Boiler thermodynamic system with smoke wastes as fuels and method thereof

A thermal system and waste technology, which is applied in the field of boiler thermal system, can solve the problems of ash accumulation and coking, unfavorable heat accumulation, and short combustion range, so as to reduce tar and particulate matter emissions, reduce exhaust heat loss, and improve fuel combustion. The best possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

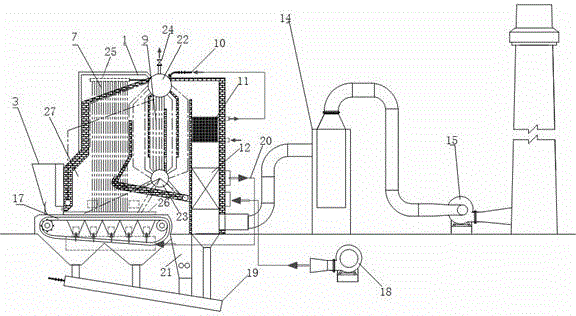

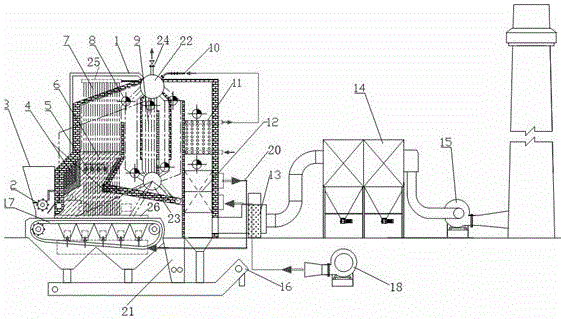

[0037] As shown in the figure, the boiler thermal system using smoke-related waste as fuel includes a boiler body 1 with a combustion chamber 27, a front hopper 3 arranged at the inlet end of the boiler body 1, a fire grate 17 arranged at the bottom of the boiler body 1, The water-cooled wall pipe 7 arranged around the combustion chamber 27, the convection pipe 9 arranged in the boiler body 1, the economizer 11 and the air preheater 12, the blower 18 connected to the inlet of the air preheater 12, and the air preheater The outlet of the heater 12 and the hot blast main pipe 20 of the lower air chamber of the fire grate 17, and the dust remover 14 and the induced draft fan 15 connected to the outlet end of the boiler body 1; The front arch and the rear arch 4, the secondary air device 5 is installed in the middle of the combustion chamber 27, and several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com