Gas-to-gas full-welding plate type heat exchanger

A plate heat exchanger, all-welded technology, used in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of easy dust accumulation, high investment cost, low heat exchange efficiency, etc. To achieve the effect of easy maintenance and cleaning, compact equipment structure, and reduce equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

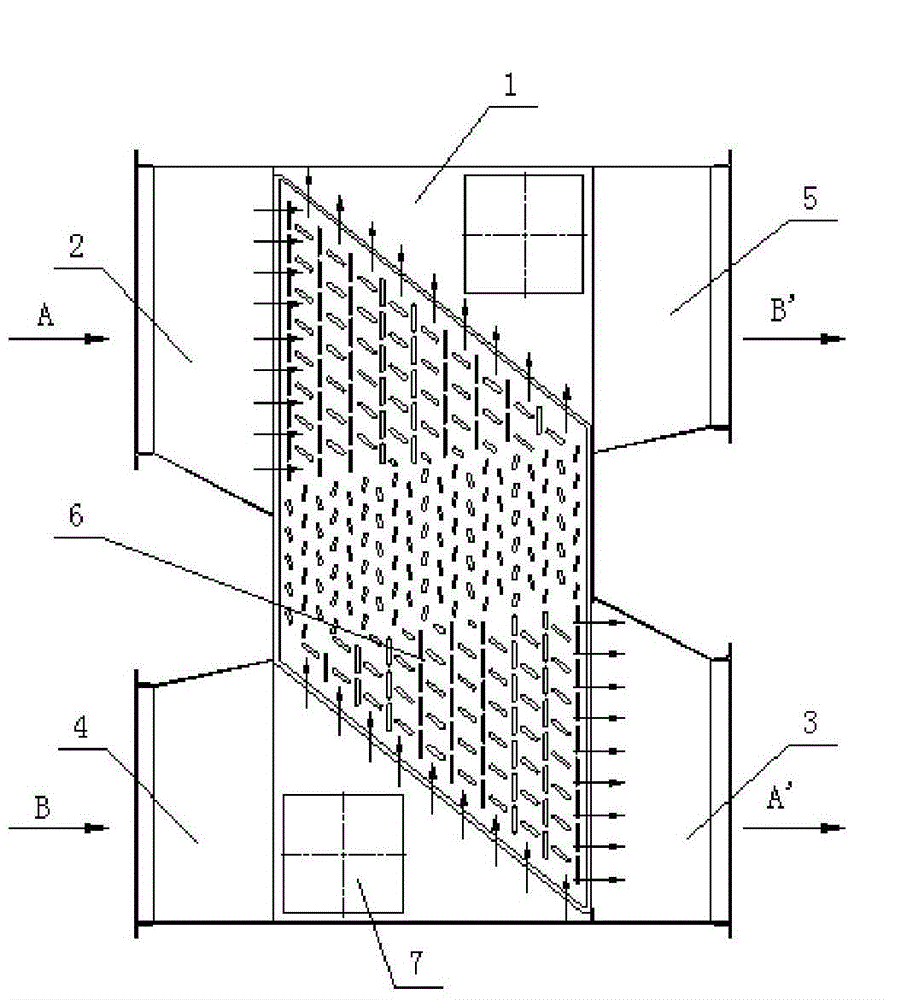

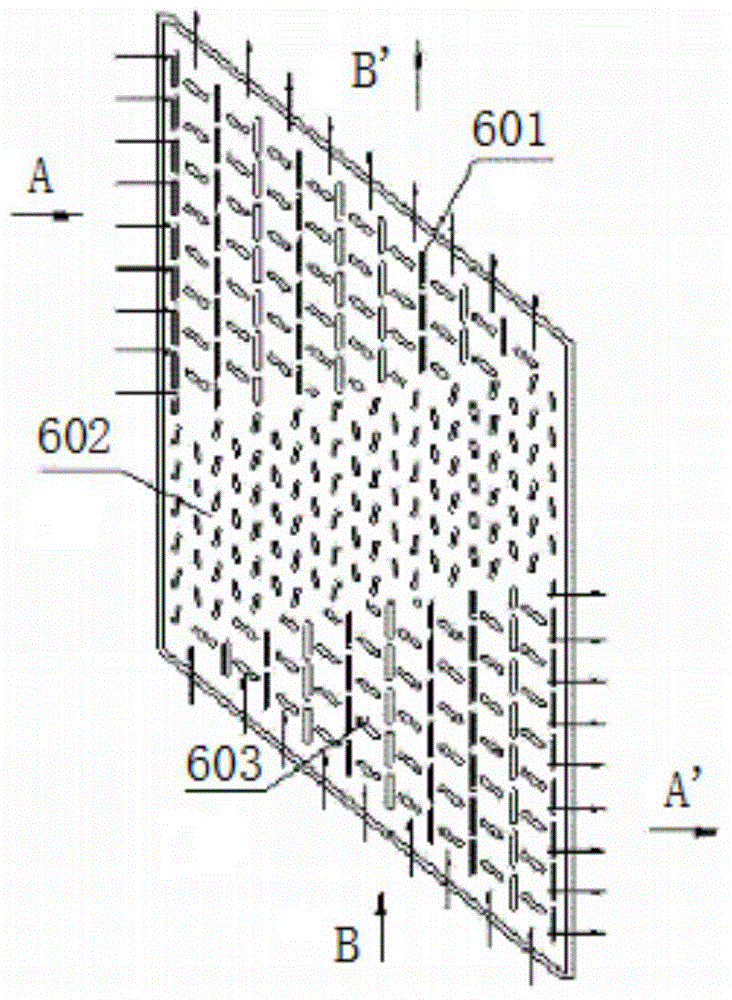

[0019] As shown in the figure, the present invention includes a box body 1, a heat exchange component arranged in the box body, a heat medium inlet tube box 2 connected to the heat exchange component, a heat medium outlet tube box 3, a cold medium inlet tube box 4 and a cooling medium Outlet pipe box 5, the heat exchange component is a quadrilateral heat transfer plate group module 6 placed vertically.

[0020] The heat medium inlet pipe box and the cold medium outlet pipe box are respectively located at the upper and lower ends of the box relative to the heat medium outlet pipe box and the cold medium inlet pipe box, and are arranged alternately.

[0021] The quadrilateral heat transfer plate group module is formed by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com