Method and device for uniform magnetron sputtering deposition on inner surface of axisymmetric curved member

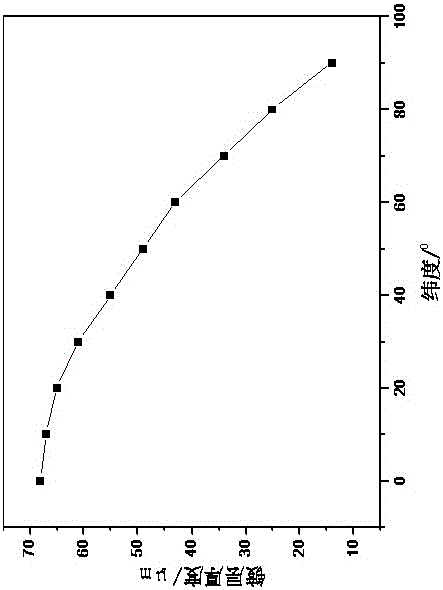

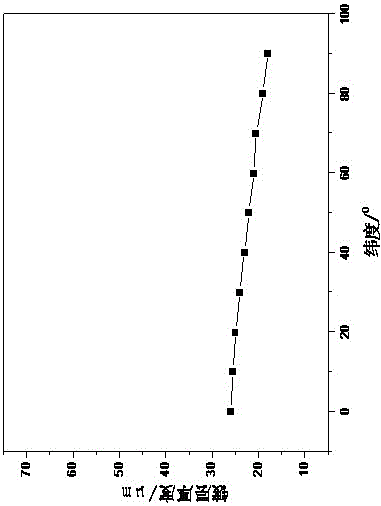

A magnetron sputtering and deposition method technology, applied in the field of magnetron sputtering and coating, can solve the problems of coating thickness difference, poor uniformity, low coating deposition rate, etc., to reduce thickness difference, improve uniformity, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

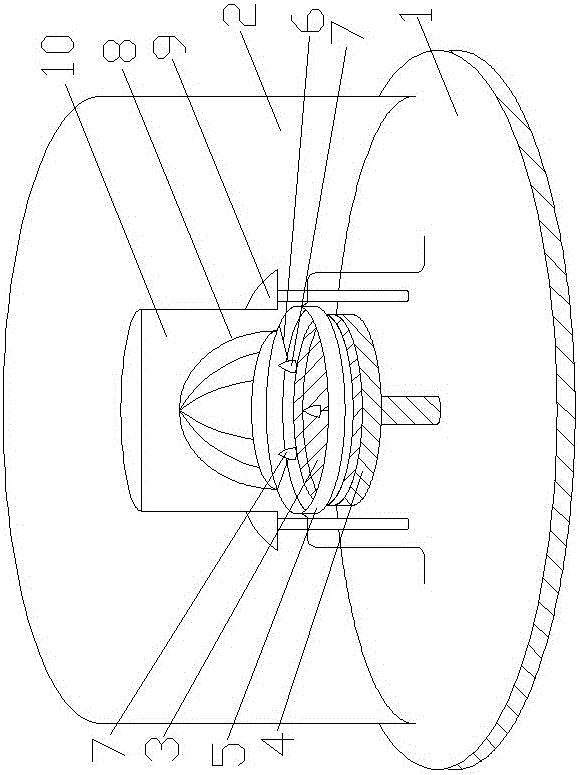

[0047] The device used in this embodiment is shown in the figure. The device includes a base, a vacuum chamber arranged on the base and matched with the base, a planar magnetron sputtering target, a sputtering target body, an auxiliary anode ring matched with the sputtering target body, a bracket, a metal baffle, and a The rotating device for the relative rotation of the axisymmetric curved surface part relative to the metal stopper, the protective cover for protecting the outer surface of the axisymmetric curved surface part, the base is connected with the vacuum chamber to form a vacuum system, the planar magnetron sputtering target, the sputtering target body, The auxiliary anode ring, support, metal baffle, rotating device, and protective cover are respectively arranged in the vacuum system, the planar magnetron sputtering target is arranged on the sputtering target body, the auxiliary anode ring is arranged above the planar magnetron sputtering target, and the sputtering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com