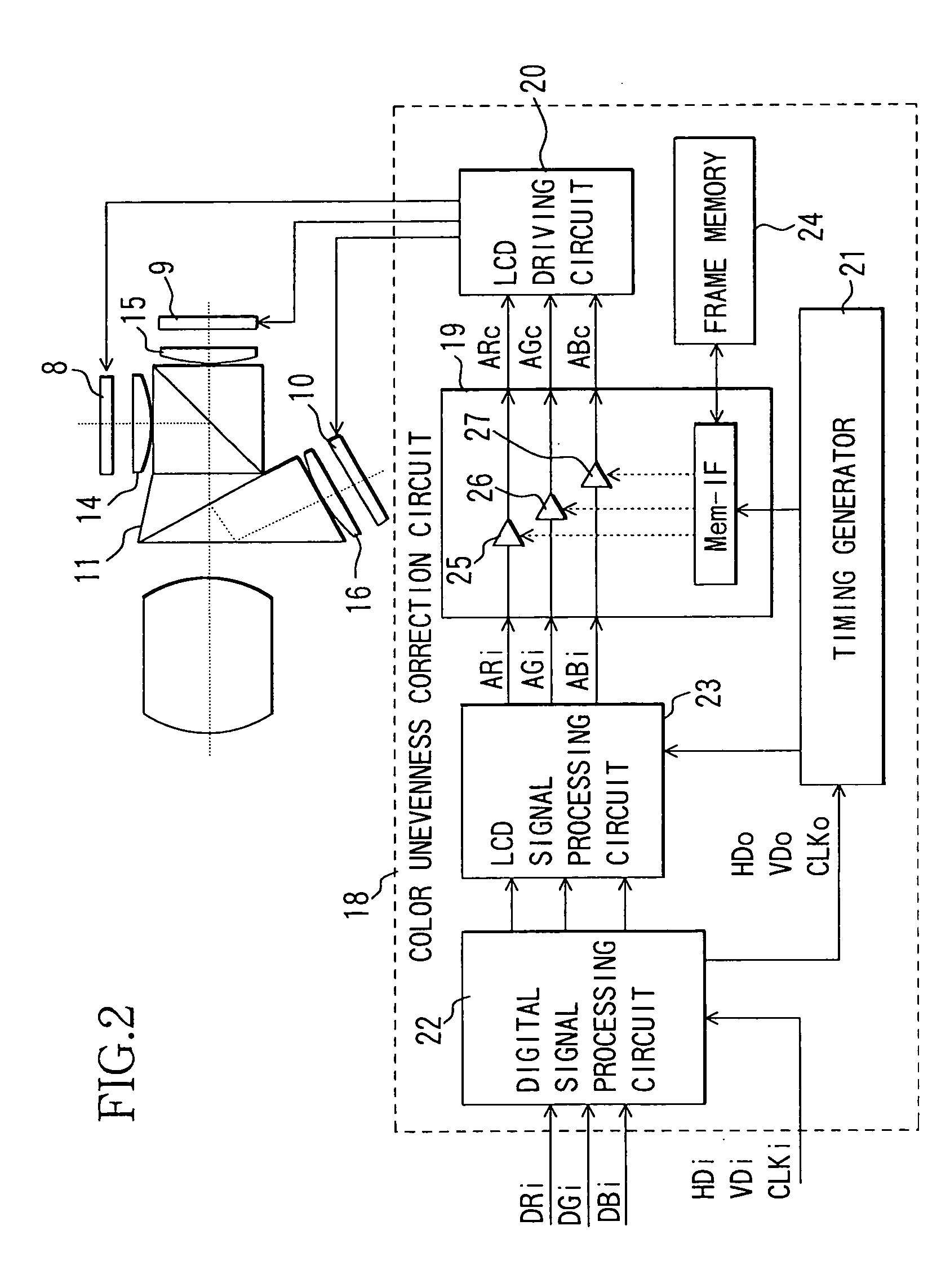

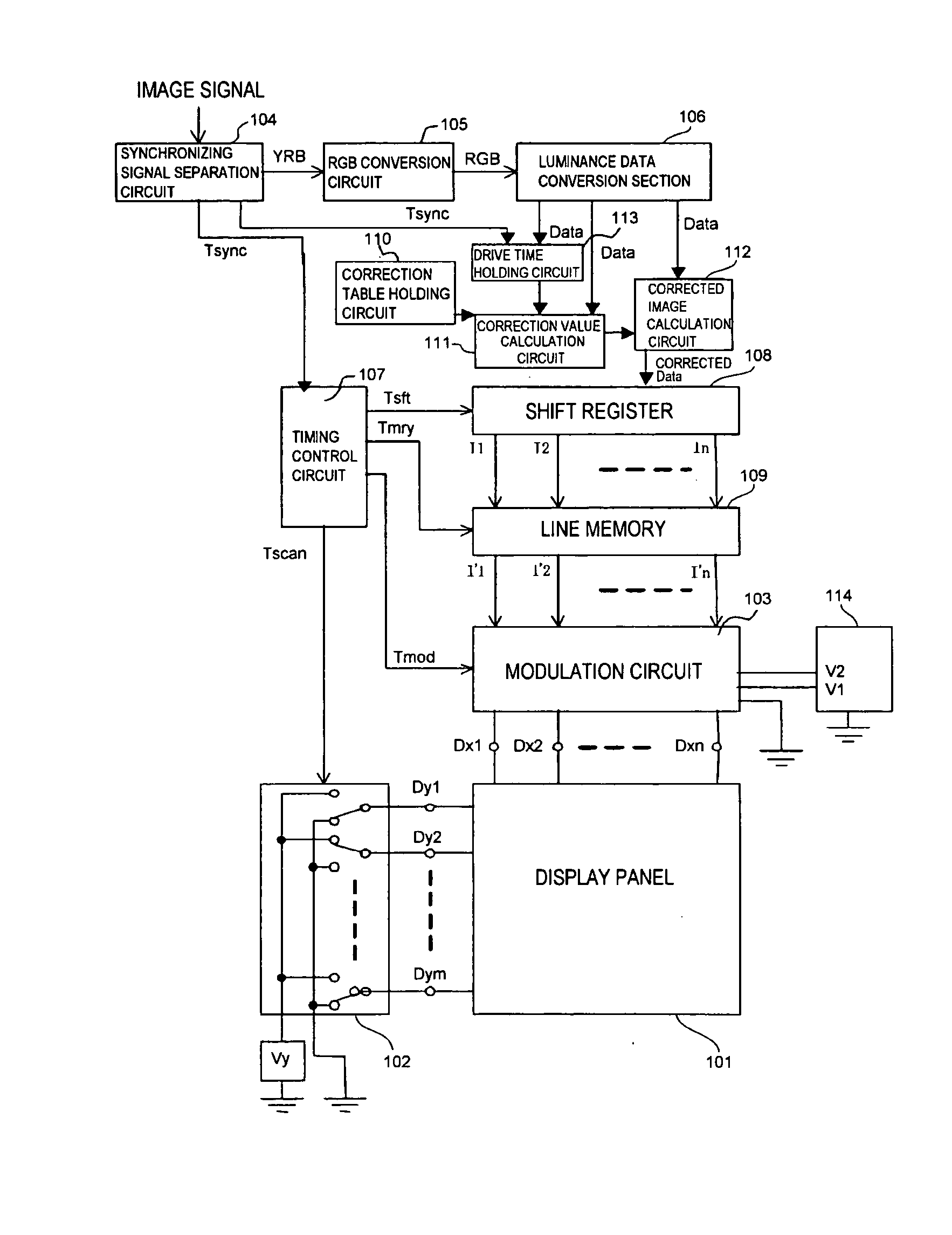

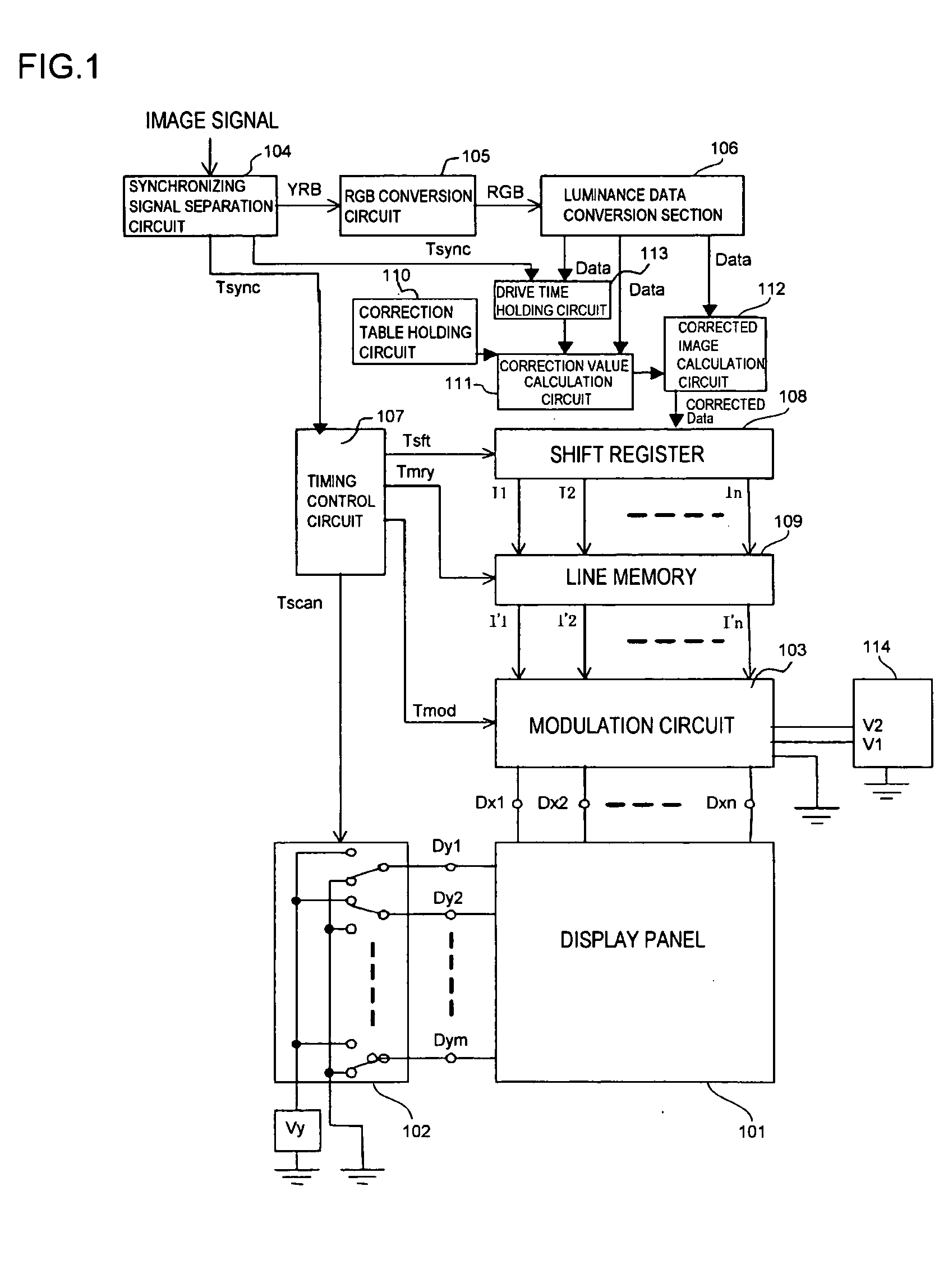

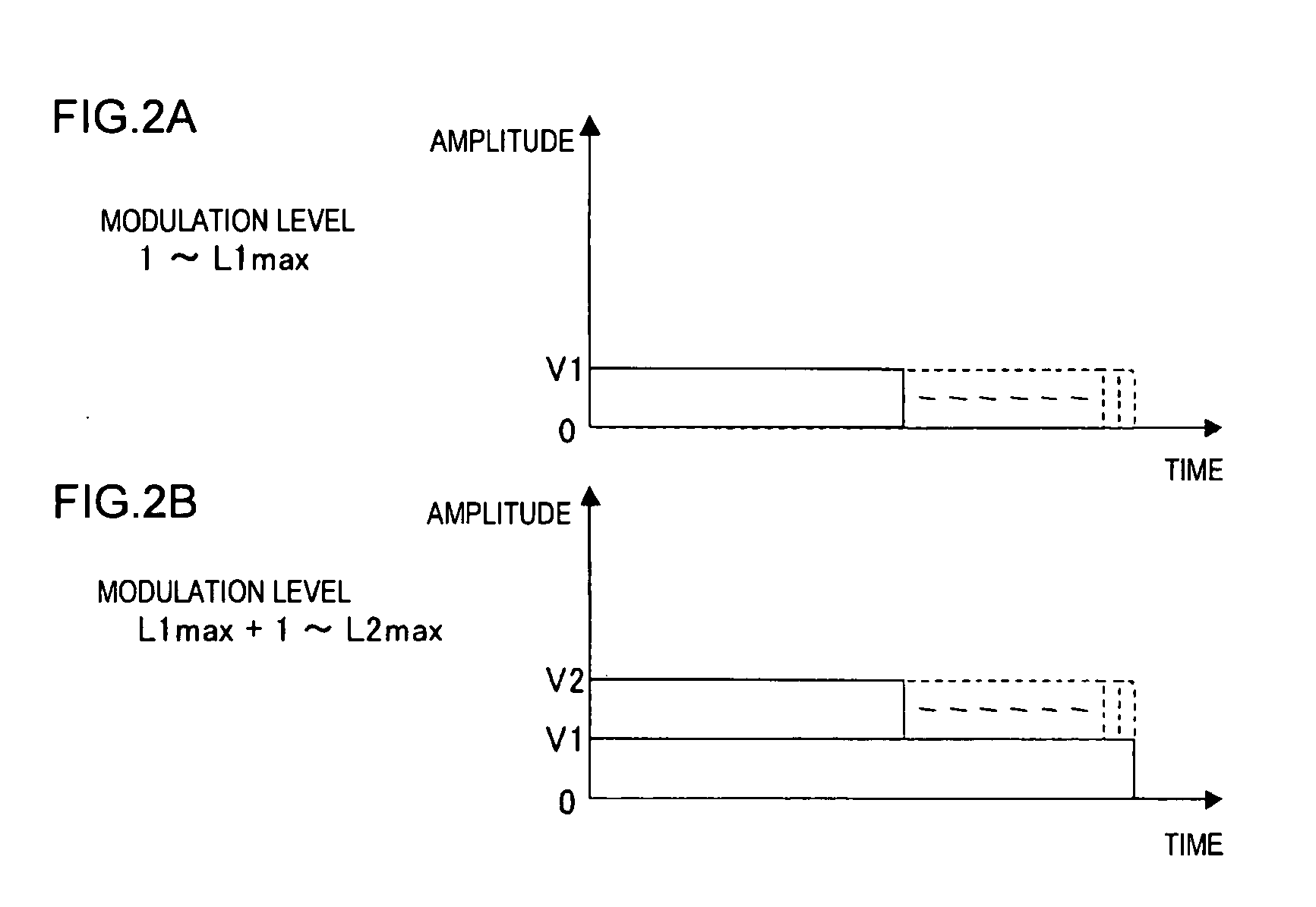

Image display apparatus, drive method for the image display apparatus, and television set

InactiveUS20050200319A1High-quality image displayNon-uniformity can be correctedElectrode and associated part arrangementsCathode-ray tube indicatorsVoltage amplitudeComputer science

In order to provide high-quality image display by correcting and uniformizing the nonuniformity of electron emission characteristics, a predetermined arithmetic operation is performed by using correction values for correcting the nonuniformities of luminance caused by the electron emission devices when a predetermined voltage is applied thereto, thereby calculating correction values when the voltage having a plurality of voltage amplitude values is applied thereto. Corrected image data are calculated on the basis of the calculated correction values, and a drive signal is outputted to drive the electron emission devices on the basis of the corrected image data.

Owner:CANON KK

Error smoothing through global source non-uniformity correction

InactiveUS20200099825A1Improve the correction effectImprove performanceImage enhancementTelevision system detailsDetector arrayComputer science

A method of determining a temperature of an element in a scene includes providing a set of targets each characterized by a target temperature and measuring pixel output values for pixels in a detector array for the targets in the set of targets. Measuring pixel output values is performed at a plurality of detector temperatures. The method also includes mapping each pixel output value to one of a plurality of constant values, each of the plurality of constant values being associated with one of the target temperatures, assembling a scene temperature profile using the mapped pixel output values, and obtaining an image of the scene including the element, wherein the element is associated with a pixel of the detector array. The method further includes determining a pixel value associated with the element and computing the temperature of the element using the scene temperature profile.

Owner:DRS NETWORK & IMAGING SYST

Projection type image display device

InactiveUS6975337B2Correcting color unevennessSimple and inexpensive structureTelevision system detailsTelevision system scanning detailsLength waveData storing

Owner:CANON KK

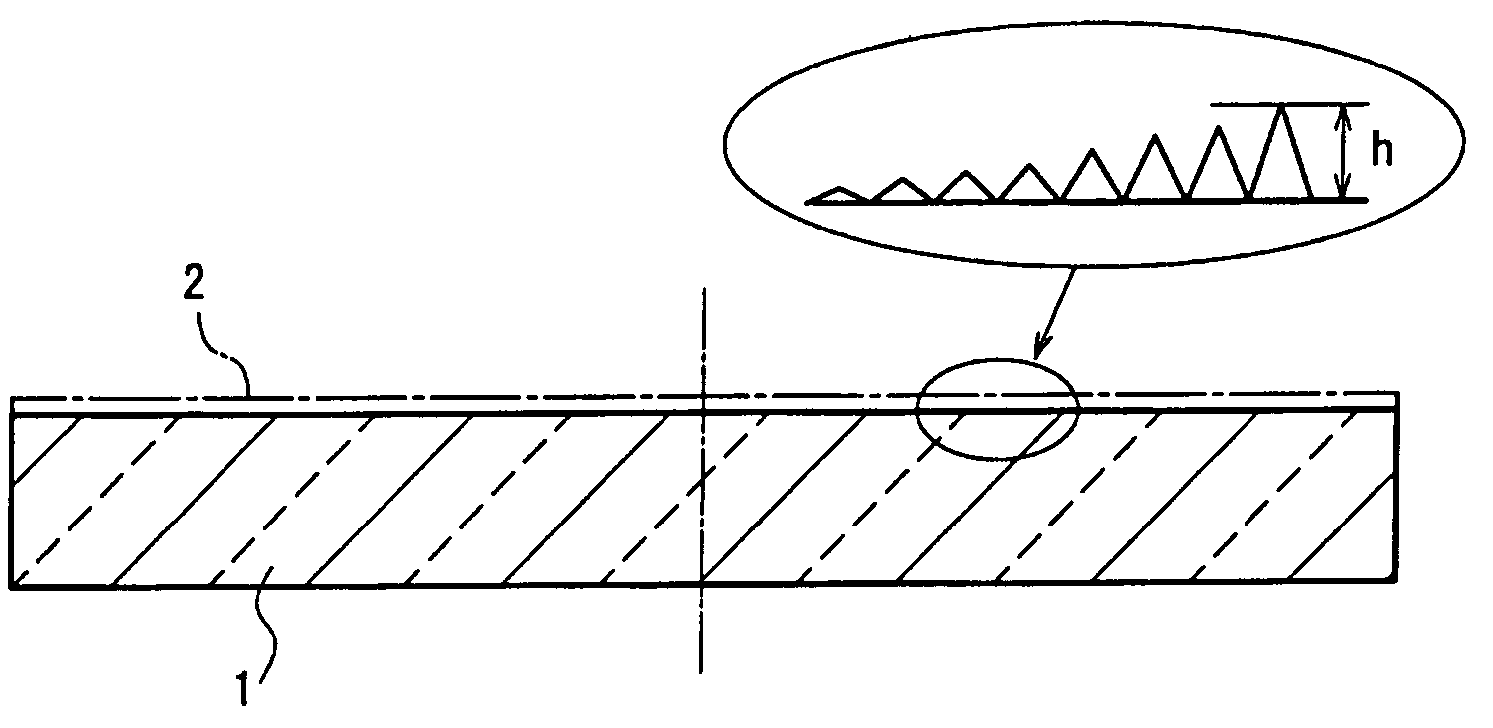

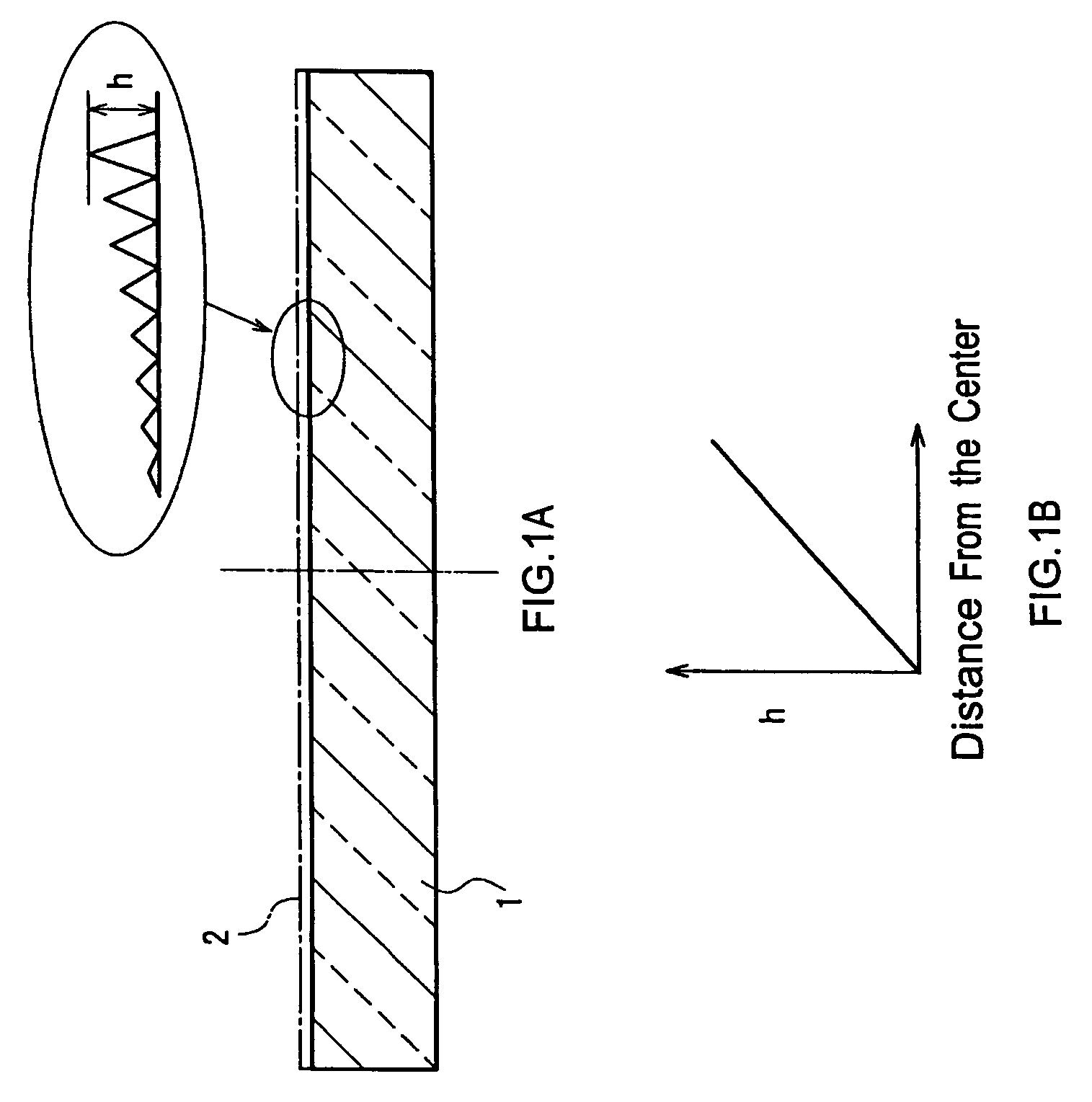

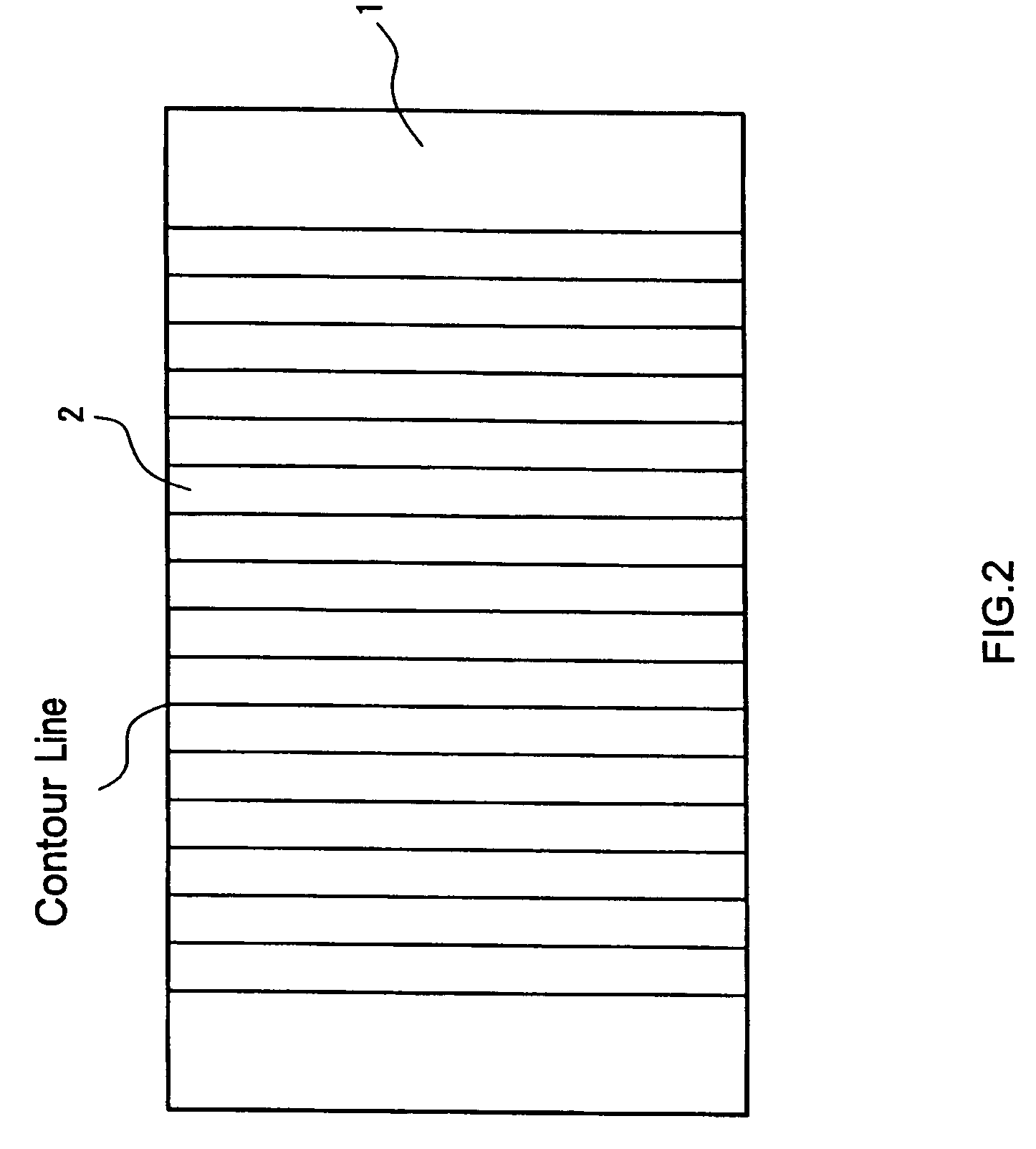

Light quantity distribution control element and optical apparatus using the same

ActiveUS7239448B2Non-uniformity can be correctedOptimal recording/reproductionDiffraction gratingsMountingsDistribution controlUltraviolet lights

A light quantity distribution control element includes a substrate of 20 mm×20 mm×3 mm made of a material that transmits light, such as optical glass or acryl, and a antireflective structure provided on a surface of the substrate. As the antireflective structure, a conical antireflective structure of a pitch of 0.15 μm (periodic structure having conical convexities) is formed. This corresponds to a antireflective structure having a pitch of a wavelength or less in the ultraviolet band (150 nm to 400 nm) at the time when ultraviolet light is used as incident light.

Owner:PANASONIC CORP

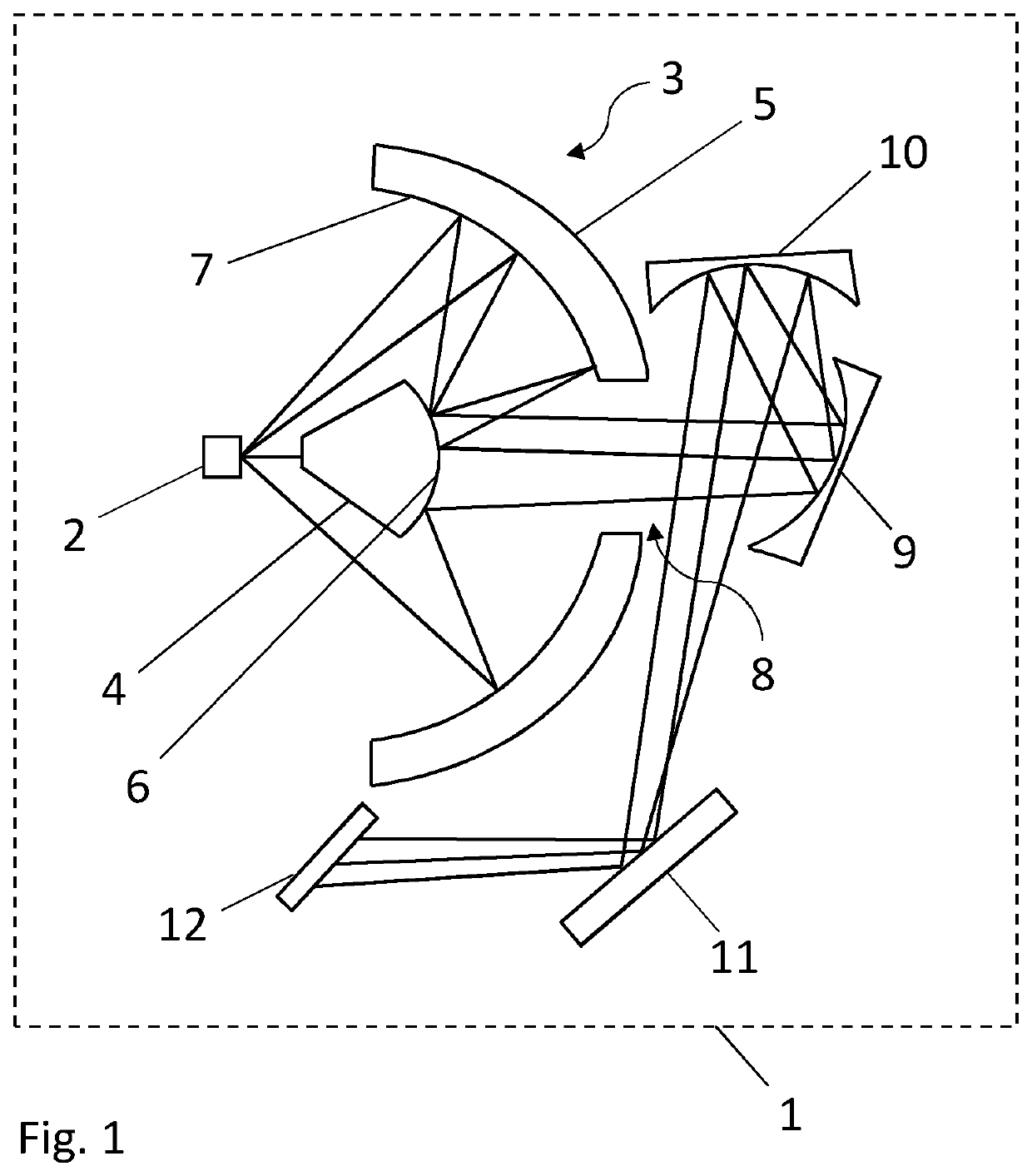

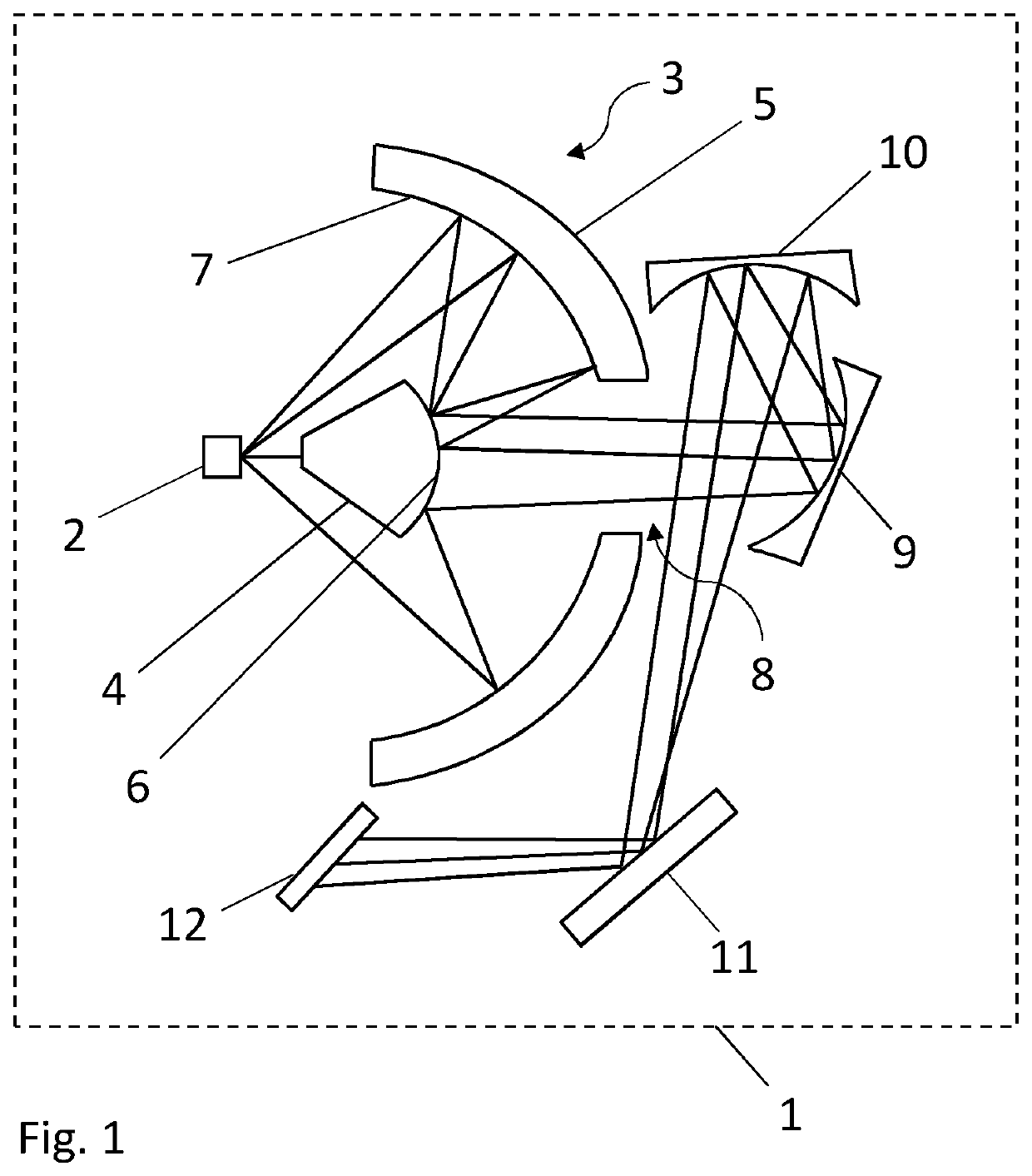

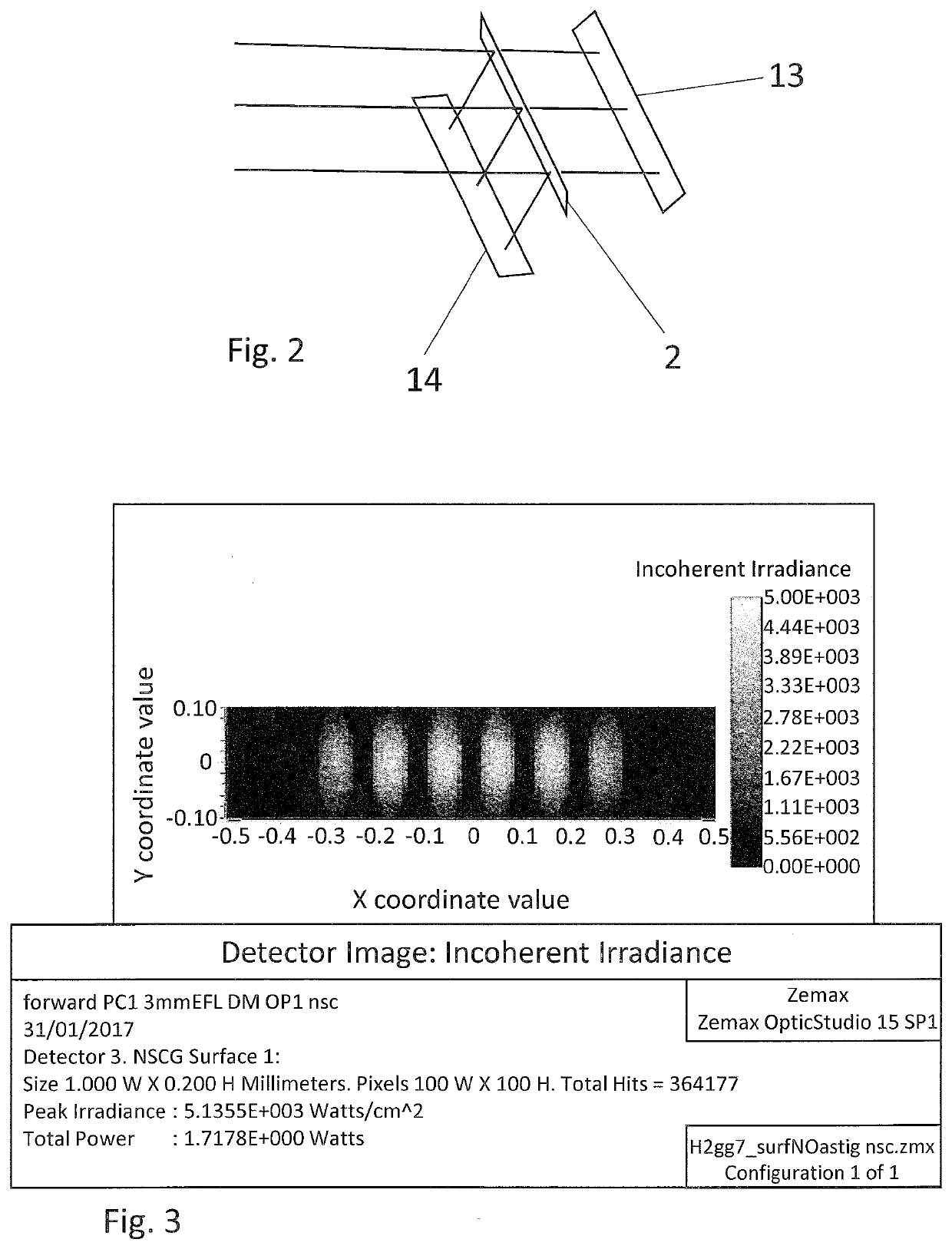

Infrared spectrophotometer

ActiveUS11092488B2Accurate measurementNon-uniformity can be correctedRadiation pyrometryAbsorption/flicker/reflection spectroscopyInfraredEngineering

An optical sensor for multispectral analysis of a fluid sample comprises at least one light source, at least one interference filter, and a plurality of light detectors arranged such that light emitted by the at least one light source is incident on the at least one interference filter. There is a spatial variation in the intensity of light incident on the said at least one interference filter.

Owner:UNIVERSITY OF THE WEST OF SCOTLAND

Method for imaging a sample by means of a microscope and microscope

ActiveUS20160054551A1Non-uniformity can be correctedImage be reducedImage enhancementTelevision system detailsReference imageImaging lens

A method for imaging a sample using a microscope having an illumination unit, an imaging lens system and an image sensor, including: illuminating an area of the sample; imaging and magnifying the sample onto the image sensor and capturing the image using a predetermined number of pixels; providing a plurality of different comparison sample areas; for each comparison sample area, performing a reference measurement, wherein the comparison sample areas are illuminated, imaged and magnified onto the image sensor and captured with the predetermined number of image pixels as a reference image; determining a brightness-correction image with the predetermined number of image pixels by determining the value for each image pixel of the brightness-correction image from the values of allocated image pixels of the reference images, and correcting the image of the area of the sample captured based on the brightness-correction image and outputting it as a corrected image.

Owner:CARL ZEISS MICROSCOPY GMBH

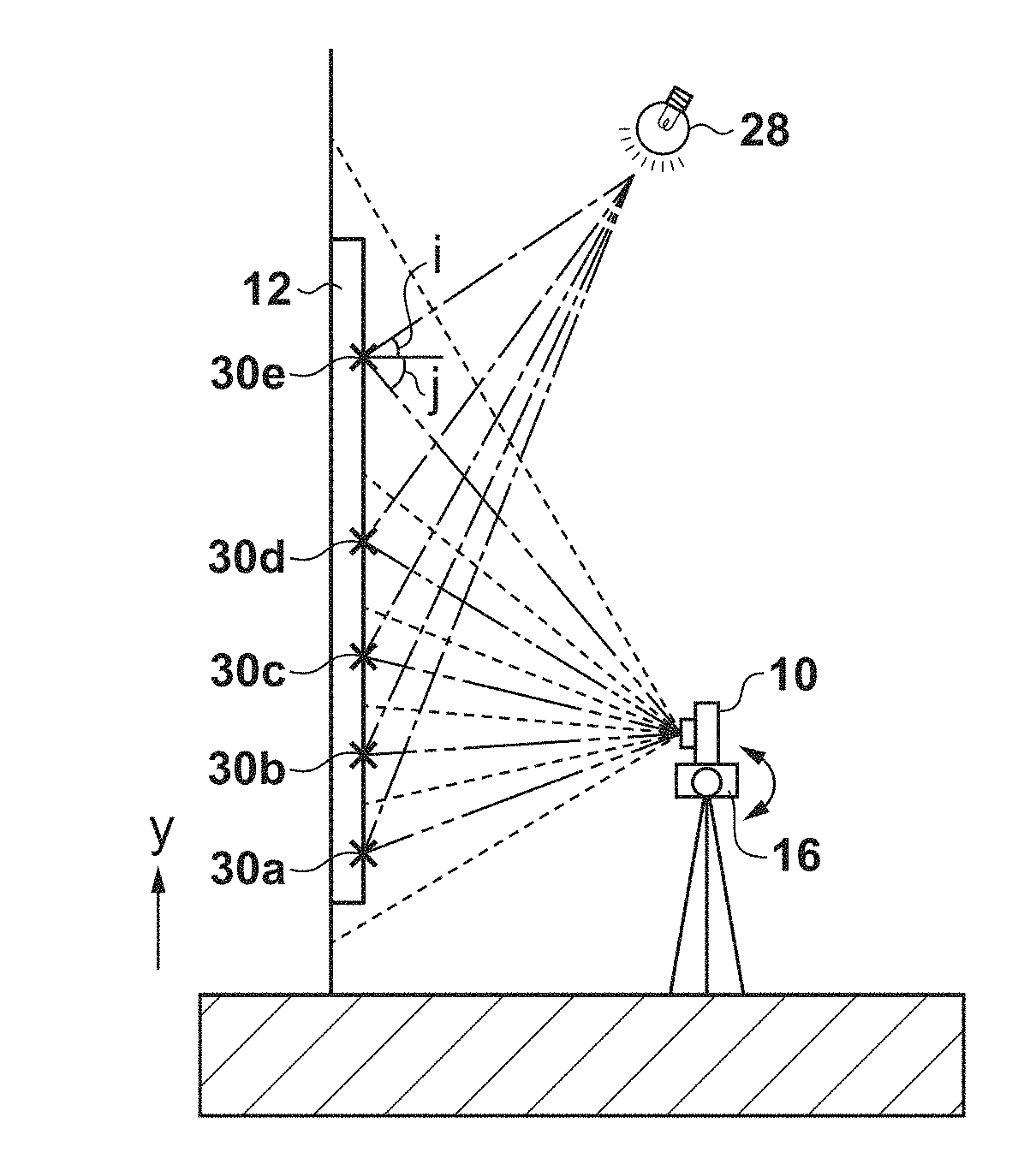

Device and method for measuring the velocity of a moving paper web

InactiveUS8080131B2Addressing slow performanceImprove accuracyLinear/angular speed measurementIndication/recording movementEngineeringTransmitted light

Device for measuring the two-dimensional velocity of a moving paper web having opposed first and second surfaces, wherein comprising: at least one light source directed at said first surface and arranged to transmit light through said paper web; at least one image capturing device directed at said second surface, and arranged to receive said transmitted light and produce a two-dimensional image of a section of said paper web; a control unit, arranged to control said at least one light source and at least one image capturing device, and to receive two-dimensional images from said at least one image capturing device, and comprising computation means arranged to compute the velocity component of said paper web in the machine direction and / or the cross direction by calculating the cross correlation of two two-dimensional images.

Owner:STFI

Real-time pixel substitution for thermal imaging systems

ActiveUS8228405B2Eliminate distractionsPrevent degradationTelevision system detailsColor signal processing circuitsImaging qualityImage quality

A non-uniformity correction (NUC) process for imaging engines is augmented with real-time pixel substitution capability. This feature checks for pixels that have significantly degraded from their factory performance. Degraded pixels found are then substituted in real time. This process eliminates distractions to the camera system operator and prevents these degraded pixels from degrading the subjective image quality.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

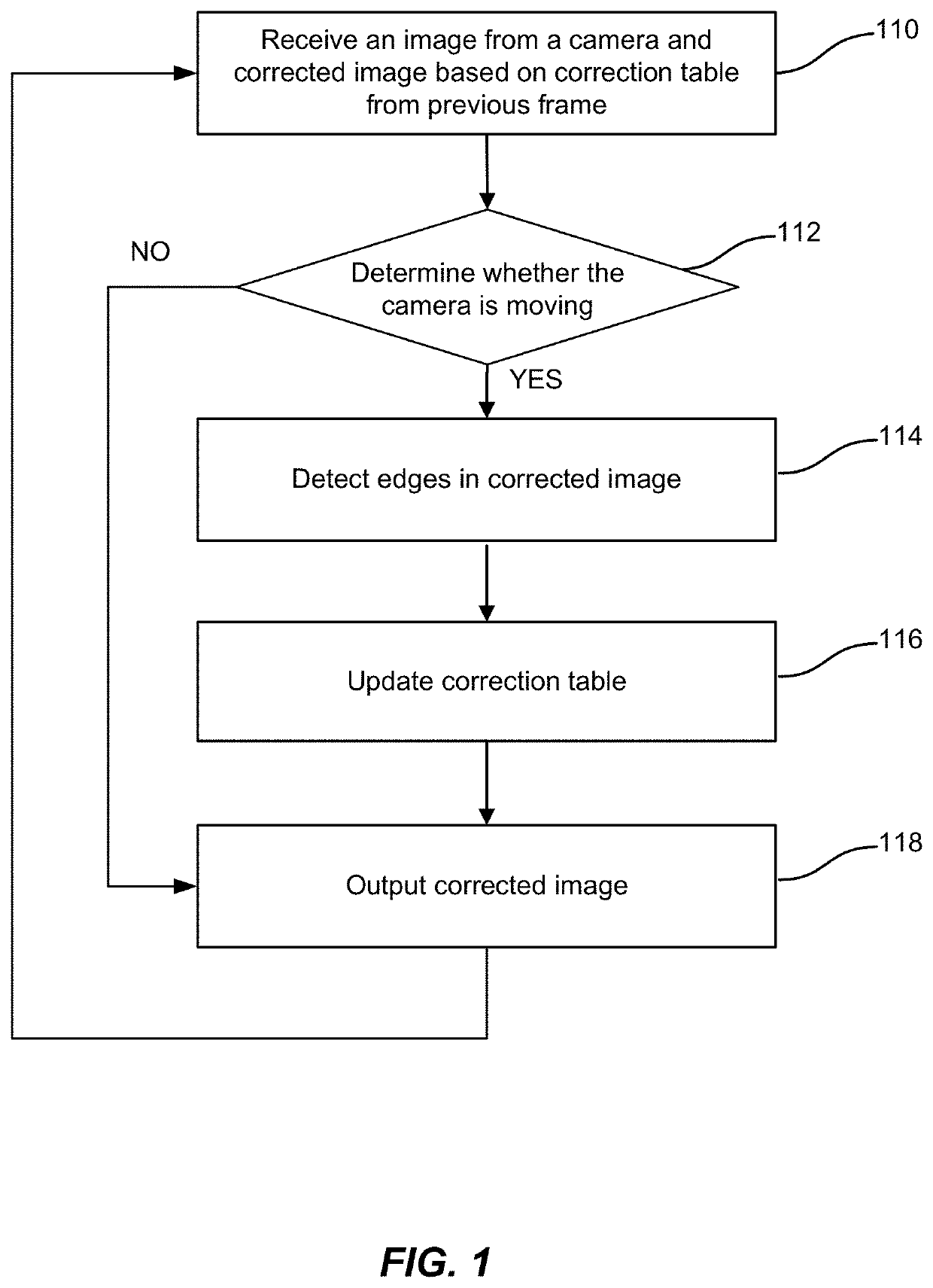

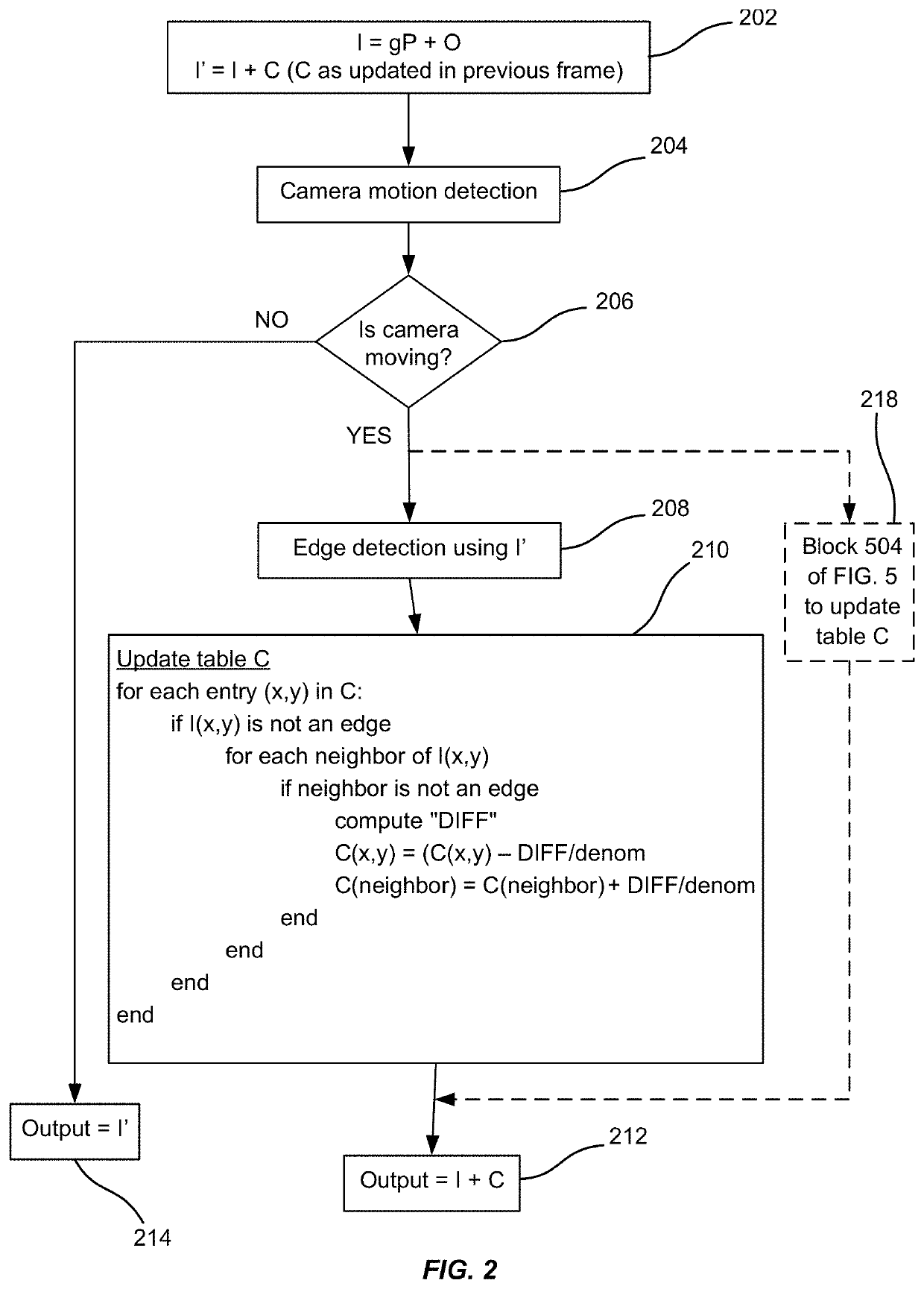

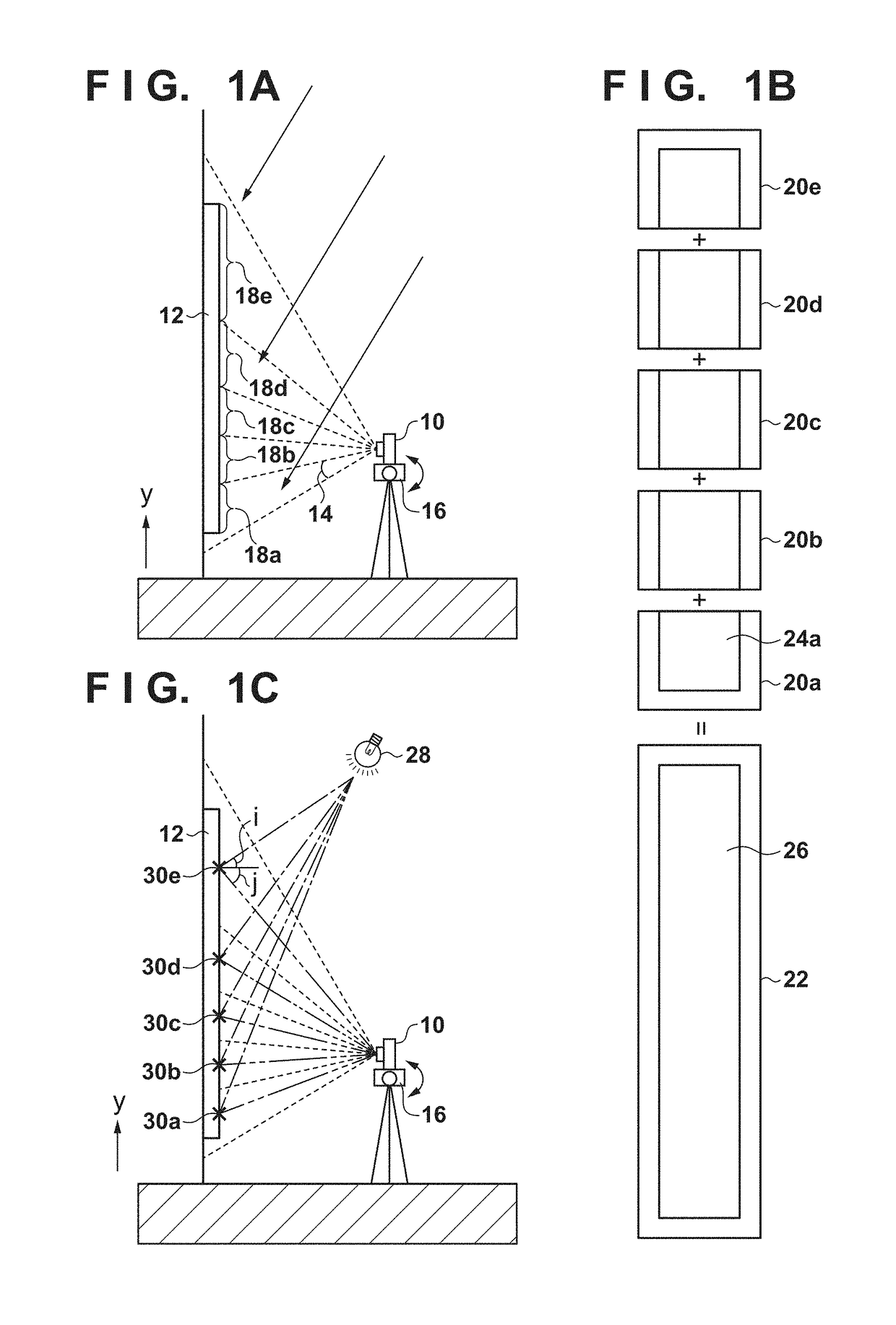

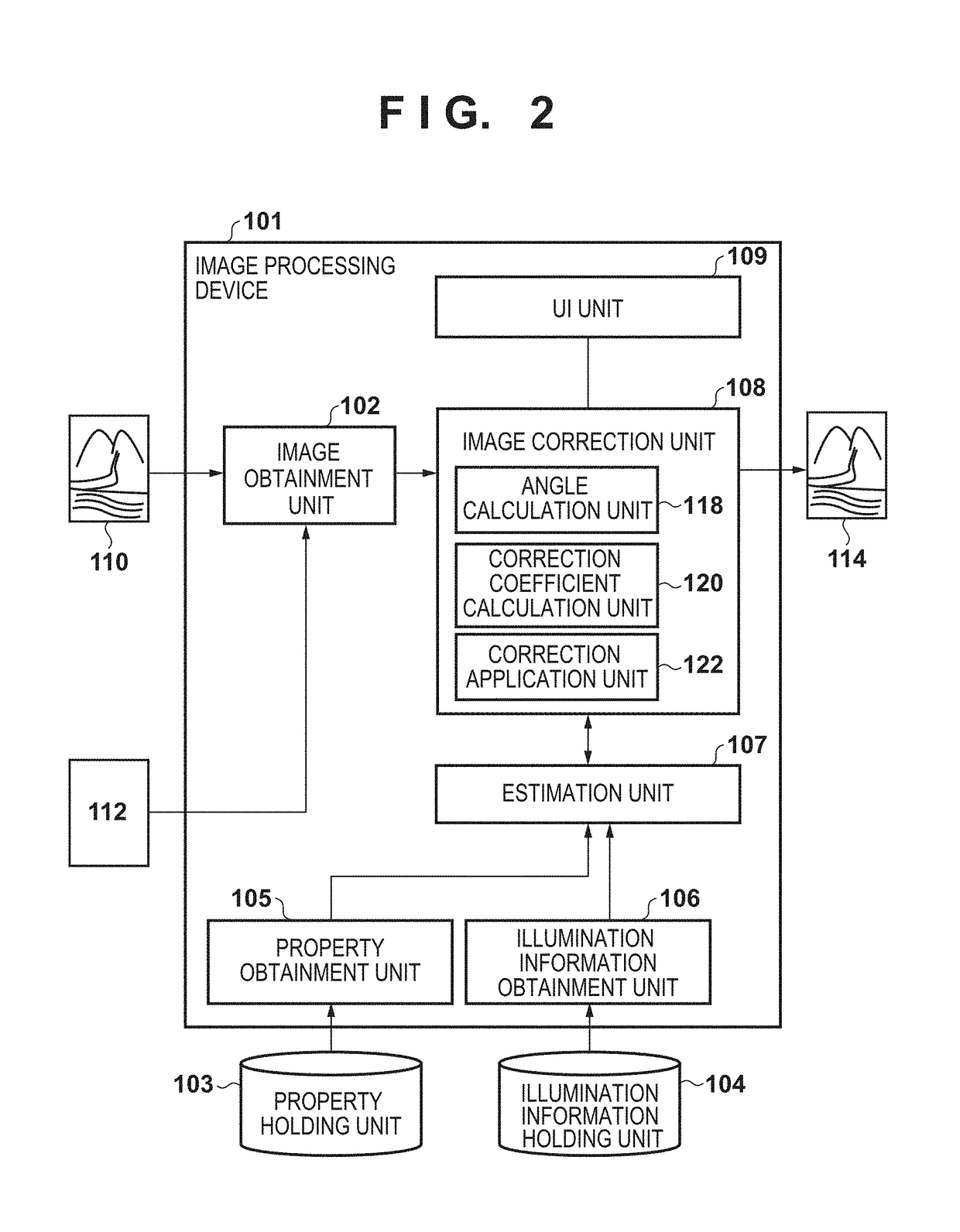

Image processing device and image processing method

ActiveUS20170374239A1Non-uniformity can be correctedTelevision system detailsImage enhancementComputer visionImage processing

An image processing device comprises a unit configured to obtain image data representing an image of an object from an image capturing device; a unit configured to obtain an angular dependency of an intensity of light reflected by the object; a unit configured to calculate an angle of the light reflected by the object to the image capturing device; and a unit configured to correct the obtained image data based on the calculated angle and the obtained angular dependency.

Owner:CANON KK

Infrared spectrophotometer

ActiveUS20200064188A1Accurate measurementNon-uniformity can be correctedRadiation pyrometryAbsorption/flicker/reflection spectroscopyInfraredOptical transducers

An optical sensor for multispectral analysis of a fluid sample comprises at least one light source, at least one interference filter, and a plurality of light detectors arranged such that light emitted by the at least one light source is incident on the at least one interference filter. There is a spatial variation in the intensity of light incident on the said at least one interference filter.

Owner:UNIVERSITY OF THE WEST OF SCOTLAND

Method for imaging a sample by means of a microscope and microscope

ActiveUS11215806B2Non-uniformity can be correctedImage be reducedImage enhancementTelevision system detailsReference imageImaging lens

Owner:CARL ZEISS MICROSCOPY GMBH

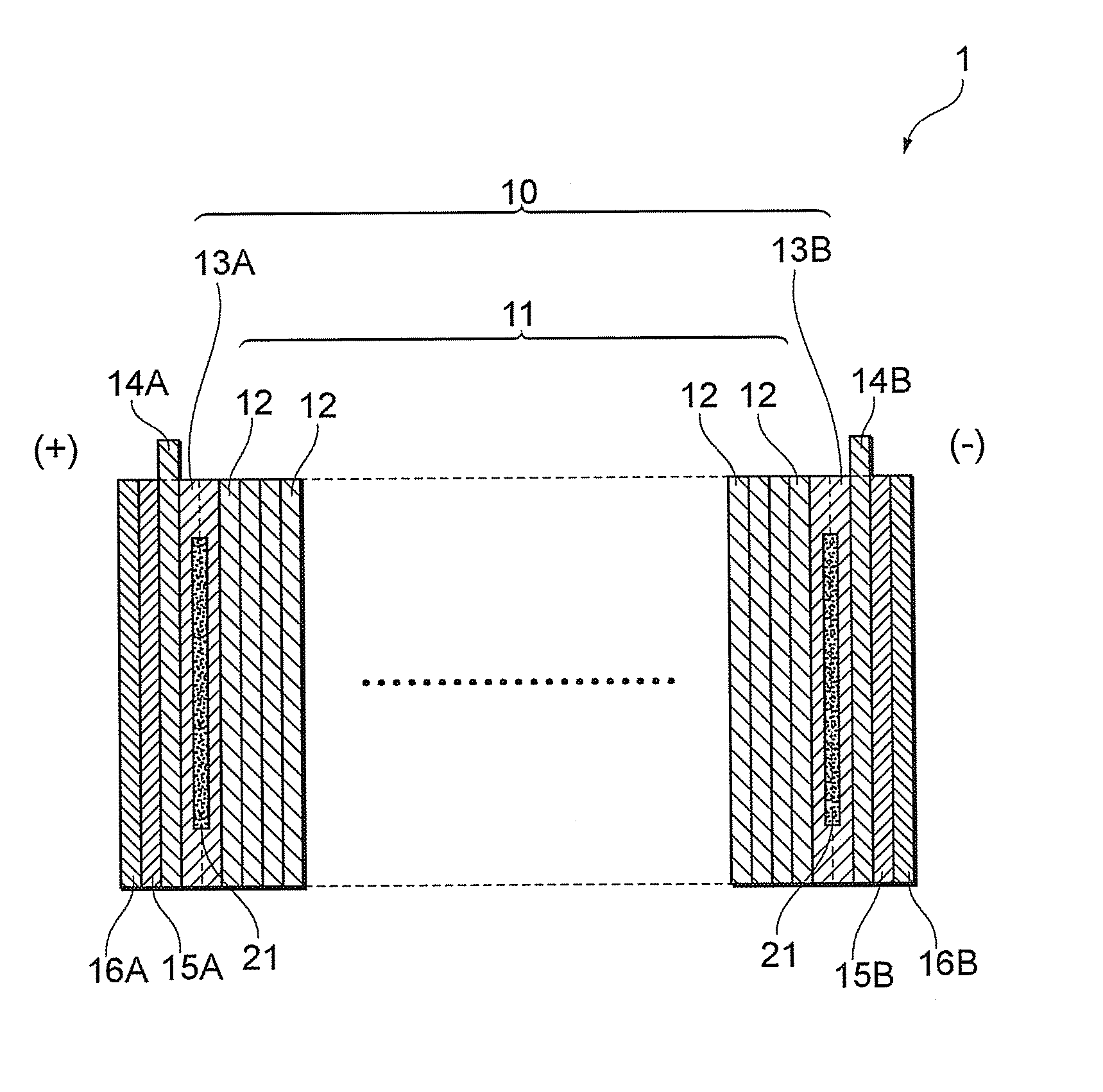

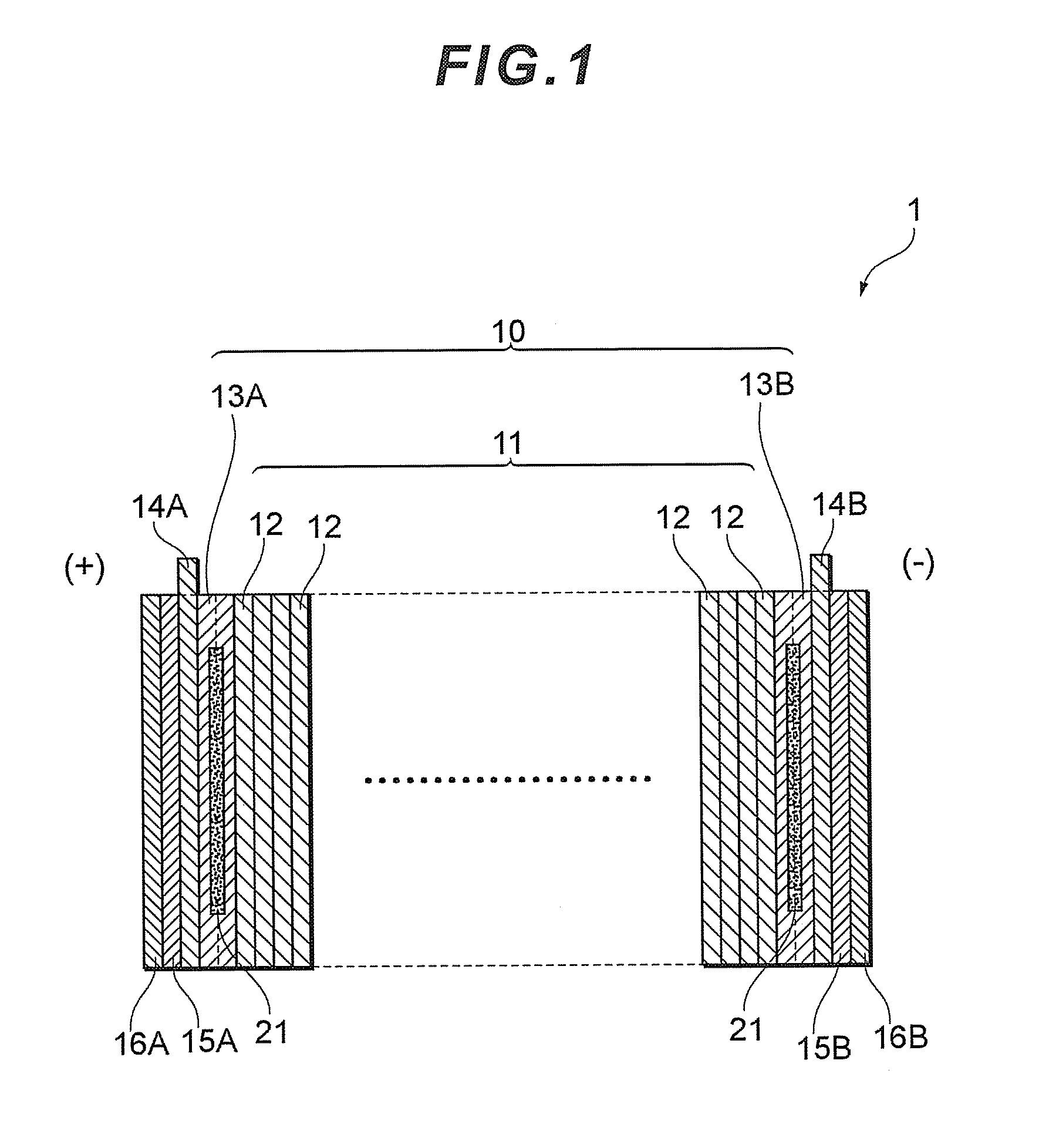

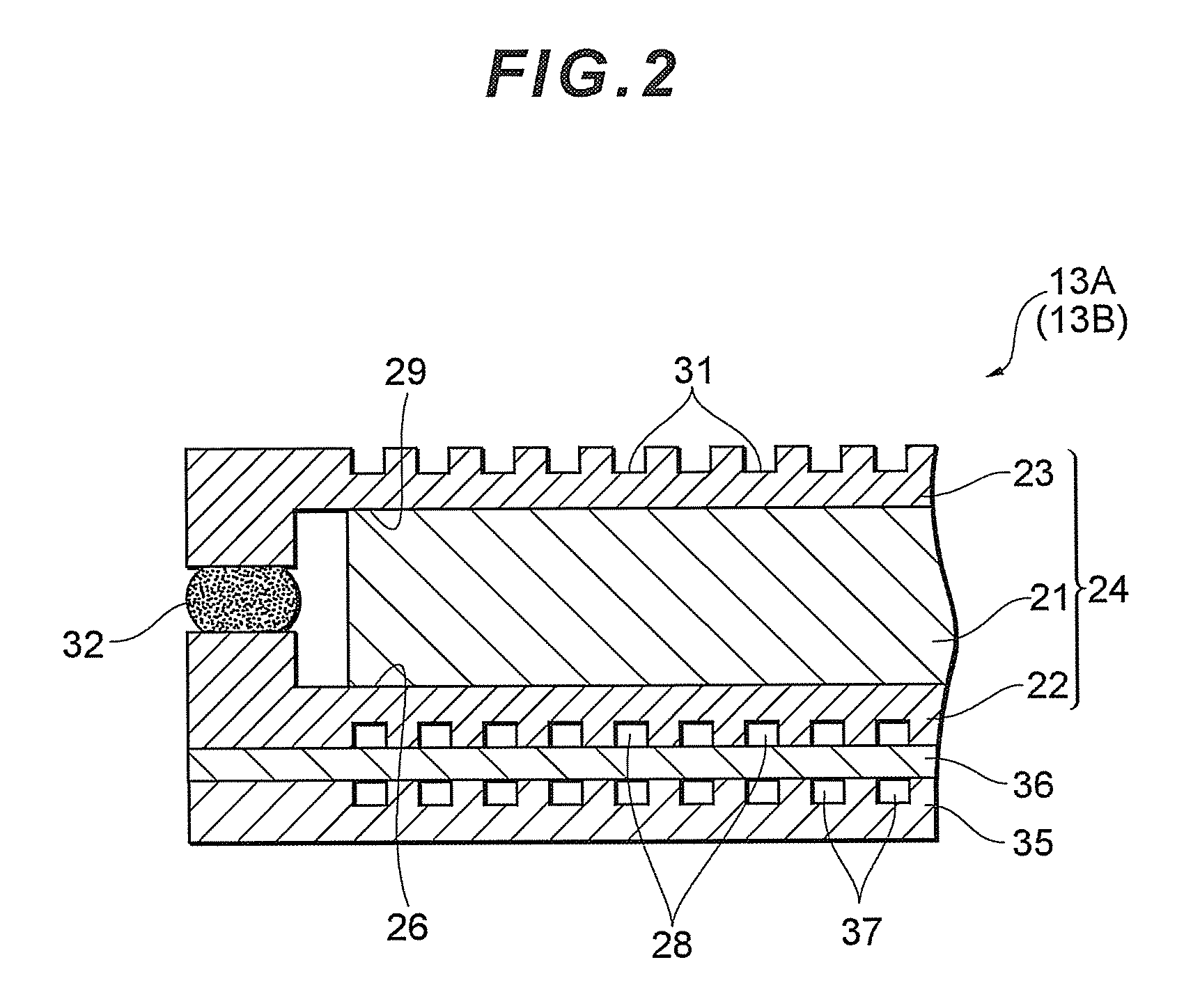

Fuel cell

InactiveUS9023546B2Improve reliabilitySuppress DiffuseFuel cells groupingFuel cell auxillariesPorosityFuel cells

There is disclosed a fuel cell in which an insulating material is disposed, whereby the thermal diffusion of the inside and outside of a fuel cell can be suppressed to suppress the deterioration of the performance of the fuel cell due to a temperature drop. Moreover, the physical properties of the insulating material are specified, whereby appropriate insulating properties required in the fuel cell can be obtained, and startup properties are improved. A fuel cell has a cell stack in which a plurality of unit cells are stacked, and terminal plates disposed on both sides of the cell stack in a cell stack direction thereof. The fuel cell comprises an insulating portion having an insulating material and holding plates which hold the insulating material from both the sides of the insulating material in the cell stack direction, the insulating material is held between the holding plates, and the insulating material has a thermal conductivity of 0.1 W / mK or less and a porosity of 70% or more.

Owner:TOYOTA JIDOSHA KK +1

Imaging optical system, camera module, and electronic device

ActiveUS11156751B2Non-uniformity can be correctedTelevision system detailsOptical filtersMedicineTransmittance

An imaging optical system according to the present disclosure includes: a lens; and an optical member, in which the optical member is configured such that a light transmittance value at least in a peripheral portion is larger than a light transmittance value in a central portion. Furthermore, a camera module according to the present disclosure includes the imaging optical system of the present disclosure. Furthermore, an electronic device according to the present disclosure includes a solid-state imaging element and the imaging optical system of the present disclosure.

Owner:SONY SEMICON SOLUTIONS CORP

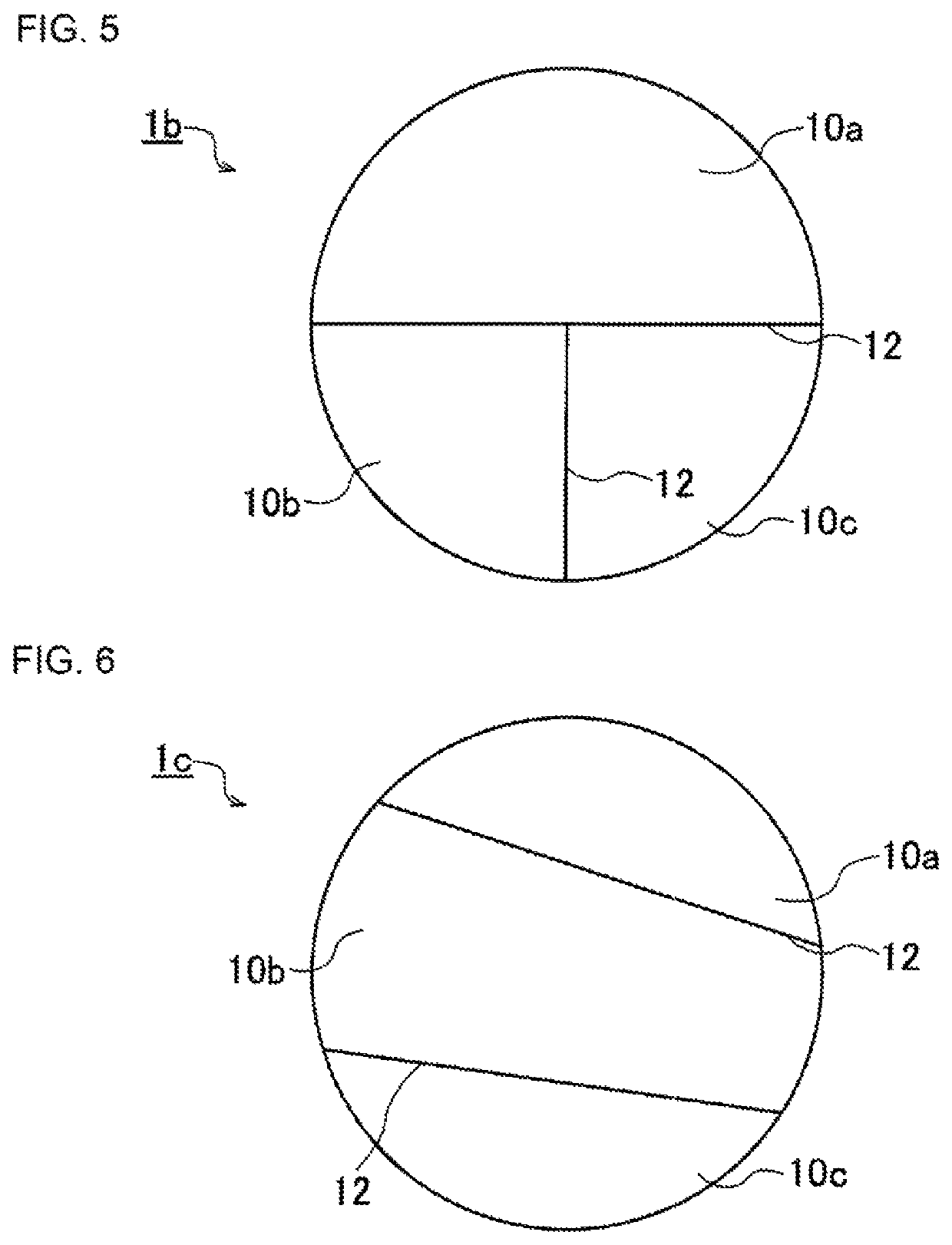

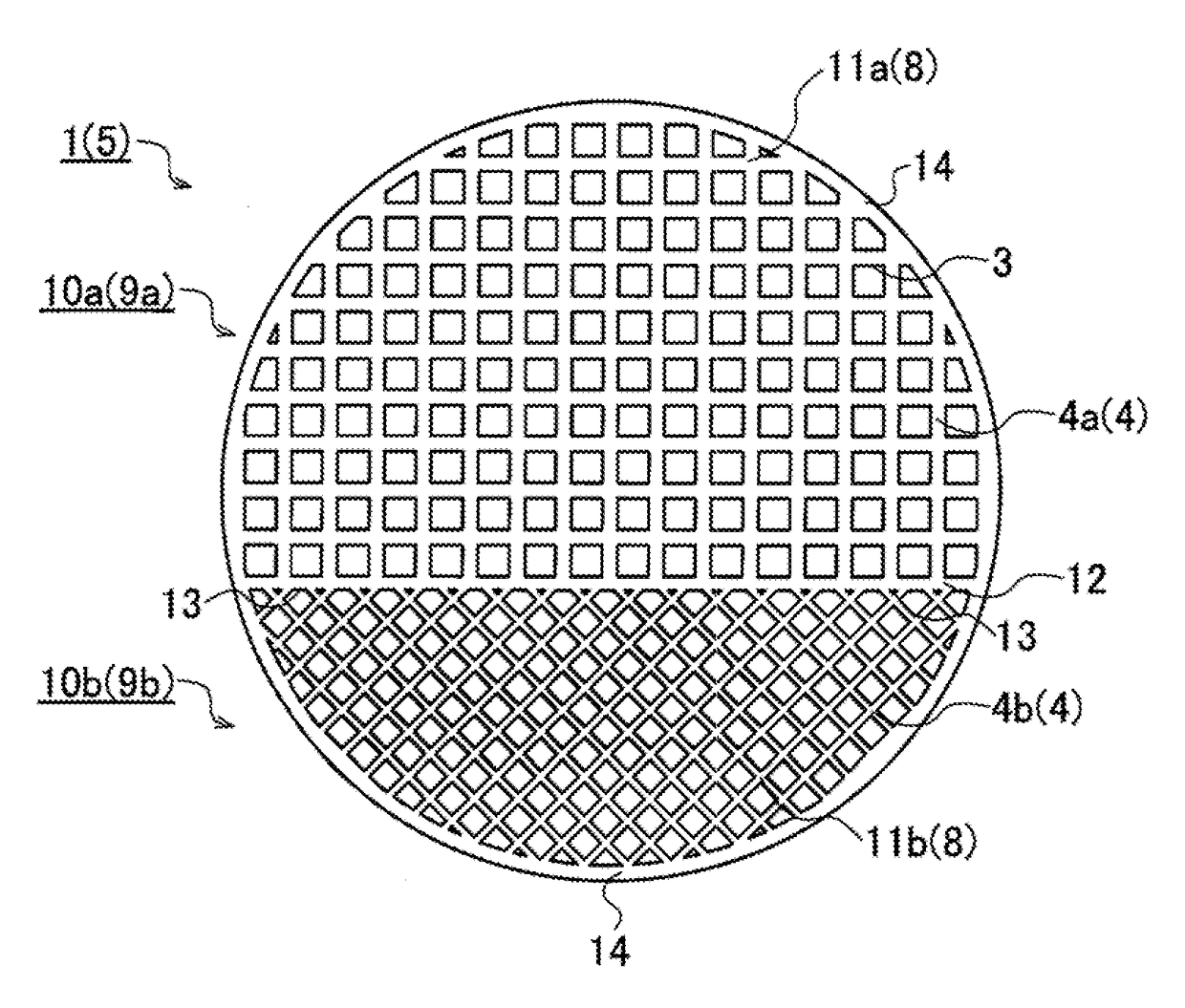

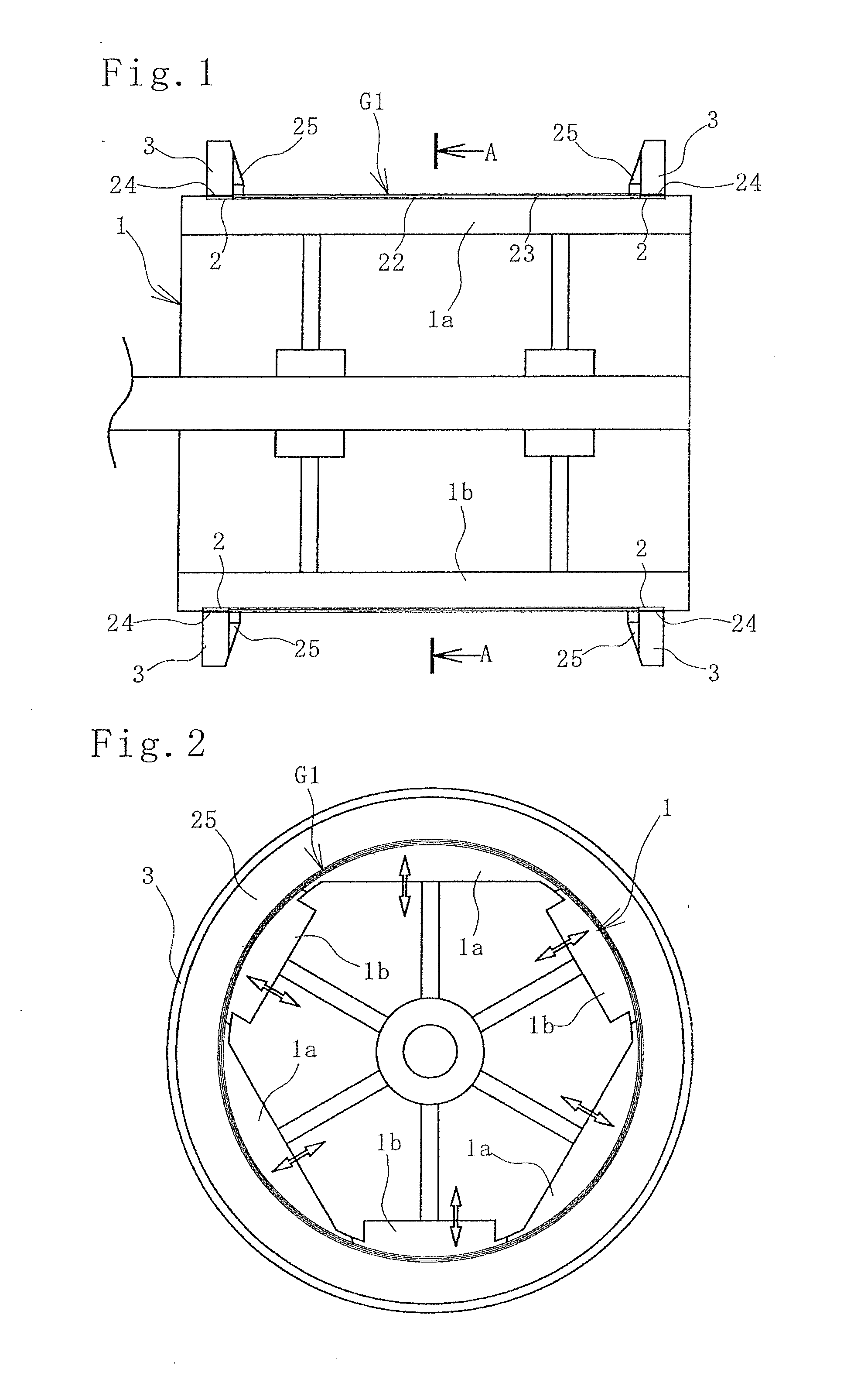

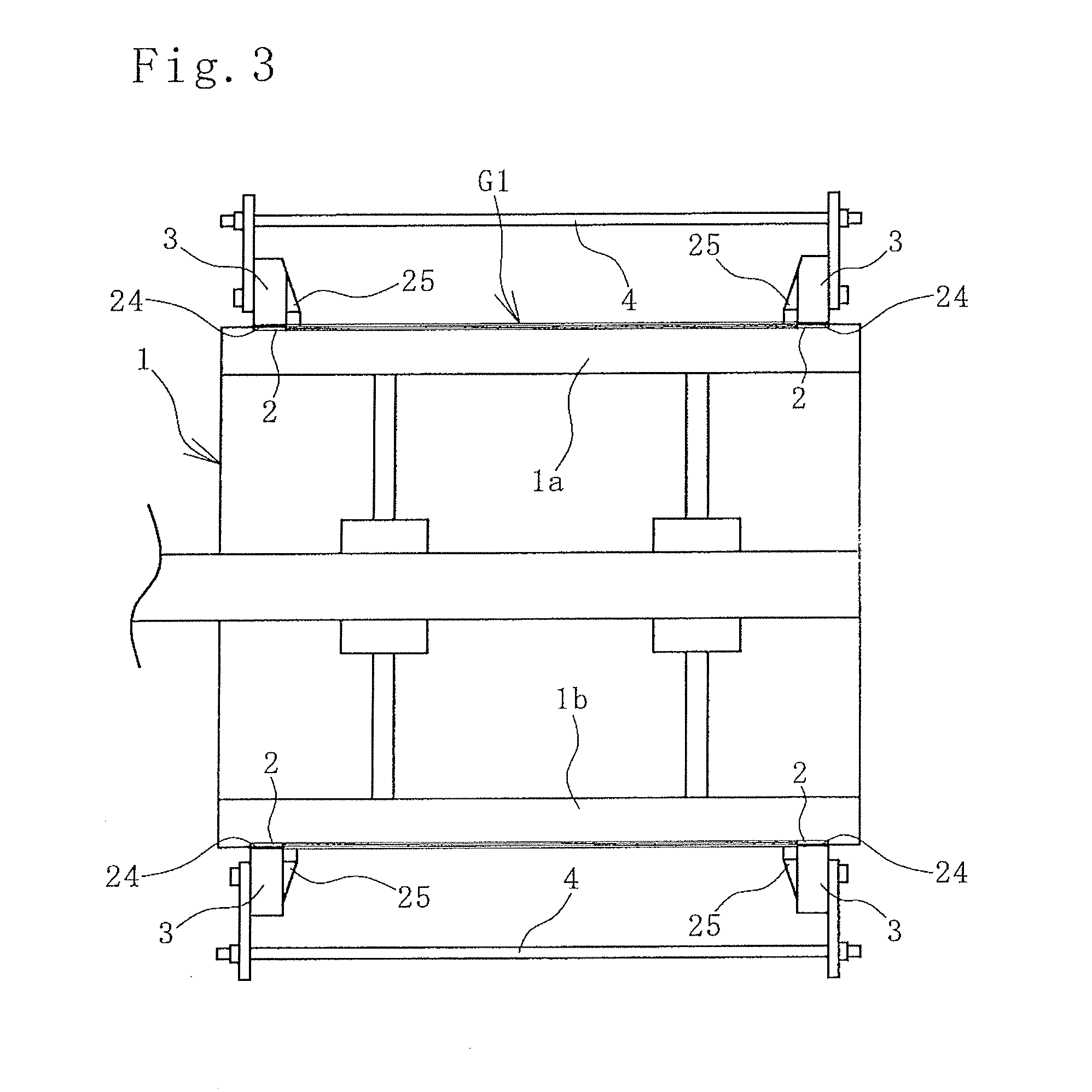

Honeycomb structure, and manufacturing method of honeycomb structure

ActiveUS10550746B2Avoid it happening againNon-uniformity can be correctedGas treatmentDispersed particle separationCell regionEngineering

Owner:NGK INSULATORS LTD

Honeycomb structure, and manufacturing method of honeycomb structure

ActiveUS20170276049A1Non-uniformity can be correctedEliminate unevennessGas treatmentDispersed particle separationUnit structureHoneycomb structure

A honeycomb structure has partition walls defining a plurality of polygonal cells which become through channels for a fluid, a structure end face vertical to an axial direction has at least two cell regions possessing mutually different cell structures and surrounded by circumferential portions, and in the cell regions adjacent to each other, to first partition walls of a first cell structure of one first cell region, second partition walls of a second cell structure of the other or second cell region are tilted.

Owner:NGK INSULATORS LTD

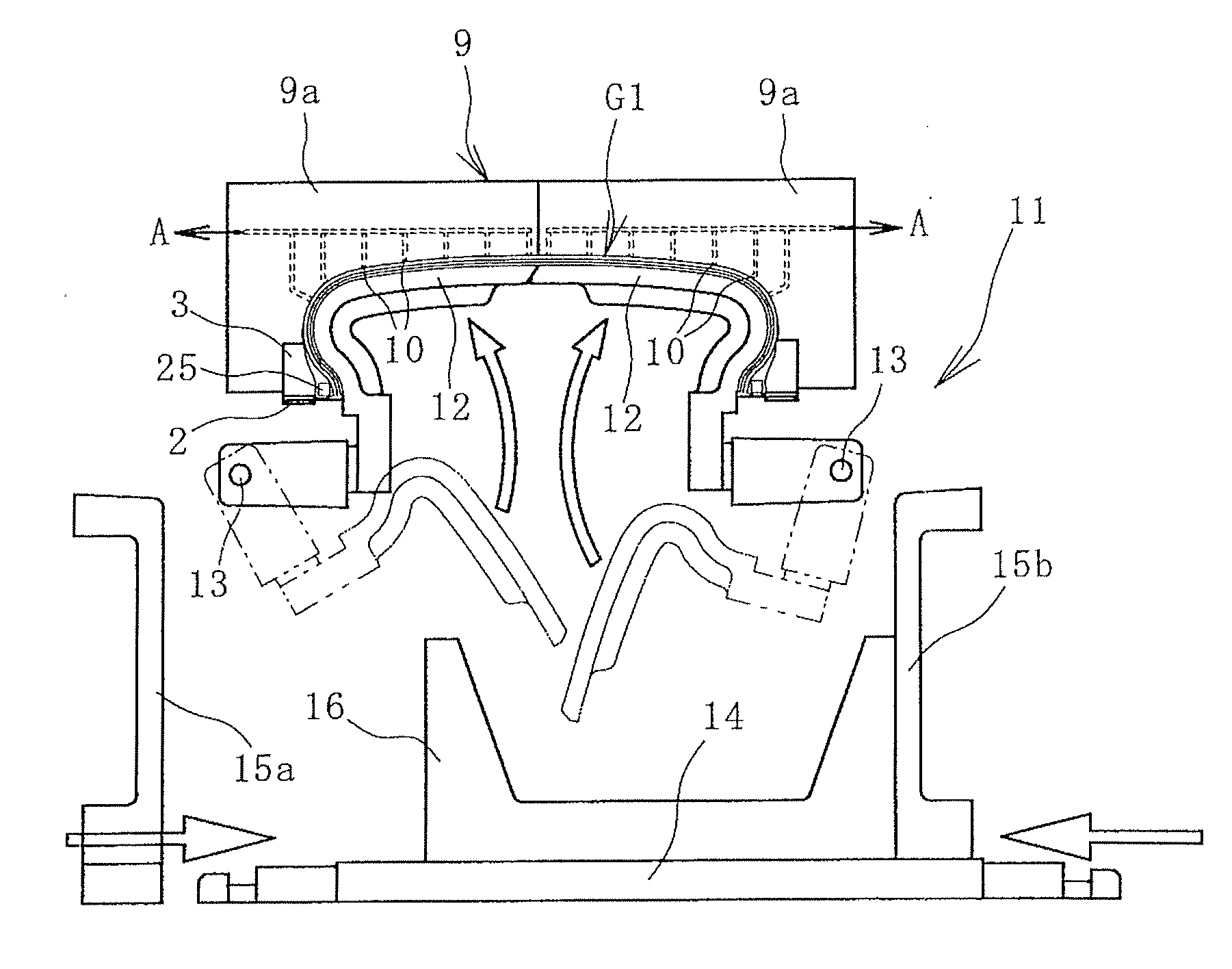

Method of manufacturing pneumatic tire

InactiveUS20120049398A1Smooth transferNon-uniformity can be correctedWithout separate inflatable insertsSpecial tyresElastomerEngineering

A cylindrical body is formed by mounting a carcass to the outer periphery of a film formed of thermoplastic resin or a thermoplastic resin elastomer composition. A molded body is formed by fitting bead rings on opposite width direction ends of the cylindrical body, and the molded body is sucked on a transfer mold's inner periphery. After a rigid inner mold is inserted into the molded body, suction stops and the molded body is transferred to the inner mold's outer periphery. Opposite carcass ends in a width direction are turned up on the inner mold, while other tire members are stacked on the molded body's outer periphery to mold a green tire. The tire and inner mold are placed in disposed inside a heated curing mold and the film is inflated to cure the tire and bond the film to the inner peripheral tire surface to form an inner layer.

Owner:YOKOHAMA RUBBER CO LTD

Inkjet recording apparatus and inkjet recording method

InactiveUS8042900B2Non-uniformity can be correctedReduce unevennessOther printing apparatusImage formationData acquisition

An inkjet recording apparatus includes: a treatment liquid deposition device which deposits on a recording medium a treatment liquid that insolubilizes or aggregates an ink; a recording head having nozzles which eject the ink; a non-uniformity correction amount storage device storing non-uniformity correction amount data which are prepared with respect to each of the plurality of nozzles and determined according to ejection characteristics of each of the plurality of nozzles; a data acquisition device which acquires density data of an image; a non-uniformity correction amount revision device which revises the non-uniformity correction amount data according to the density data related to another nozzle which ejects the ink that overlaps on the recording medium with the ink ejected by each of the plurality of nozzles, in such a manner that the non-uniformity correction amount data are determined; a non-uniformity correction device which corrects the density data according to the non-uniformity correction amount data; and an image forming device which controls the recording head according to the density data in such a manner that the image is formed on the recording medium.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com