Low-temperature squeezer for tea oil

A press, low temperature technology, applied in the field of tea oil low temperature press, can solve the problems of poor effect, low utilization rate of tea seeds and high cost, and achieve the effect of enhancing pressing effect, reducing temperature and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the drawings and specific embodiments.

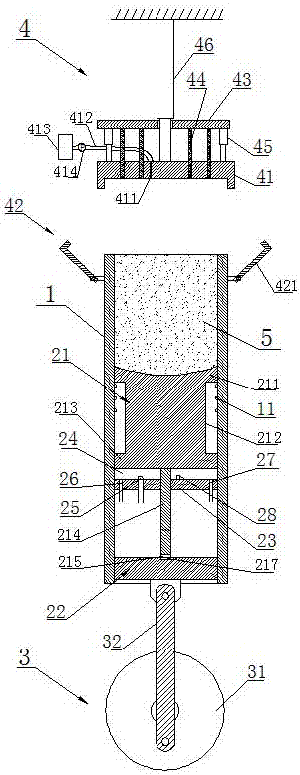

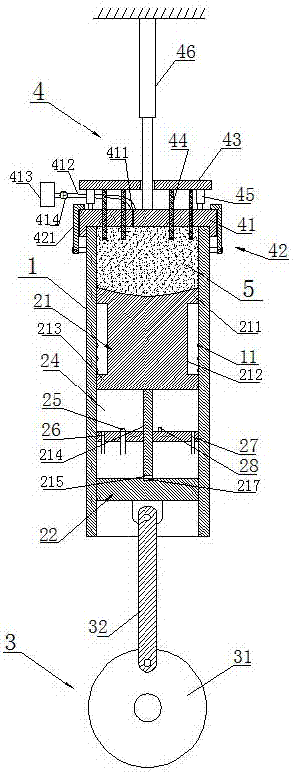

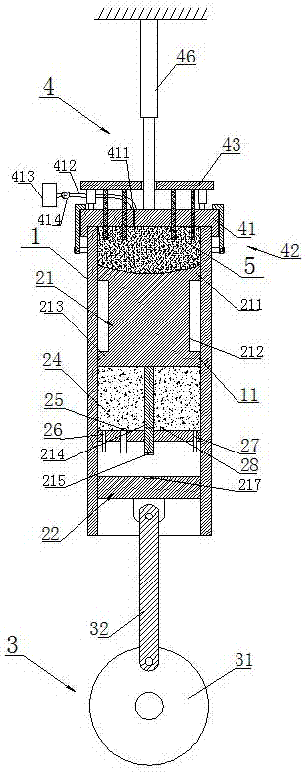

[0048] See Figure 1 to Figure 6 , A low-temperature tea oil press, comprising a vertically fixed cylinder 1, a piston assembly sealed and sliding sleeved in the cylinder 1, an eccentric assembly 3 arranged under the cylinder 1, and a cylinder 1 The upper slag discharging assembly 4; the piston assembly includes an upper piston 21 and a lower piston 22 arranged in parallel and spaced apart; a sealing partition plate 23 is fixed in the cylinder 1 between the upper piston 21 and the lower piston 22; An upper rod 214 vertically fixed at the center of the lower end of the upper piston 21 slides downward through the sealing partition plate 23 in a sealing manner; the lower end of the upper rod 214 is provided with a first magnet 215; the upper end of the lower piston 22 is provided with a first magnet 215; The second magnet 217 attracted by the magnet 215; the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com