Multifunctional composite modificator for cast steel

A modifier and multifunctional technology, applied in the field of multifunctional composite modifiers, can solve the problems of high content of sulfur and phosphorus, low toughness and wear resistance, coarse grains, etc. The effect of reducing cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A multifunctional compound modifier suitable for cast steel, comprising the following components in mass percentage:

[0045] Si 3 N 4 : 20%, AlN: 18%, Fe-SiRE: 7%, Al: 16%, Mg: 6%, Nb: 8%, V: 8%, CaO: 17%.

[0046] When in use, the molten steel is operated according to the normal smelting process, the modifier is added into the ladle, and the impact force of the molten steel is used to stir it evenly.

Embodiment 2

[0048] A multifunctional compound modifier suitable for cast steel, comprising the following components in mass percentage:

[0049] Si 3 N 4 : 22%, AlN: 16%, Fe-SiRE: 8%, Al: 17%, Mg: 7%, Nb: 7%, V: 9%, CaO: 16%.

[0050] When in use, the molten steel is operated according to the normal smelting process, the modifier is added into the ladle, and the impact force of the molten steel is used to stir it evenly.

Embodiment 3

[0052] A multifunctional compound modifier suitable for cast steel, comprising the following components in mass percentage:

[0053] Si 3 N 4 : 23%, AlN: 16%, Fe-SiRE: 6%, Al: 18%, Mg: 5%, Nb: 7%, V: 10%, CaO: 15%.

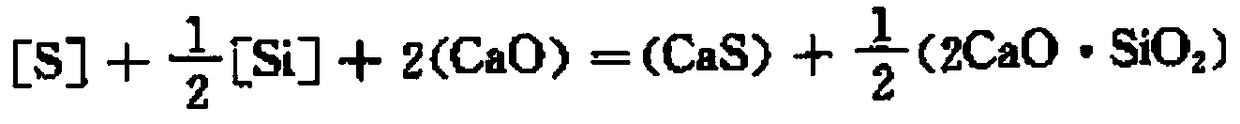

[0054] The desulfurization reaction is as follows:

[0055]

[0056]

[0057] [S]+[C]+(CaO)=(CaS)+{CO}

[0058] The reaction of desulfurization phosphorus oxygen is as follows:

[0059] [P]+5[O]+4(CaO)=(4CaO·P 2 o 5 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com