Crusher with functions of impact crushing and extrusion shearing crushing

A pulverizer and functional technology, which is applied in cocoa, grain processing, food science, etc., can solve problems such as excessive angle, achieve the effect of improved pulverization function, powerful pulverization function, and less consumption of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Directions Instructions:

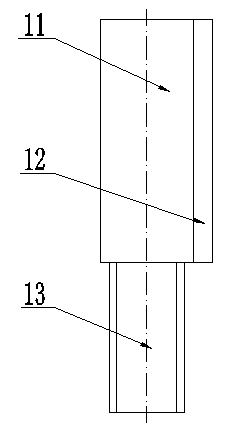

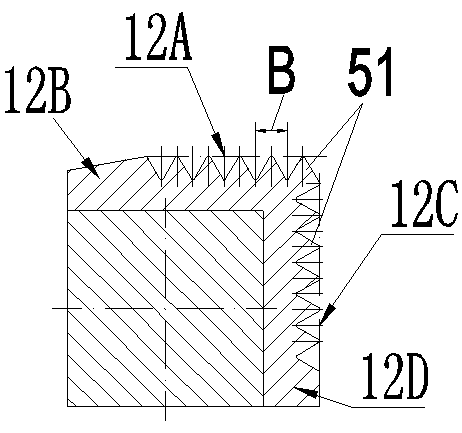

[0028] The pins installed on the rotor disc 8 and the stator disc 7 (including the rotor pin 6 and the stator pin 5) and other parts are inward in the direction close to the axis of the rotor disc 8 or stator disc 7, and outward in the opposite direction; The tangential direction of the shaped rotor disc 8 or the stator disc 7 is tangential, Figure 4 The direction indicated by the middle arc arrow is the rotation direction of the rotor disk 8 .

[0029] Structure description:

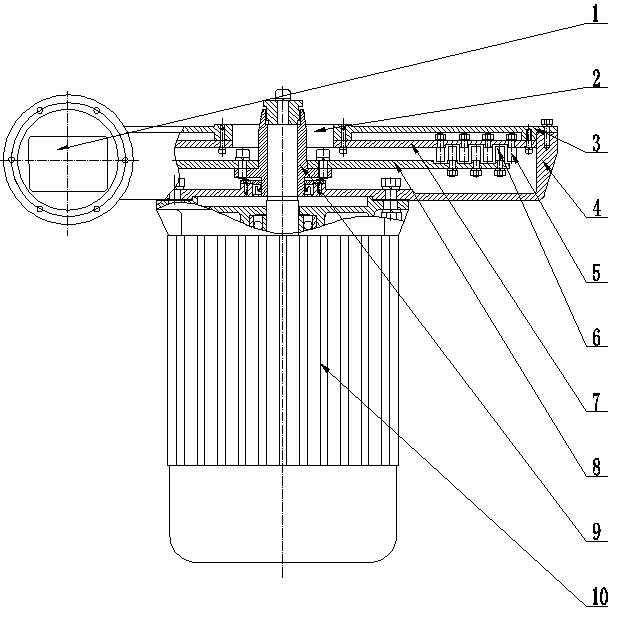

[0030] Such as figure 1 as well as Figure 2 to Figure 4 As shown, the pulverizer with impact crushing and extrusion shearing crushing functions of the present invention includes a motor 10, a casing 4, a rotor component and a stator component. The casing 4 is a disc-shaped shell with high sides on the periphery. The casing 4 is provided with a rectangular discharge port 1 along the tangential direction. The lower end surface of the casing 4 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com