Plate type air condenser

An air-condensing, plate-type technology, applied in steam/steam condensers, engine components, machines/engines, etc., can solve the problems of scaling, fouling, low energy consumption, etc., achieve compact equipment, improve heat transfer efficiency, high The effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

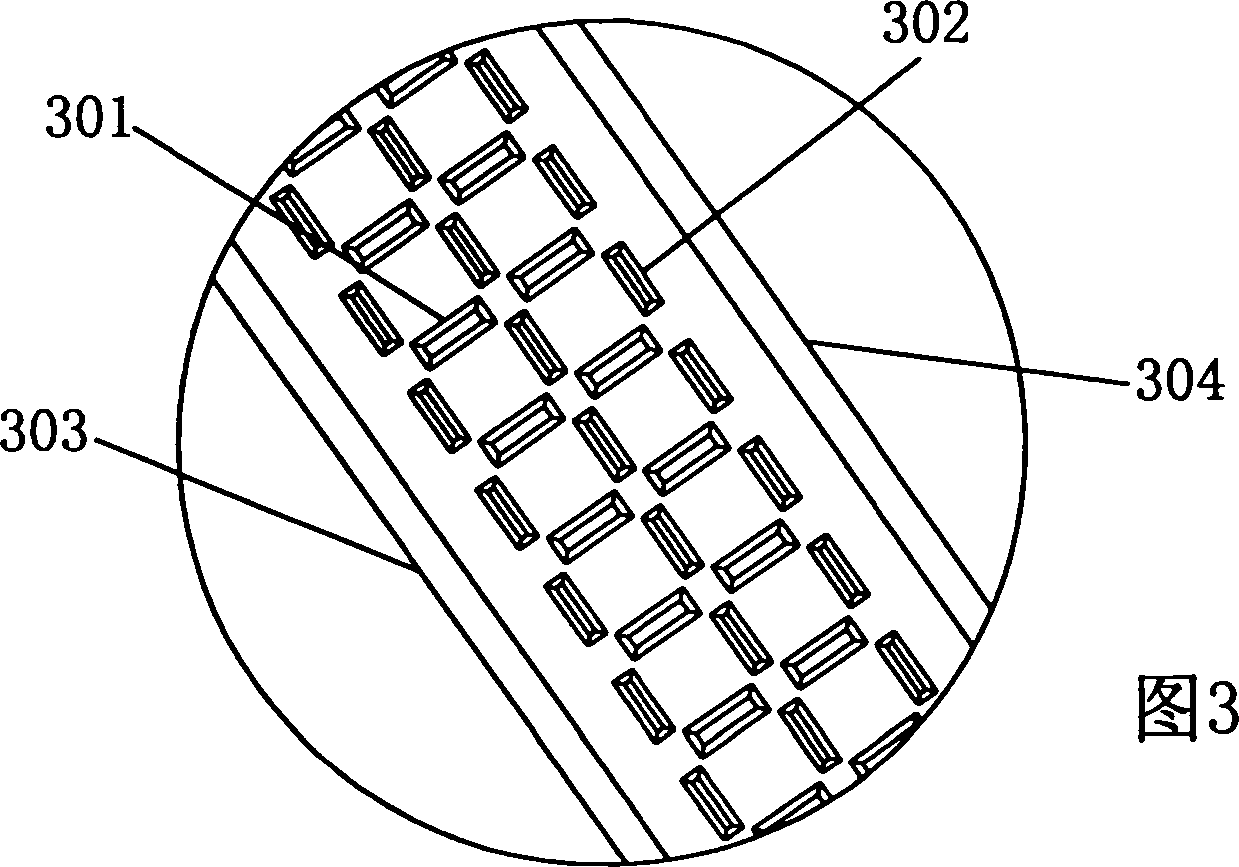

[0042] Figure number

[0043] 1. Plate bundle 2. Plate tube 3. Plate 301. Row corrugation 302. Column corrugation

[0044] 303. Longitudinal edges 304. Longitudinal edges 305. Horizontal edges 306. Horizontal edges

[0045] 4. Plate 401. Row corrugation 402. Column corrugation 403. Longitudinal edge

[0046] 404. Longitudinal edge 405. Transverse edge 406. Transverse edge 5. Longitudinal channel

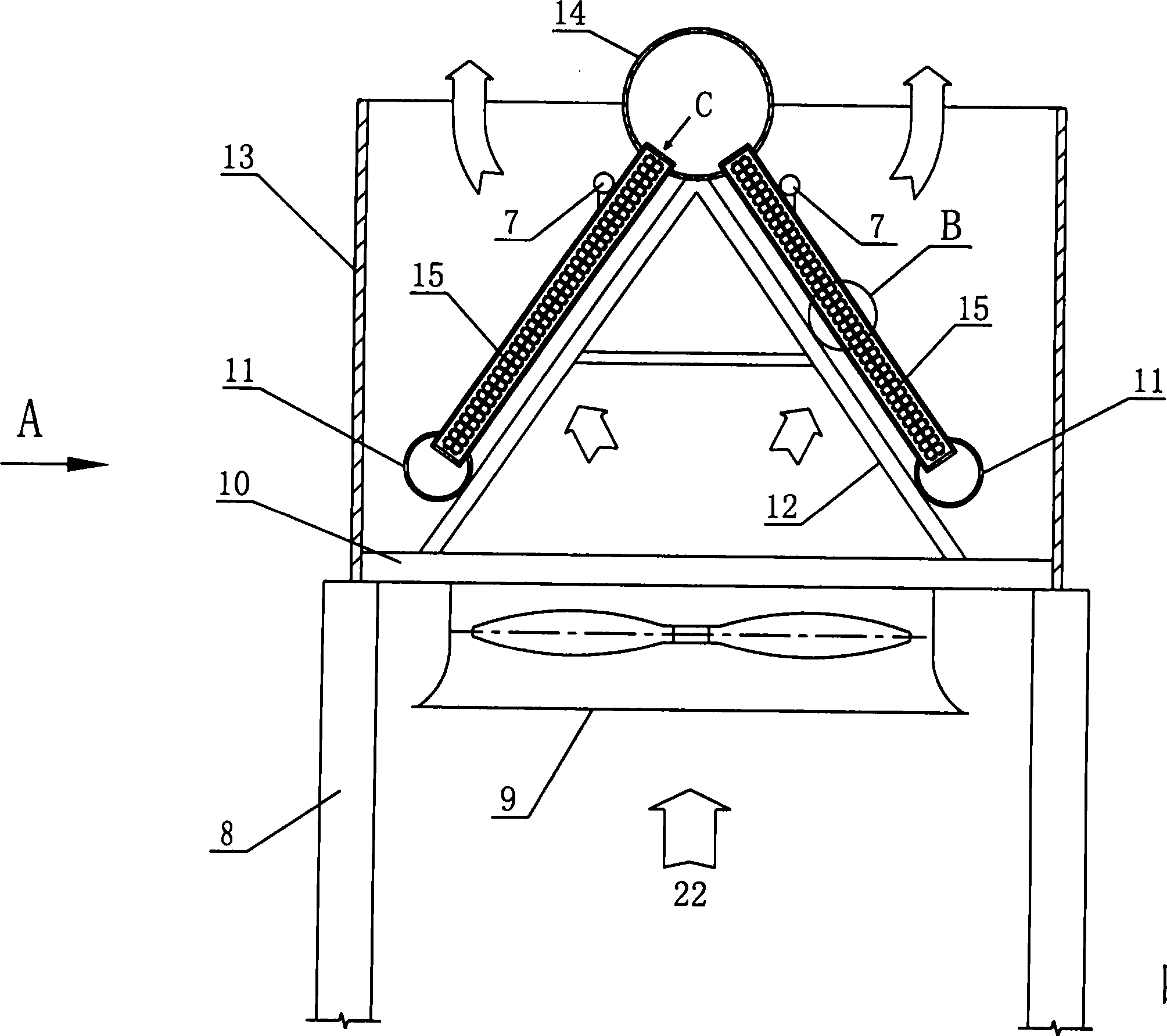

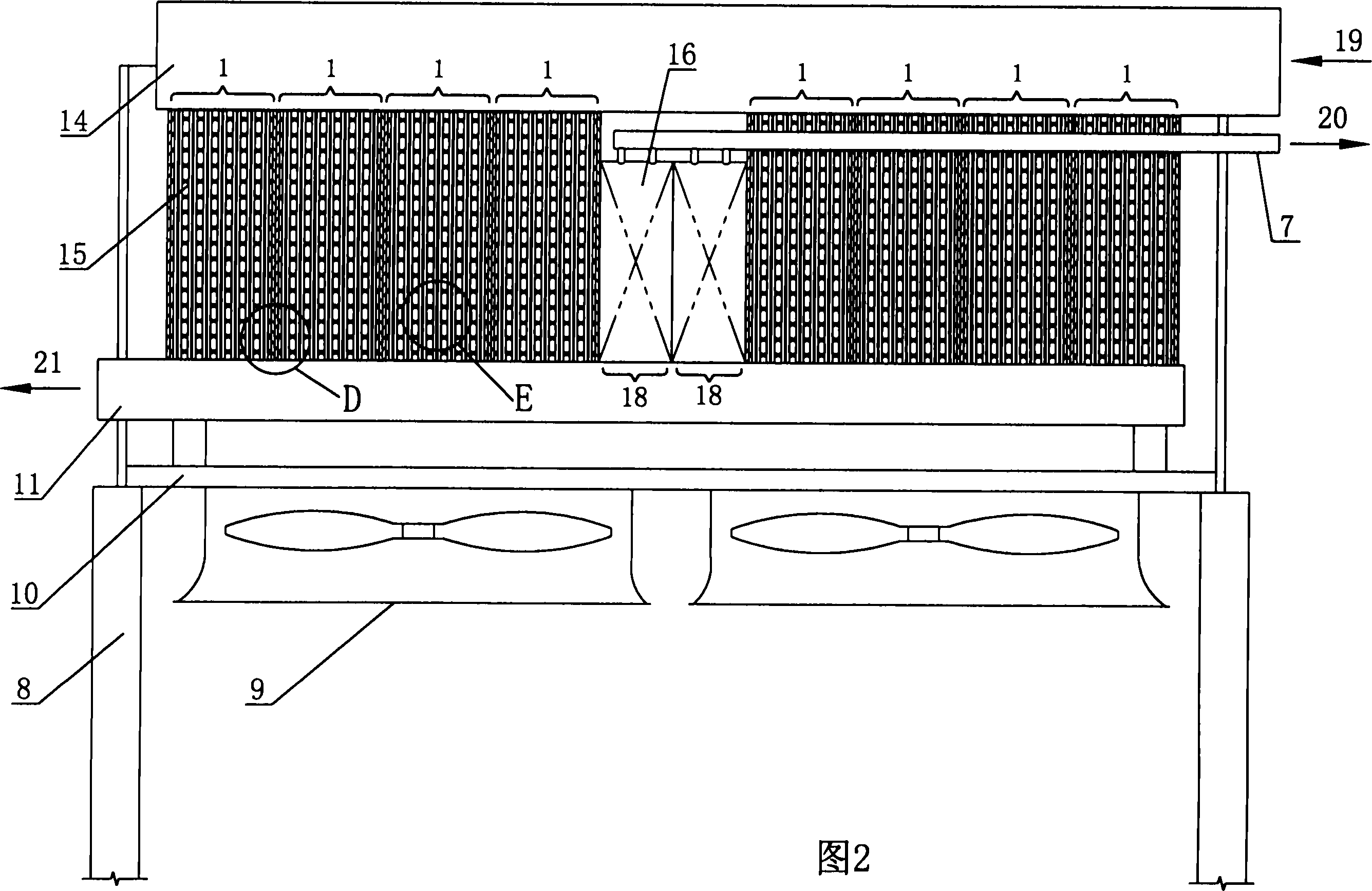

[0047] 6. Horizontal channel 7. Exhaust pipe 8. Bracket 9. Fan 10. Platform

[0048] 11. Condensate collection pipe 12. "A" shaped frame 13. Windshield wall 14. Steam distribution pipe

[0049] 15. Downstream plate heat transfer element 16. Counterflow plate heat transfer element 17. Separator 18. Plate bundle

[0050] 19. Arrow 20. Arrow 21. Arrow 22. Arrow

[0051] Please refer to figure 1 , Figure 2, Figure 3, Figure 4 , Figure 5 , Image 6 , the present invention is a plate-type air condensing device, its structure is: there is a platform 10 on the support 8, a fan 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com