Method for producing liquid crystal display

A technology of liquid crystal display and manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of time-consuming, affecting the process yield, and cumbersome process steps of the alignment layer, and achieve the effect of reducing the difference in thickness and improving the process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

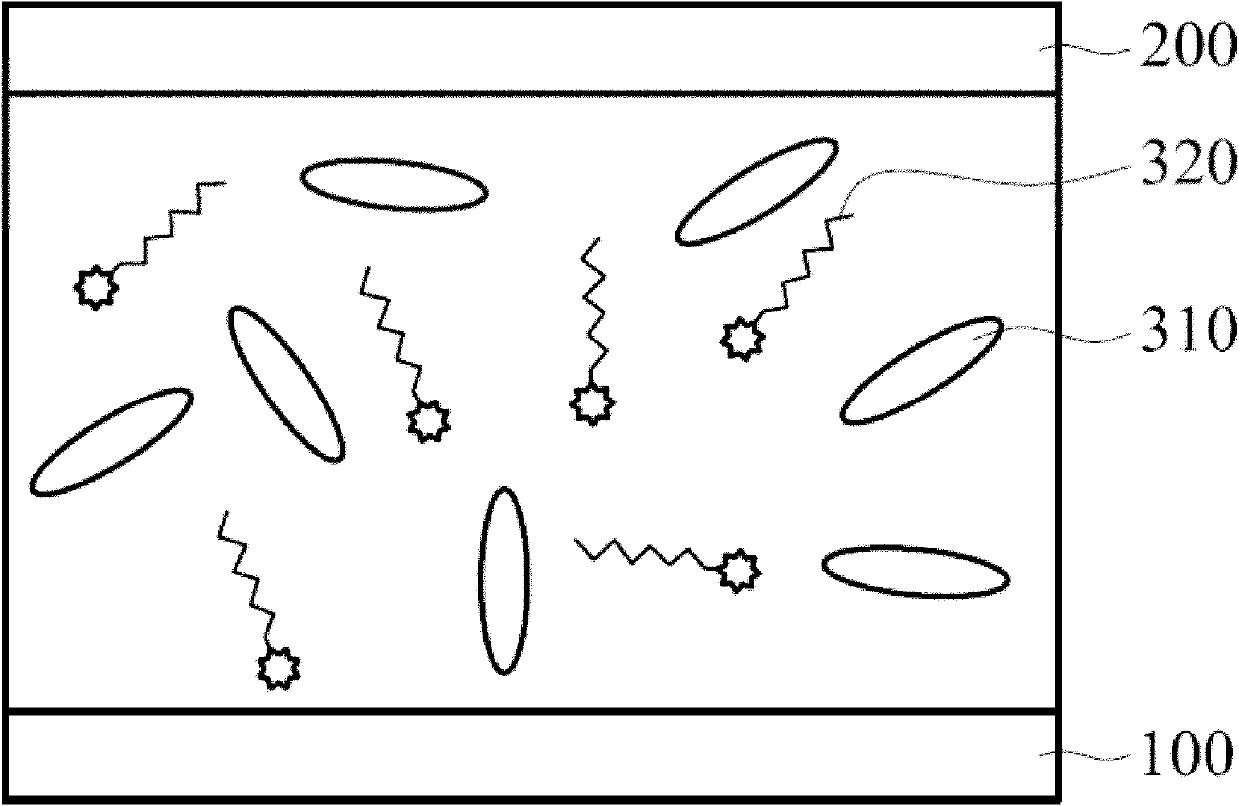

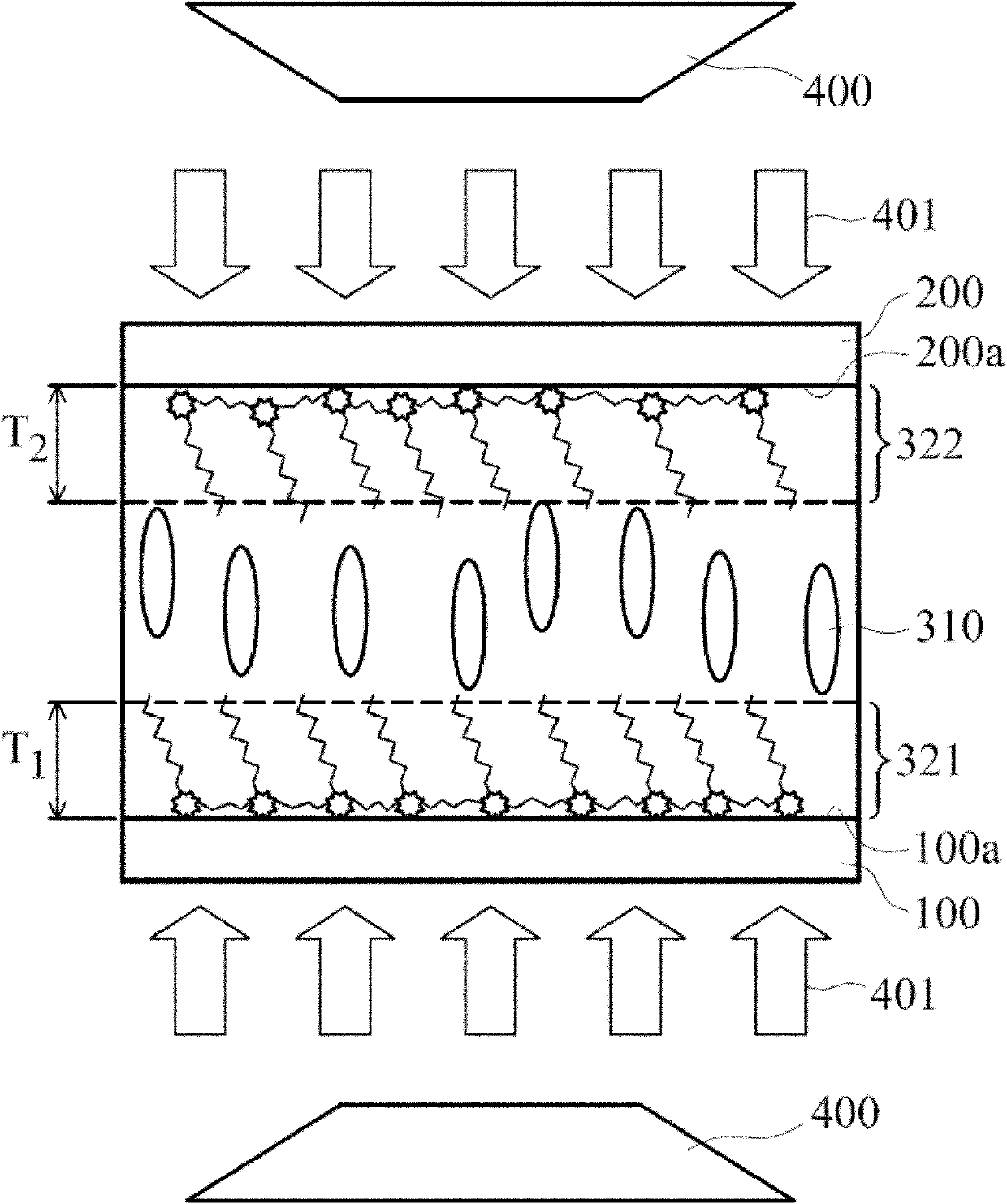

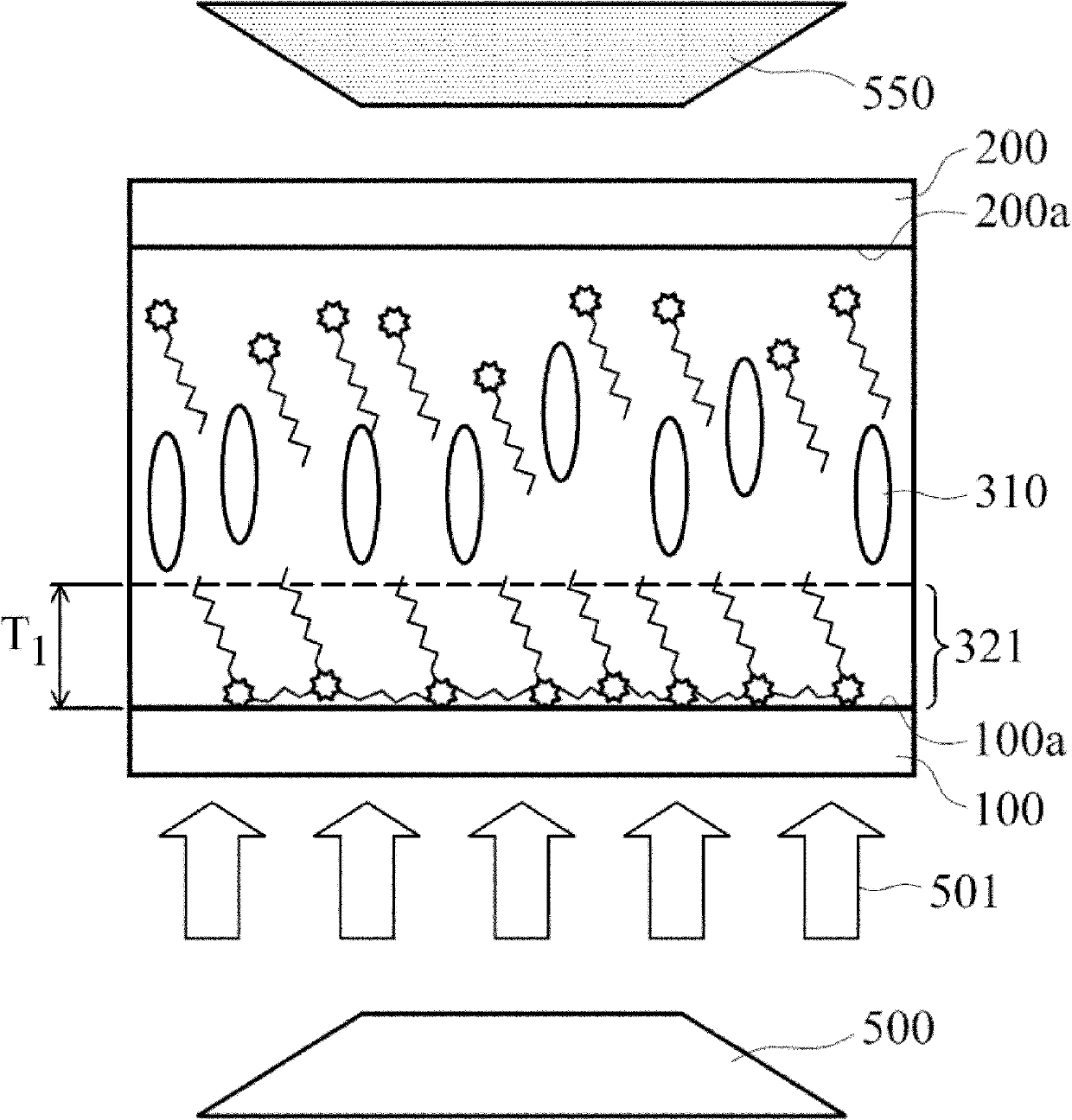

[0029] The present invention provides a method for manufacturing a liquid crystal display, Figure 1 to Figure 2 Process steps of a liquid crystal display according to an embodiment of the present invention are shown. First, see figure 1 , the first substrate 100 and the second substrate 200 are provided, wherein the first substrate 100 and the second substrate 200 are disposed opposite to each other. In one embodiment, the first substrate 100 is a thin film transistor substrate, and the second substrate 200 is a color filter substrate, wherein the thin film transistor substrate 100 further includes pixel control structures such as thin film transistor structures, pixel electrodes, scan lines and data lines ( not shown in the figure).

[0030] After that, the mixed solution is filled between the first substrate 100 and the second substrate 200, and the mixed solution can be injected into the first substrate 100 and the second substrate by one drop filling (ODF) or injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com