Efficient waste paper pulverizing device

A high-efficiency crushing and waste paper technology, applied in the field of papermaking, can solve the problems of long working stroke, poor practicability, and inapplicability of the crank-connecting rod structure, and achieve the effect of convenient operation and maintenance for workers, convenient operation and maintenance, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

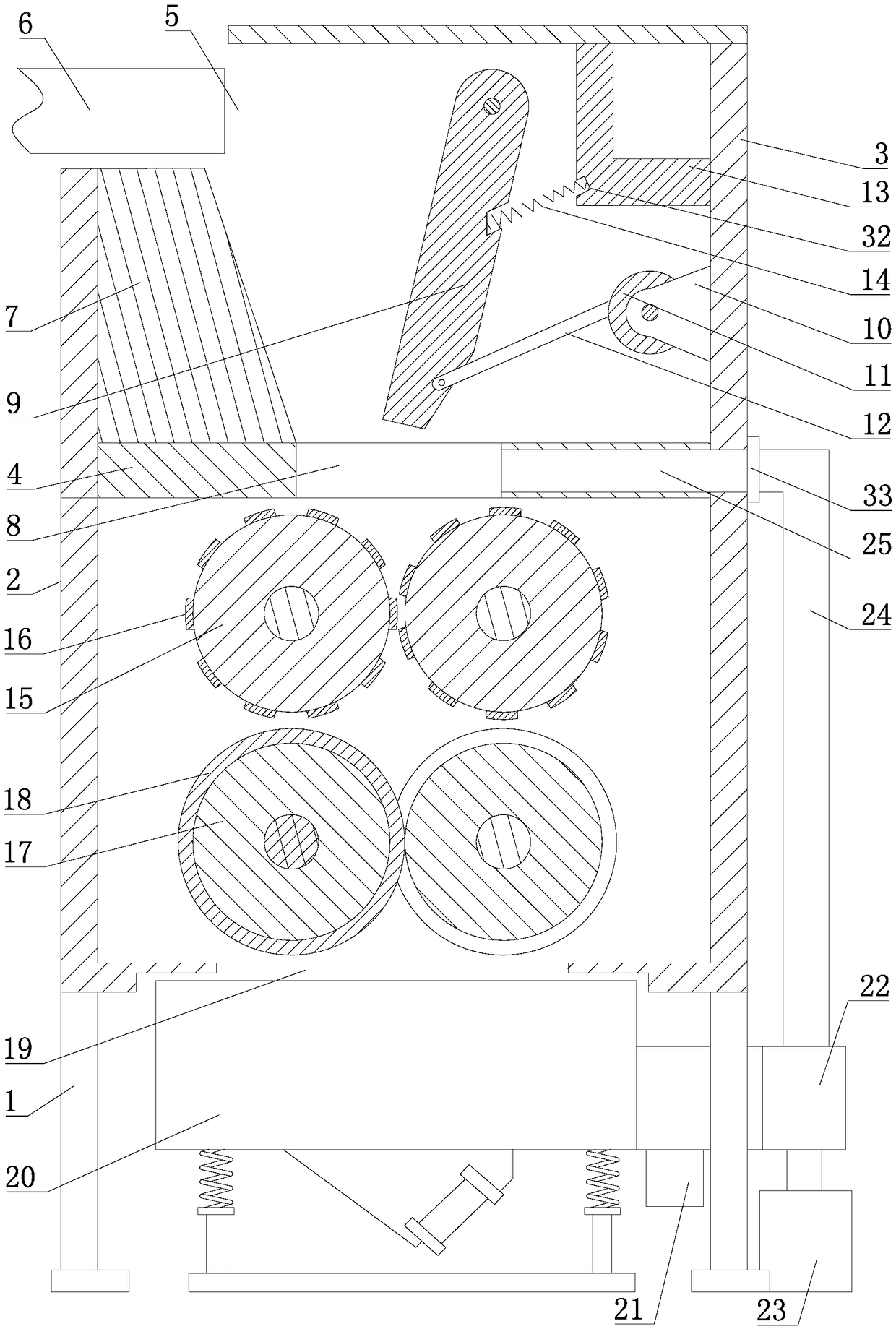

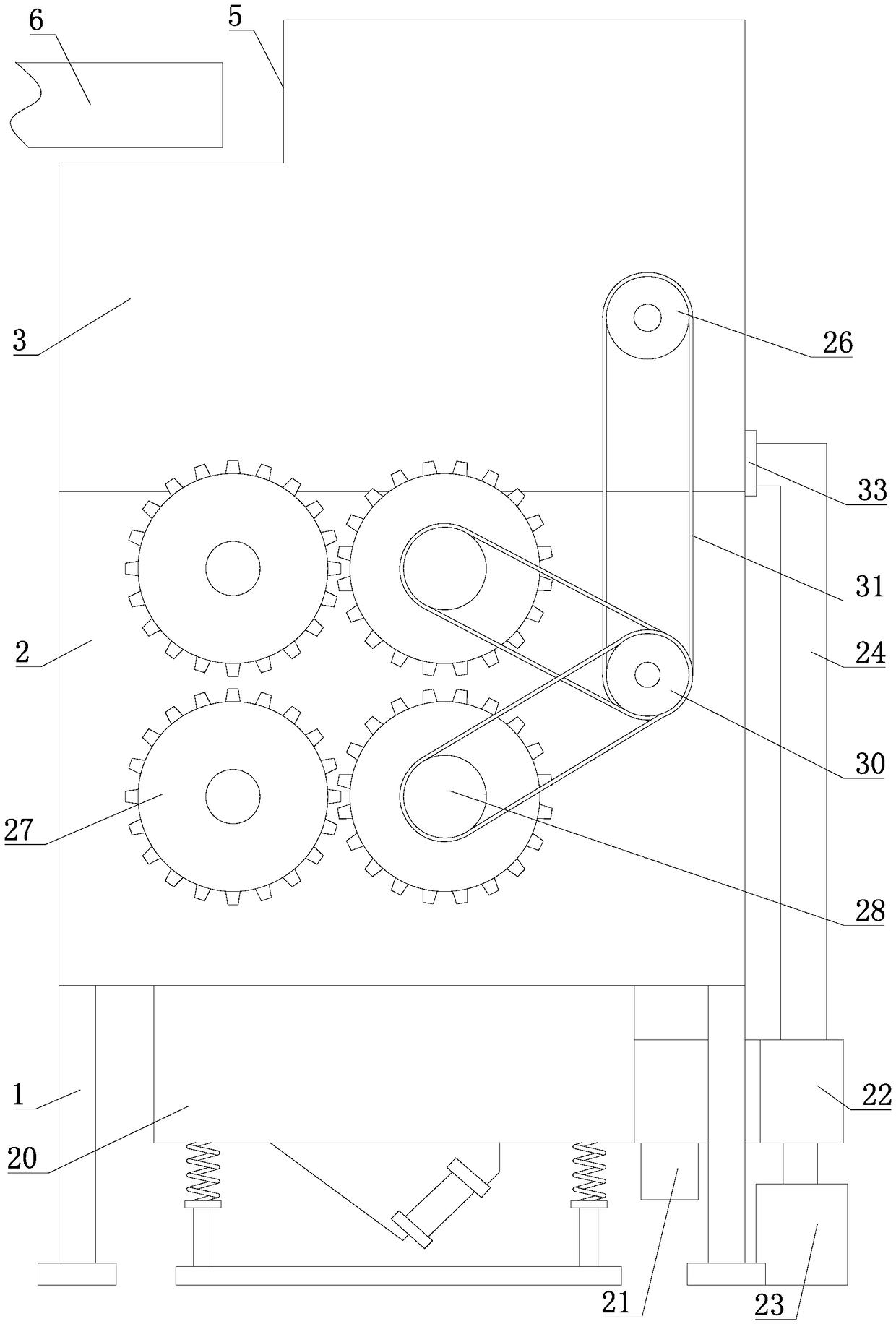

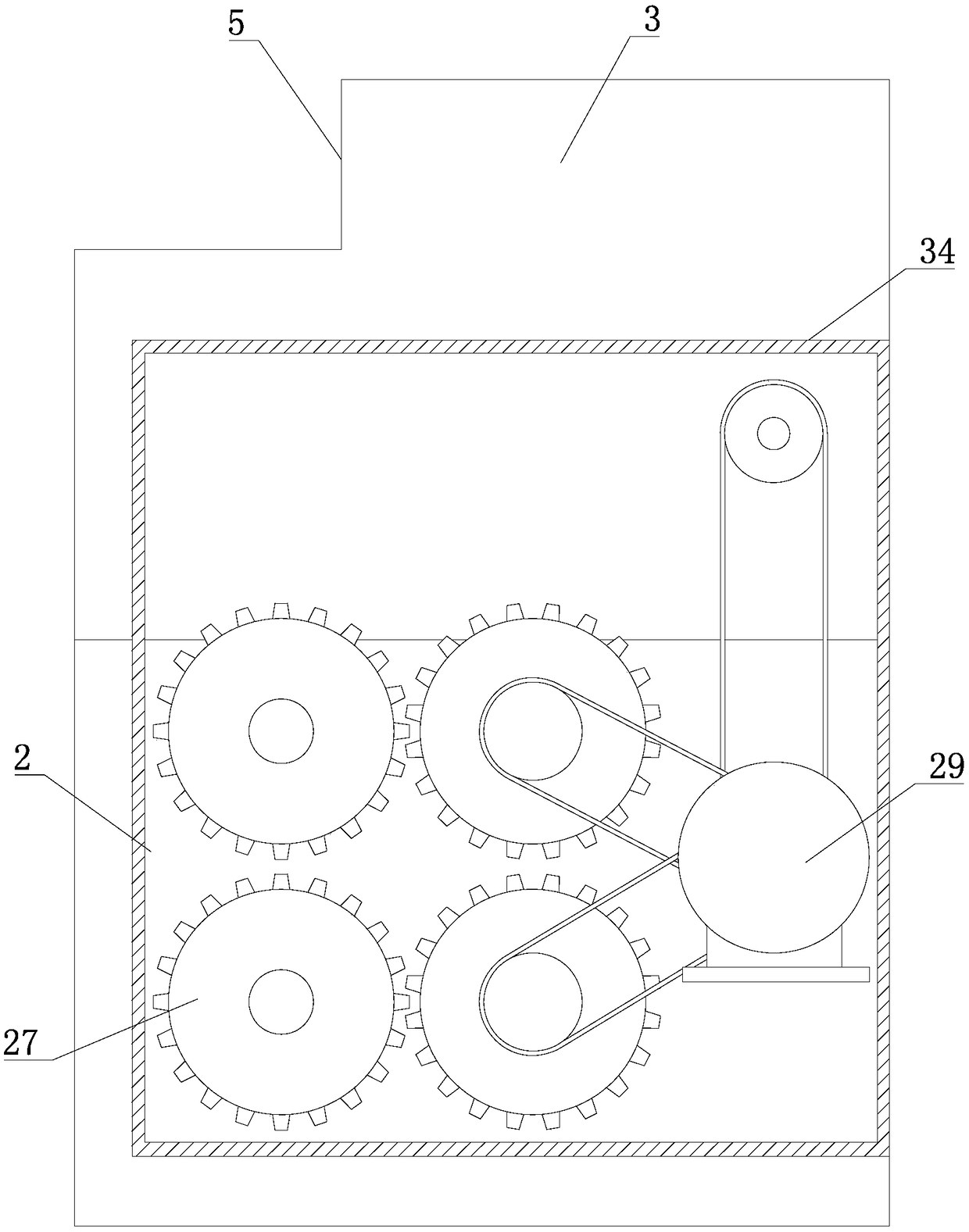

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0024] Such as Figure 1-6 As shown, a waste paper high-efficiency shredding device includes a support frame 1 arranged horizontally, a crushing box 2 is arranged on the top of the support frame 1, and a paper feeding box 3 is arranged on the top of the crushing box 2. The connection between the crushing box 2 and the paper feeding box 3 A partition 4 is arranged horizontally, and a feed port 5 is provided on the top of the carton 3, and a conveyor belt 6 for transporting waste paper is correspondingly provided at the position of the feed port 5; a partition at the bottom of the carton 3 below the feed port 5 A material guide frame 7 is provided on the top, and a through hole 8 is correspondingly provided on the partition plate 4 outside the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com