Method for making shock-resistant and energy-dissipating framework by mixing resin concrete and reinforced concrete

A technology of resin concrete and reinforced concrete, which is applied in the fields of earthquake resistance, building components, construction, etc., can solve problems such as structural damage, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

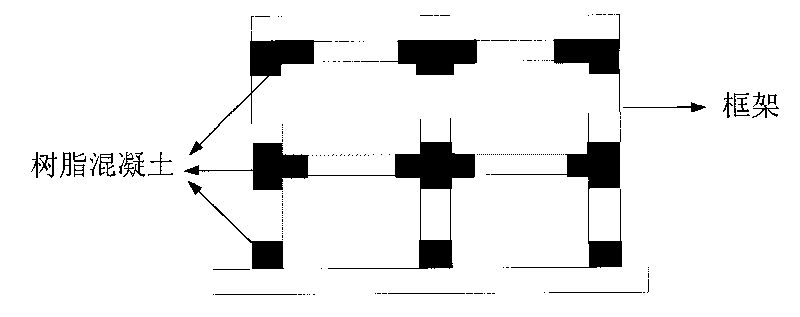

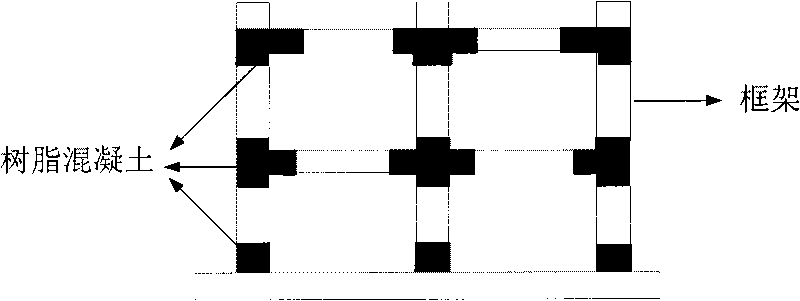

[0025] The present invention will be further described below with specific examples, and the resin concrete mixed reinforced concrete frame structure schematic diagram of anti-seismic energy dissipation of the present invention is shown in figure 1 shown.

[0026] The invention discloses a method for preparing an anti-seismic and energy-dissipating resin concrete mixed reinforced concrete frame. The resin concrete can be manually stirred or stirred by an ordinary concrete mixer according to the size of the reinforced concrete. Specific steps are as follows:

[0027] Step 1: After the frame steel bars are bound, reserve the beam-column joints and column roots of the frame structure (that is, the positions where plastic hinges may appear in the frame), and pour other parts according to the original construction design;

[0028] Step 2: After the concrete poured in the frame has been cured for 14 days, the stubble of the concrete around the reserved position is chiseled out (to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com