Plate type air-air heat exchanger

A gas-air heat exchanger, plate-type technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed plate conduit components, etc., can solve the problems of easy dust accumulation, long-term operation cost, low heat transfer efficiency, large volume, etc. , to achieve the effect of large-scale equipment, convenient soot blowing, and low production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

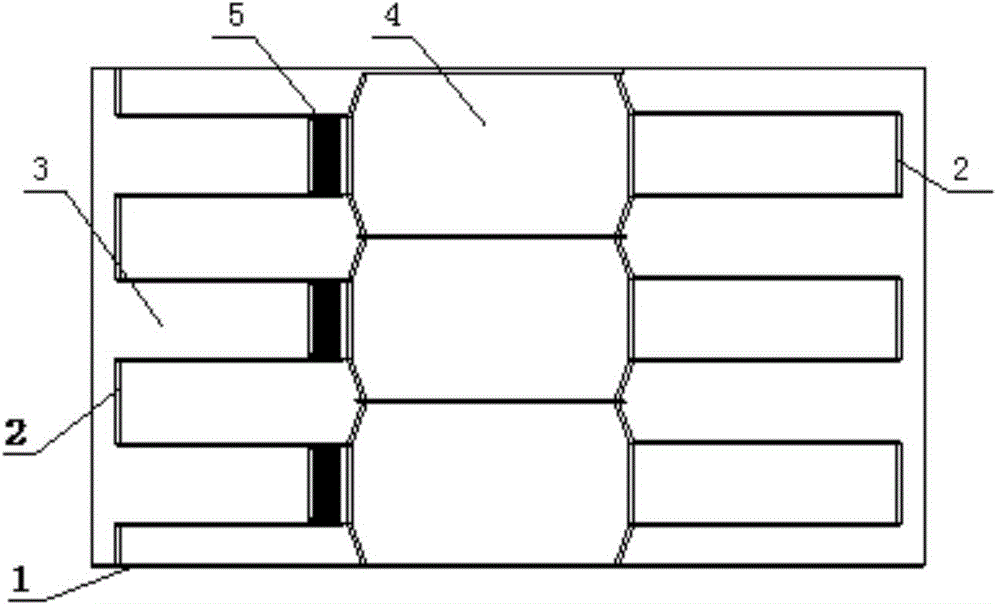

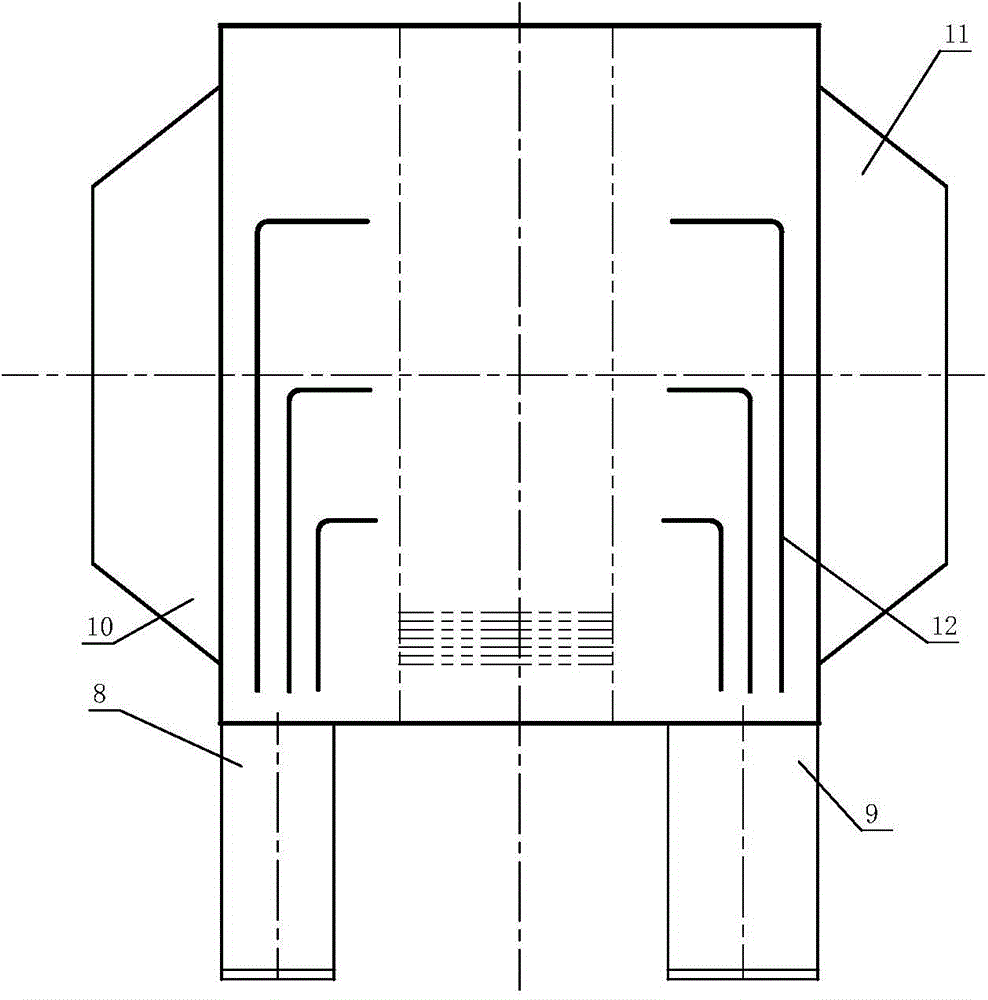

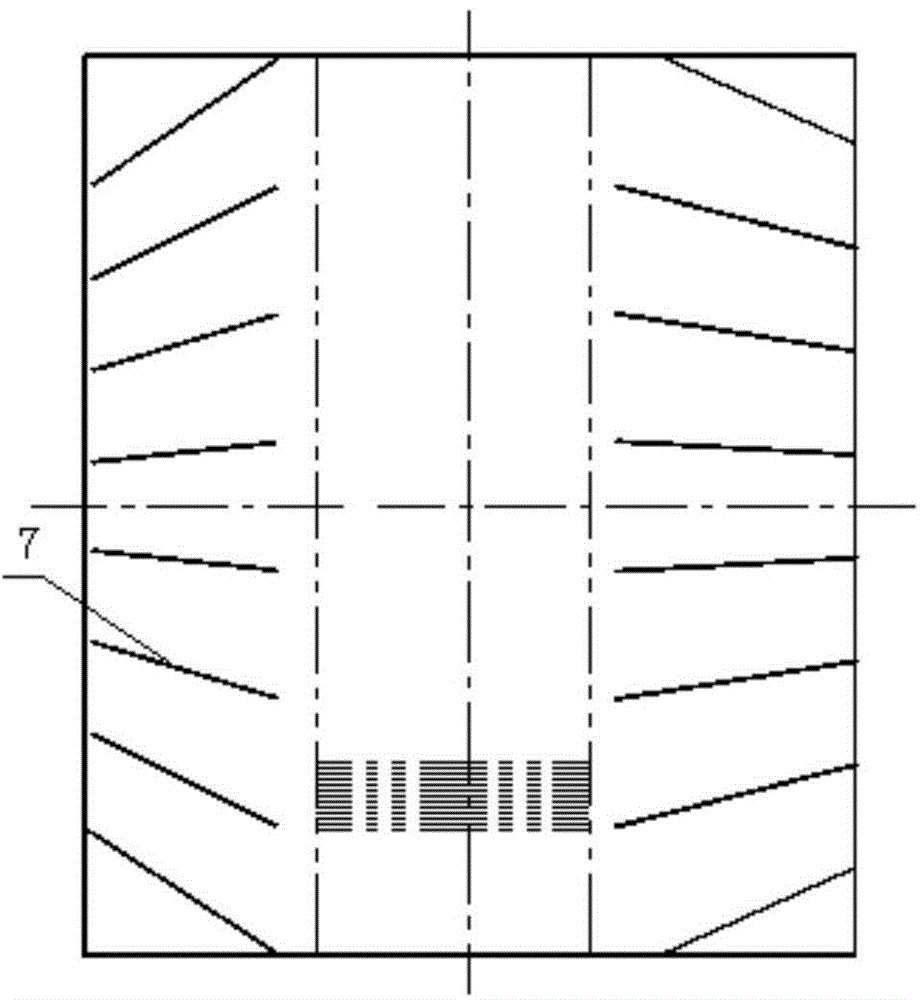

[0022] As shown in the figure, the two media are cold flow and hot flow. The present invention includes a box body 1, a plate bundle assembly 4 positioned horizontally inside the box body, and an inlet and outlet pipe box for the two media connected to the plate bundle assembly. The inlet and outlet pipe boxes of the two kinds of media mentioned above are located on the left and right sides of the box, the medium inlet and outlet boxes 10 on the left and right sides of the box, the medium outlet pipe boxes 11 on the left and right sides of the box, and the inlet and outlet of the other medium The pipe box is located at one or both ends of the front and back of the box body. In this example, it is set as the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com