Automatic horizontal flue-cured tobacco bale loosing device of tobacco slice making line in cigarette factory

A silk-making line, automatic technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of uneven thickness of slices, unsatisfactory moisture regaining effect, fiber crushing, etc., and achieves good working environment, rapid overall action, and crushing. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

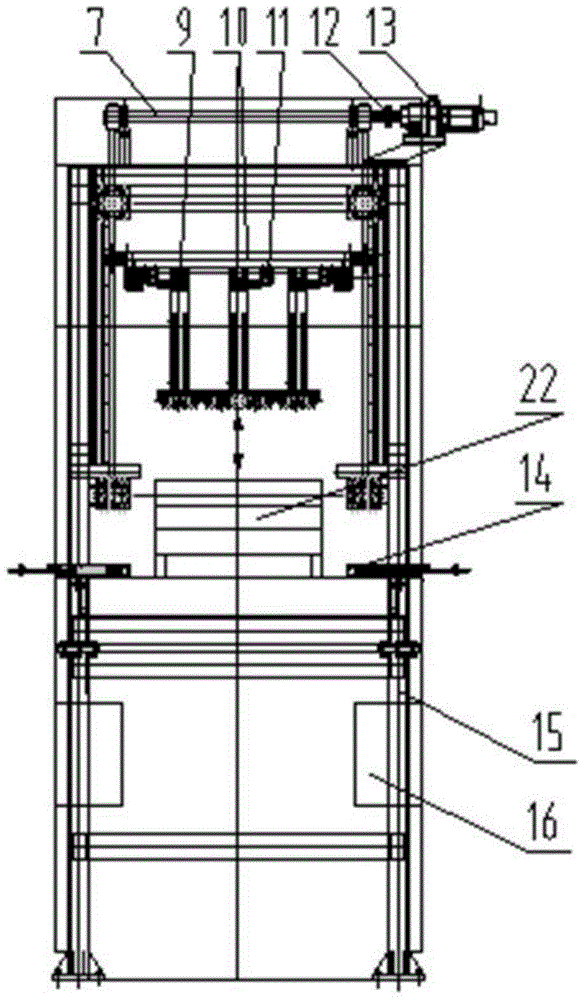

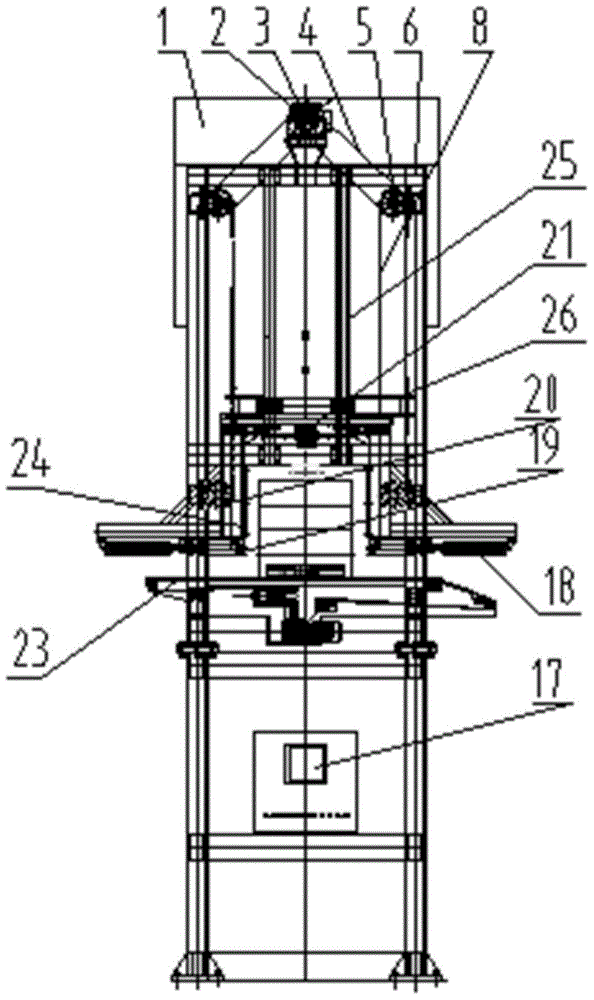

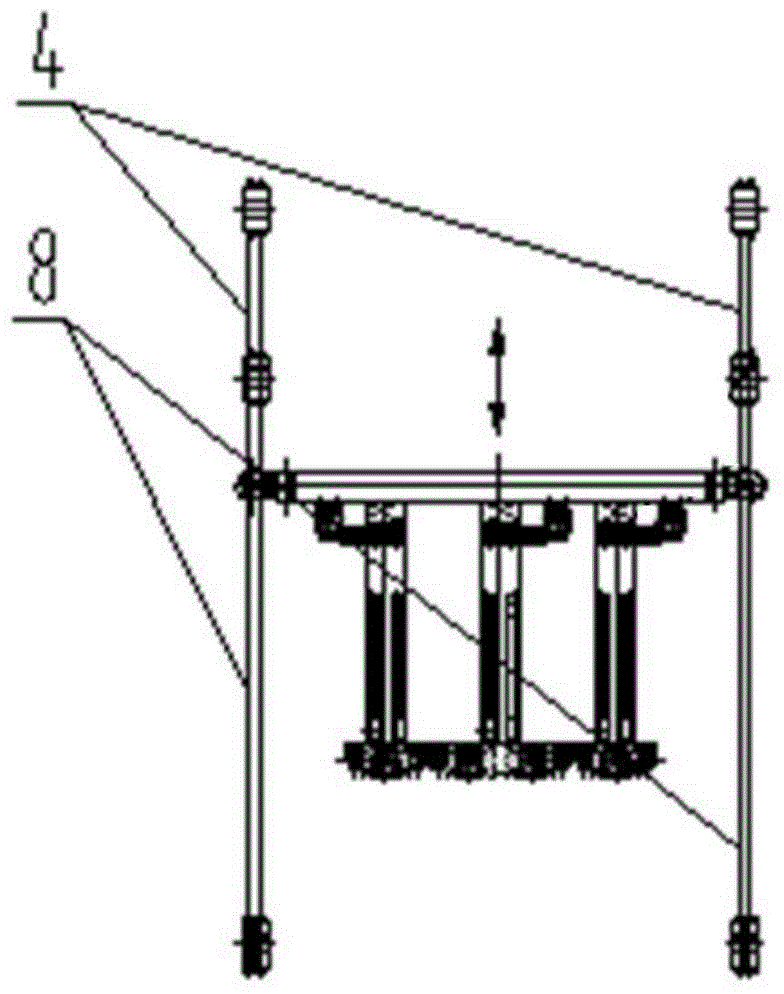

[0017] See Figure 1-Figure 8 As shown, a tobacco factory-made silk thread automatic roasting sheet cigarette bale horizontal loosening device, the present invention is composed of upper frame 6 and lower frame 15; conveyor 23 is arranged at the lower end of upper frame 6, above conveyor 23 A clamping cylinder and a push plate 14 are provided, and the mounting base 10 is connected to the upper part of the upper frame 6 through a chain and a chain connecting pin 26. The mounting base 10 is connected to the clamping leg 9 through a slider, and the clamping leg 9 is clamped by connecting a quick connection. Leg drives the cylinder 11; a knife-inserting drive cylinder 18 with a knife 19 is connected to the inner side of the clamping leg 9, and the clamping legs 9 on both sides are connected by a slider crank mechanism 21. Power is provided by the clamping leg driving cylinder 11 , and the closing and opening of the clamping leg 9 is realized through a crank slider mechanism 21 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com