Method for precisely controlling thinning of wafer

A technology of precise control and thin thickness, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unsatisfactory and unsatisfactory thickness control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

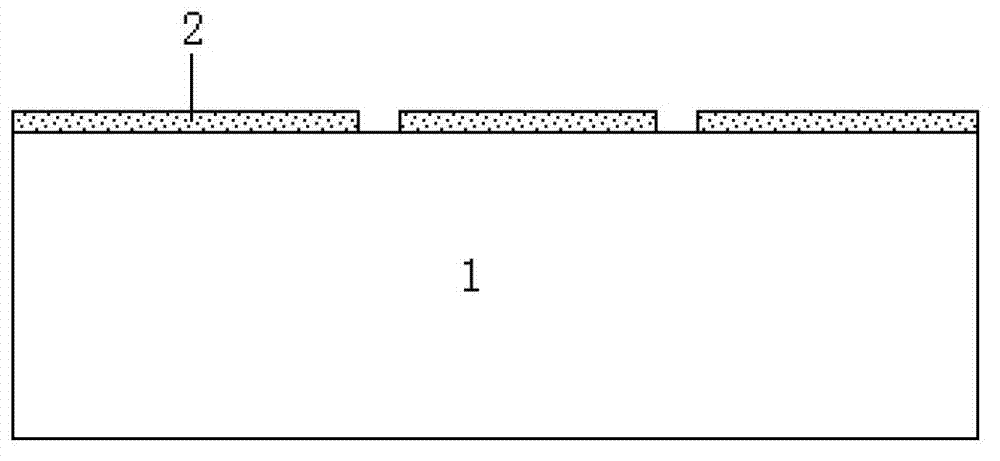

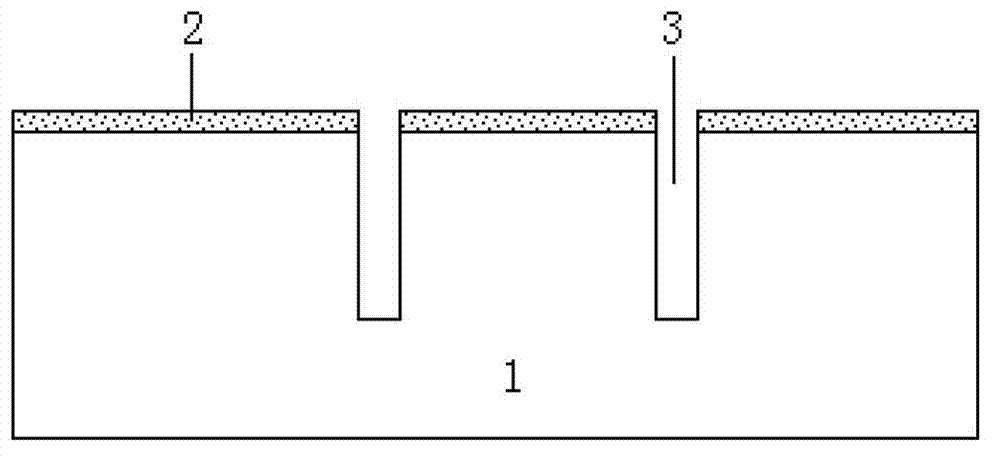

[0055] 1) Coat a layer of 4 micron photoresist 2 on the silicon wafer 1, and form a groove 3 pattern (such as a rectangle) at the cutting line.

[0056] 2) Using the plasma silicon etching method, the pattern of the trench 3 on the scribe line is etched to a specified thinning thickness of 15 microns (that is, the depth of the trench 3 is 15 microns).

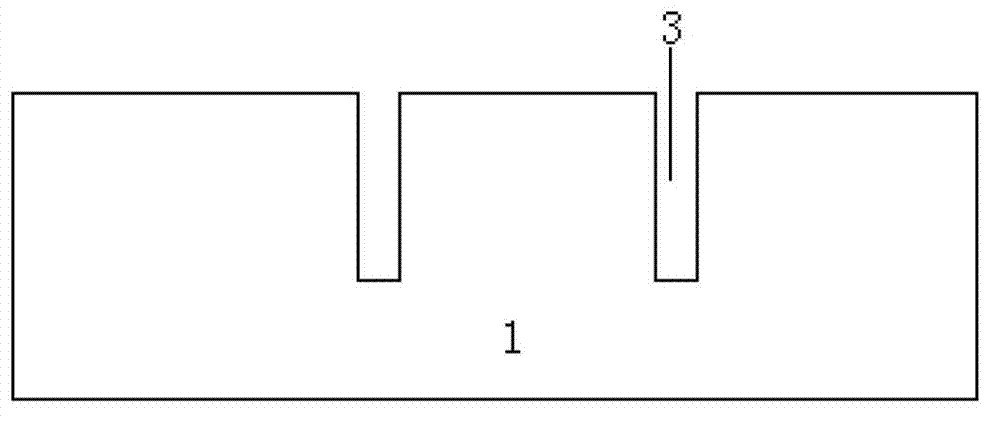

[0057] 3) A photoresist ashing machine is used to remove the photoresist 2 on the surface of the silicon wafer 1 .

[0058] 4) The groove 3 is filled with tungsten by using a low-pressure chemical vapor deposition method.

[0059] 5) Complete the wafer process.

[0060] 6) Paste the blue film on the front of the wafer.

[0061] 7) The wafer is thinned to the bottom of the groove by Taikoo, and the thinning machine is controlled to stop on the tungsten at the bottom of the groove 3 by means of current rise.

[0062] 8) Peel off the front blue film, and the wafer thinning is completed.

[0063] The advantage of wafer thinning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com