Multifunctional copper wire separator

A copper rice machine, multi-functional technology, applied in grain processing, dispersed particle separation, chemical instruments and methods, etc., can solve environmental and operator damage, a large amount of harmful dust, electrostatic separator and bag filter equipment cost Increase and other problems to achieve the effect of preventing physical health and good screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

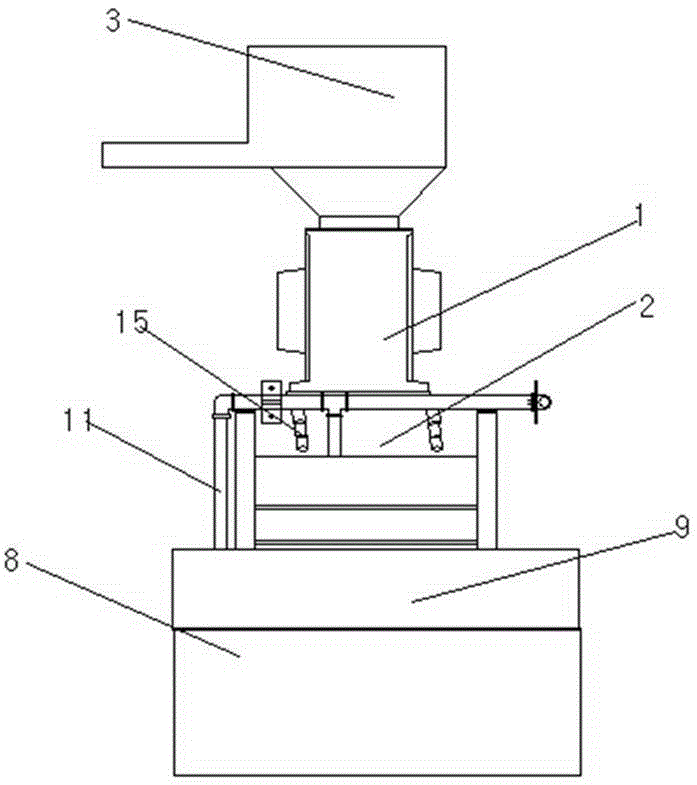

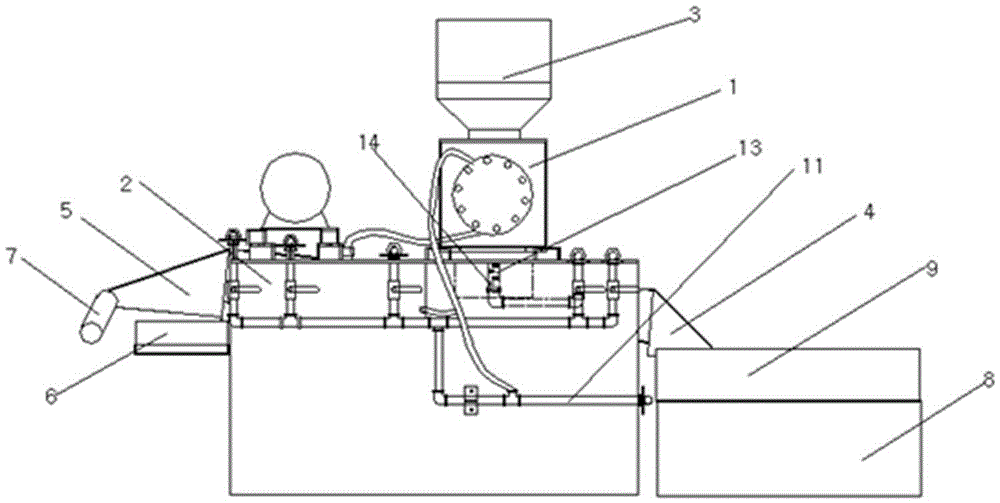

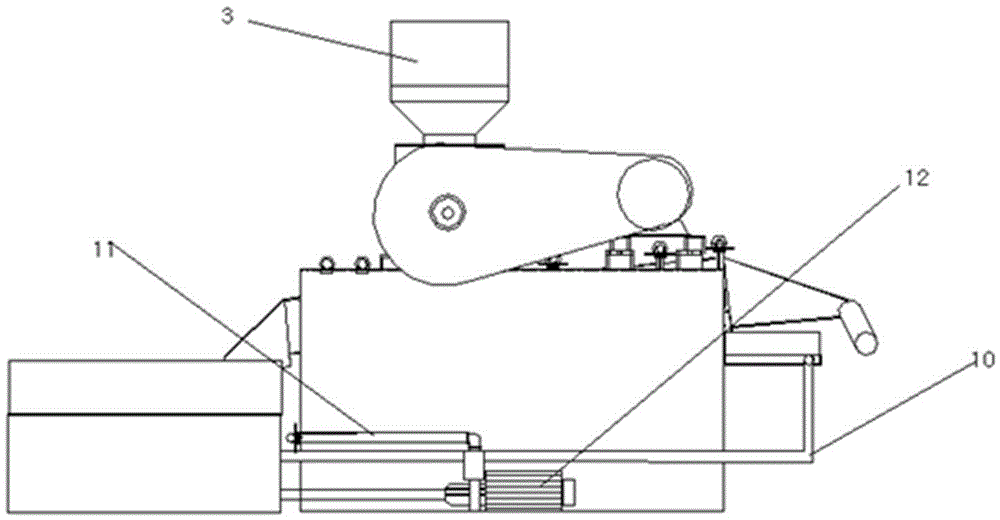

[0020] The present invention will be further described below in conjunction with accompanying drawing: As shown in the figure,

[0021] A multifunctional copper rice machine, comprising a frame, on which a pulverizer 1 and a separator 2 are sequentially arranged from top to bottom, wherein the upper end of the pulverizer 1 is provided with a feeding port, and the lower end of the pulverizer 1 is provided with a separator The discharge port connected to the feed port can also be provided with a feed hopper 3 at the feed port of the pulverizer. One side of the feed hopper is provided with a feed port, and the lower end of the feed hopper is provided with a discharge port connected to the pulverizer. At the feed port, in order to prevent the dust generated by the pulverizer from spreading into the air and harm the health of the workers, a dust-proof curtain can also be installed at the feed port. In order to prevent the dust generated by the pulverizer from diffusing into the air,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com