Method for preparing ultrafine grained high performance anisotropic Nd-Fe-B permanent magnet

An anisotropic, NdFeB technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of limiting magnet energy product, inhomogeneity, deformation magnet inhomogeneity, etc., to improve the magnet Performance, improvement of uniformity, effect of inhibiting grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, the raw material is commercial MQU-F quick-quenching powder, and the anisotropic single-phase NdFeB permanent magnet block material is prepared by hot pressing and hot deformation method, as follows:

[0029] (1) The nanocrystalline MQU-F powder was pressed into a vacuum induction hot pressing furnace to obtain an isotropic magnet. The specific molding conditions are: the vacuum degree before heating up is better than 4×10 -2 Pa, then heat up at a heating rate of 80-150° C. / min to a pressing temperature of 650° C. for hot pressing at a pressing pressure of 210 MPa, and hold the pressure for 3 minutes after hot pressing.

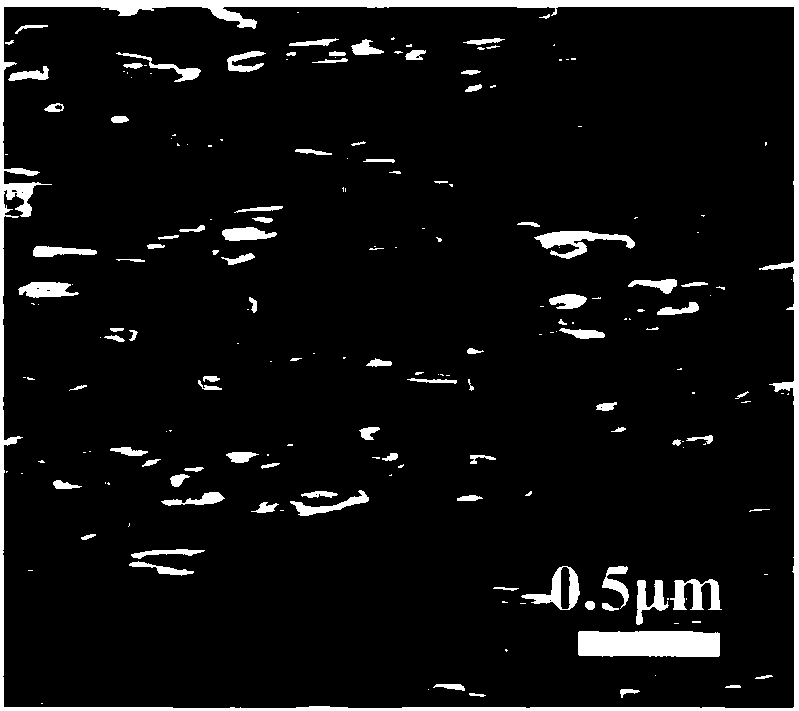

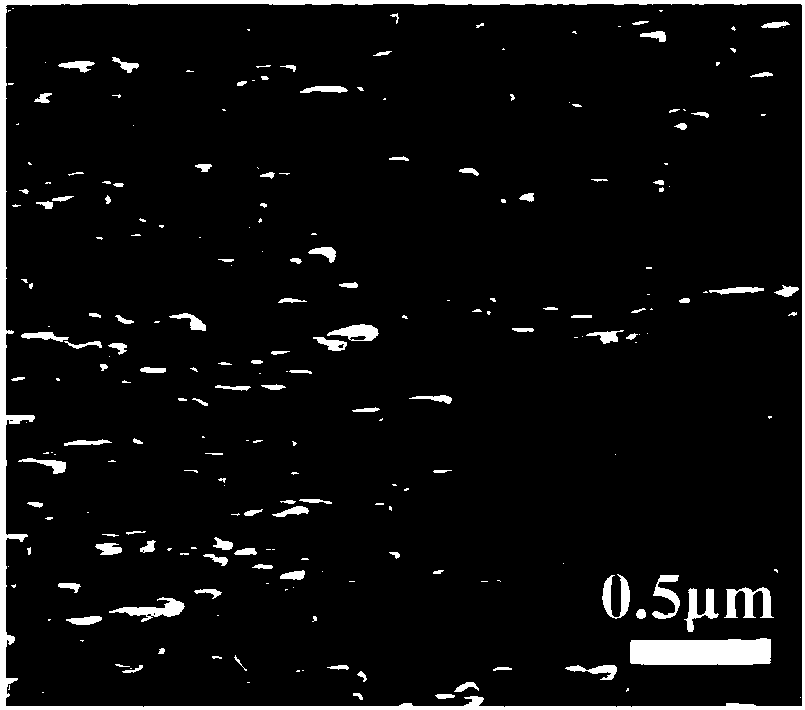

[0030] (2) Put the isotropic magnet obtained in (1) into the Cu sheath and then put it into the mold, and press and deform it to the predetermined size in a vacuum induction hot-pressing furnace at 550°C to obtain Anisotropic NdFeB magnets. The specific deformation process is: vacuumize the sample chamber to 5×10 before thermal defor...

Embodiment 2

[0032] In this embodiment, the raw materials are exactly the same as those in Example 1, and the anisotropic single-phase NdFeB permanent magnet block material is prepared by hot pressing and thermal deformation method, as follows:

[0033] (1) is exactly the same as the step (1) of embodiment 1;

[0034] (2) It is basically the same as step (2) of Example 1, except that the deformation temperature is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com