Optimized production method of Tri (tribromophenyl) cyanurate

A production method, bromotriazine technology, applied in the field of optimized bromotriazine production, can solve the problems of complex bromination of phenol, difficult control of process parameters, large consumption of raw materials, etc., to reduce the content of benzene waste and avoid Hydrolysis of cyanuric chloride, good fluidity of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

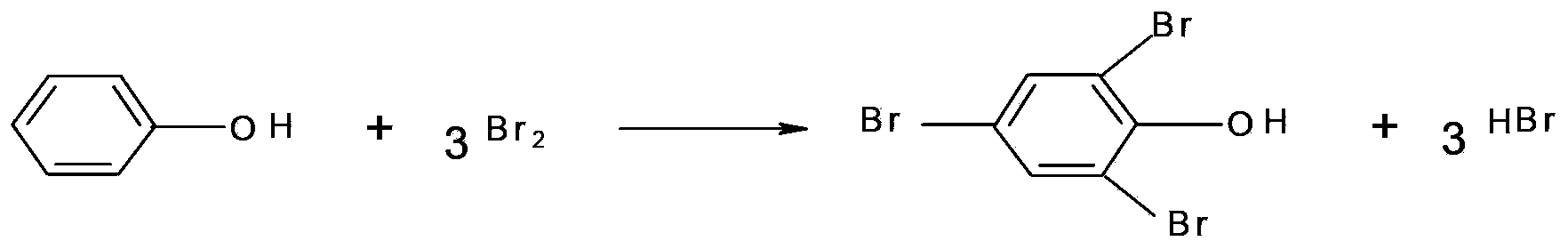

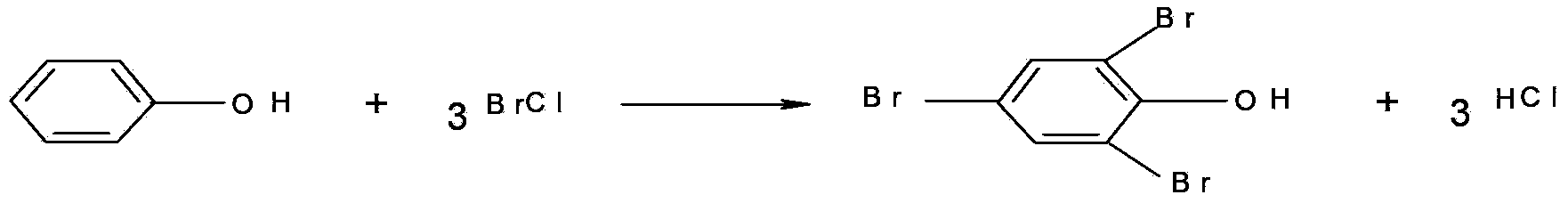

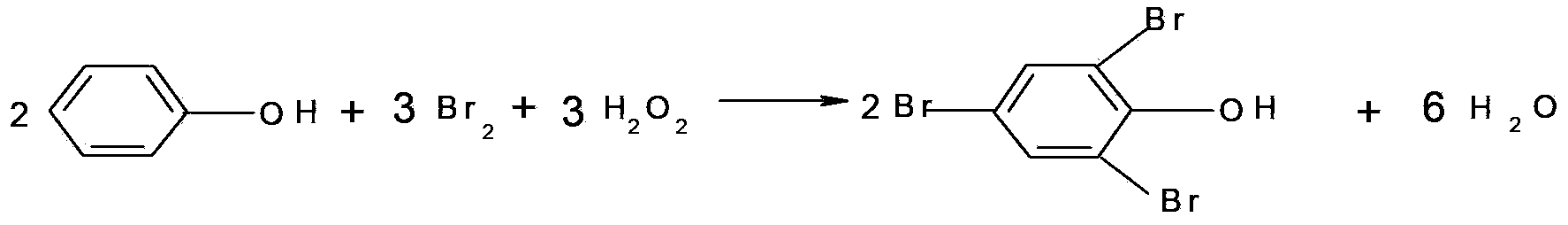

Method used

Image

Examples

Embodiment 1

[0063] (1) Add chlorobenzene to the reactor, then add phenol, and then add 27.5wt% hydrogen peroxide and bromine to it in a dislocation manner. The dislocation addition refers to adding hydrogen peroxide first, and then adding bromine to it after 0.5 hours. The molar ratio of bromine, hydrogen peroxide and bromine is controlled at 1:2.3, the reaction temperature is 20°C, and the reaction is continued for 1.5 hours after the bromine is added dropwise. , to obtain the washing solution and the reaction solution after washing;

[0064] (2) Add a certain amount of acid to the washing liquid in step (1), control the pH value at 2, use chlorobenzene to extract, and combine the obtained extract with the washed reaction liquid in step (1) to obtain tribromophenol Mixture with chlorobenzene;

[0065] (3) Add the mixture of tribromophenol and chlorobenzene obtained in step (2) into the reactor, add cyanuric chloride to it, then add the initiator (hexadecyltrimethylammonium bromide), anh...

Embodiment 2

[0068] (1) Add chlorobenzene to the reactor, then add phenol, and then add 27.5wt% hydrogen peroxide and bromine to it dislocation dropwise, the dislocation dropwise addition refers to adding hydrogen peroxide dropwise first, and then adding bromine dropwise to it after 0.7 hours The molar ratio of bromine, hydrogen peroxide and bromine is controlled at 1:3, the reaction temperature is 30°C, and the reaction is continued for 1.5 hours after the dropwise addition of bromine, and the pH value is adjusted to 3.5. After the material liquid turns blood red, it is washed with alkali and water , to obtain the washing solution and the reaction solution after washing;

[0069] (2) Add a certain amount of acid to the washing liquid in step (1), control the pH value at 3, use chlorobenzene to extract, and combine the obtained extract with the washed reaction liquid in step (1) to obtain tribromophenol Mixture with chlorobenzene;

[0070] (3) Add the mixture of tribromophenol and chlorob...

Embodiment 3

[0073] (1) Add chlorobenzene to the reactor, then add phenol, and then add 27.5wt% hydrogen peroxide and bromine to it dislocationally, and the dislocation dropwise refers to adding hydrogen peroxide dropwise first, and then adding bromine dropwise to it after 1 hour The molar ratio of hydrogen peroxide and bromine is controlled at 1:2, the reaction temperature is 10°C, and the reaction is continued for 1.5 hours after the bromine is added dropwise, and the pH value is adjusted to 3.5. Washing to obtain a washing solution and a reaction solution after washing;

[0074] (2) Add a certain amount of acid to the washing liquid in step (1), control the pH value at 2.5, use chlorobenzene to extract, and combine the obtained extract with the washed reaction liquid in step (1) to obtain tribromophenol Mixture with chlorobenzene;

[0075] (3) Add the mixture of tribromophenol and chlorobenzene obtained in step (2) into the reactor, add cyanuric chloride to it, then add the initiator (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com