Patents

Literature

35results about How to "Even fluid distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

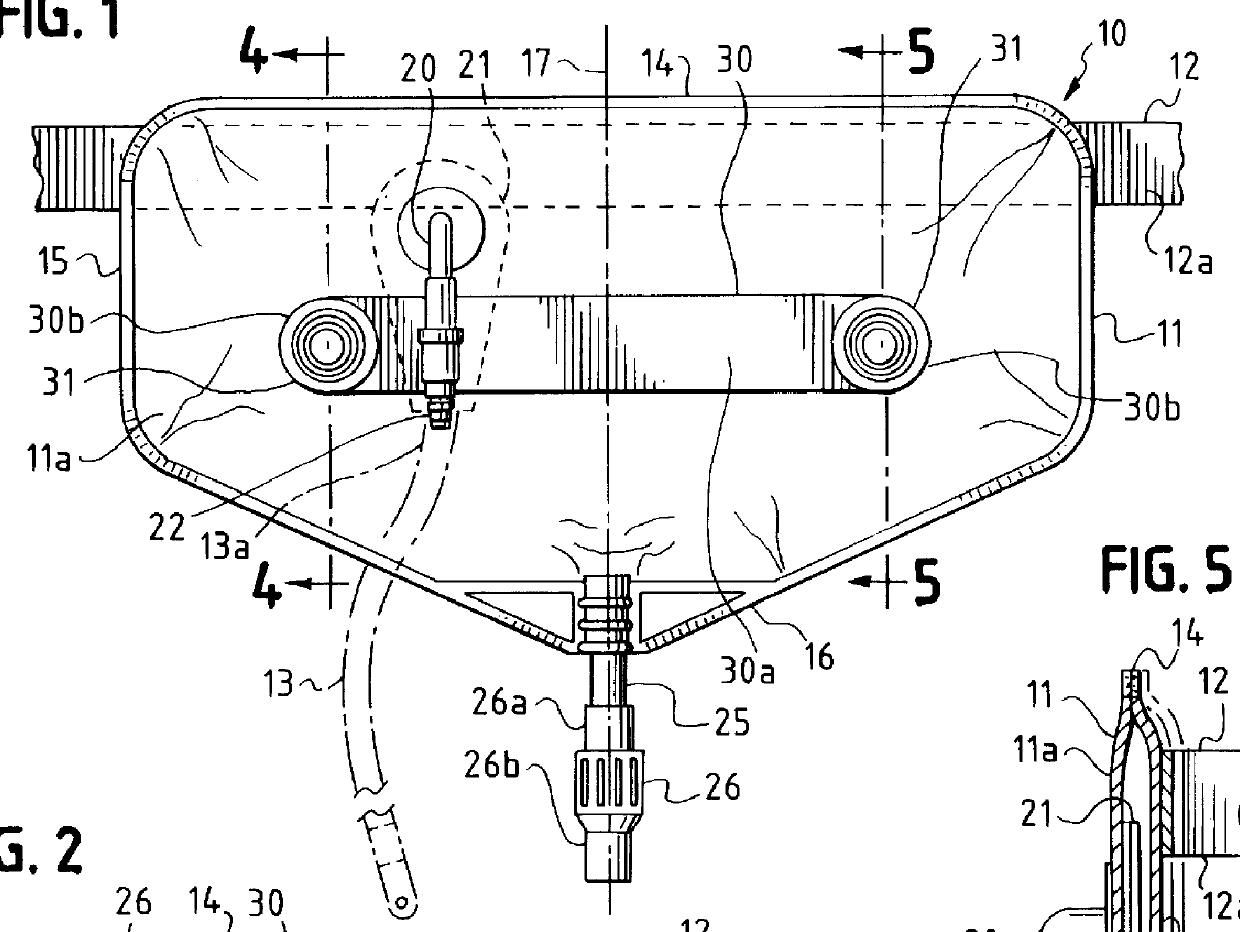

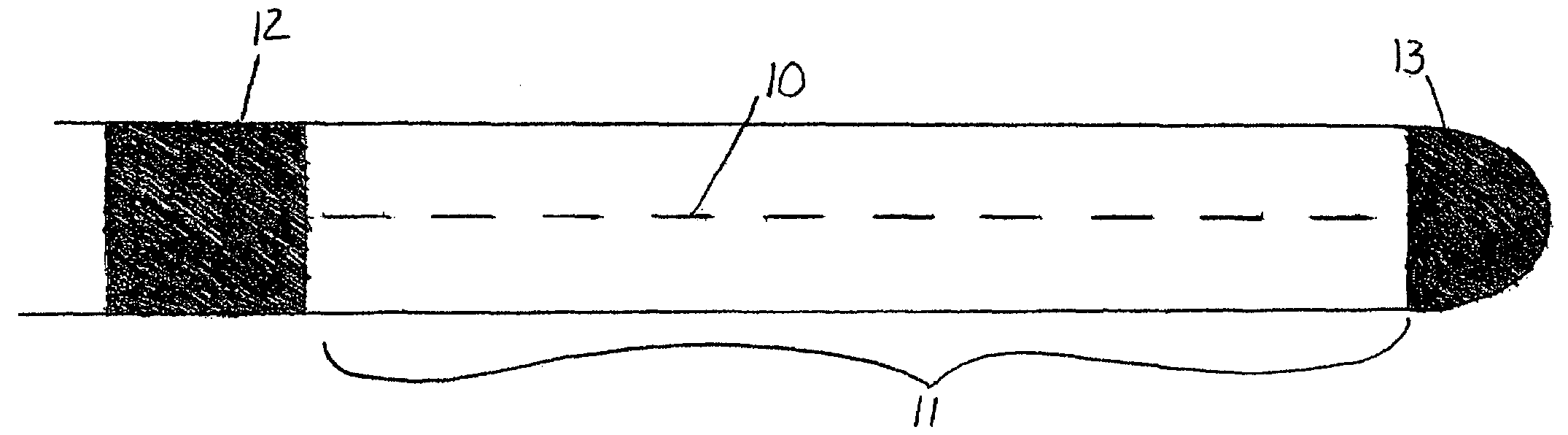

Urine collection device

InactiveUS6045542AUniform fluid distributionReinforces connectionSurgeryWound drainsUrinary drainageUrethral catheter

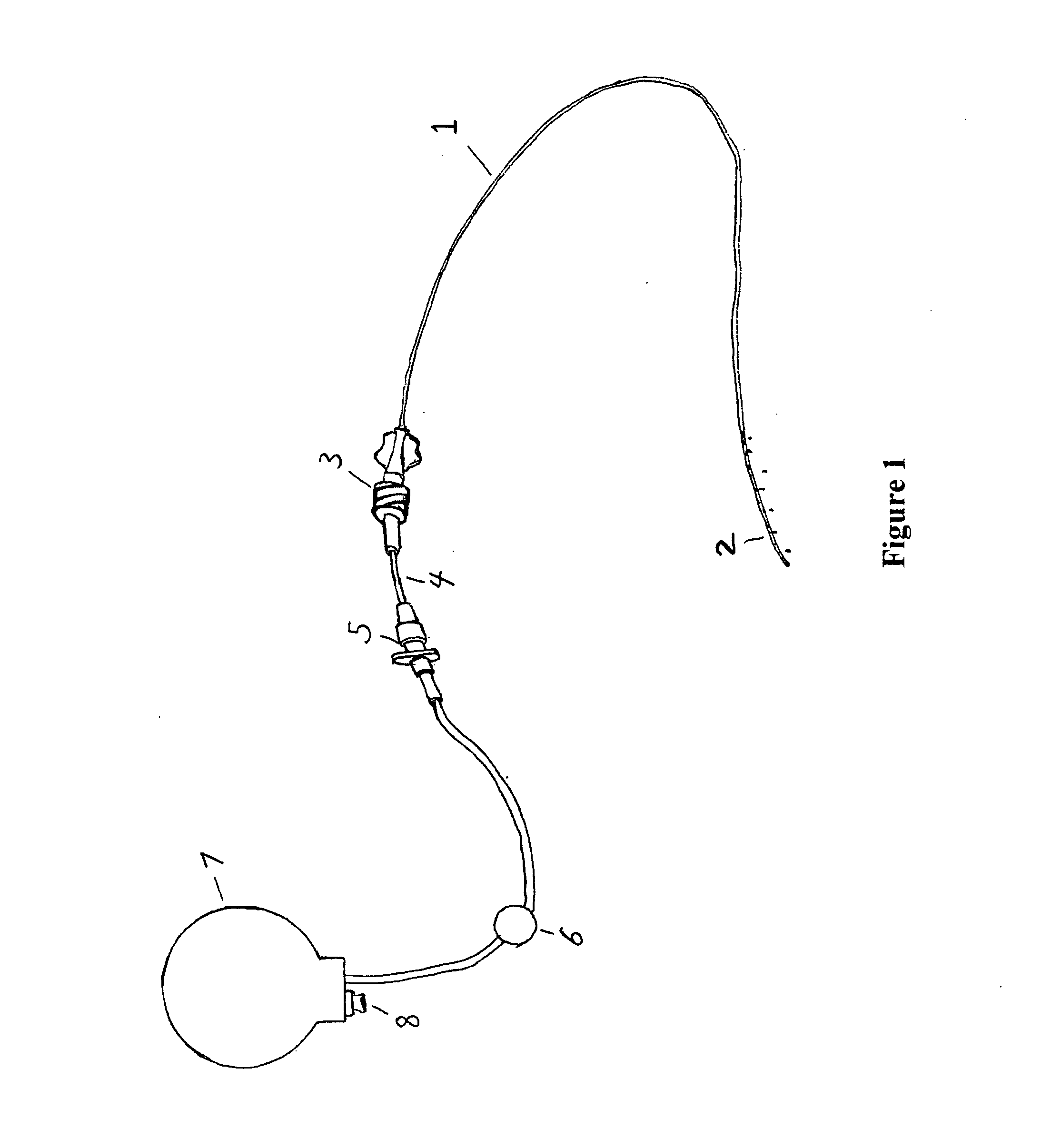

A flat urinary drainage bag that can be worn by a patient over the abdomen with the bag suspended from a waist-encircling belt is disclosed. The device includes an inlet tube for connection to a urethral catheter and a valve-equipped drain tube that extends downwardly from the bag when the drain tube is used to drain the contents therefrom. The lower end of the bag is foldable upwardly to position the drain tube in an upwardly-facing raised position against the bag's front wall, and a retaining strap is located across the front wall for holding the drain tube in its raised position. Spot attachments that secure the ends of the strap to the bag's front wall also secure the front and rear walls of the bag together, thereby performing multiple functions of limiting bulging of the bag in use, reducing sloshing of the bag's contents, and securing the retaining strap (and the raised drainage tube) in place.

Owner:CAWOOD FAMILY PARTNERSHIP

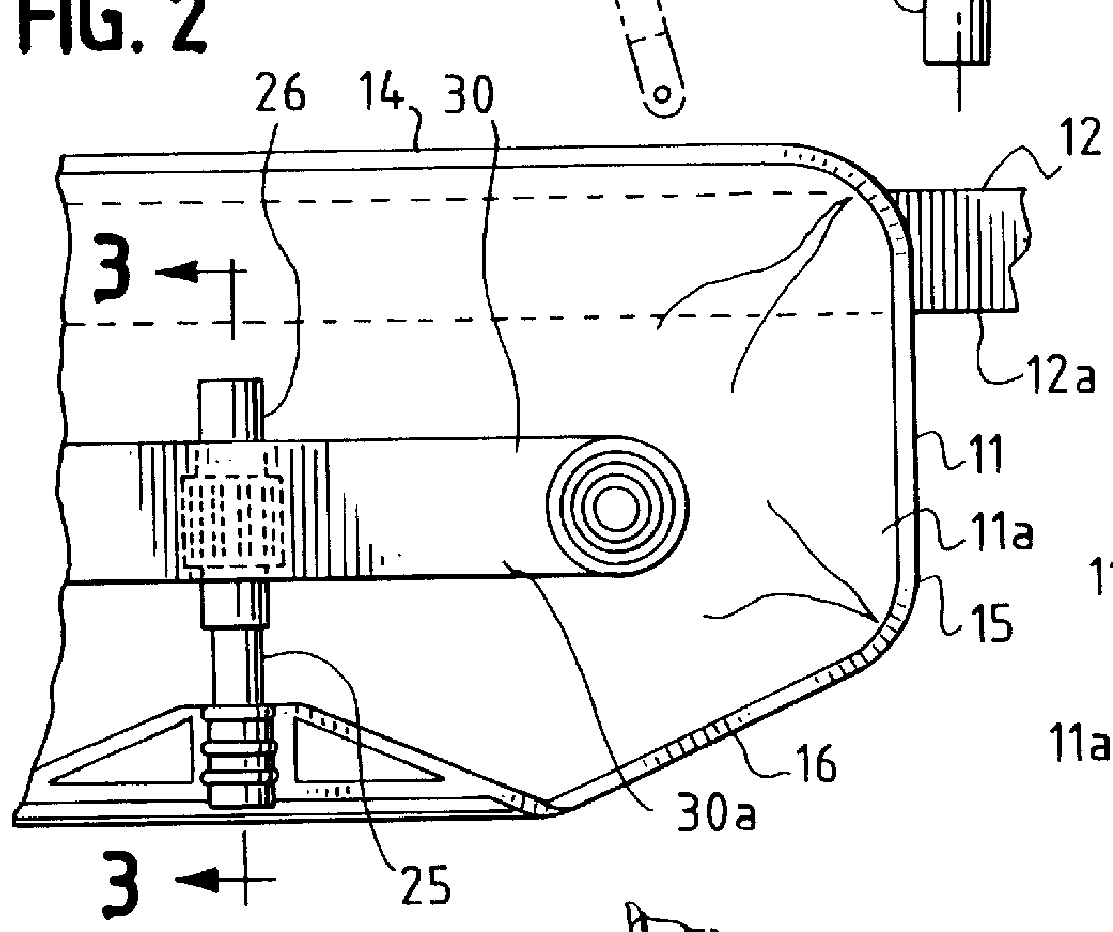

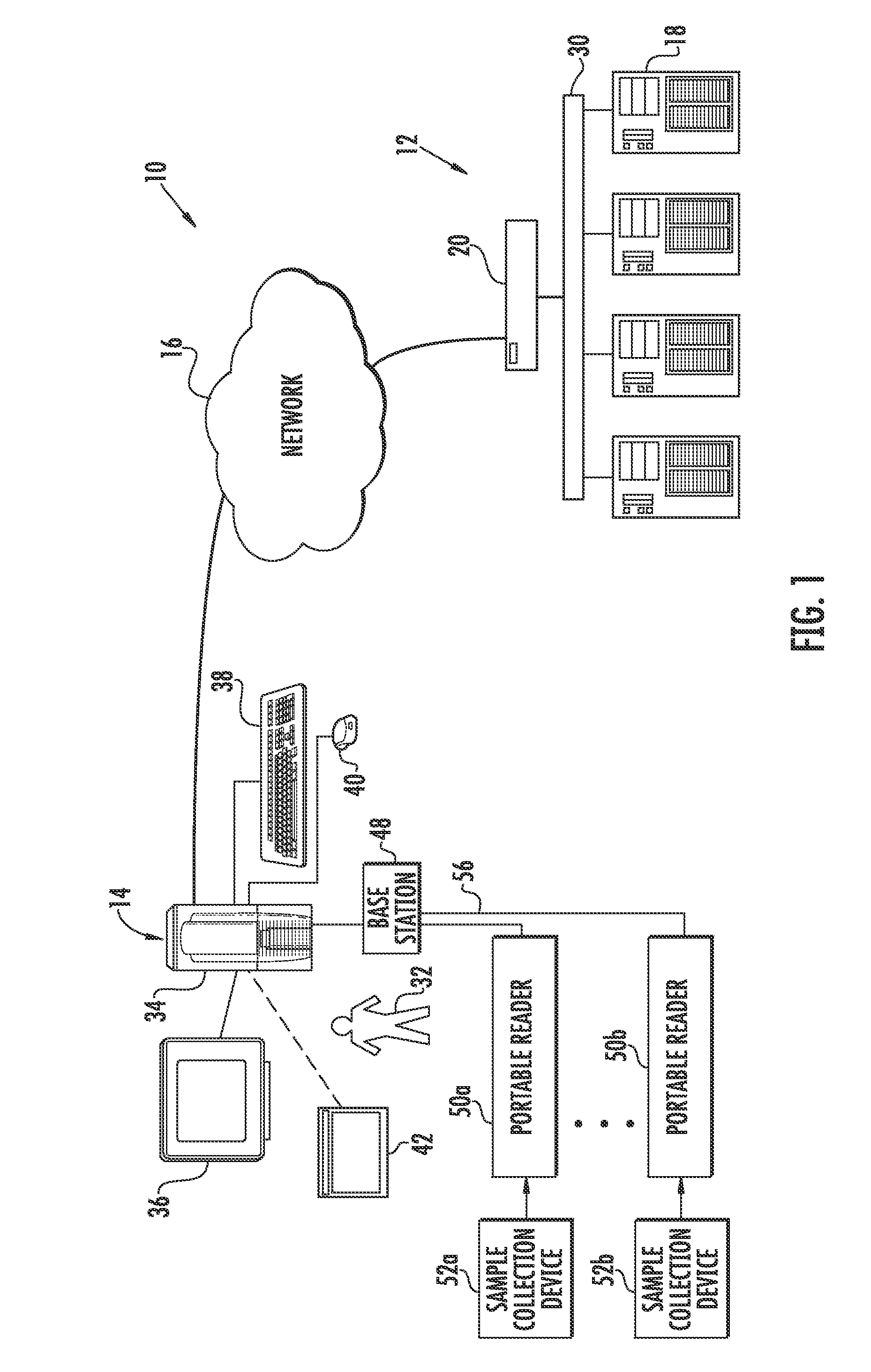

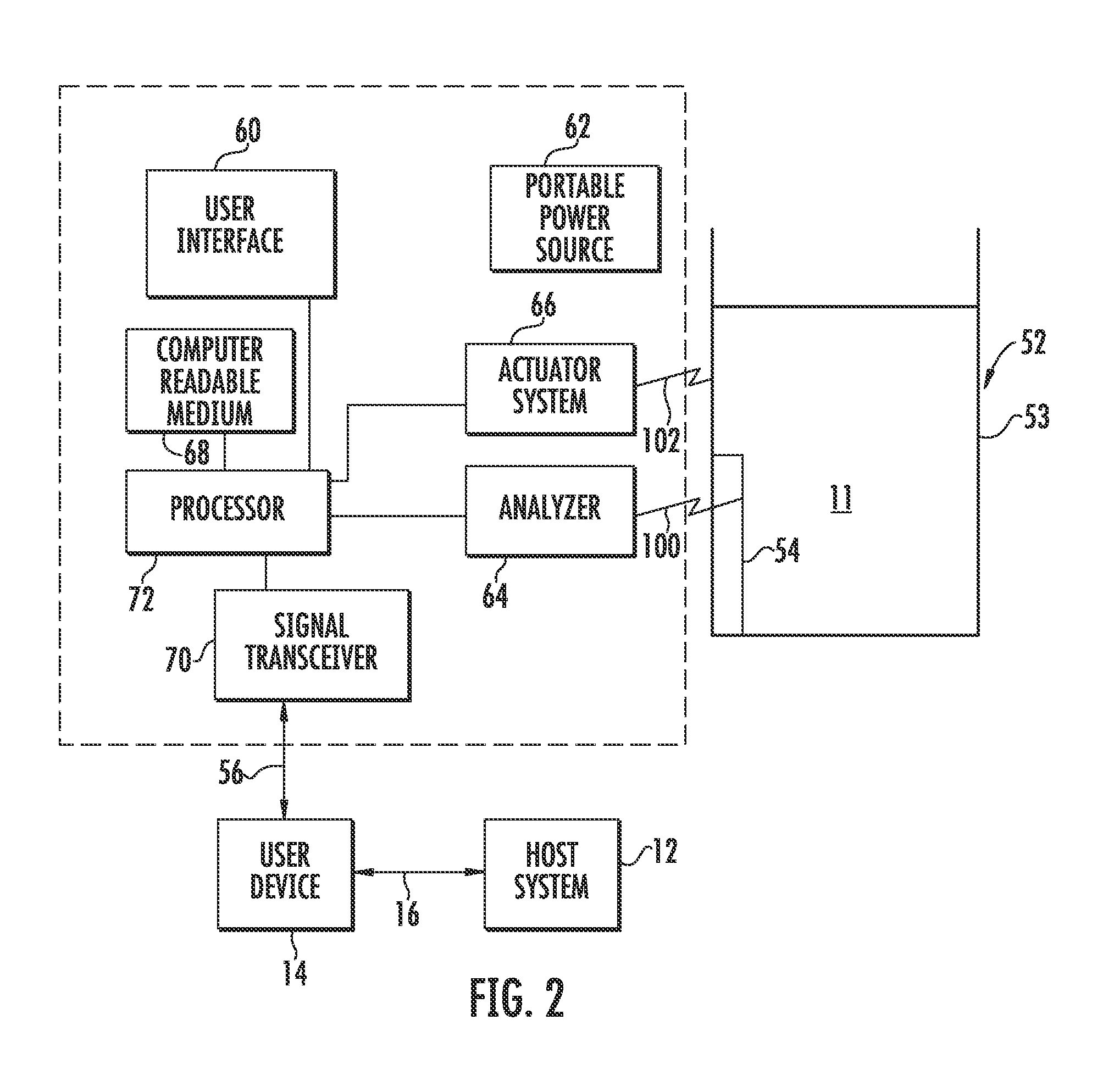

Sample analysis system and method of use

InactiveUS20130041236A1Accurate and repeatable assayEven fluid distributionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringReaction chamber

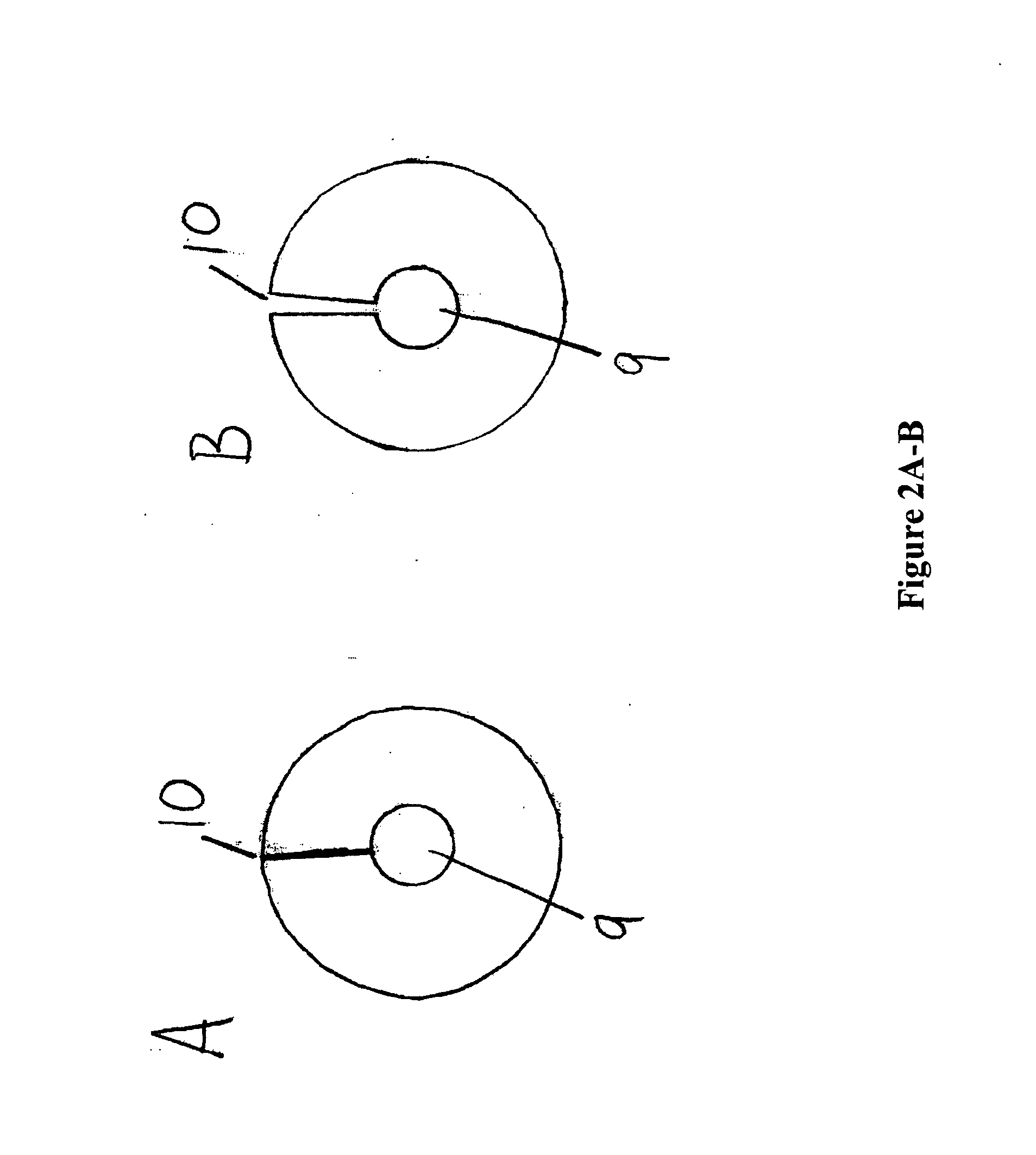

A sample collection device having a sample container and microfluidic device having one or more microfluidic circuits, the system for analyzing biological samples. The microfluidic device has a sample inlet port, a microconduit in communication with the inlet port and with reaction chamber. The reaction chamber is connected to an air vent via another microconduit. Air may be vented from the microfluidic circuit via the air vent of the microfluidic circuit via an air vent in the sample container.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

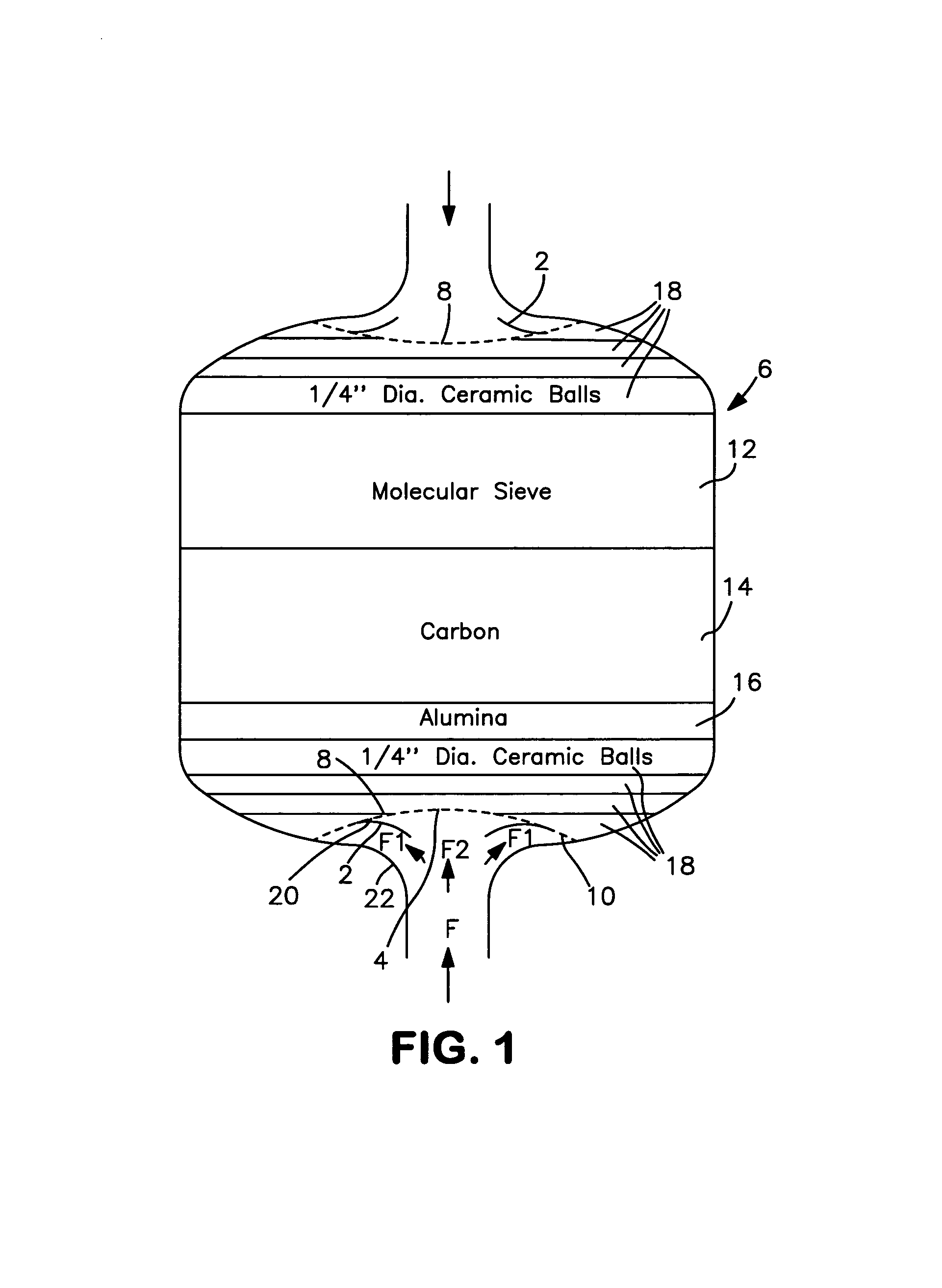

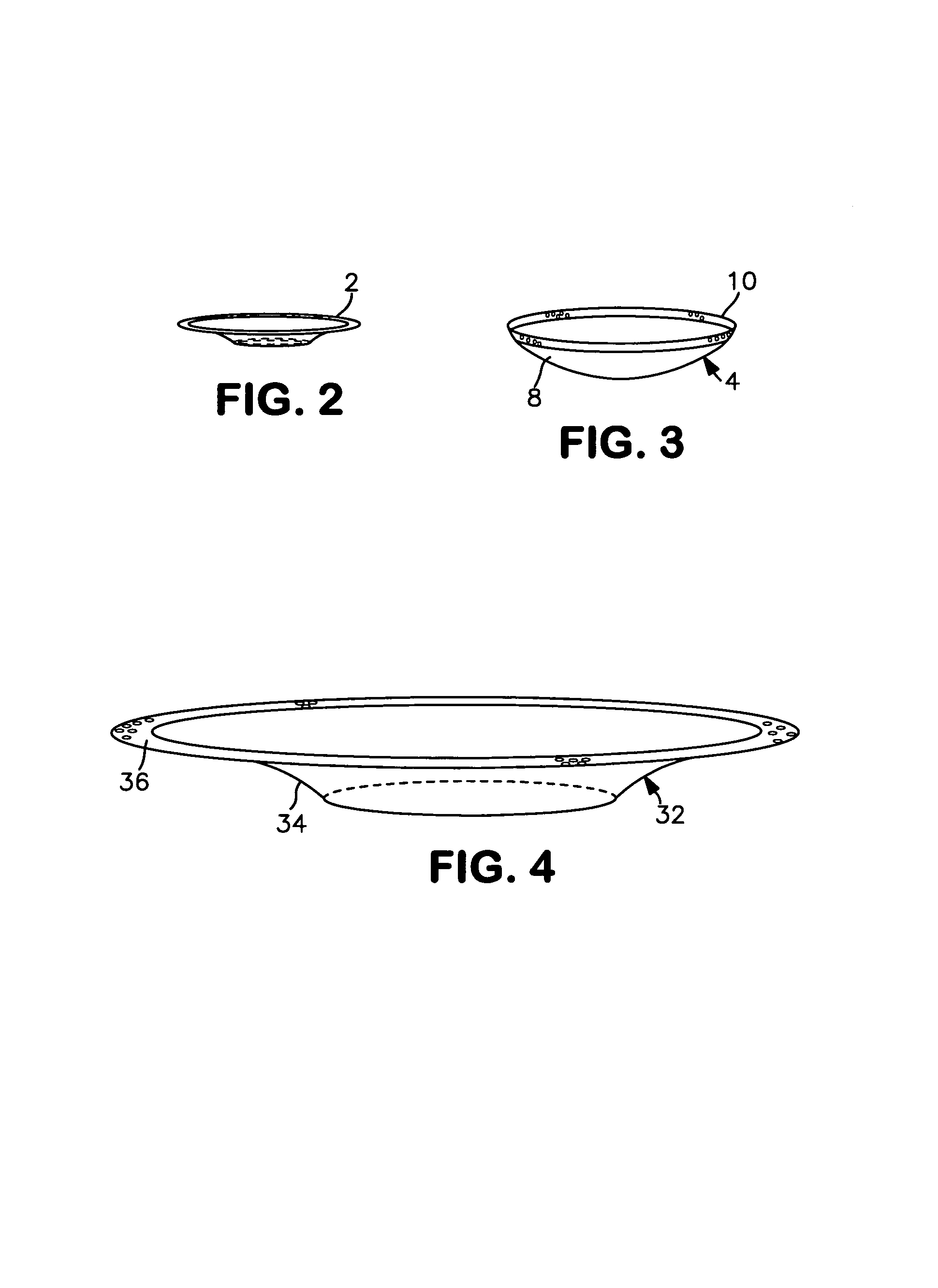

Flow distributor for PSA vessel

ActiveUS20050155492A1Effective even distributionEven fluid distributionGas treatmentAuxillary pretreatmentEngineeringDistributor

The present invention is a PSA system having at least one vessel that uses a multi-segmented flow distributor to provide a uniform fluid across the adsorbent bed in the vessel.

Owner:PRAXAIR TECH INC

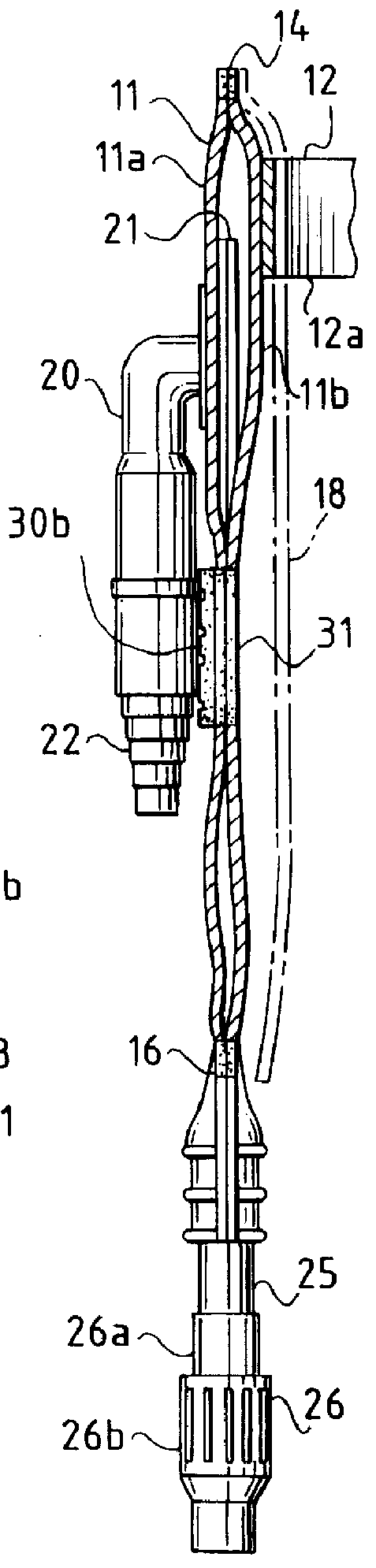

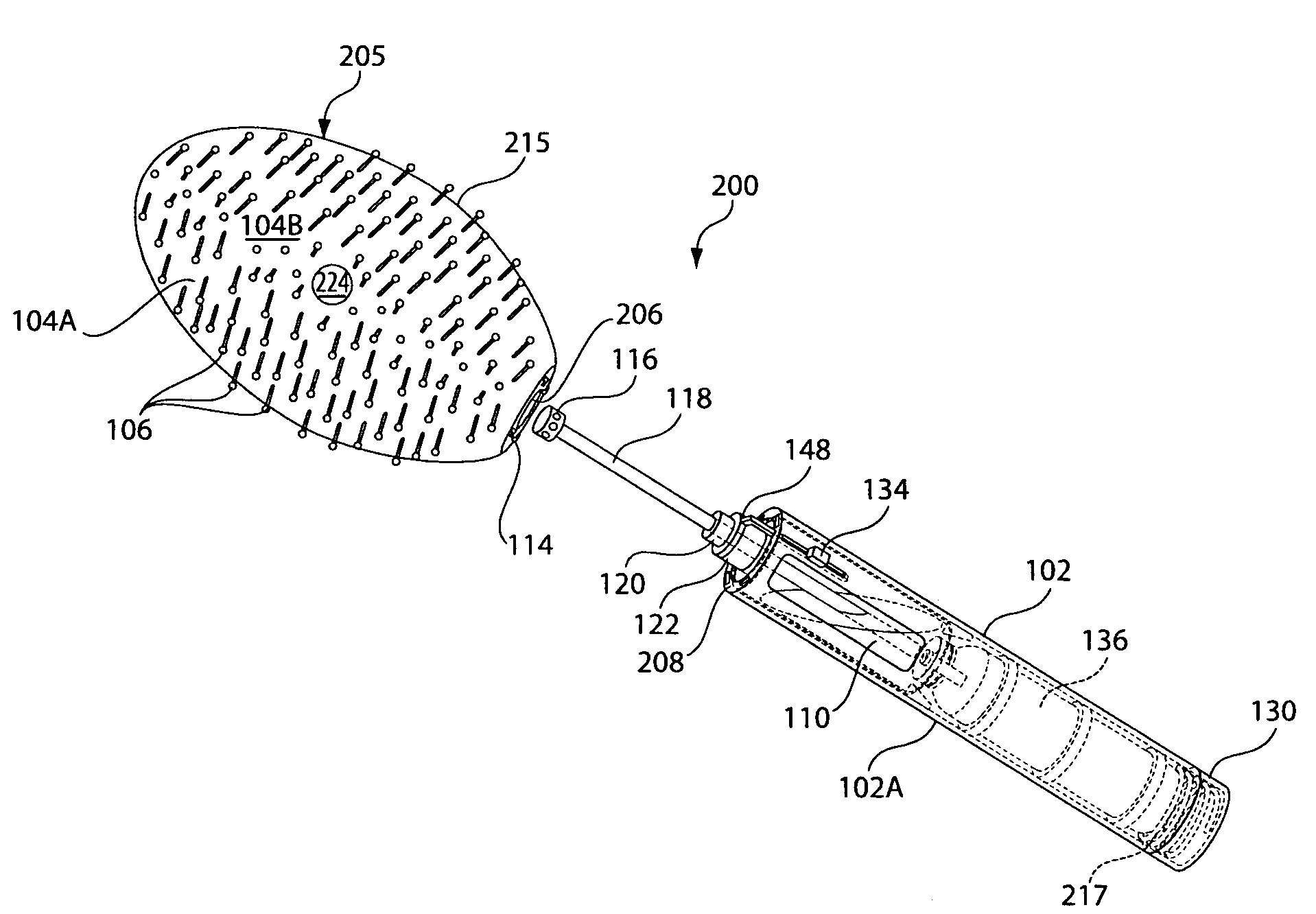

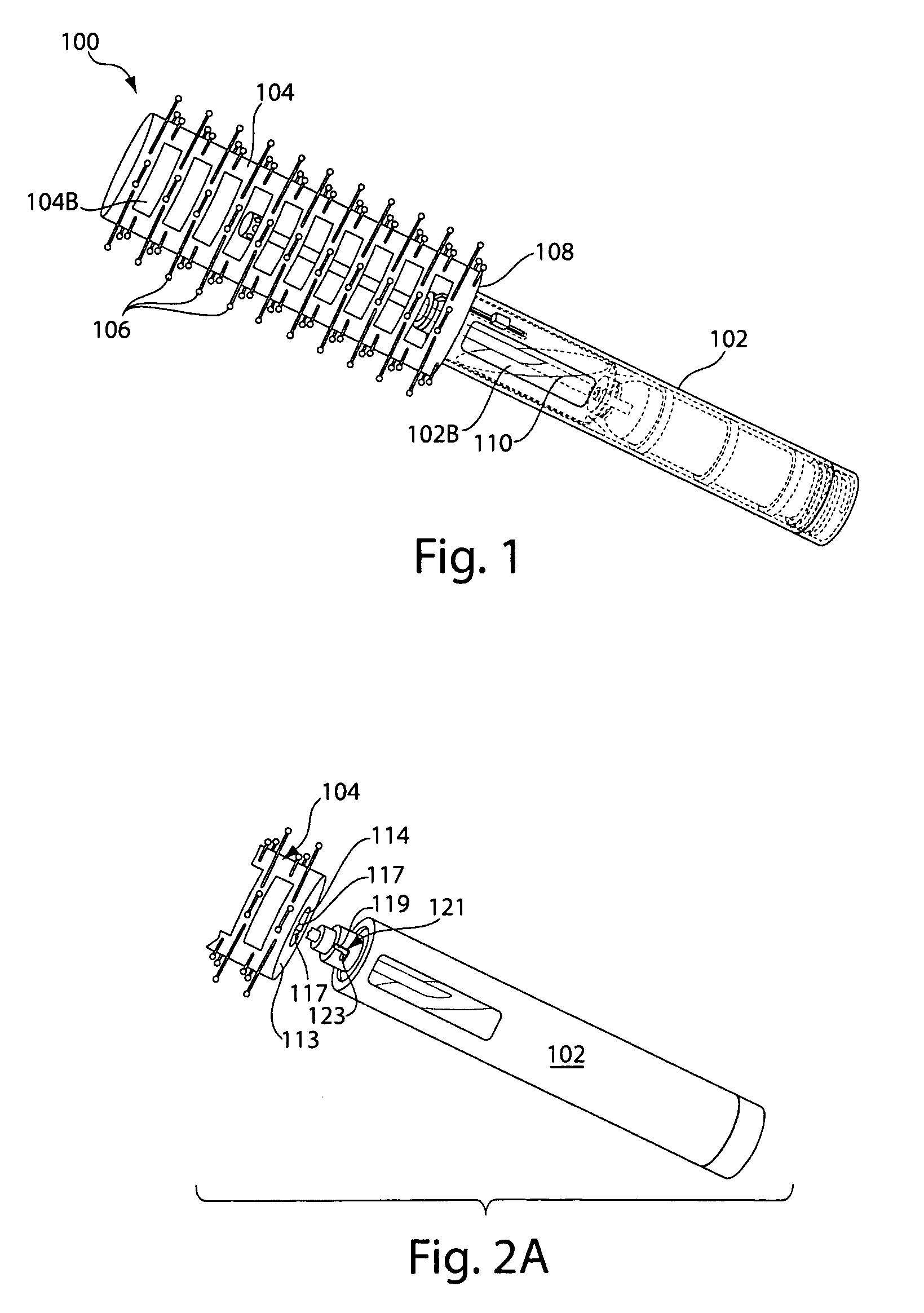

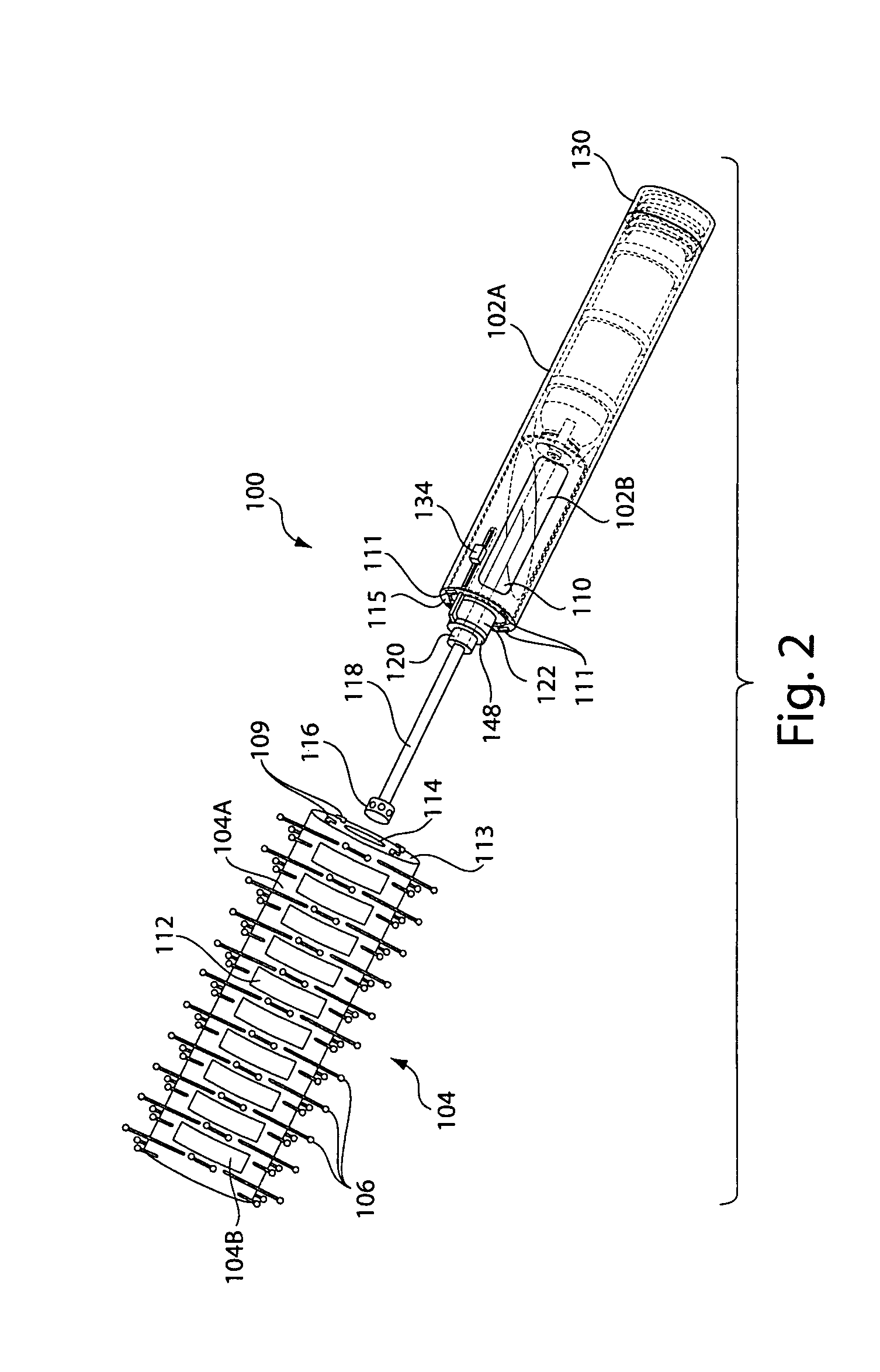

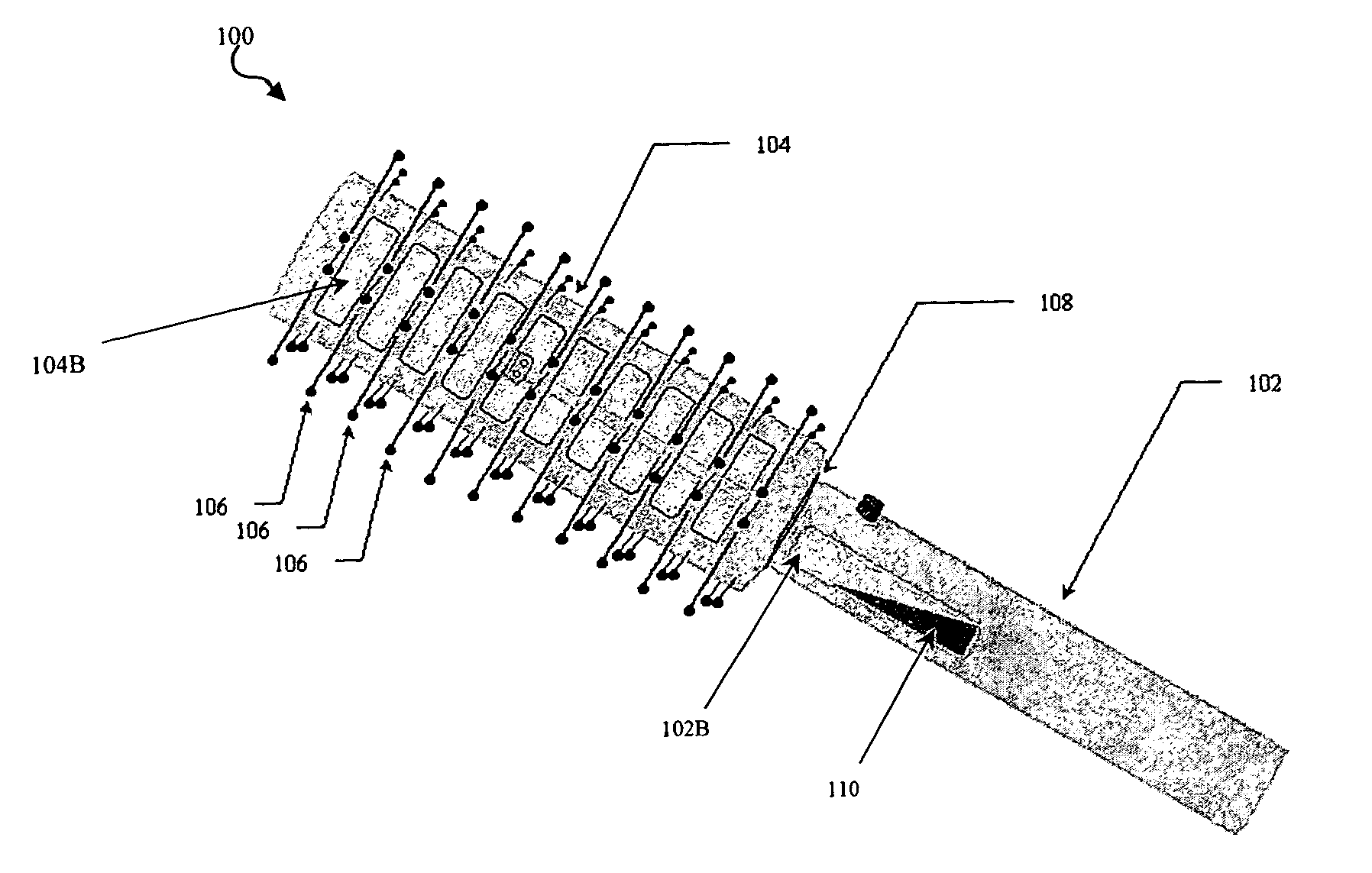

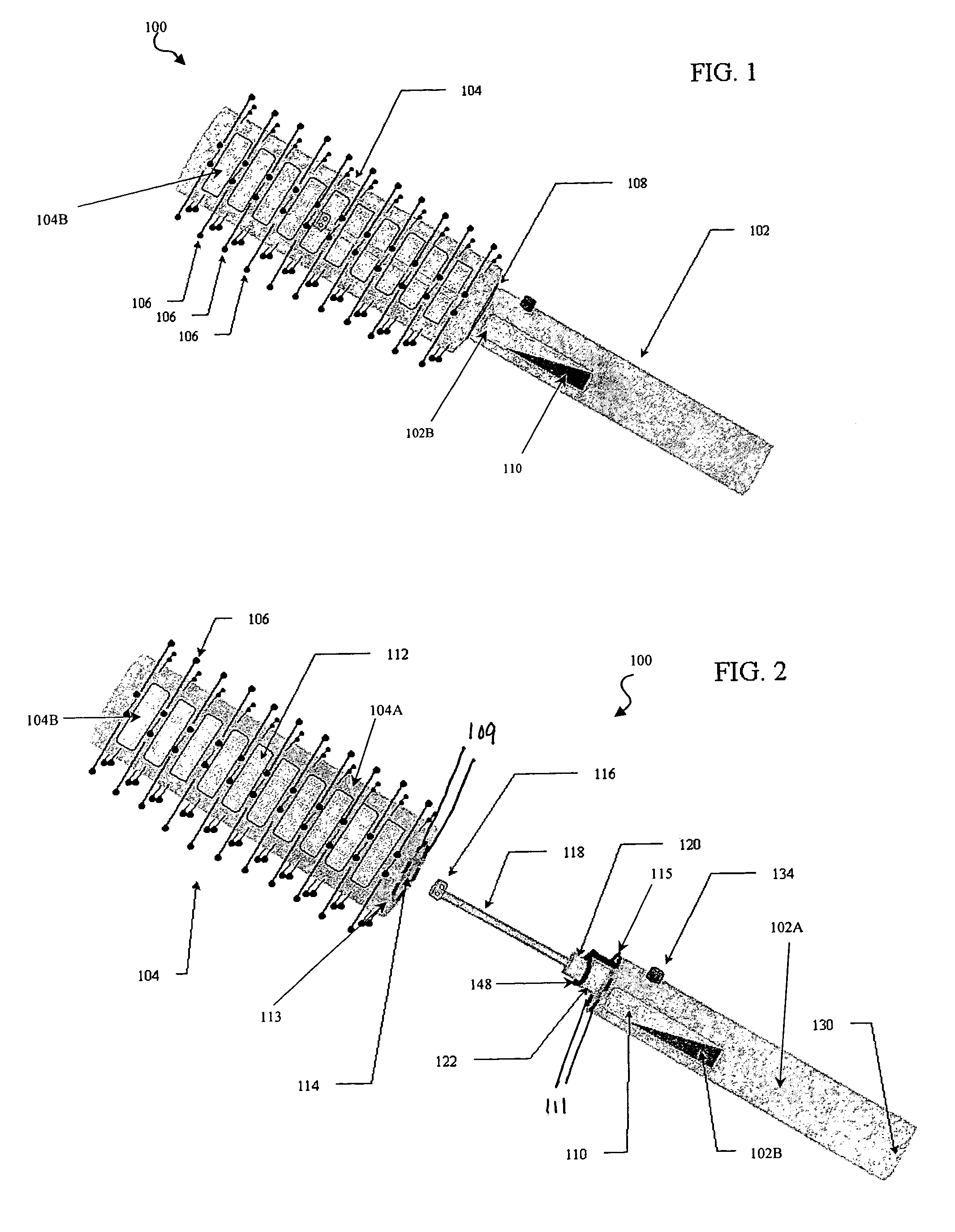

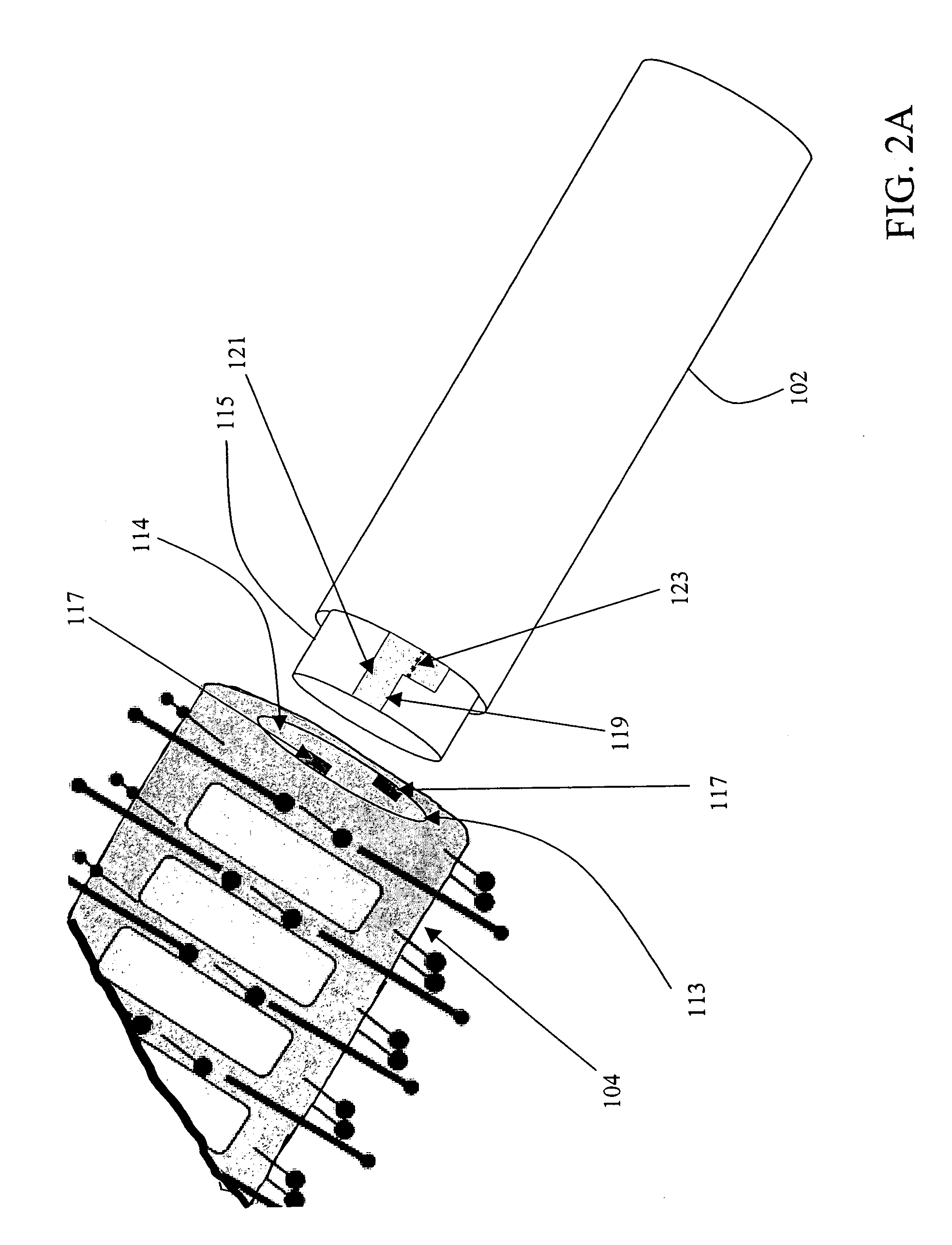

Fluid dispensing device

InactiveUS7011468B1Improve abilitiesMinimize/reduce applicationCarpet cleanersFloor cleanersBristleBiomedical engineering

A fluid dispensing device configured as a brush is provided. The device includes a hollow barrel having a plurality of bristles disposed along its surface and a plurality of openings in fluid communication with a chamber defined therein. The barrel is engaged to a hollow handle defining a chamber configured to contain an enclosed pressurized fluid reservoir containing a quantity of fluid. A user switch disposed along a surface of the device helps to discharge a volume of pressure from the fluid reservoir to thereby discharge a volume of fluid. The brush dispenses the volume of discharged fluid through the plurality of openings as a fluid spray or a fluid mist. In one embodiment according to the invention, the device permits a user to apply and to distribute a fluid through their hair, while the user brushes and / or styles their hair with the device.

Owner:CLIO DESIGNS INC

Fluid dispensing device

InactiveUS6974092B1Improve style capabilityMinimize/reduce applicationMovable spraying apparatusBrushesBiomedical engineeringBristle

A fluid dispensing device configured as a brush is provided. The device includes a hollow barrel having a plurality of bristles disposed along its surface and a plurality of openings in fluid communication with a chamber defined therein. The barrel is engaged to a hollow handle defining a chamber configured to contain an enclosed pressurized fluid reservoir containing a quantity of fluid. A user switch disposed along a surface of the device helps to discharge a volume of pressure from the fluid reservoir to thereby discharge a volume of fluid. The brush dispenses the volume of discharged fluid through the plurality of openings as a fluid spray or a fluid mist. In one embodiment according to the invention, the device permits a user to apply and to distribute a fluid through their hair, while the user brushes and / or styles their hair with the device.

Owner:CLIO DESIGNS INC

Infusion catheters with slit valves and of simplified construction

InactiveUS20090254062A1Facilitates flow and deliveryEven fluid distributionMulti-lumen catheterMedical devicesInfusion catheterVALVE PORT

The present invention relates to catheters to deliver a fluid to a patient. A catheter of the invention comprises a plurality of slits through which the fluid is delivered to the patent. A catheter of the invention is designed in a simple manner to lower costs and provide a reliable means to deliver fluids to a patient. The invention further comprises methods for making a catheter of the invention and methods of delivering a fluid to a patient with a catheter of the invention.

Owner:KIMBERLY-CLARK WORLDWIDE INC

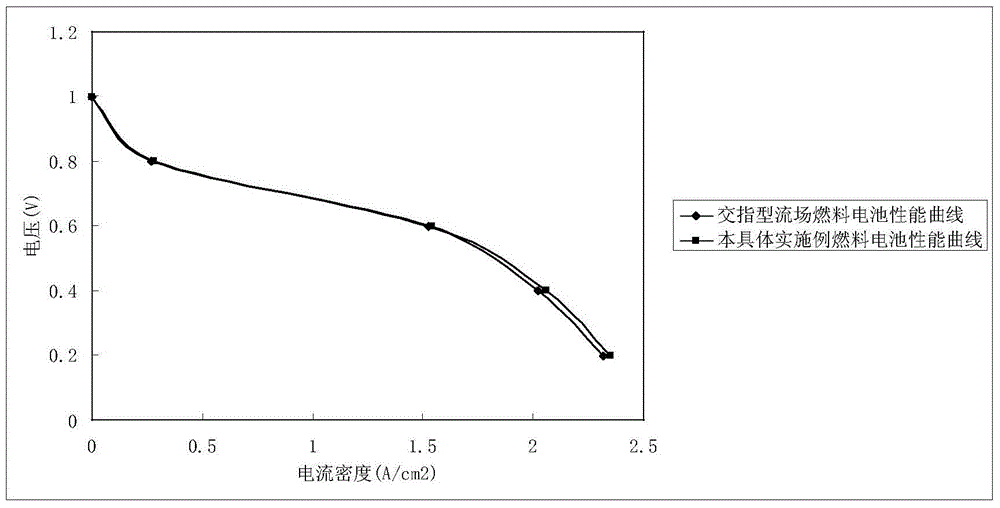

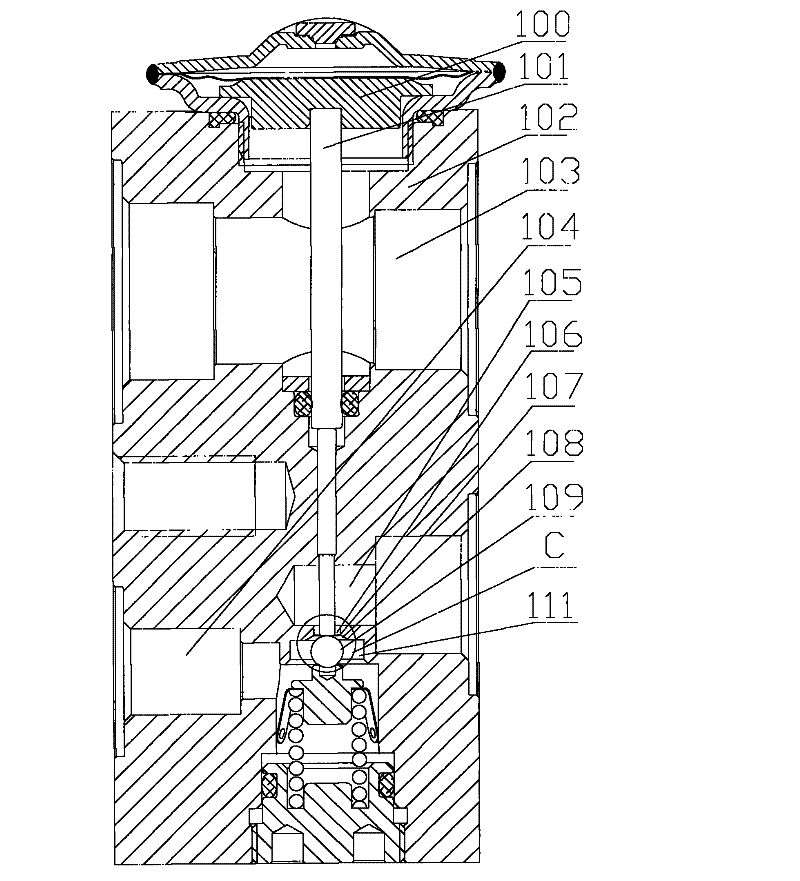

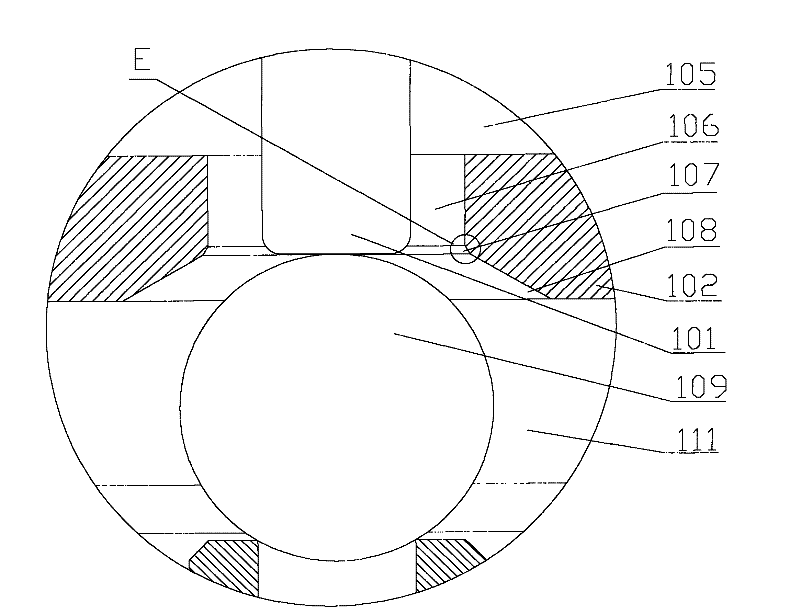

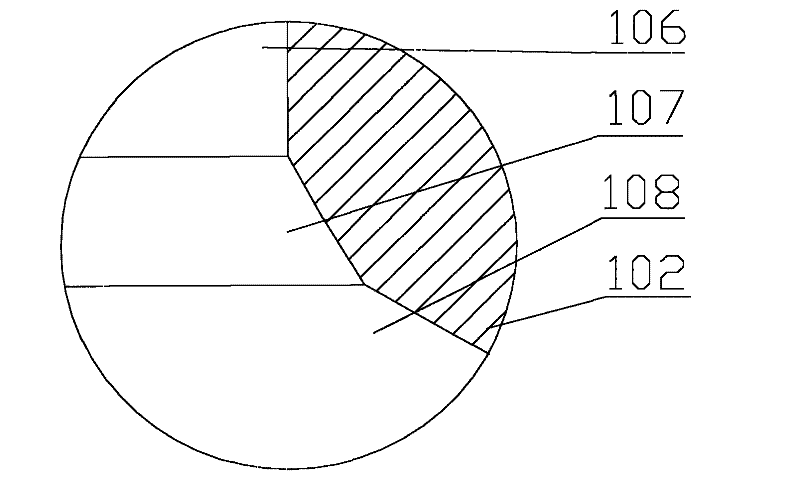

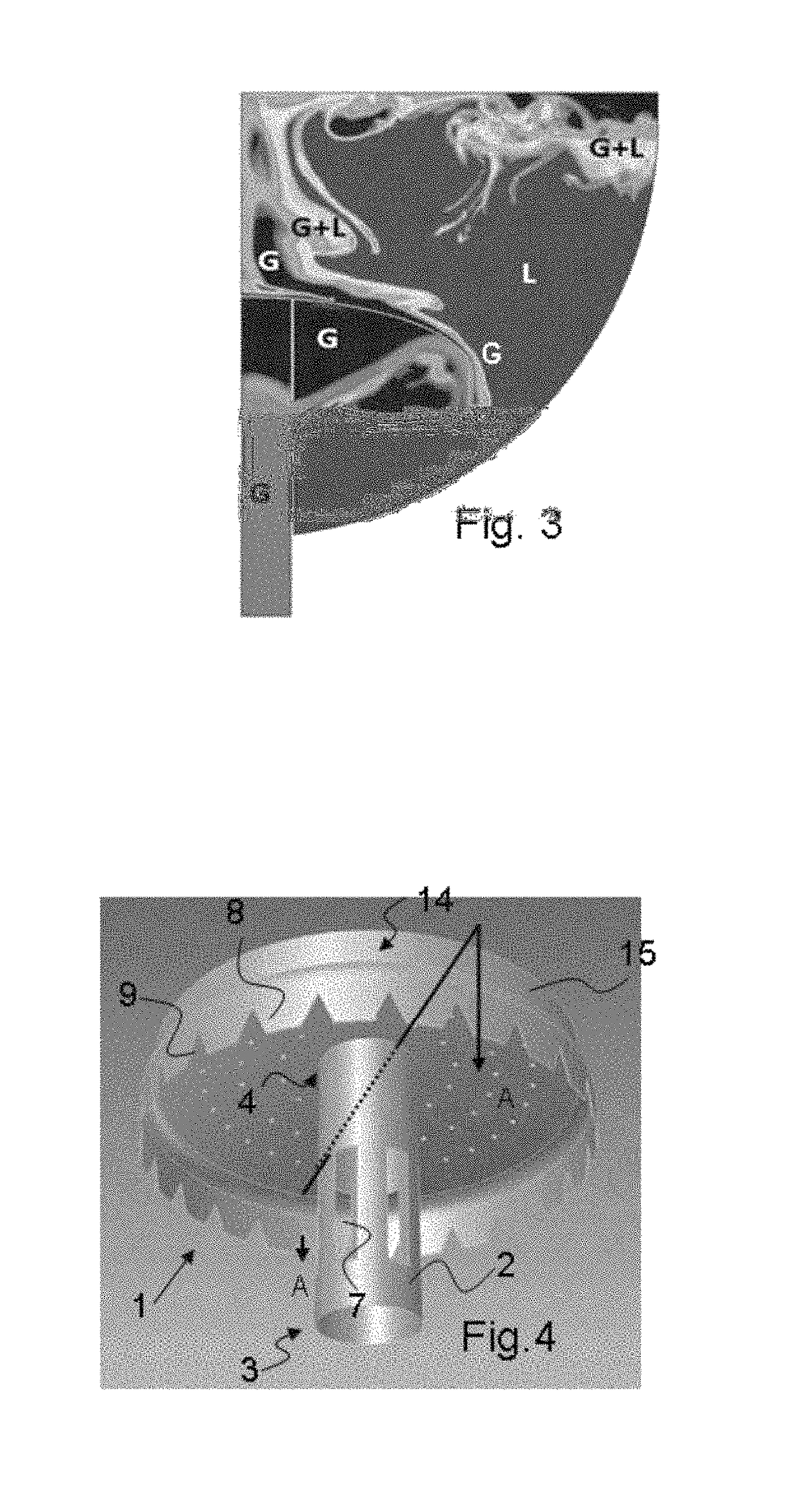

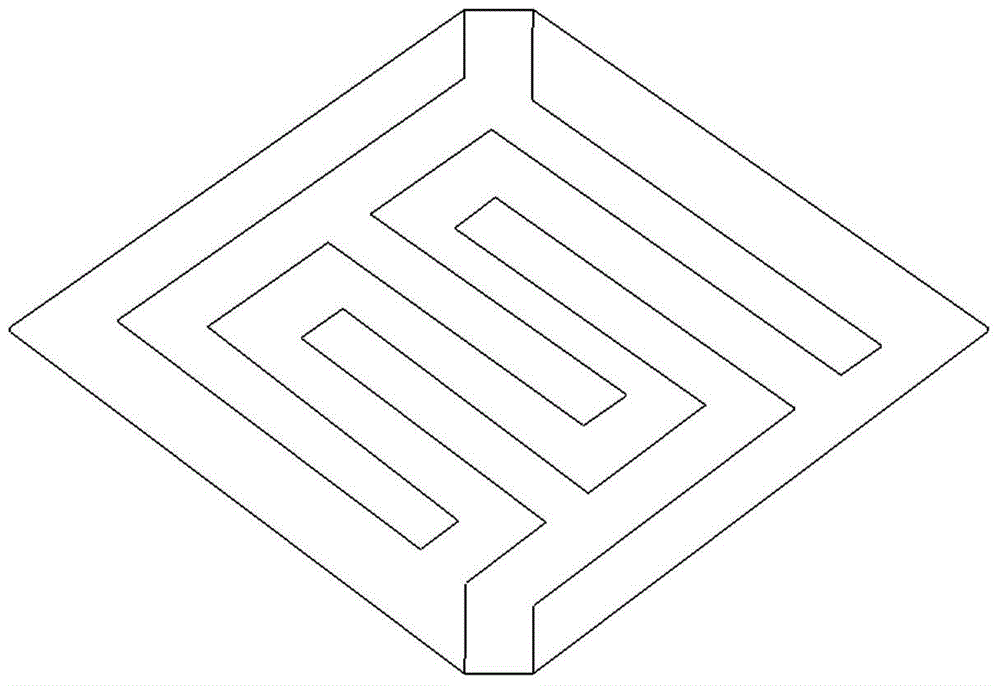

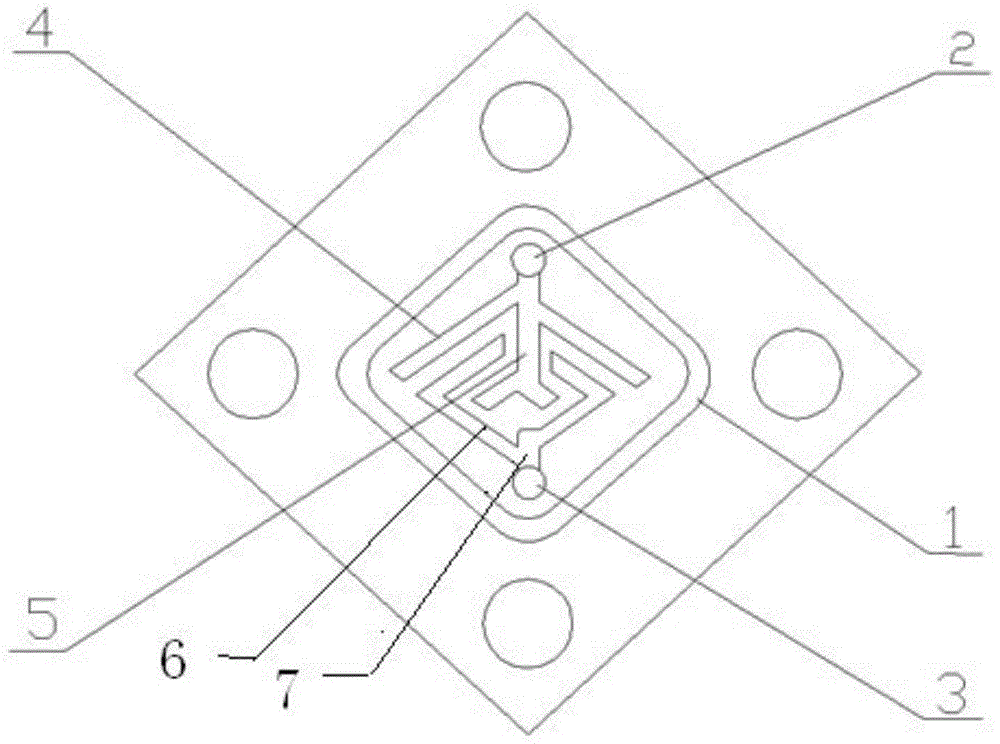

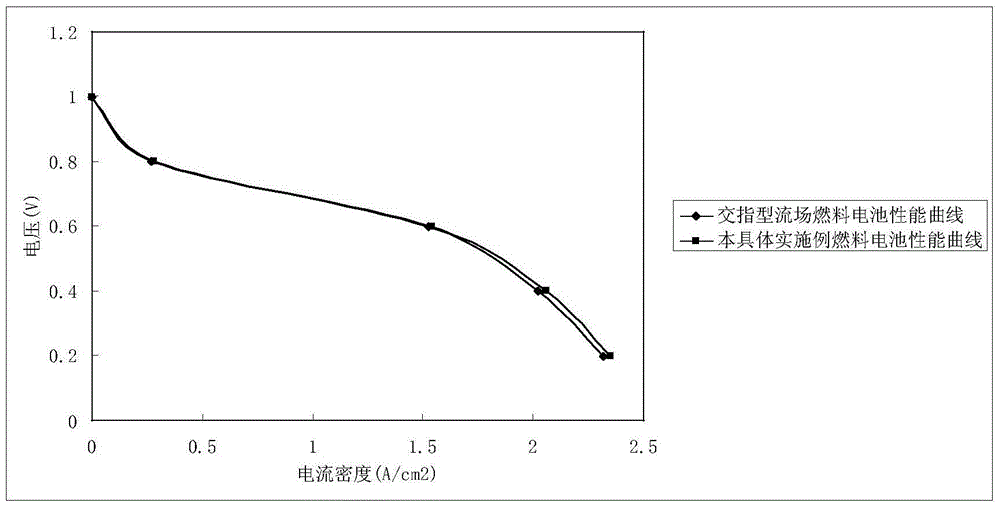

Vein-like fuel cell flow field structure, fuel cell bipolar plate, and fuel cell

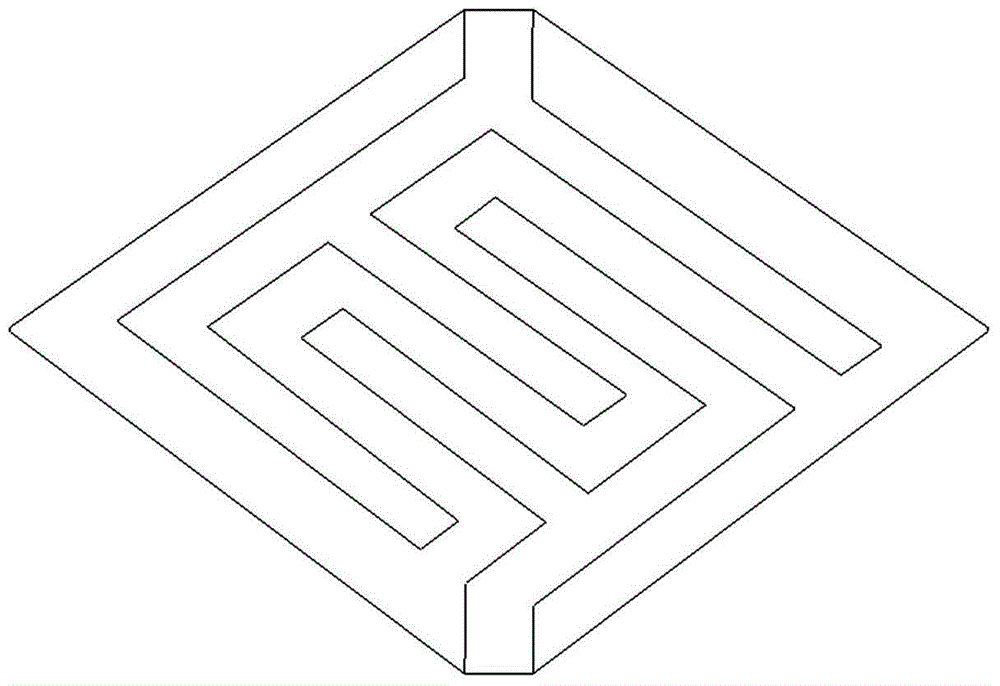

ActiveCN104821407ALow flow resistanceImprove performanceCell electrodesSolid electrolyte fuel cellsFuel cellsFlow resistivity

The invention relates to a vein-like fuel cell flow field structure, wherein the gas flow field structure is a vein-like flow field and comprises a reaction gas inlet, a reaction gas outlet and a gas flow channel, the reaction gas inlet is arranged on the petiole position of the vein, and the reaction gas outlet is arranged on the leaf apex position of the vein. According to the present invention, the vein structure is introduced into the flow field design, such that the characteristics of low fluid flow resistance and uniform flow field distribution in the vein are applied in the flow field design so as to improve the battery performance.

Owner:ZHEJIANG UNIV OF TECH

Thermal expansion valve

ActiveCN102538316AIncrease the throttling area of the refrigerantComply with refrigerant flow requirementsFluid circulation arrangementLow loadThermal expansion

The invention relates to a thermal expansion valve which comprises a valve body. The valve body comprises an inlet port, a valve chamber, a valve hole, an outlet port and a reflux channel, wherein the inlet port is used for importing a high pressure refrigerant; the valve chamber is communicated with the inlet port; the valve hole is arranged in the valve chamber; the outlet port is used for exporting out the refrigerant expanded due to opening and closing of the valve hole; the reflux channel is used for the refrigerant which flows through an evaporator and is returned towards a compressor; a valve rod is arranged in the valve body in a sliding mode and passes through the reflux channel and the valve hole, one end of the valve rod is connected a valve element and the other end of the valve rod is pushed by a thermal element so as to control the opening of the valve hole; the valve hole is a horn hole and comprises a section of cylindrical hole and at least two adjacent cone holes which are provided with gradually enlarging openings and are connected with one end of the cylindrical hole; and when the valve element is in contact with the side walls of the cone holes, the valve hole is closed. Compared with the thermal expansion valve in the prior art, the thermal expansion valve disclosed by the invention has the advantage that the matching problem of a low-superheat-degree air conditioning system under the high-load and low-load working conditions is solved.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

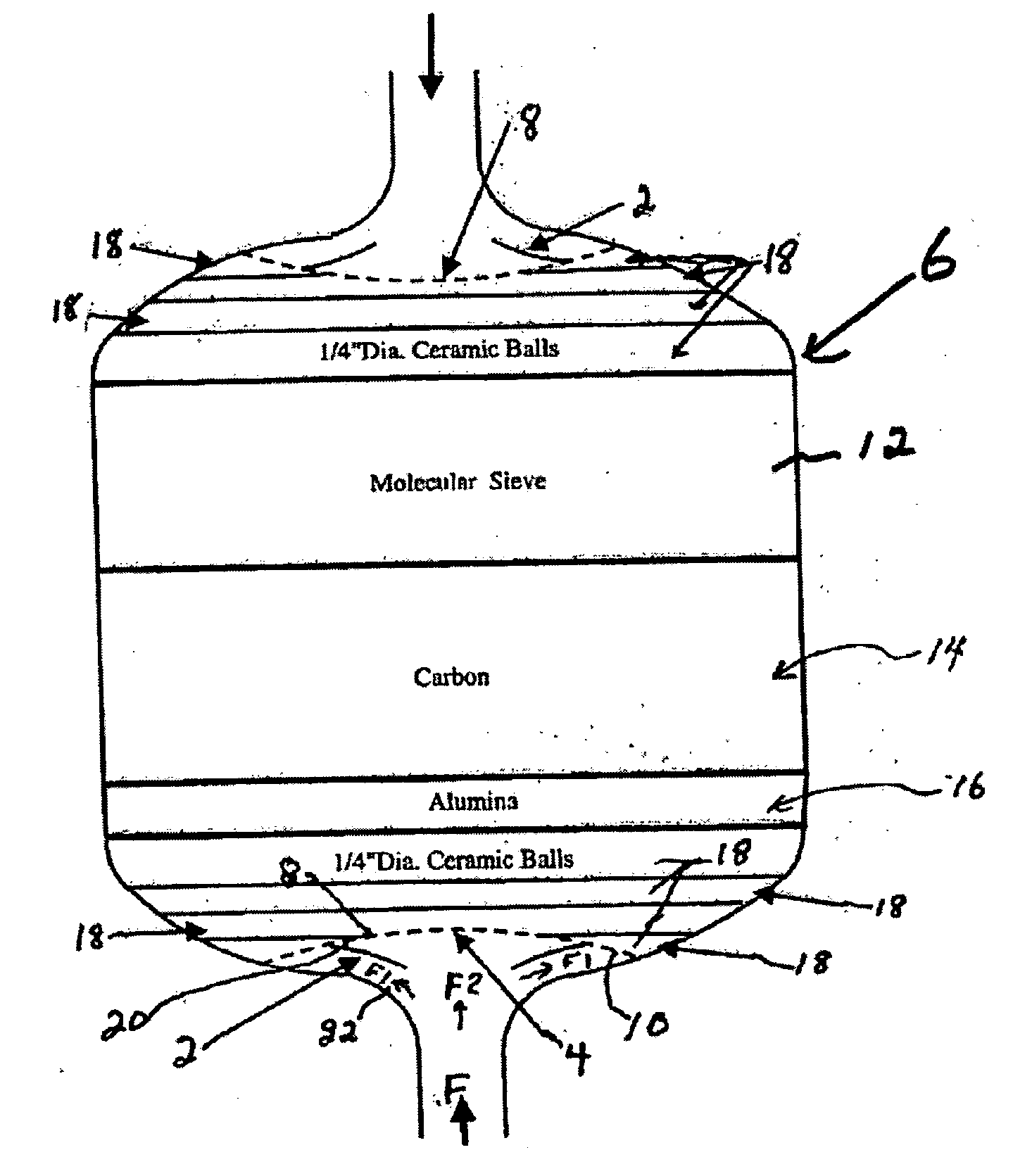

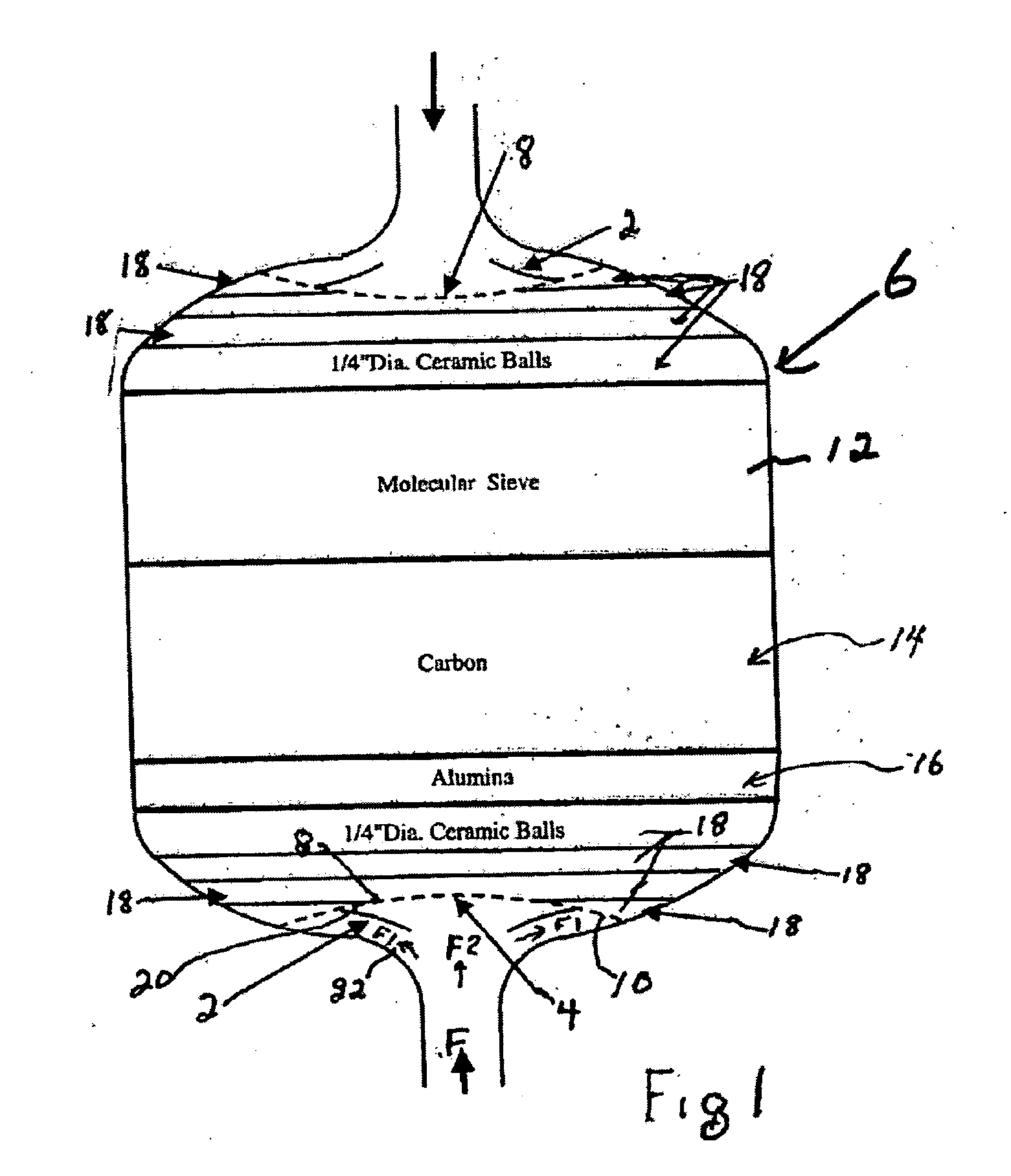

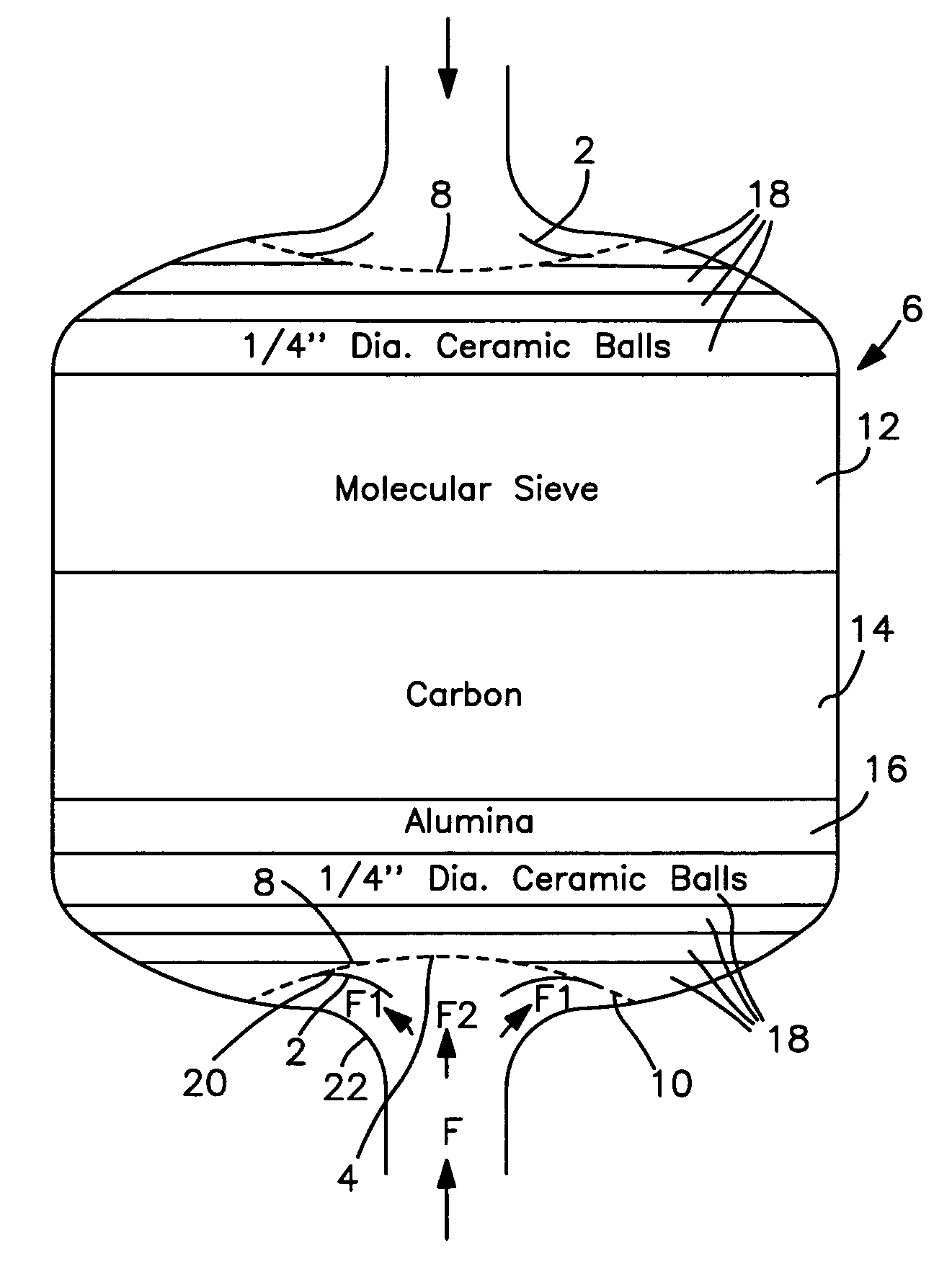

Flow distributor for PSA vessel

ActiveUS7166151B2Effective even distributionEven fluid distributionGas treatmentAuxillary pretreatmentEngineeringDistributor

The present invention is a PSA system having at least one vessel that uses a multi-segmented flow distributor to provide a uniform fluid across the adsorbent bed in the vessel.

Owner:PRAXAIR TECH INC

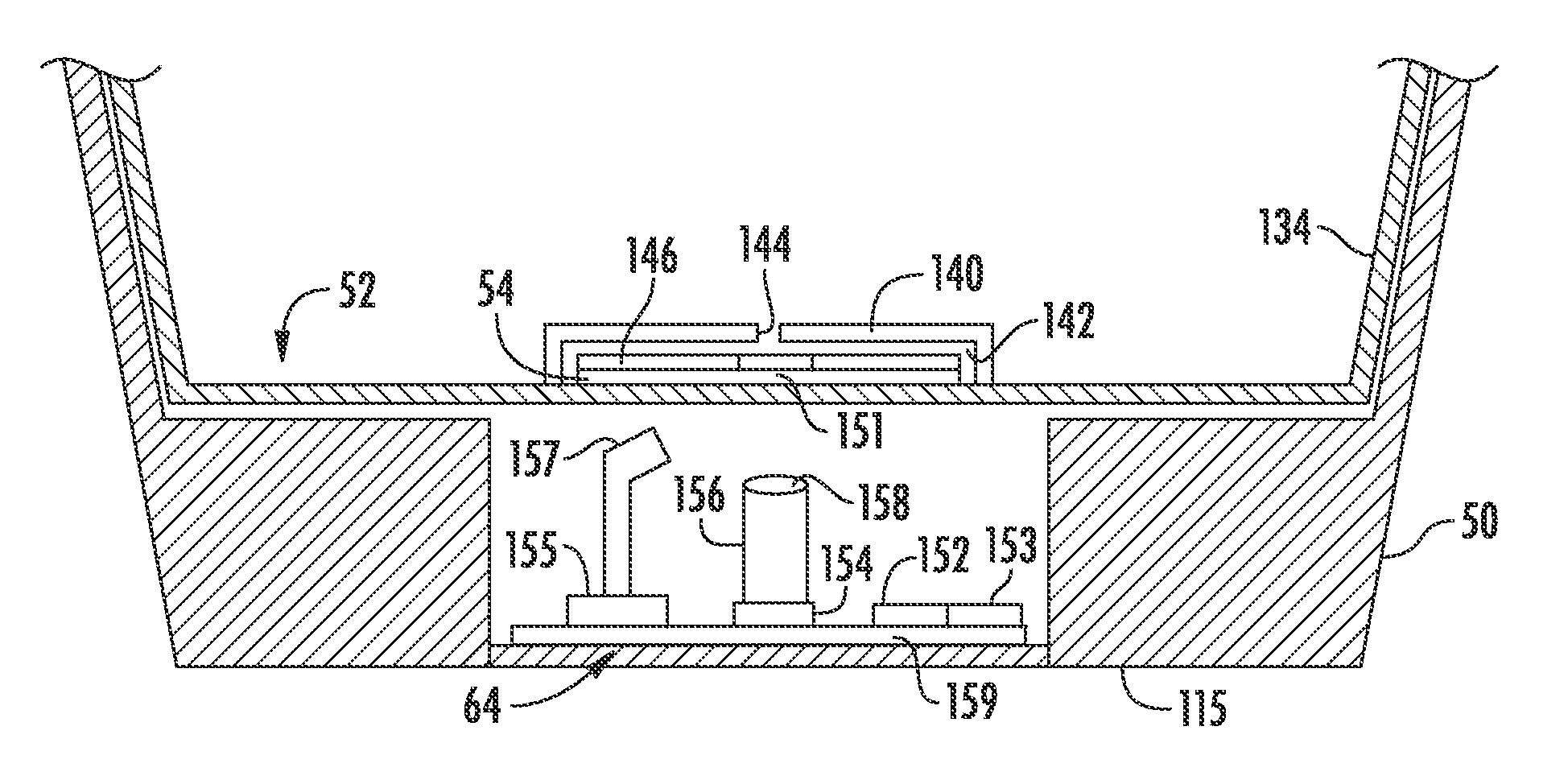

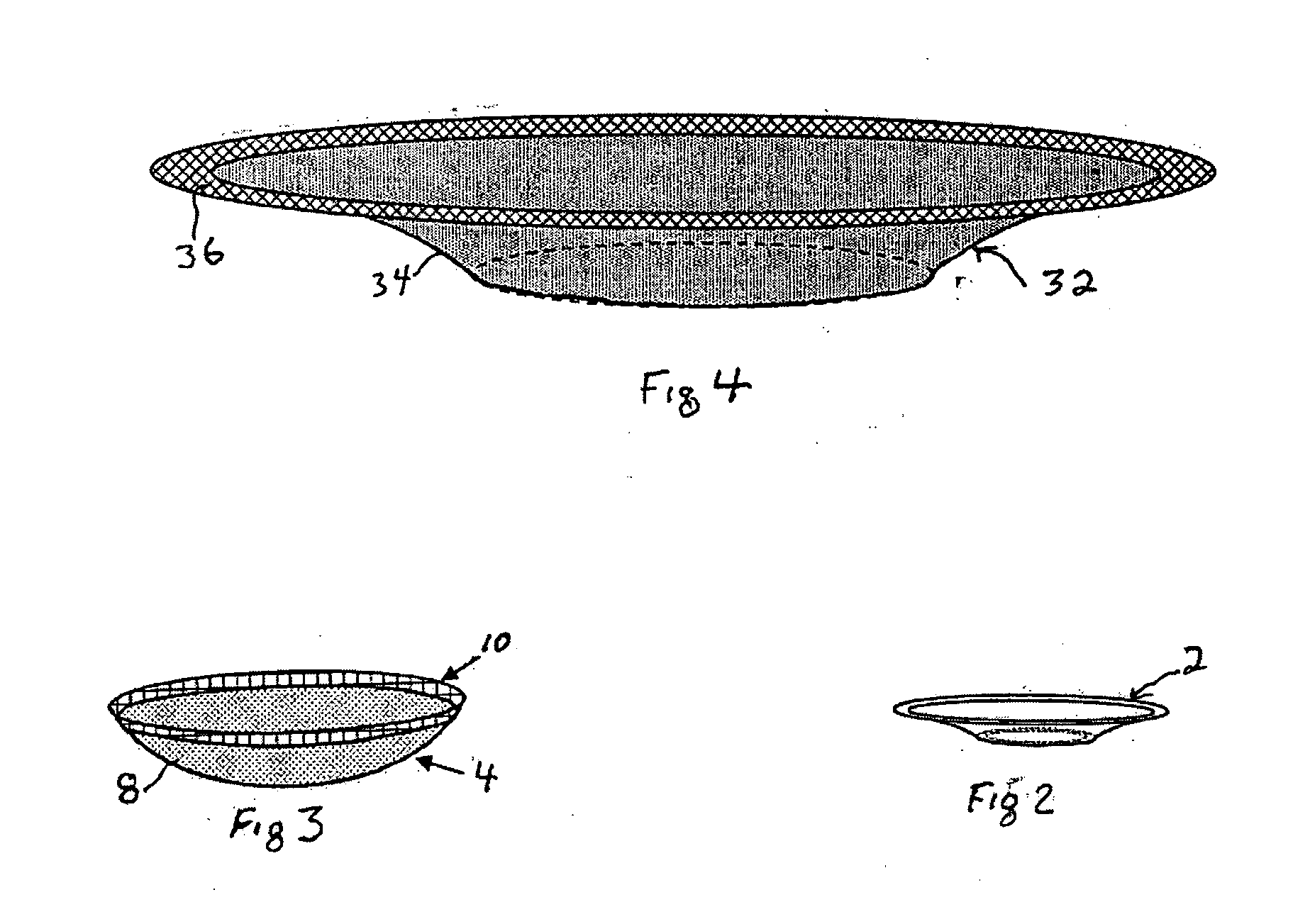

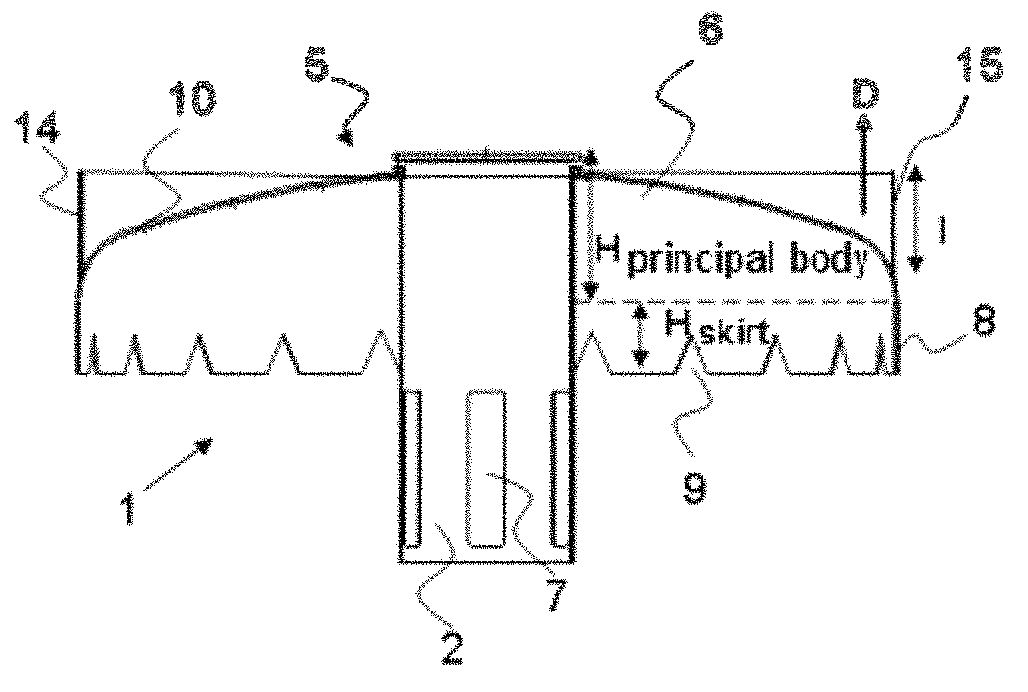

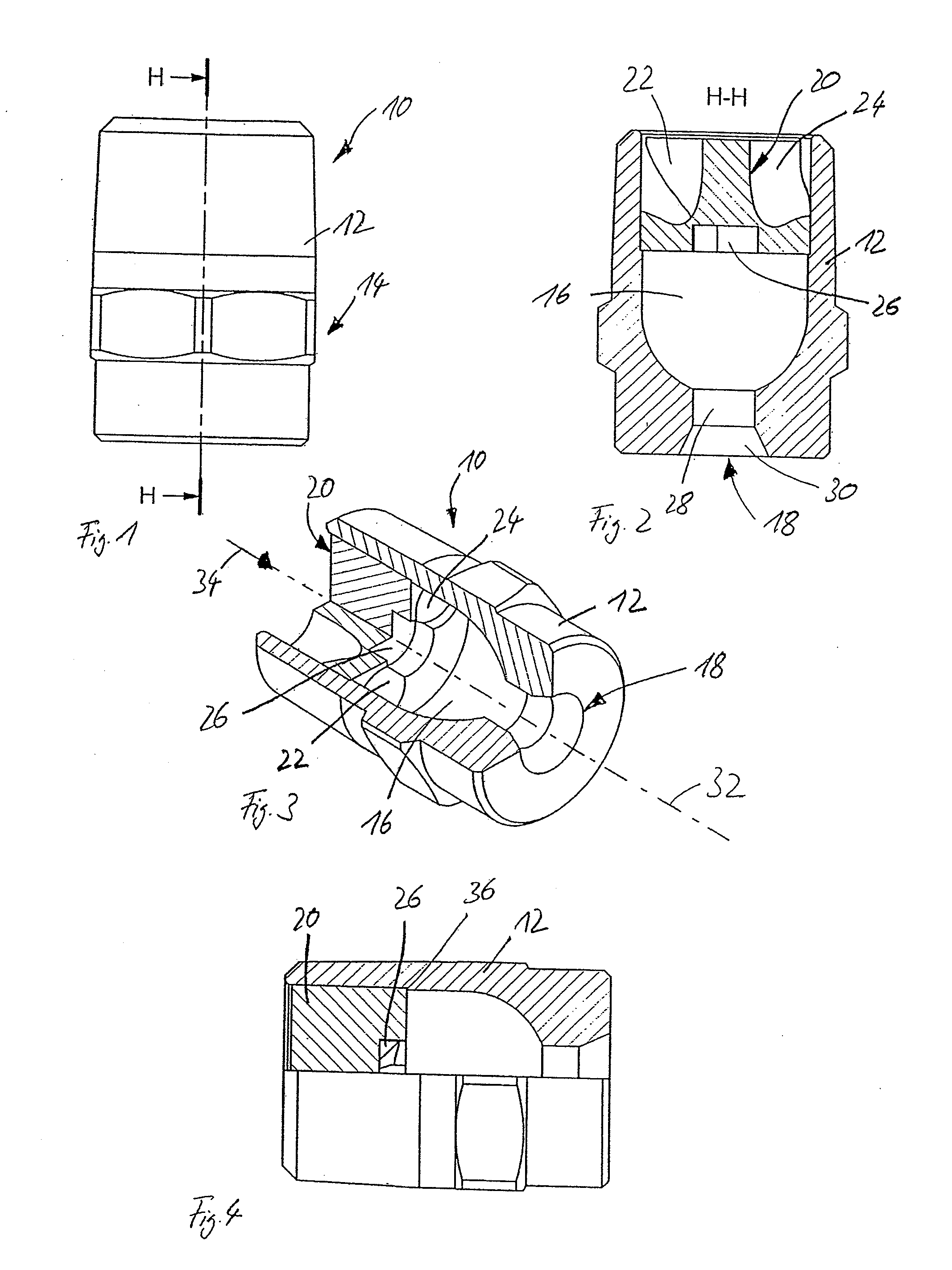

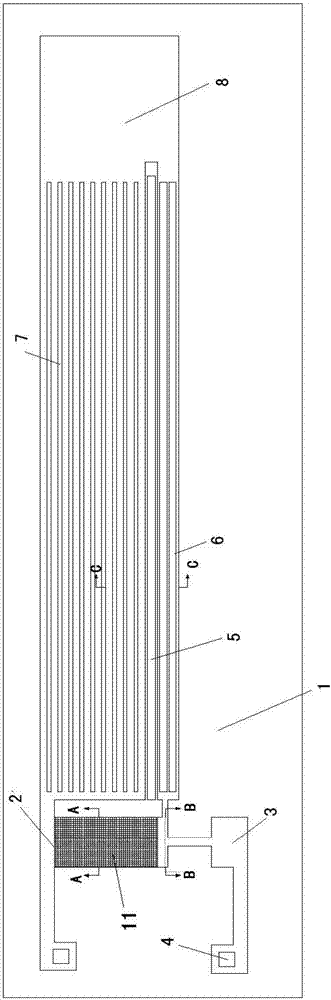

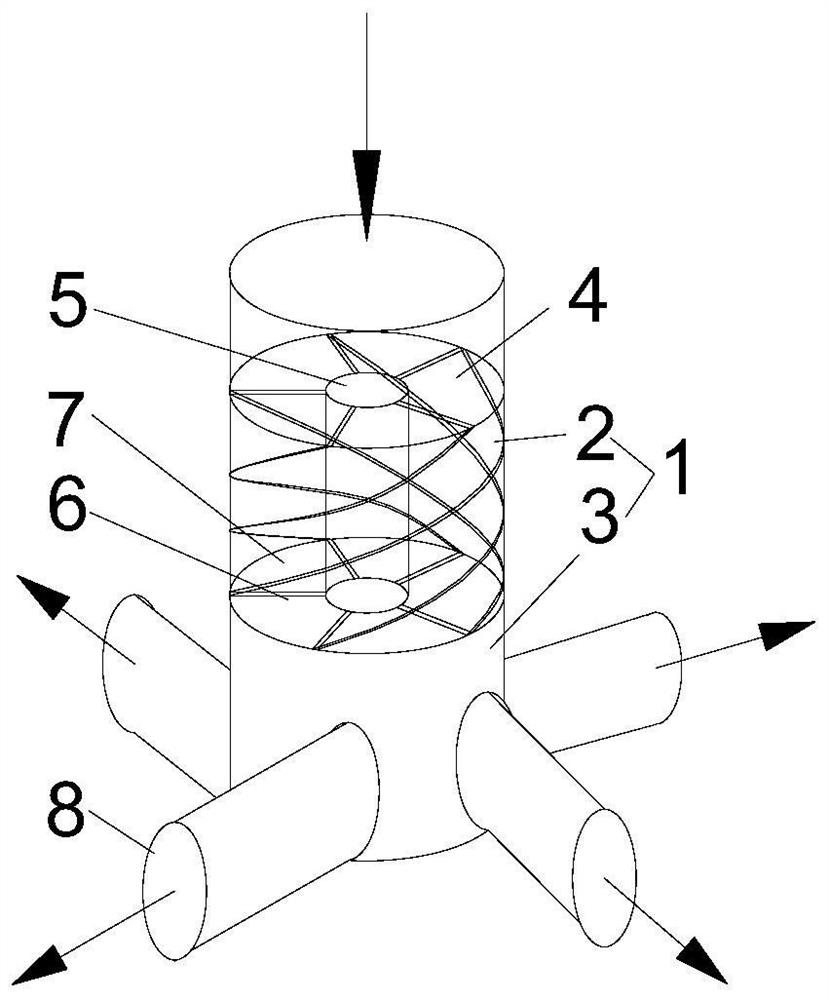

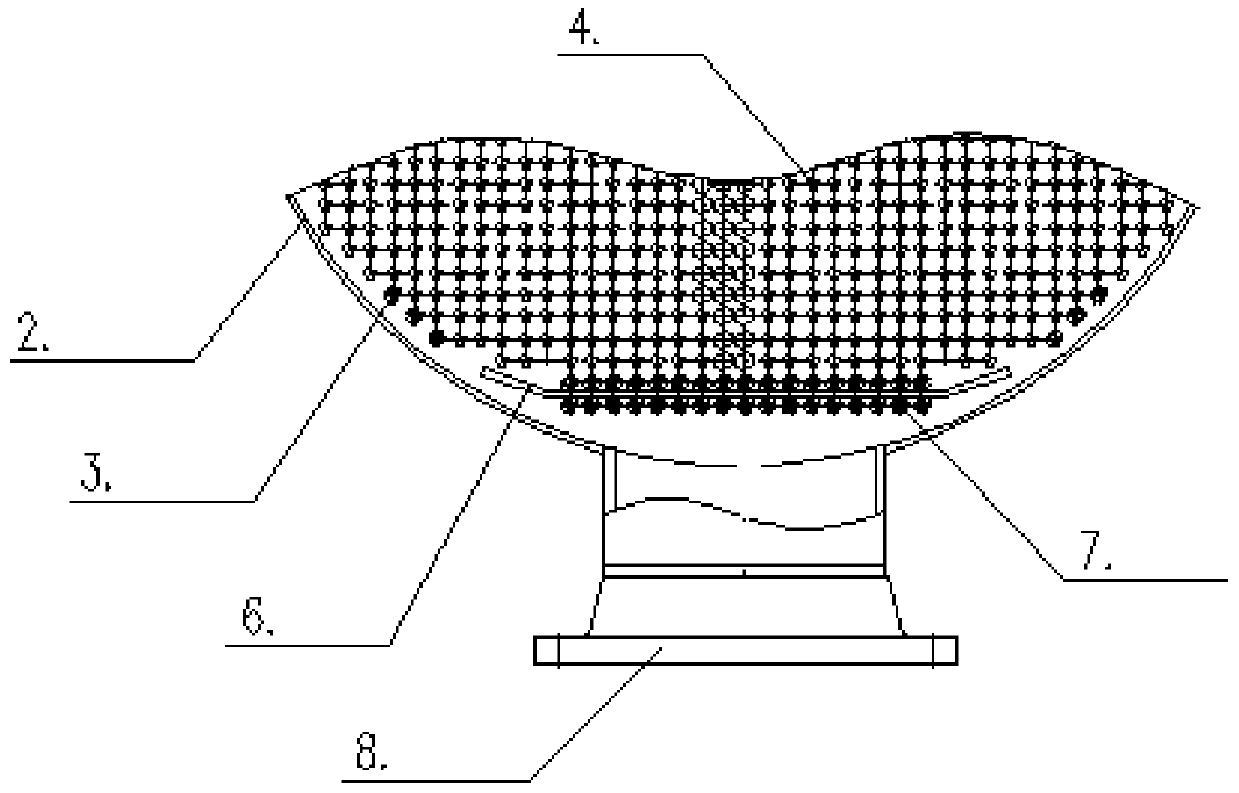

Fluid distribution device

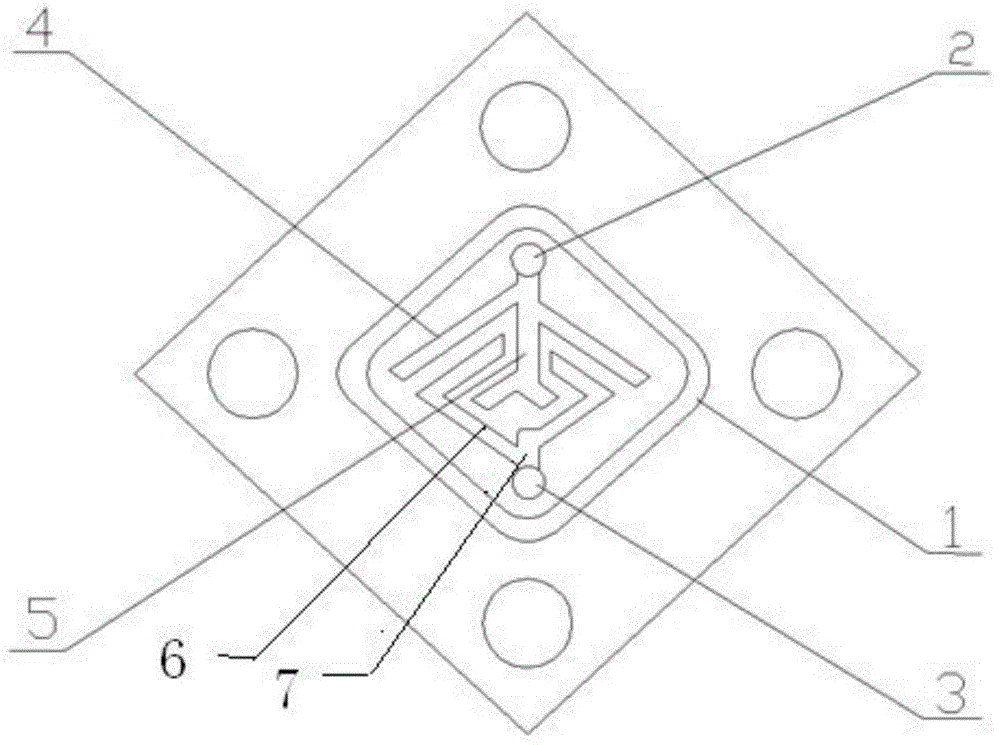

ActiveUS9833759B2Reduce centripetal forceEven fluid distributionCatalytic crackingEnergy recuperation in distillationBiomedical engineeringCircular section

The invention concerns a fluid distribution device (1) comprising:at least one inlet tube (2) comprising openings (7) and having a first and a second end (3, 4);a cap (5) comprising a principal body (6) with a lenticular shape and with a circular section elongated by a skirt (8) extending in the direction of the second end (4) towards the first end (3) of the inlet tube (2), said cap (5) having an outer surface and an inner surface, the cap being integral with the second end (4) of the tube via the inner surface and the principal body (6) being provided with a plurality of holes (10);and in which the cap (5) comprises at least one deflection means (14) disposed on its outer surface and configured to direct or maintain the gas towards or at the periphery of said cap (5).

Owner:AXENS SA

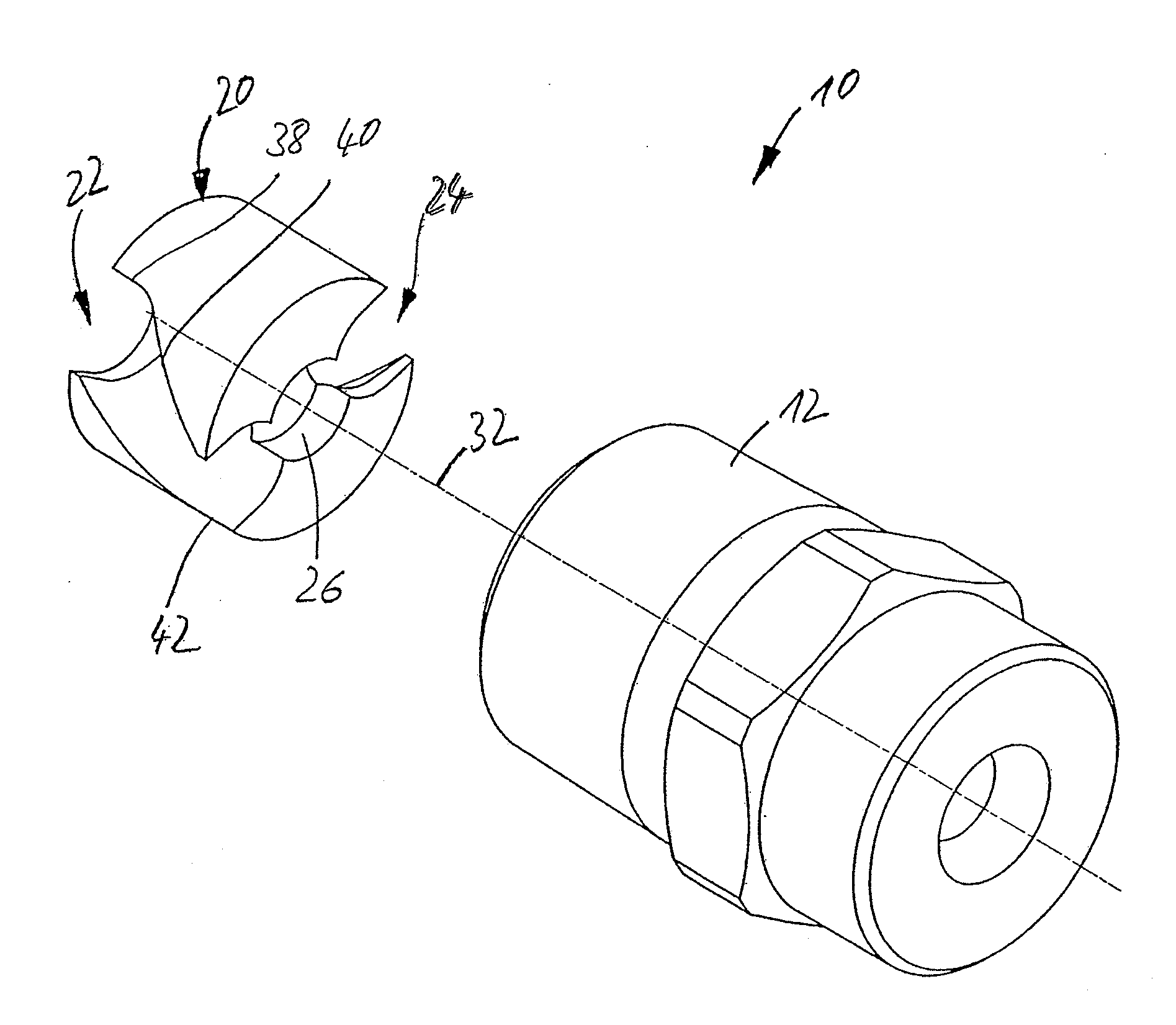

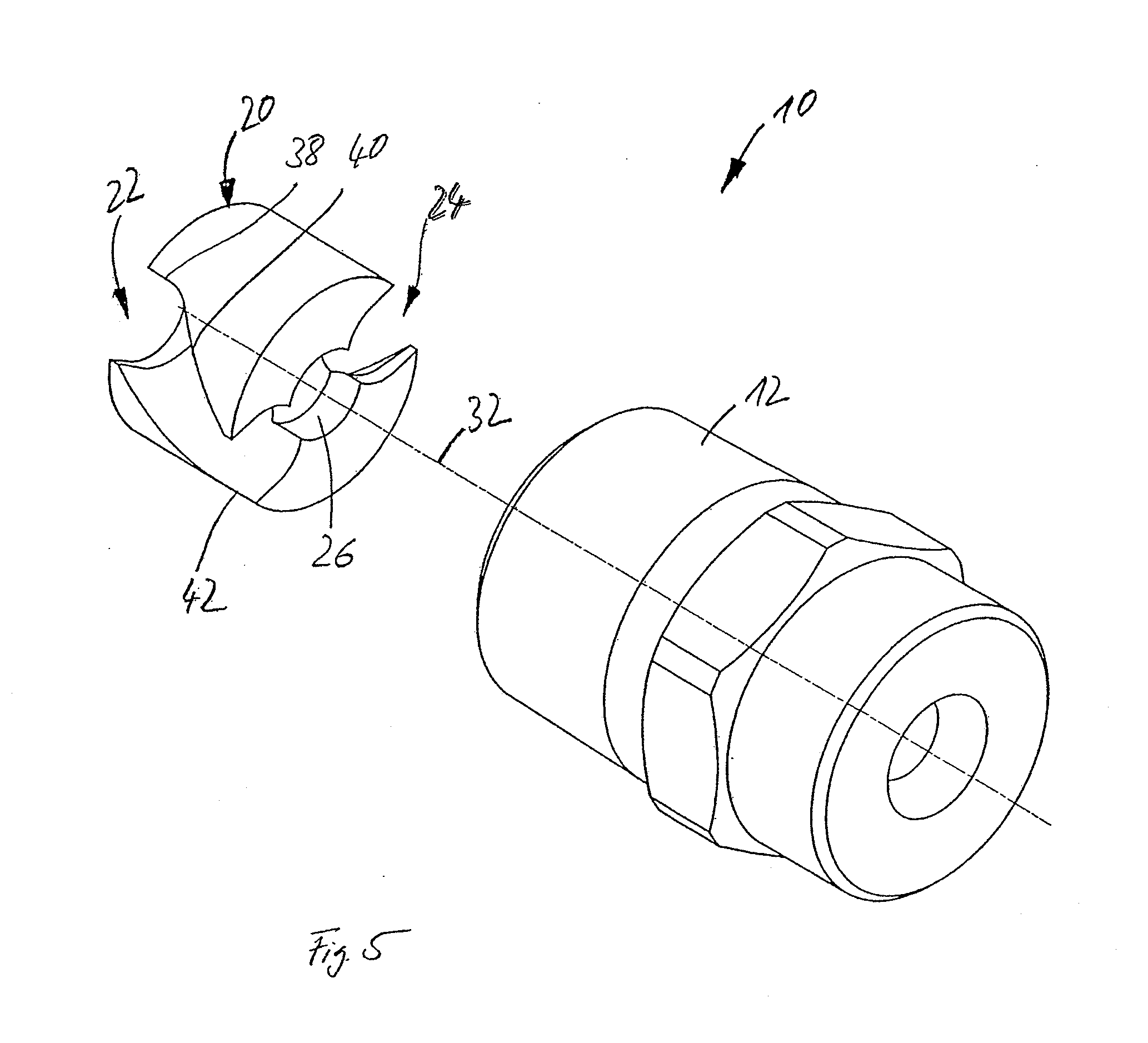

Solid cone nozzle

ActiveUS20130001325A1Avoid many problemsLess susceptible to choking effectSpray nozzlesEngineeringSolid cone

A solid cone nozzle comprises a nozzle housing and a swirl insert, wherein said nozzle housing has an outlet chamber including a discharge orifice and wherein the outlet chamber is disposed downstream of the swirl insert. The swirl insert has on its external periphery at least one swirl duct, which extends, in a swirl portion, helically or at an angle to the longitudinal center axis of the swirl insert and which extends in the axial direction in an outlet portion, which outlet portion extends from the end of the swirl portion to the downstream end of the swirl duct.

Owner:LECHLER SPA

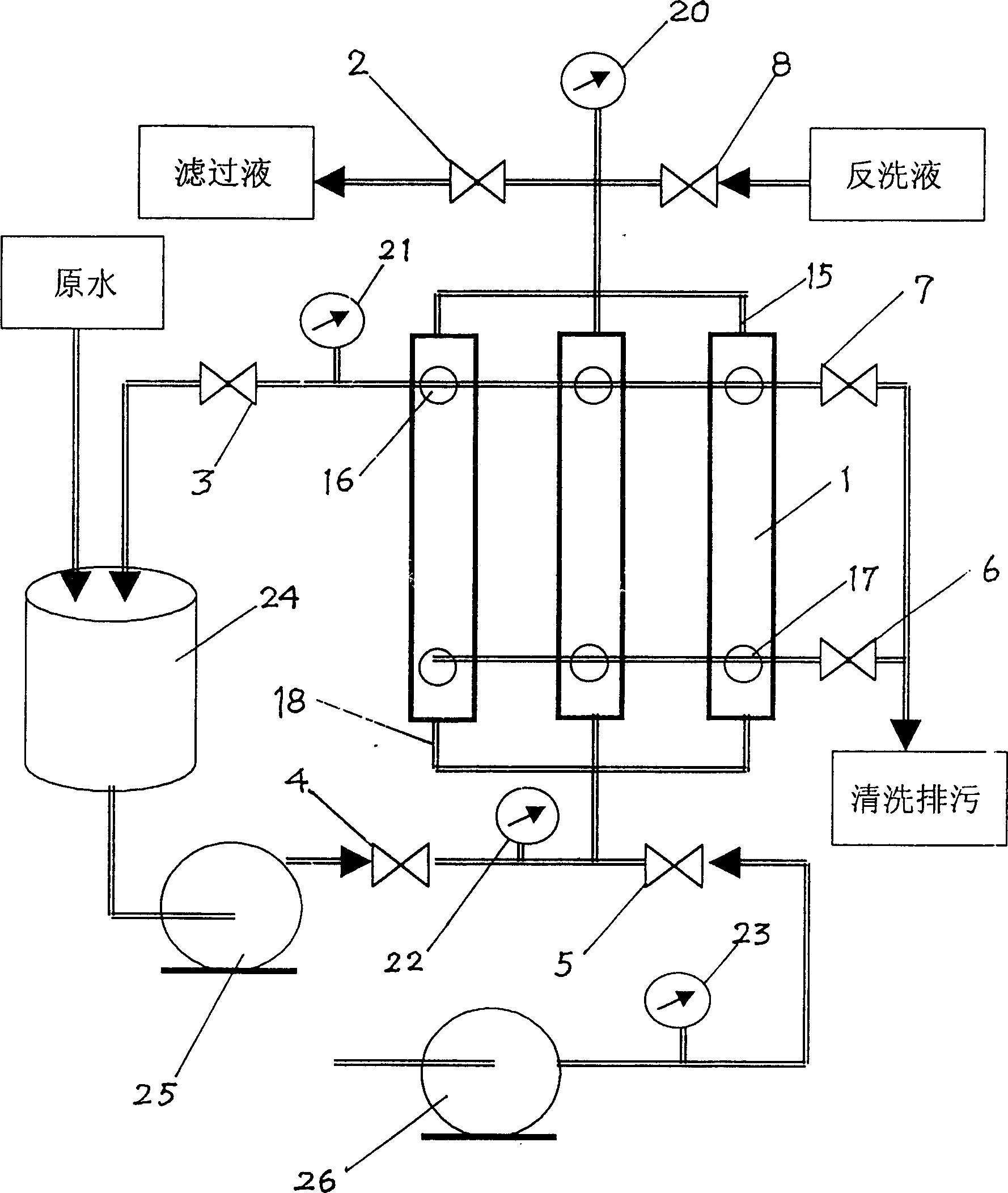

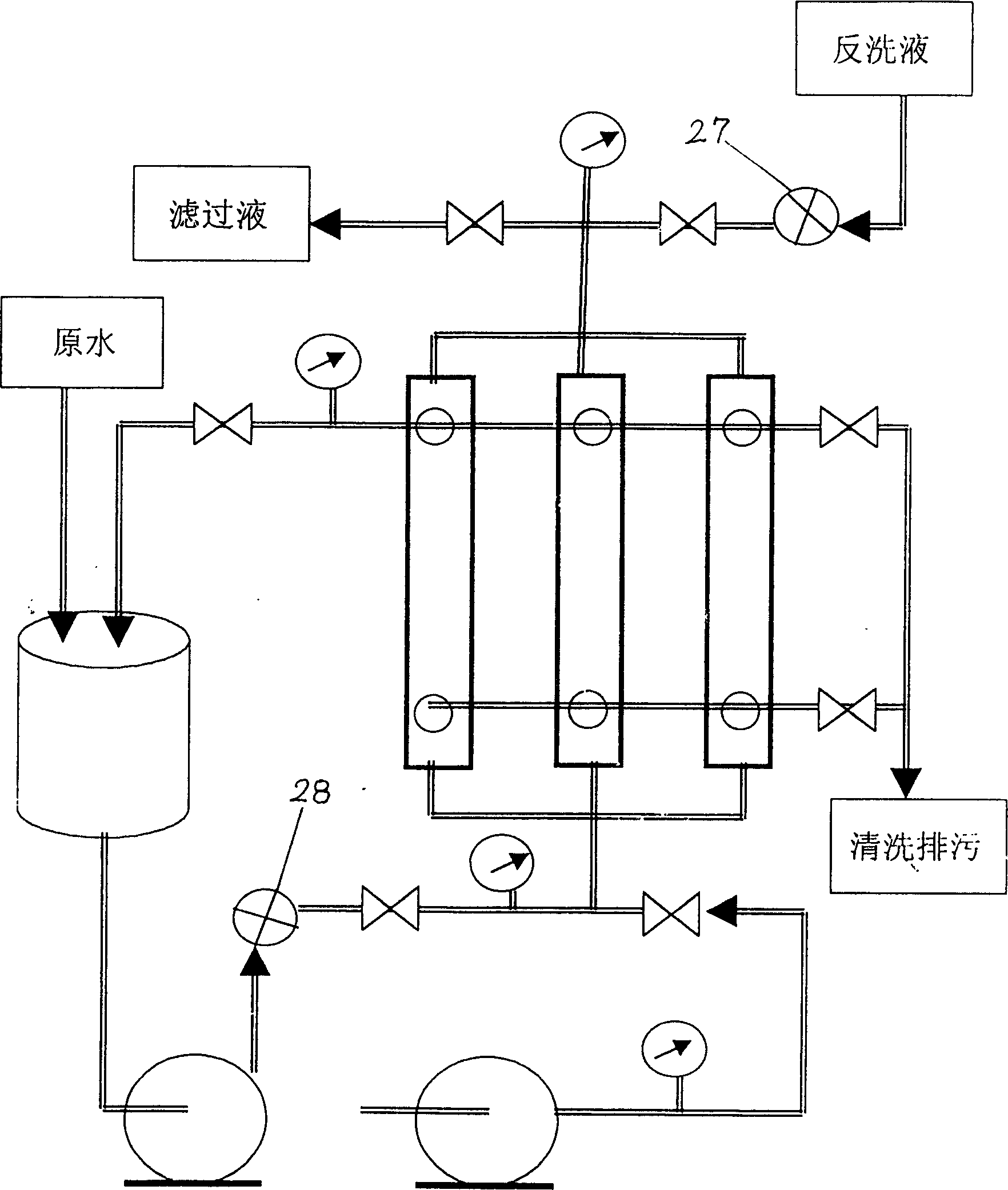

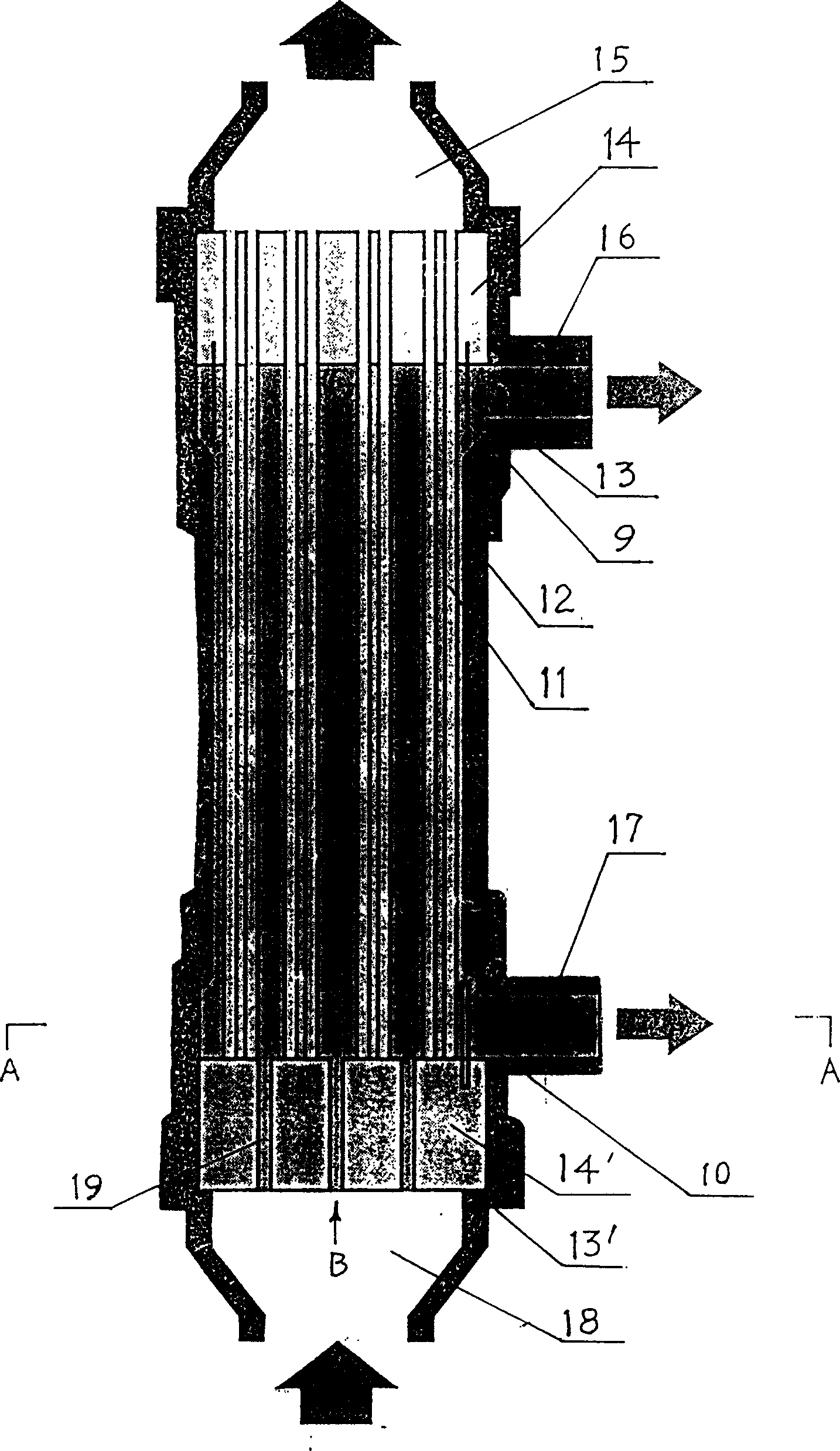

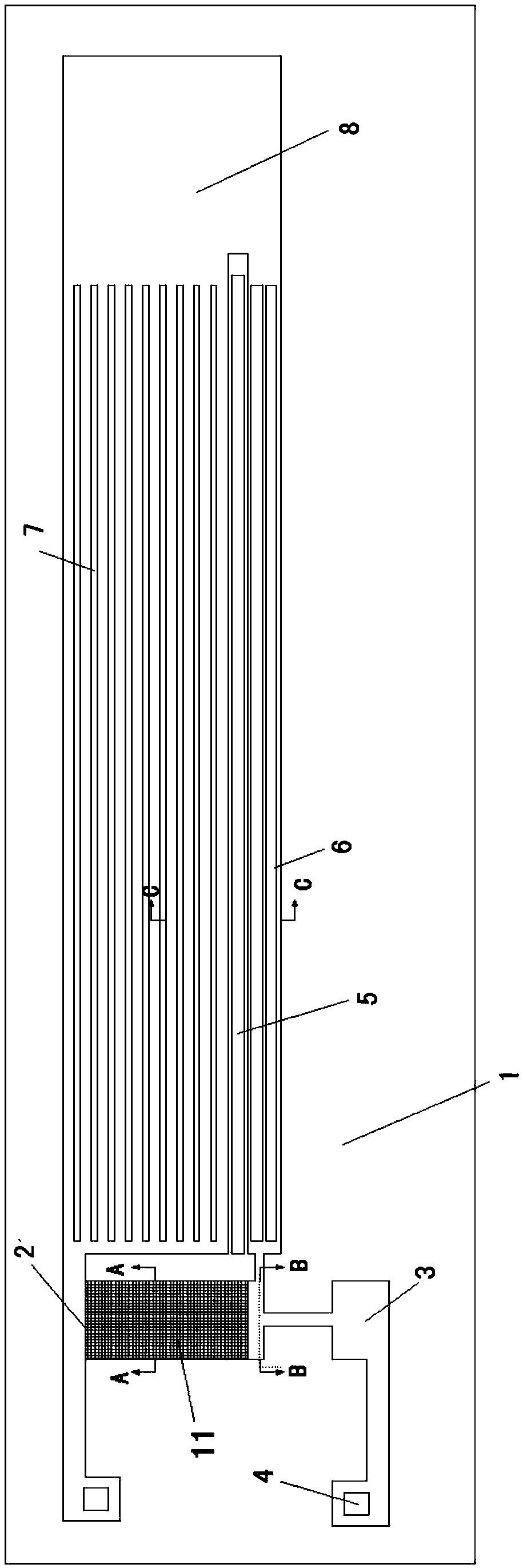

External pressing hollow fibre membrane separator and use method thereof

InactiveCN1214851CEasy to cleanImprove cleaning efficiencyUltrafiltrationHollow fibre membraneMembrane configuration

The external pressure hollow fibre membrane separation equipment incldues the common parts of membrane component, etc. and the interior of said membrane component is equipped with packed membrane whose upper casting end has opened hole and lower casting end has closed hole, several guide holes are set on the lower casting end, and one path of lower end hole of said membrane component is connected with pump by means of pipe, and its another path is connected with air compressor by means of pipe. It is characterized by that the upper end hole of membrane component is passed through pressure gauge, then its one path is passed through control valve, and is connected with filtrate tank via pipe, and another path is passed through control valve, and is connected with back-flushing liquid tank via pipe, and one path of upper side hole of the membrane component is passed through pressure gauge and control valve, and is connected with feed liquid tank by means of pipe, and its another path is passed through control valve, and is connected with blow-off pipeline, and the lower side hole also is connected with blow-off pipeline.

Owner:TIANJIN MOTIMO MEMBRANE TECH

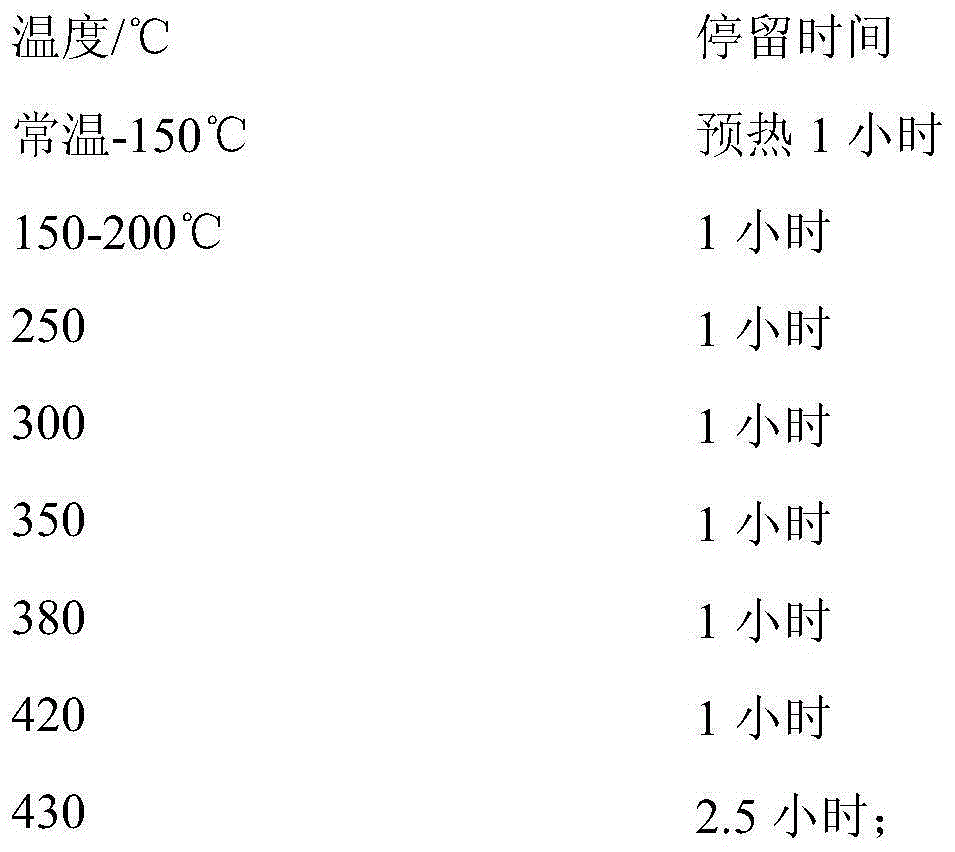

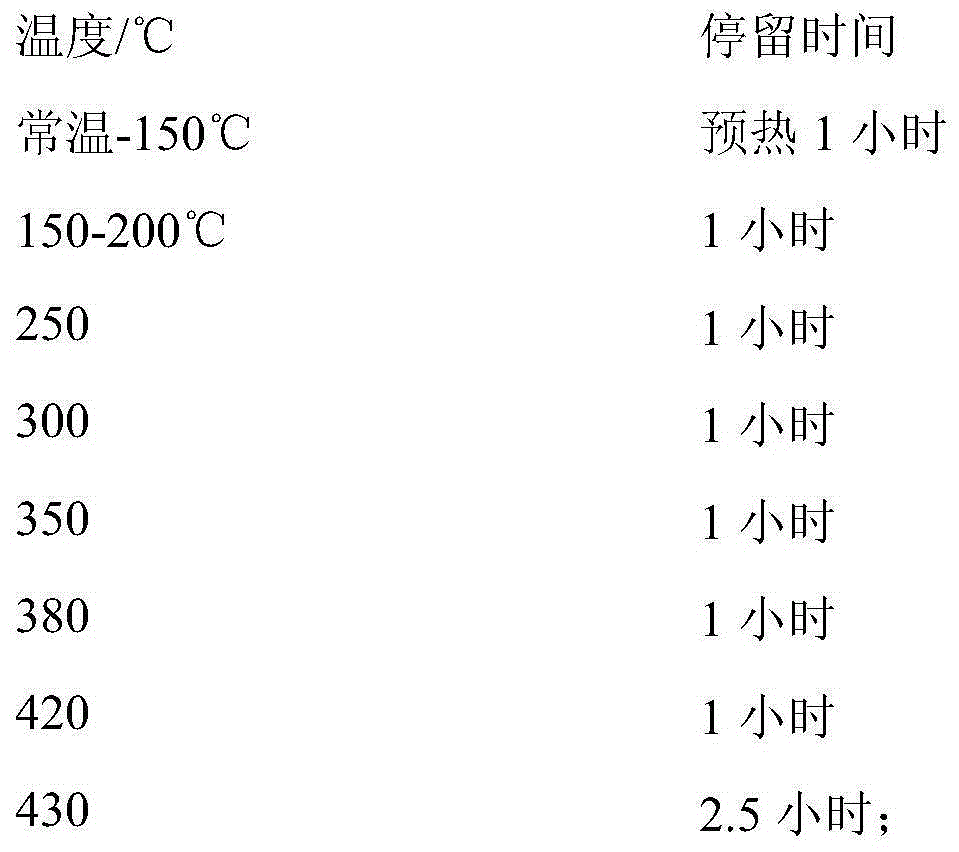

Alumina carrier hydrogenation catalyst regeneration utilization method

ActiveCN106475114ARestore activityRestore stabilityMetal/metal-oxides/metal-hydroxide catalystsBelt speedEngineering

The present invention discloses an alumina carrier hydrogenation catalyst regeneration utilization method, which comprises: screening a failure catalyst through a vibration sieve to remove unwanted carbon powder and ceramic balls so as to separate a spent catalyst; conveying the spent catalyst into a mesh belt moving bed type flame separation tunnel regeneration furnace using natural gas as a fuel, continuously heating through different temperature sections, cooling, and discharging the material to obtain a regeneration catalyst primary product, wherein the thickness of the material layer is 35-40 mm, and the mesh belt speed is 4 m / h; and screening the regeneration catalyst primary product through the vibration sieve to remove the carbon powder and the ceramic balls to obtain the qualified regeneration catalyst. According to the present invention, by controlling the moving speed of the material layer in the furnace, the charring quality can be ensured, the strength, the specific surface area and the pore capacity of the failure catalyst can be recovered, the activity and the stability of the catalyst can be well recovered, the regeneration catalyst activity recovery rate can achieve more than 90% of the activity of the new catalyst, and the practical value is provided.

Owner:JIANGSU KECHUANG PETROCHEM

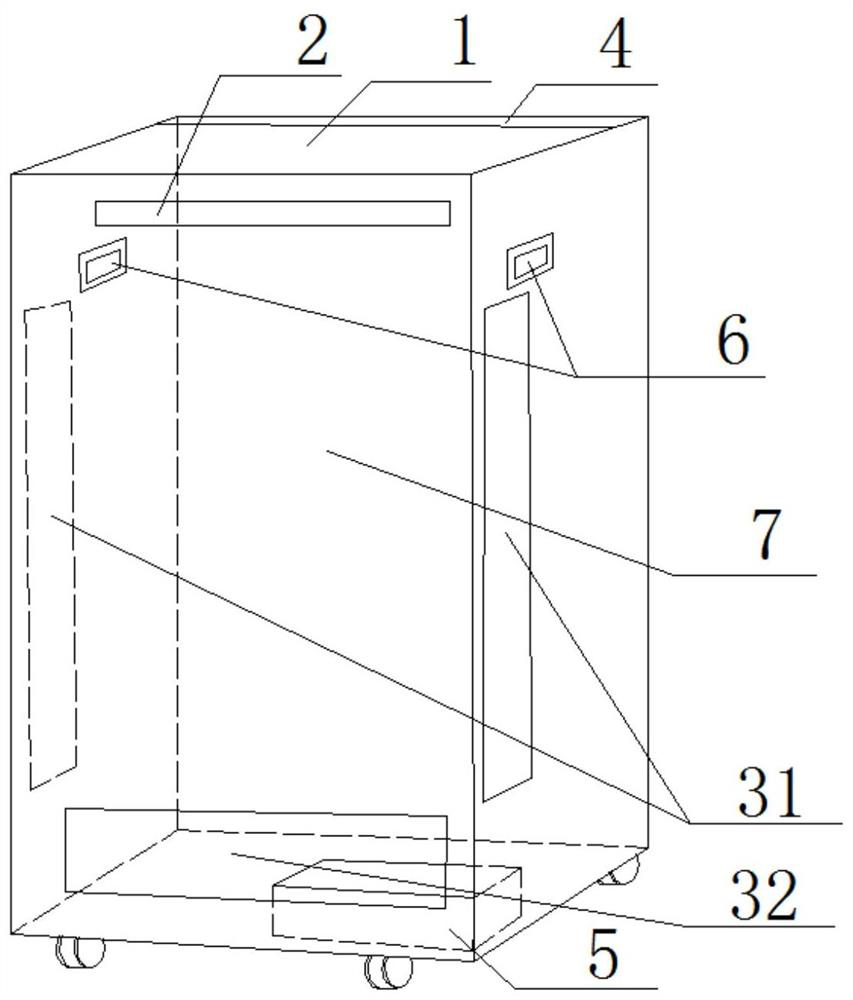

Three-unit UV ambient air purification device

InactiveCN111804143AImprove efficiencyEnhance the quantum effectBiocideCombination devicesParticulatesUltraviolet

The invention discloses a three-unit UV high-performance ambient air purification device, and belongs to the technical field of high-performance novel ambient air purification. The device comprises amachine body, a display panel, an exhaust inlet, an exhaust outlet, a humidity adjusting device, a fixed handle, a power supply, a high-power mute variable-speed turbofan, a UVA ultraviolet lamp bank,a photocatalytic oxidation unit reactor, an electrostatic dust collection device, a primary filter screen, an activated carbon filter screen and a composite Ag<+> / TiO2 sterilization-disinfection filter screen. The three-unit UV high-performance ambient air purification device is characterized in that a machine body shell and part of parts are made of metal materials; air is sucked in from three sides and is exhausted from the top; particulate matters in the air can be subjected to dust removal and purification, and indoor dust is reduced; and volatile organic compounds are degraded through photocatalysis, the effects of sterilization, disinfection and epidemic prevention are achieved, planktonic bacteria and viruses in air can be efficiently killed, cross infection of epidemic situationsis controlled, indoor air is purified, and public health and safety are guaranteed.

Owner:CHINA CATALYST HLDG CO LTD

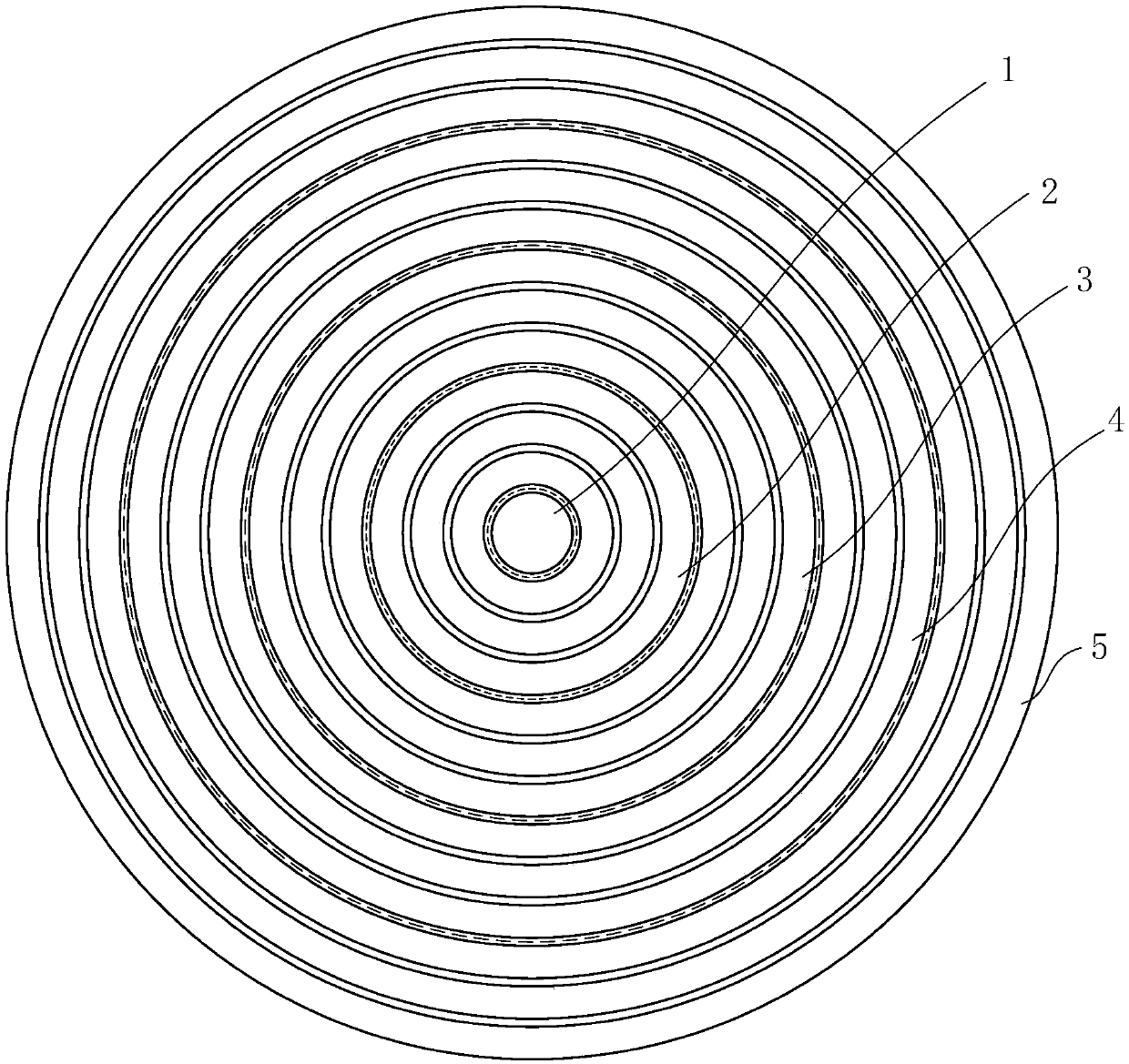

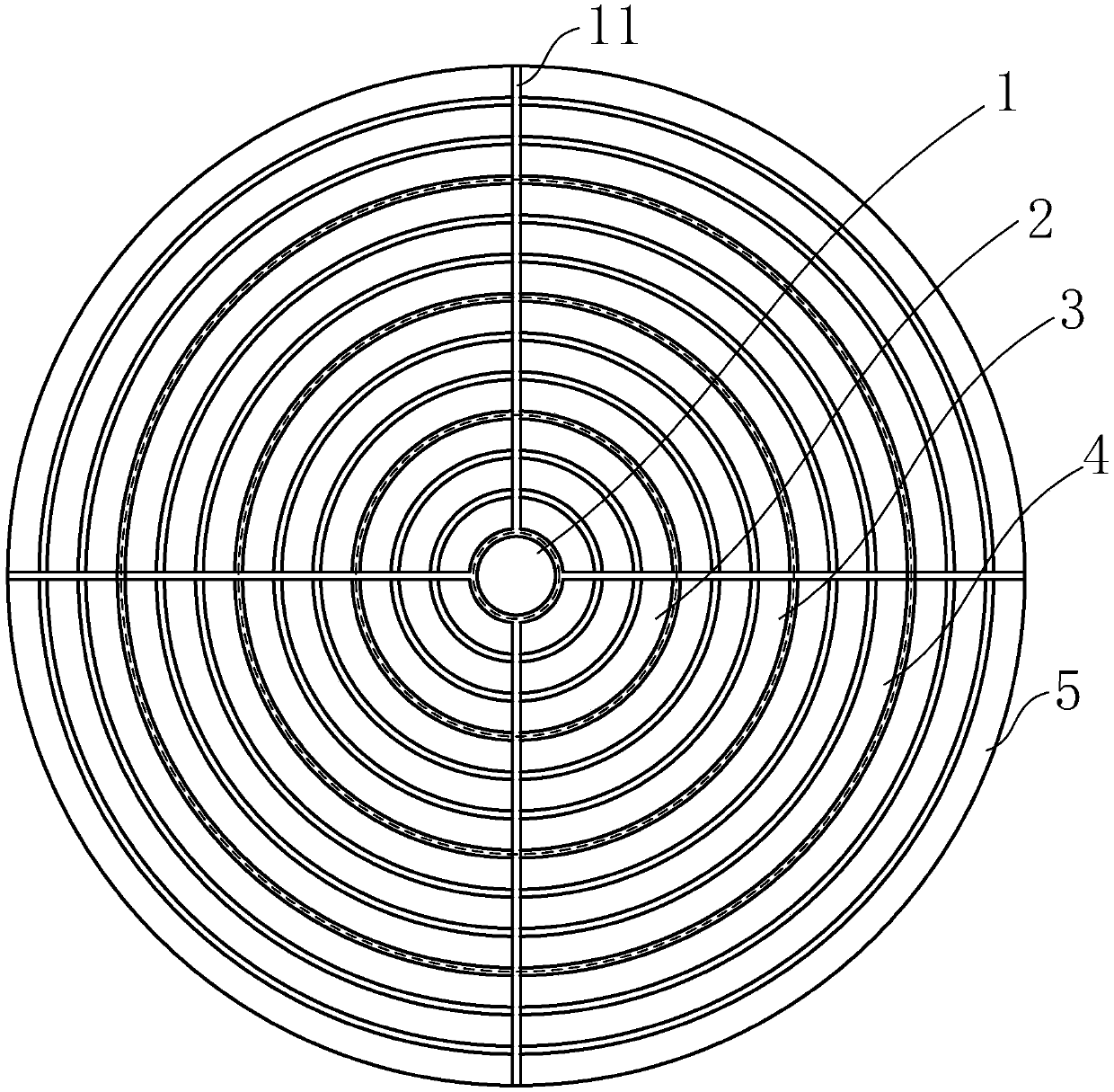

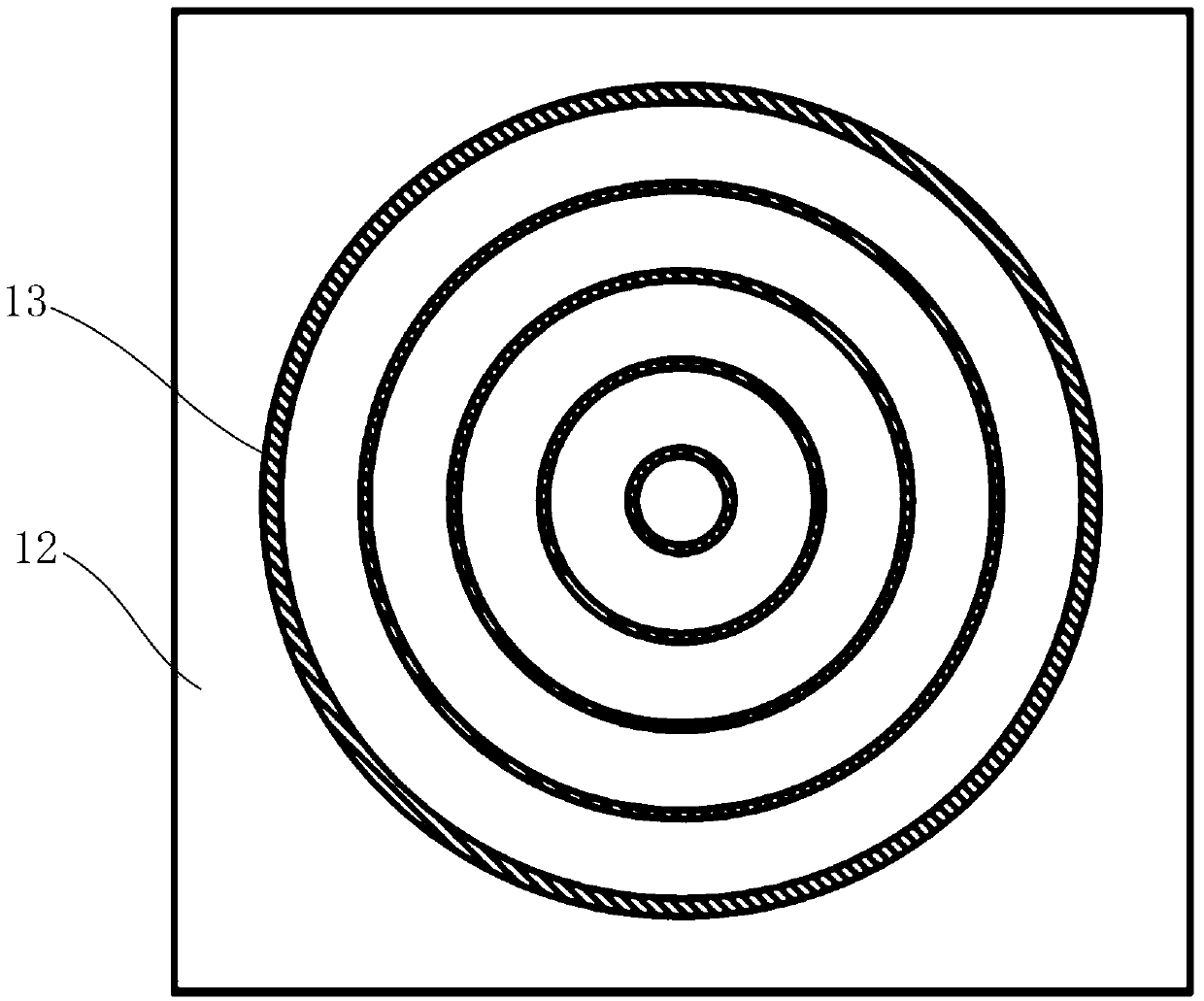

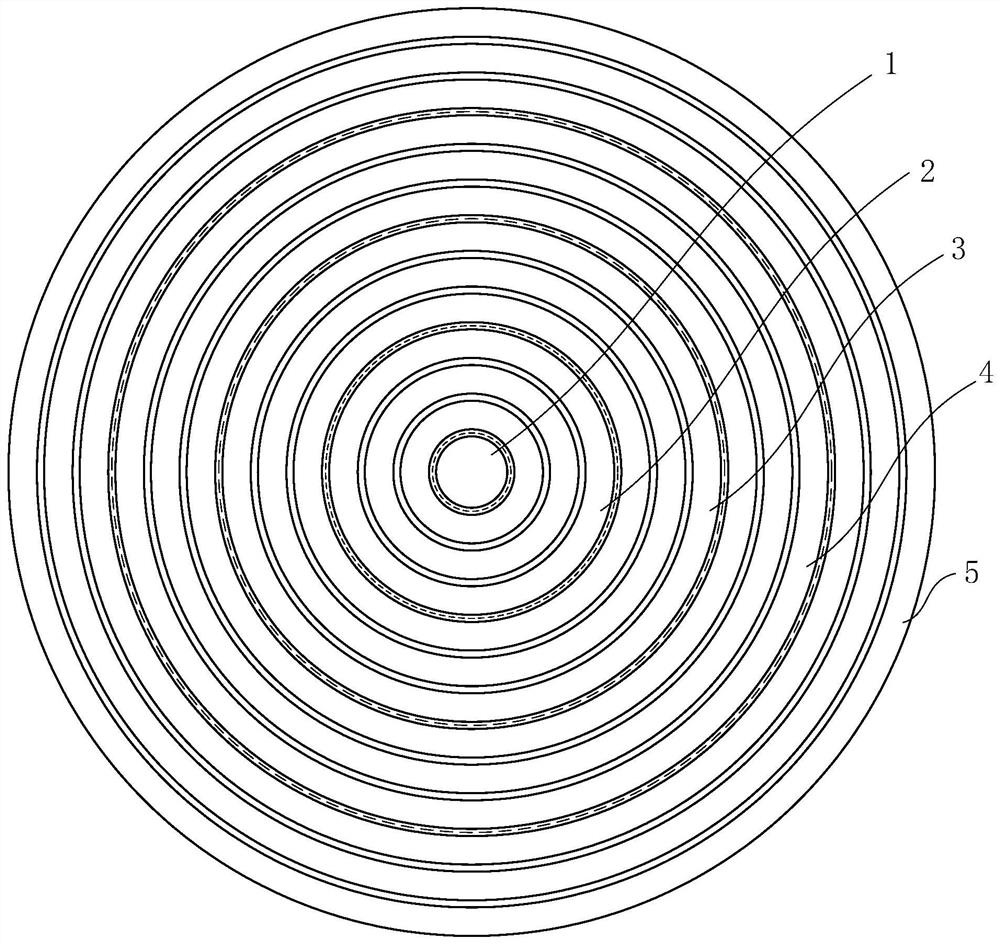

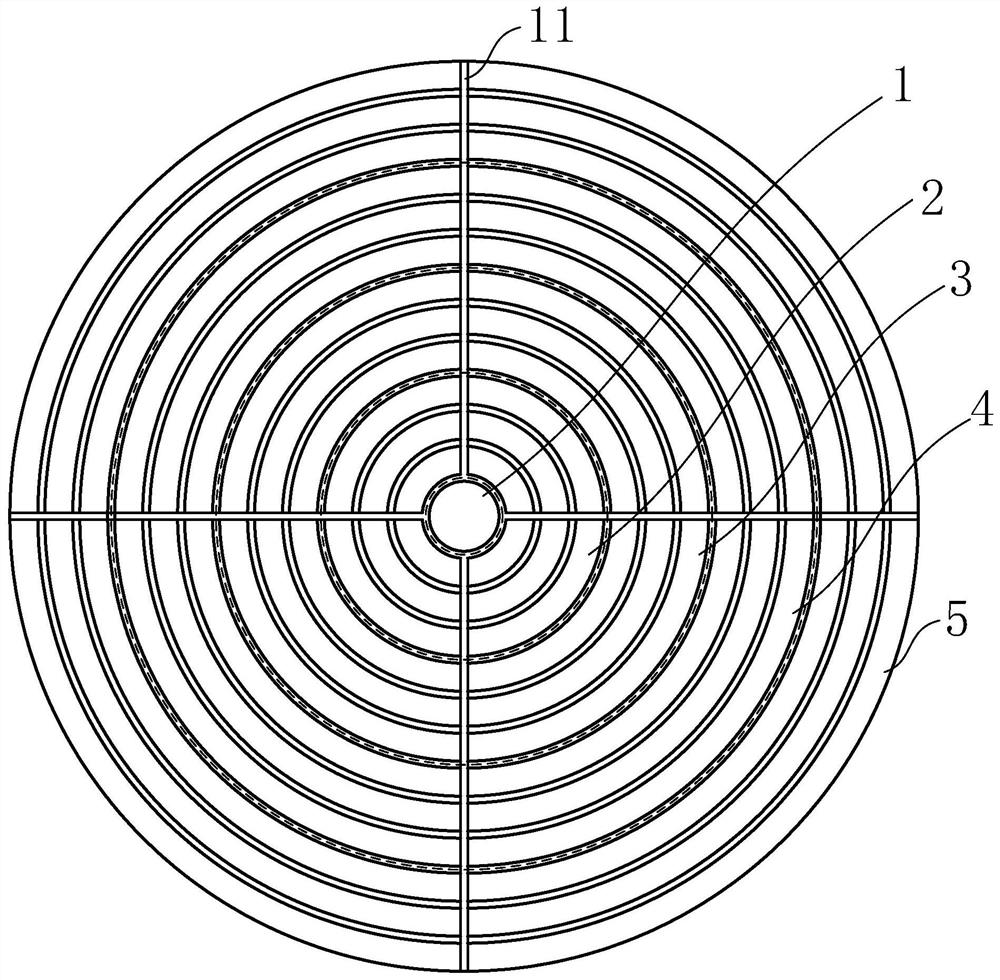

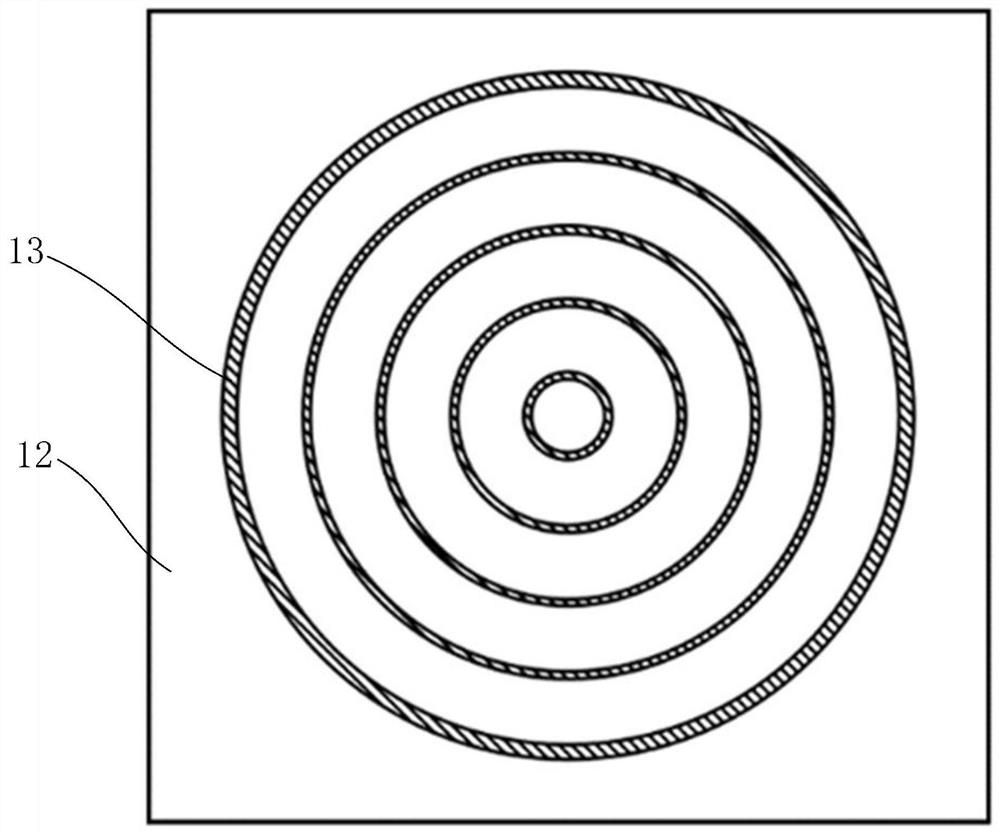

Polishing pad and preparation method and application thereof

ActiveCN110815038ACompensate for differences in linear velocityImproved polishing planarization efficiencyAbrasion apparatusLapping toolsWaferingPolishing

The invention discloses a polishing pad and a preparation method and application thereof. The polishing pad is provided with combination pieces and a bottom lining, the combination pieces are fixed tothe bottom lining, the combination pieces form a polishing layer together, the polishing layer is provided with a central polishing area, one or more intermediate polishing areas which are sequentially arranged around the central polishing area and outer edge polishing areas which are arranged around the intermediate polishing areas, the central polishing area is circular, the intermediate polishing areas are annular, and the outer edge polishing areas are annular; annular gaps are correspondingly formed between adjacent two polishing areas, and are used for receiving polishing fluid in the polishing process; the shore hardness of the polishing layer is sequentially decreased in the direction from the central polishing area to the outer edge polishing areas; and the shore hardness gradient of the two adjacent polishing areas is 0.5-5 D. The hardness of the polishing pad is decreased gradually in the diameter direction, in the process of mechanical polishing, the wear rate of the polishing pad is basically kept to be same, thus the surface of a to-be-polished crystal plate can be flat, and the flattening efficiency is high.

Owner:HUBEI DINGLONG CO LTD +1

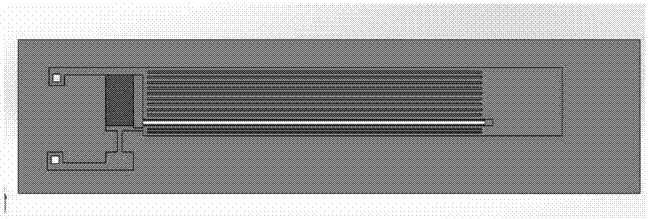

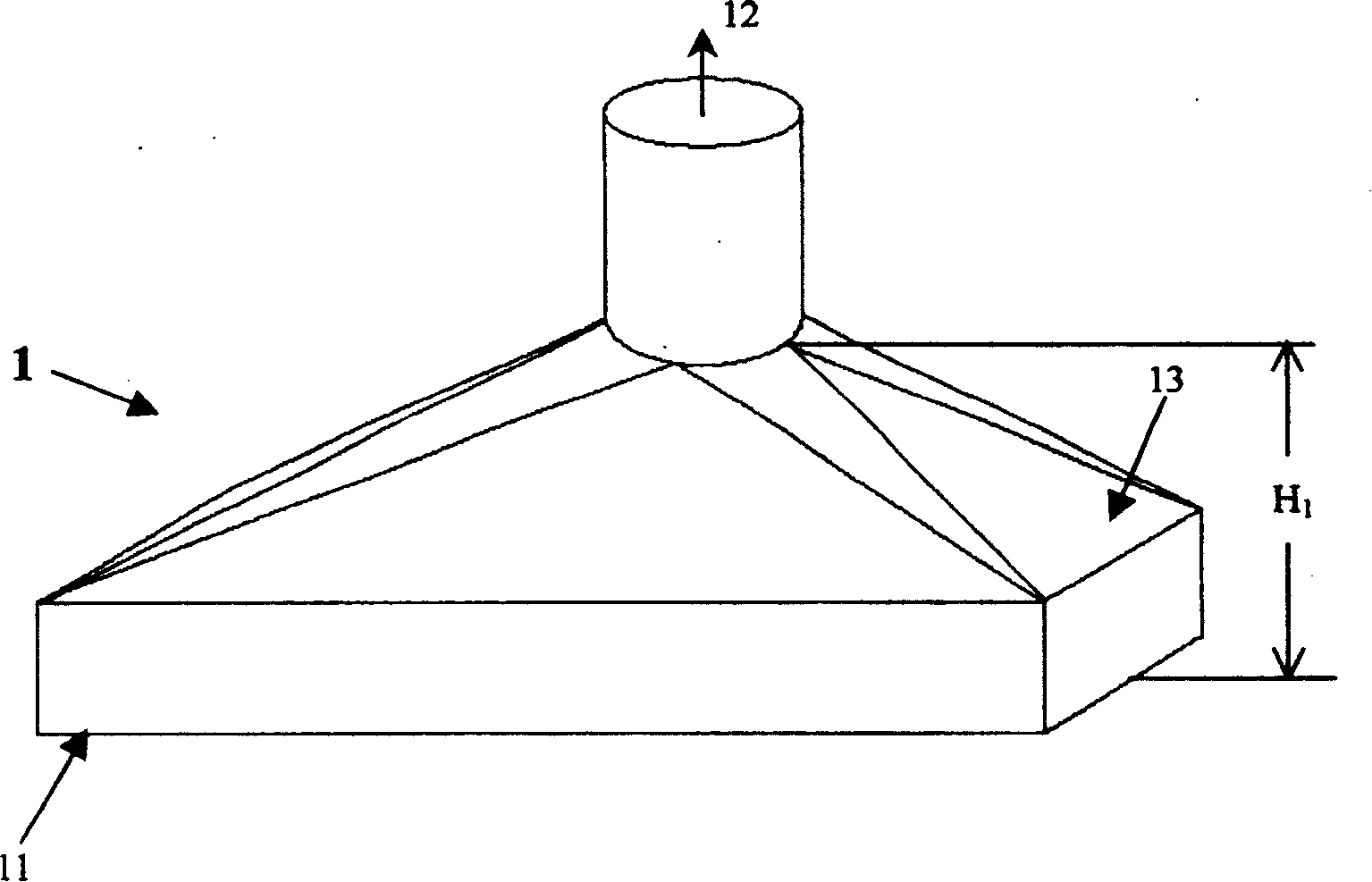

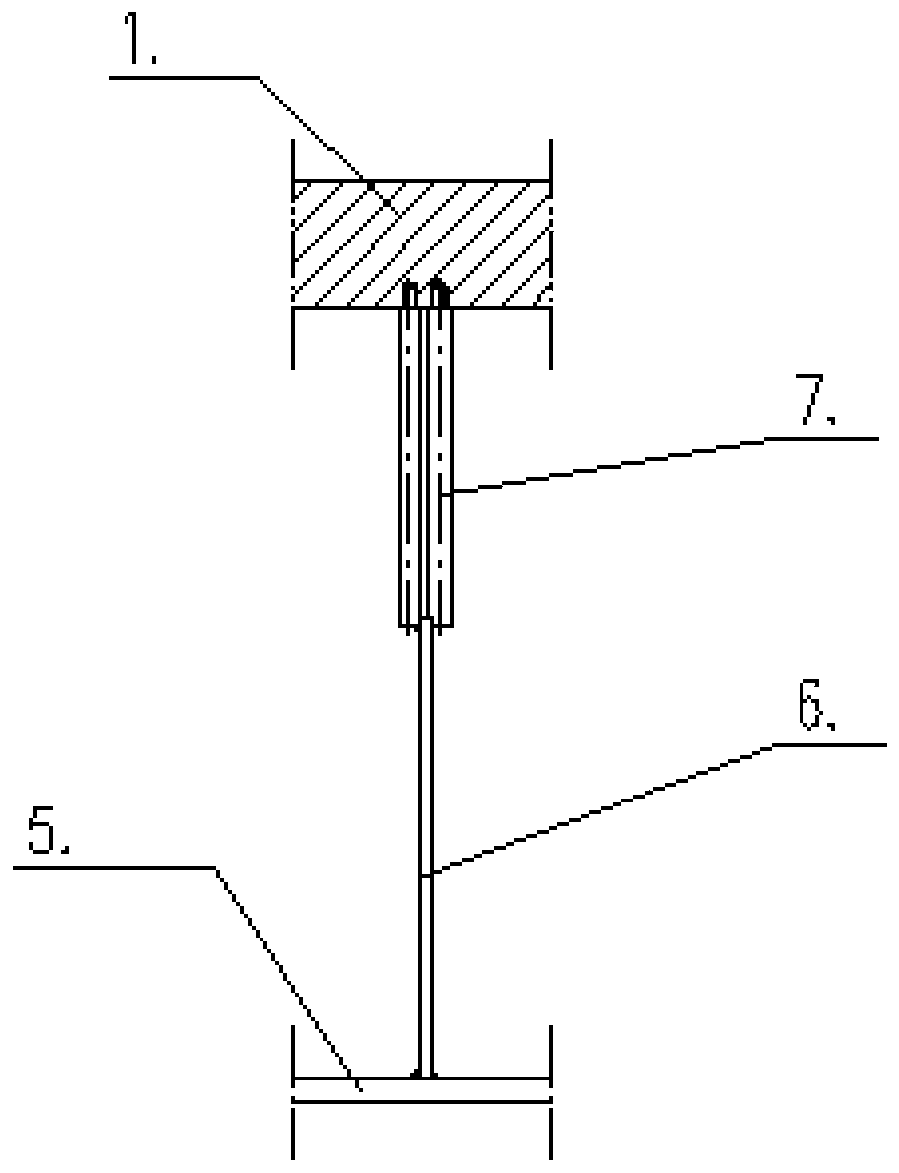

Flat plate type micro loop heat pipe for changing capillary force of capillary core

ActiveCN107091582AQuick suctionIncrease the number ofIndirect heat exchangersCooling/ventilation/heating modificationsMicro-loop heat pipePorous medium

The invention provides a flat plate type micro loop heat pipe. The flat plate type micro loop heat pipe comprises a main plate and an upper cover plate; the upper cover plate and the main plate are packed together; the main plate comprises an evaporation chamber and a condensation chamber; a steam pipe and a liquid pipe are connected between the evaporation chamber and the condensation chamber; the evaporation chamber and the liquid pipe communicate through a capillary force channel; porous medium sheets are arranged in the evaporation chamber; and the capillary force of the porous medium sheets in different positions are gradually improved in the capillary force direction of porous medium capillary cores in the direction from the liquid pipe to the steam pipe. The capillary force of the capillary cores in different positions of the porous medium sheets is gradually improved, so that liquid can be quickly sucked to the upper part, the number of fluids at the upper part is increased; and the liquid is evaporated at the upper part to enter the steam pipe at the upper part, so that the purposes of uniform distribution of the fluids and uniform distribution of the temperature are achieved.

Owner:SHANDONG UNIV

Vein-shaped fuel cell flow field structure, fuel cell bipolar plate and fuel cell

ActiveCN104821407BLow flow resistanceImprove performanceCell electrodesSolid electrolyte fuel cellsFlow resistivityFuel cells

Owner:ZHEJIANG UNIV OF TECH

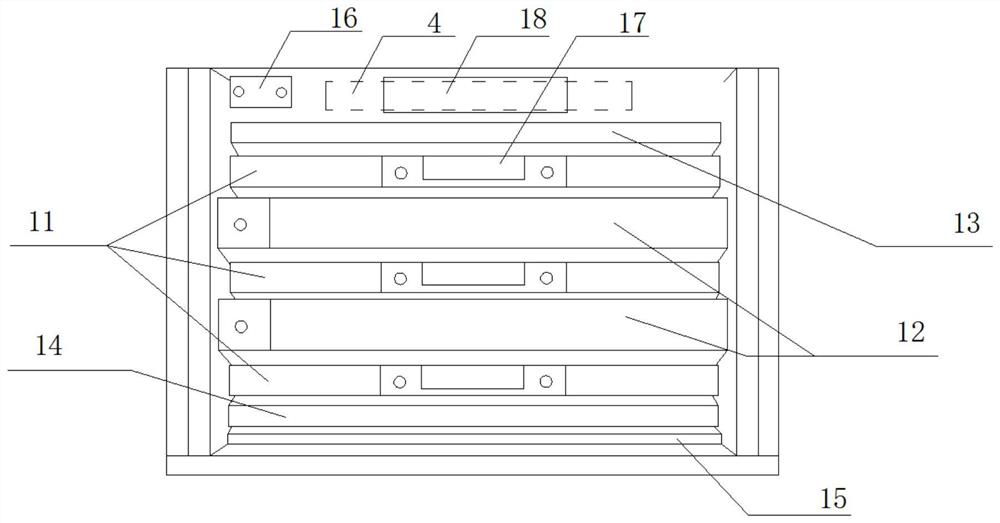

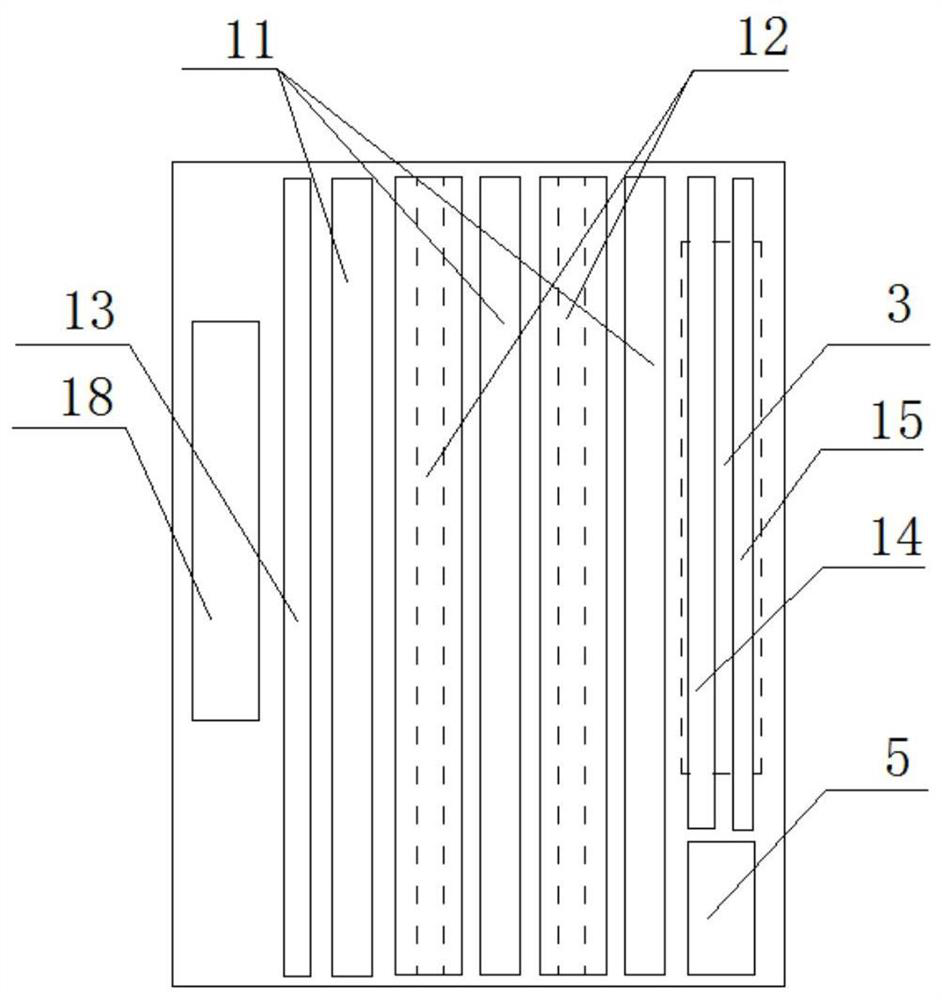

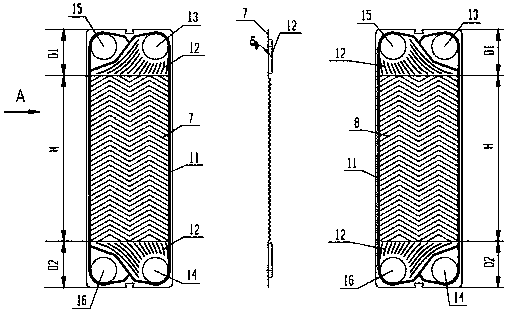

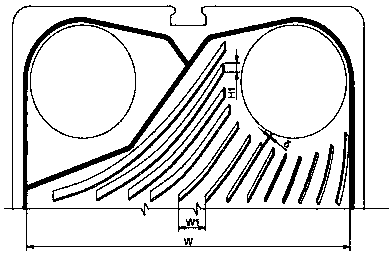

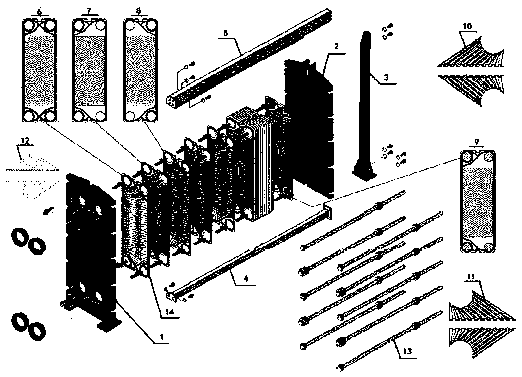

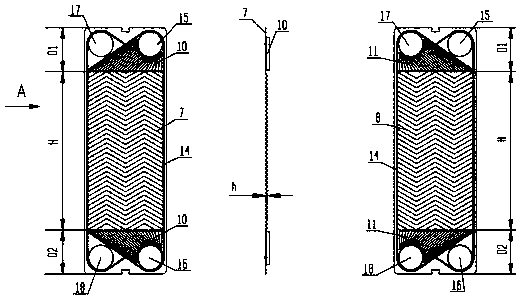

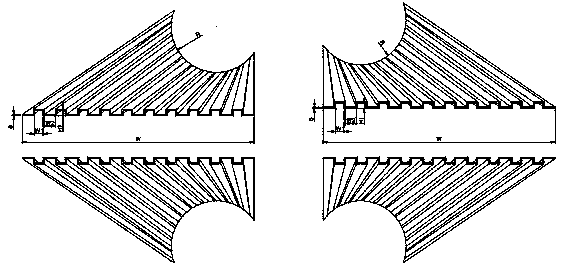

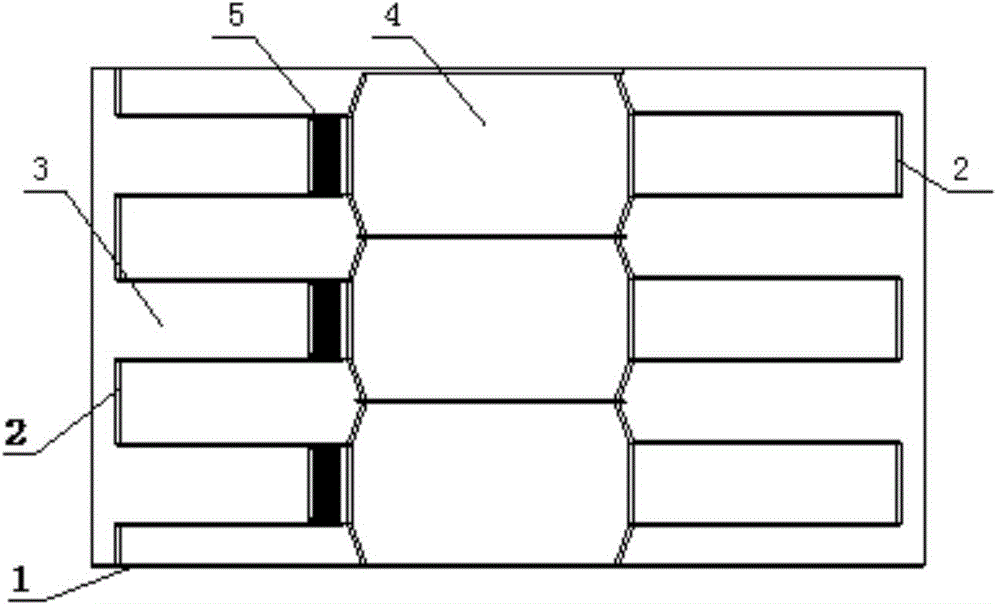

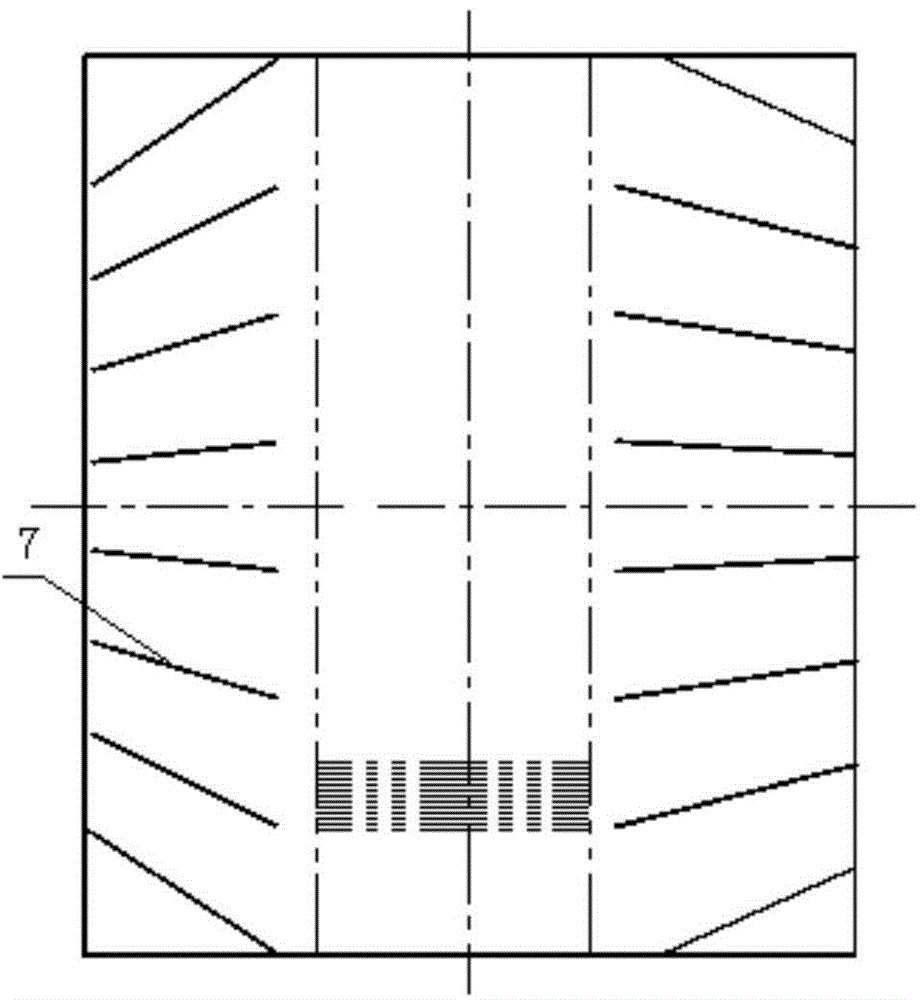

Reverse flow type plate heat exchanger with diversion plate set welded

InactiveCN111121500AImprove the diversion effectReduce heat transfer dead zoneChemical industryHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a reverse flow type plate heat exchanger with diversion plates welded in the technical field of petrochemical industry heat exchangers. The reverse flow type plate heat exchanger comprises heat transfer plates, sealing gaskets, a fixed pressing plate, a movable pressing plate, pressing bolts and nuts, an upper guide rod and a lower guide rod. The reverse flow type plate heat exchanger with the diversion plates welded is characterized in that the diversion area of the heat transfer plates is a flat plate, a diversion plate set is welded in the diversion area of the heattransfer plates, and the shape of the diversion plate set is the same with that of the diversion area of the heat transfer plates. By the adoption of the reverse flow type plate heat exchanger with the diversion plates welded, the diversion area of the heat transfer plates is the flat plate, concave or convex blocks are not pressed, and the diversion plates are welded in the diversion area of theplates. The reverse flow type plate heat exchanger has the beneficial effects that the diversion effect of the diversion plates at the inlet is good, fluid distribution is uniform, a heat exchange dead area of the plate heat exchanger can be effectively reduced, and the heat exchange efficiency is improved; and the thickness of the diversion plates is small, the occupied circulation area is small,and the pressure of the diversion area at the inlet is low.

Owner:SINOPEC GUANGZHOU ENG +1

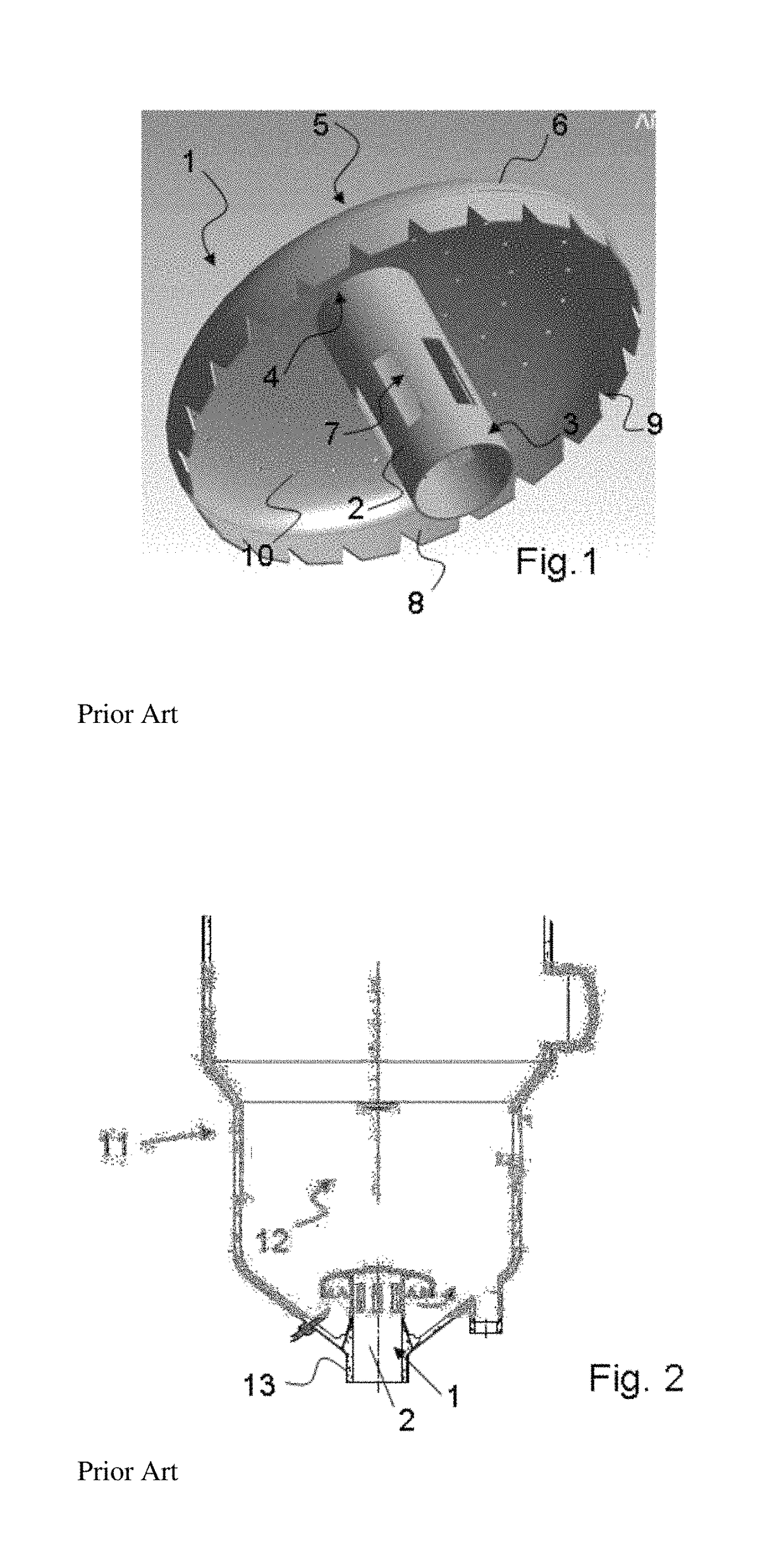

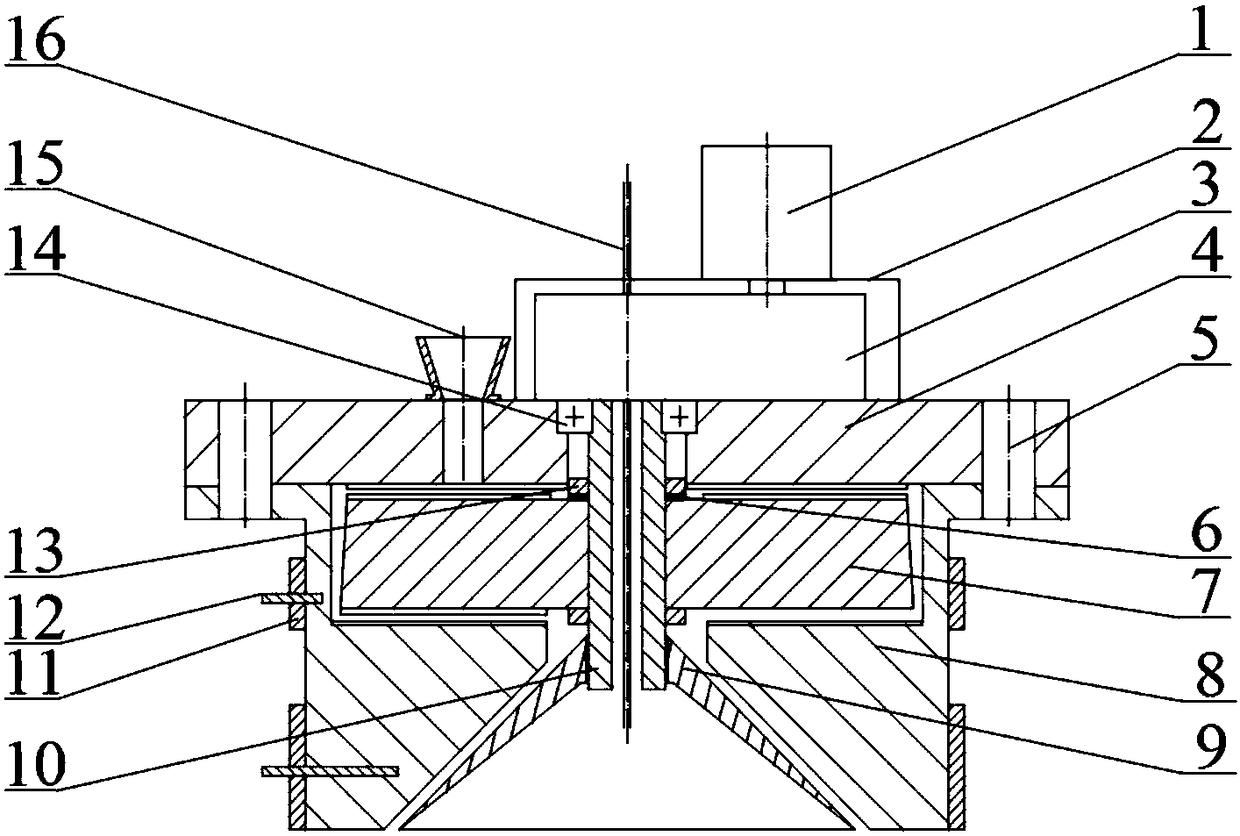

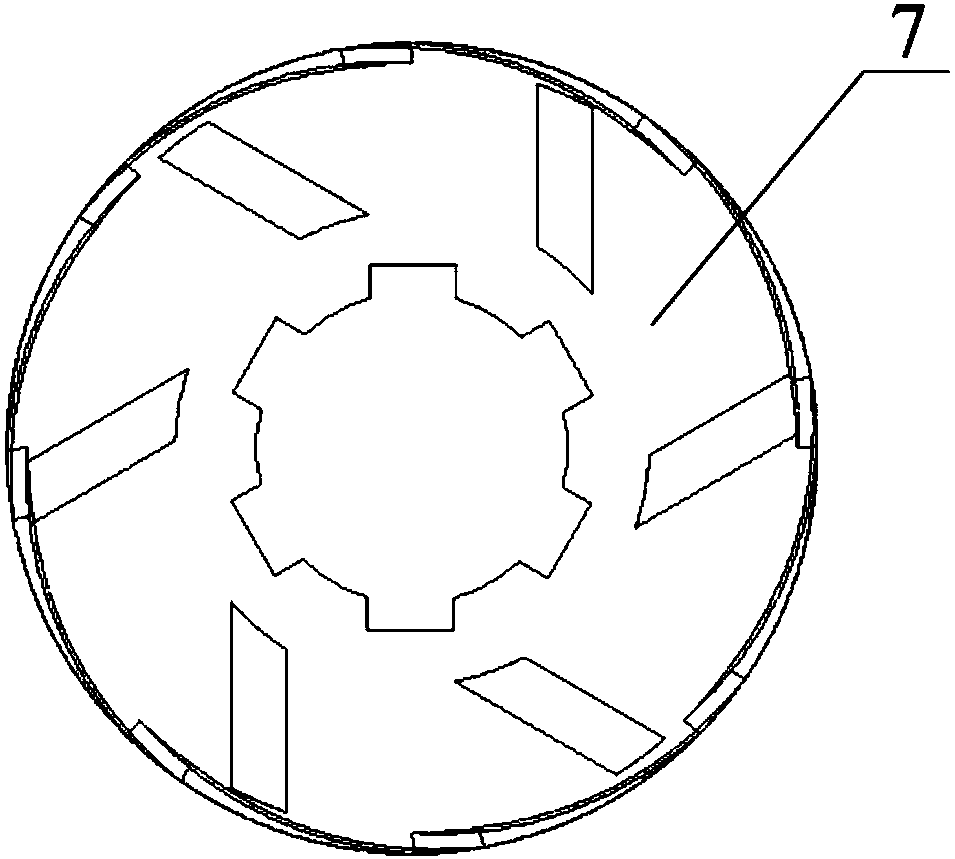

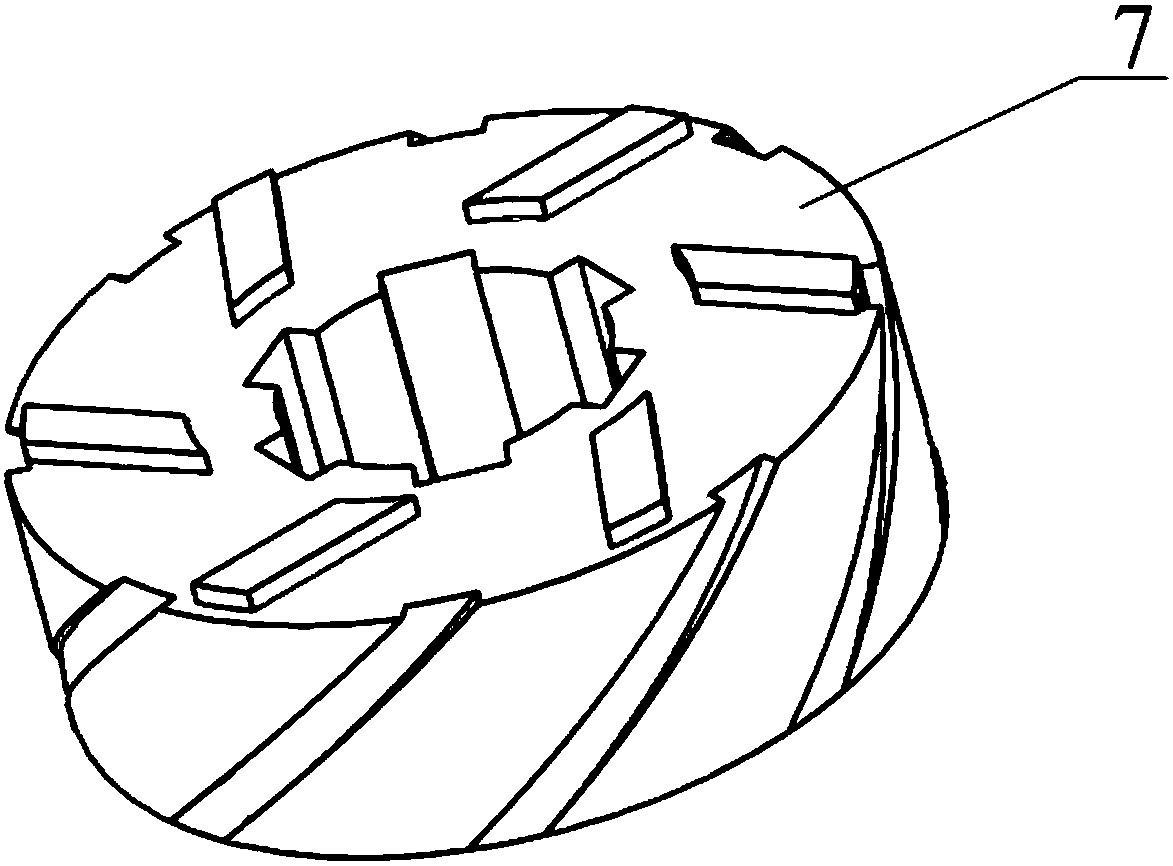

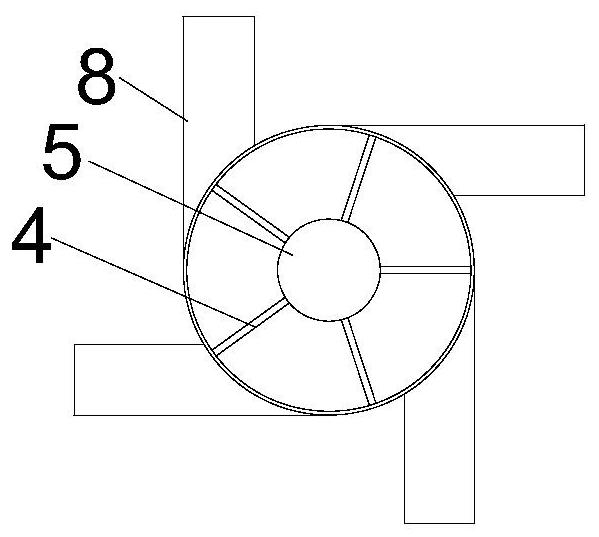

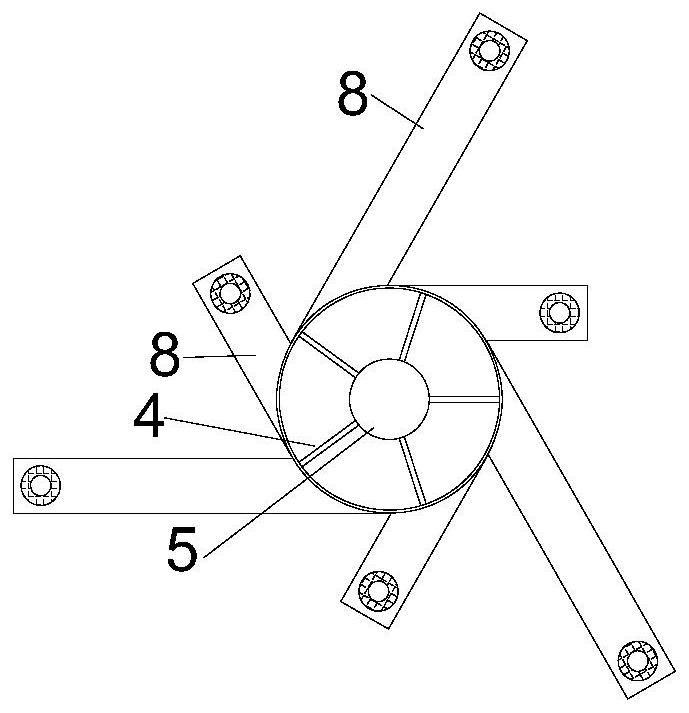

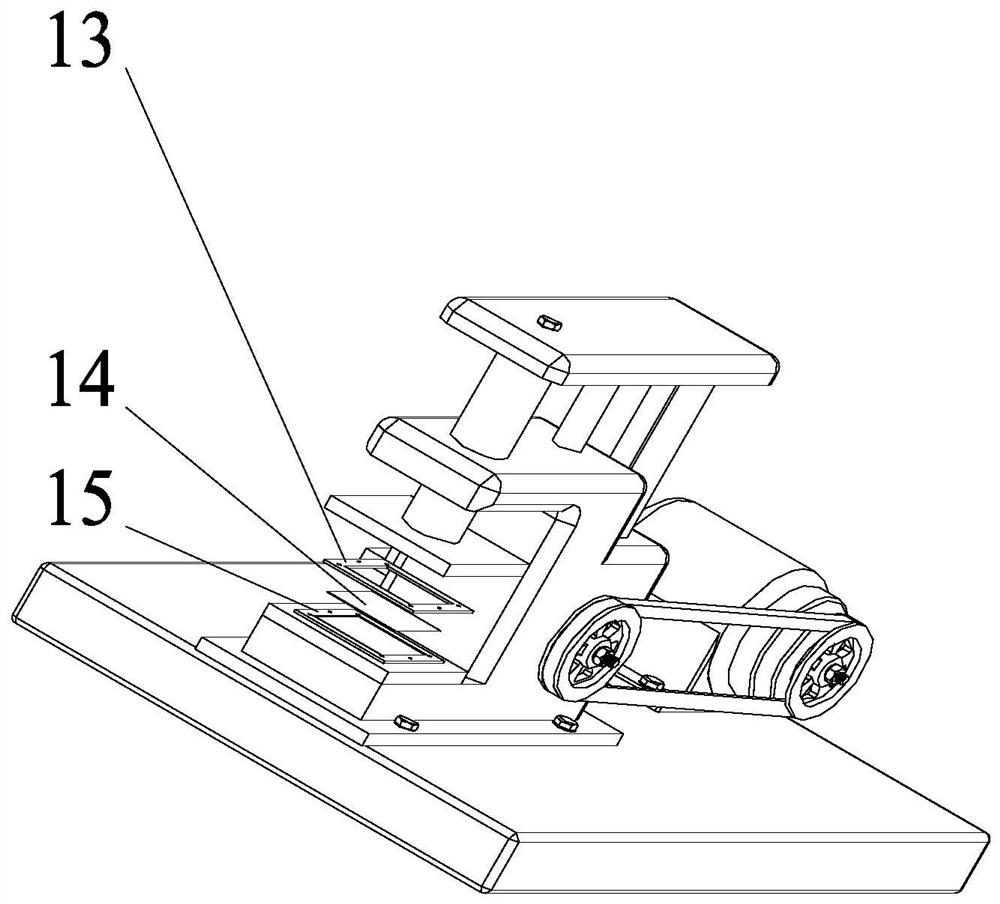

Millstone type melt differential electrostatic spinning device

PendingCN108374205AIncrease productionShortened melt flowFilament/thread formingDecompositionSelf locking

The invention discloses a millstone type melt differential electrostatic spinning device, which mainly consists of a driving motor, a motor supporting frame, a speed reducer, an end cover, a machine barrel, a fixing bolt, a moving millstone, a nozzle, a driving shaft, a self-locking nut, a gasket, a heating device, a temperature sensor, a bearing, a feed cylinder and an air flow duct. The device utilizes a millstone extruder for feeding. The flow is precisely controlled and the melt process is shortened. The decomposition of the polymer melt due to the long process is effectively prevented. The device has the advantages of simple structure, small volume, small occupied space, no special requirement on the feeding mode and suitability of small size granule granules and powder. Large particulate material has advantages due to the existence of the millstone. The side of the moving millstone is provided with a spiral gradual flow passage, gradually becoming shallow from top to bottom and providing additional conveying force to the melt and also uniformly distributing the melt on the outer diameter of the moving millstone. The clearance between the moving millstone and the machine barrel of the end cover is adjustable. The process requirements of processing more kinds of materials can be met.

Owner:BEIJING UNIV OF CHEM TECH

New type uniform diffuser for flow field

InactiveCN100395389CEven fluid distributionSmall footprintDrafting machinesContinuous wound-up machinesDiffusion theoryEngineering

Owner:DONGHUA UNIV

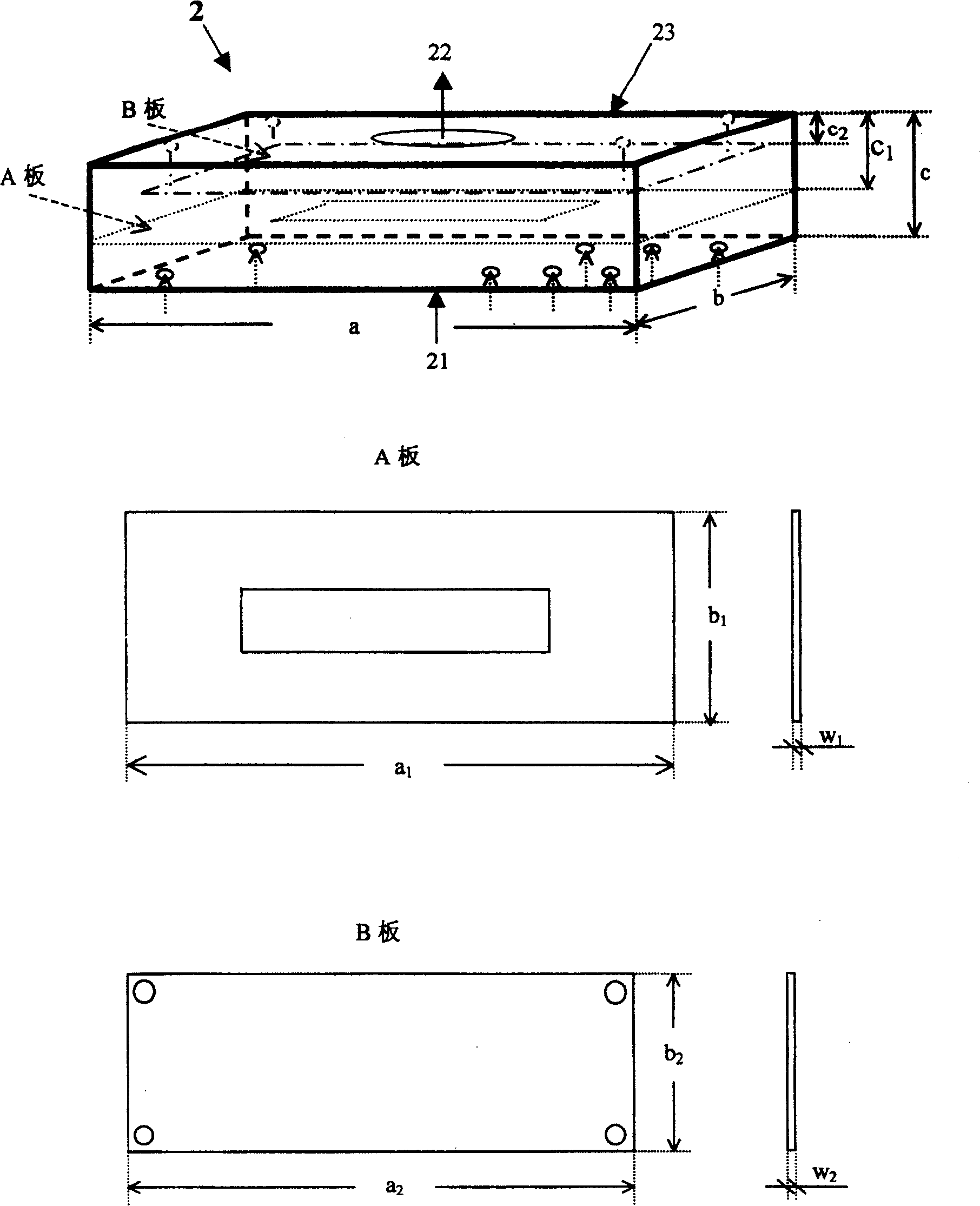

Liquid distributor, multi-stage efficient distributor and washing liquid spraying method

ActiveCN112474087ASimple structureEven fluid distributionUsing liquid separation agentSpray nozzlesModular constructionEngineering

The invention provides a liquid distributor, a multi-stage efficient distributor containing the liquid distributor and suitable for liquid spraying and an arrangement method of the multi-stage efficient distributor. The liquid distributor comprises a vertical cylinder, the cylinder comprises a feeding cavity at the upper portion and a distribution cavity at the lower portion, spiral blades are annularly arranged on the inner wall of the feeding cavity, the inner side edges of the spiral blades are connected to a vertical fixing column, the distribution cavity comprises a plurality of partitionplates, the partition plates divide the distribution cavity into a plurality of independent cavities, a through hole is formed in the outer wall of each independent cavity, and an outlet pipe is connected to each through hole. The efficient distributor may include a multi-stage distributor. The liquid distributor serves as a center distributor, each outlet pipe is connected with a second-stage distributor through a connecting pipe, each second-stage distributor comprises an outlet pipe, the outlet pipes are downwards connected with vertical extending pipes, and the bottoms of the vertical extending pipes are connected with nozzles. The liquid distributor and the efficient distributor are simple in structure, uniform in fluid distribution, sufficient in coverage area and high in washing efficiency, and meanwhile a modular structure enables installation and maintenance to be more convenient.

Owner:EAST CHINA UNIV OF SCI & TECH

Counter flow type plate heat exchanger comprising independent flow guide plates

InactiveCN111121499AGood diversion effectEven fluid distributionHeat exchanger casingsHeat exchanger fasteningPetrochemicalCounter flow

The invention discloses a counter flow type plate heat exchanger comprising independent flow guide plates in a petrochemical device. The counter flow type plate heat exchanger comprising the independent flow guide plates comprises heat transfer plates, sealing gaskets, a fixed pressing plate, a movable pressing plate, pressing bolts and nuts, and upper and lower guide rods. The counter flow type plate heat exchanger comprising the independent guide plates is characterized in that flow guiding areas of the heat transfer plates are flat plates, the flow guiding areas of the heat transfer platesare fixedly provided with the independent flow guide plates, the thickness of the independent flow guide plates are equal to that of the heat transfer plates, and the shape of the independent flow guide plates is consistent with that of the flow guiding areas of the heat transfer plates. The counter flow plate heat exchanger with the independent flow guide plates has the advantages that the flow guide effect of the independent flow guide plates at an inlet is good, the fluid is uniformly distributed, the heat exchange dead zone of the plate heat exchanger can be effectively reduced, and the heat exchange efficiency is improved.

Owner:SINOPEC GUANGZHOU ENG +1

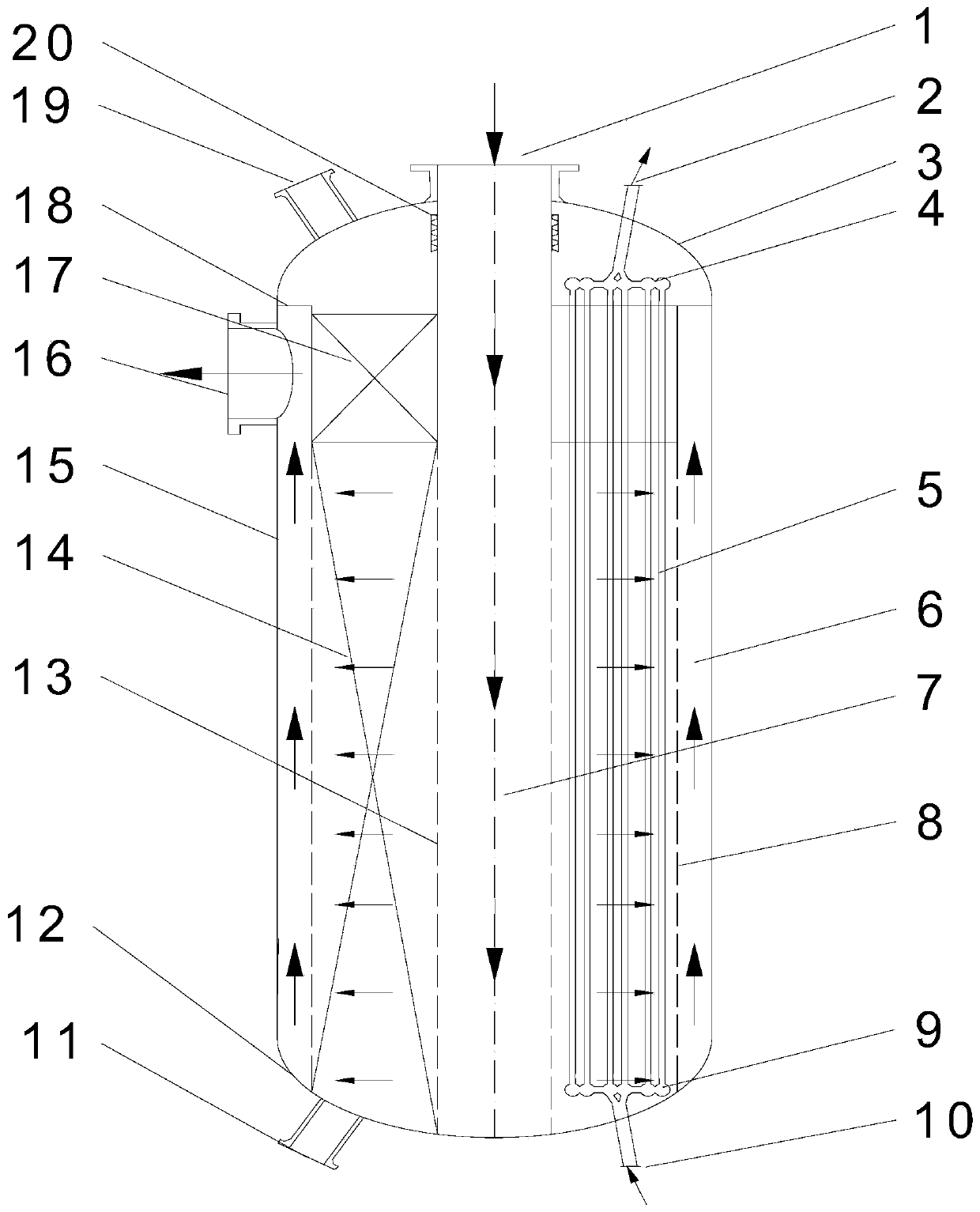

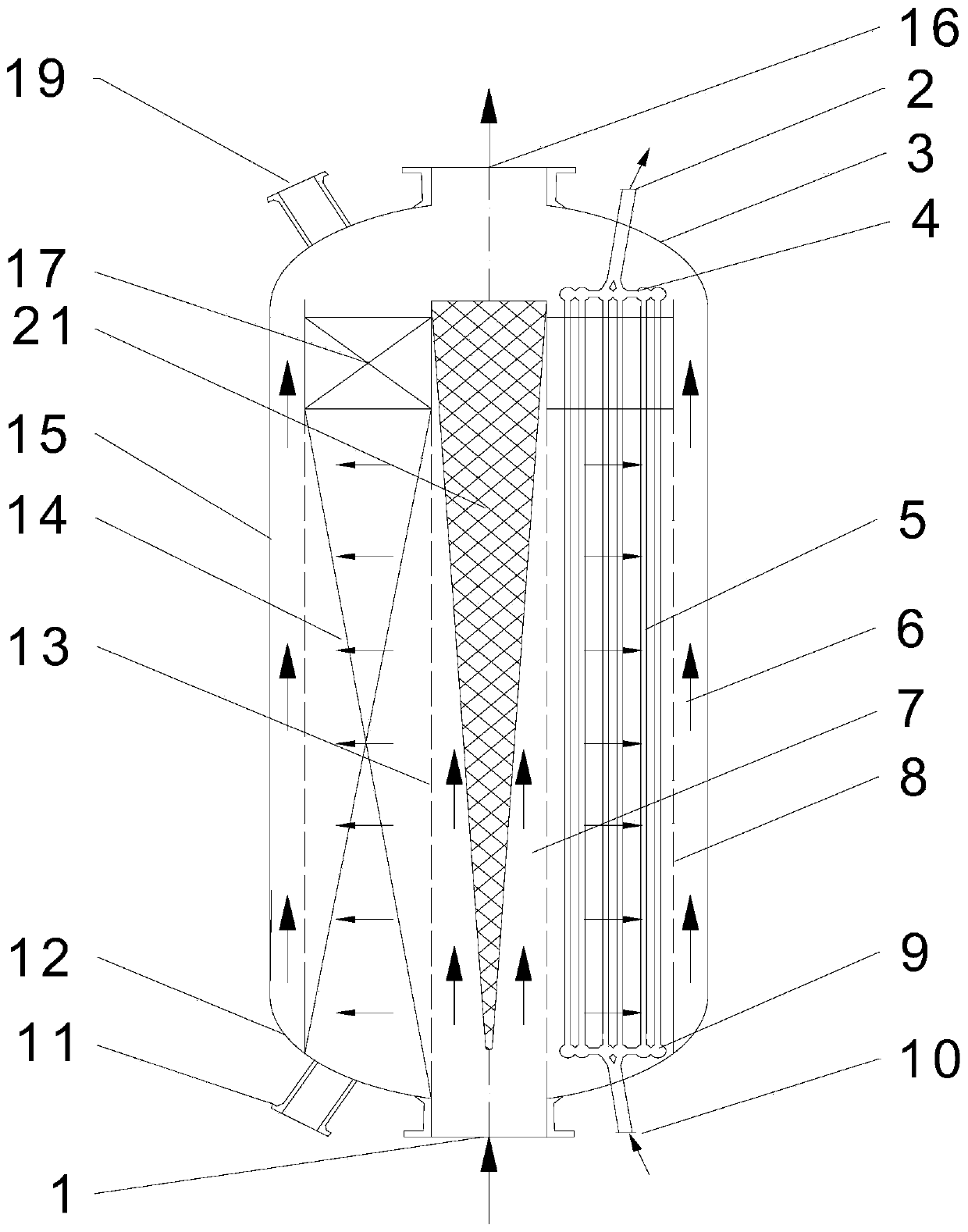

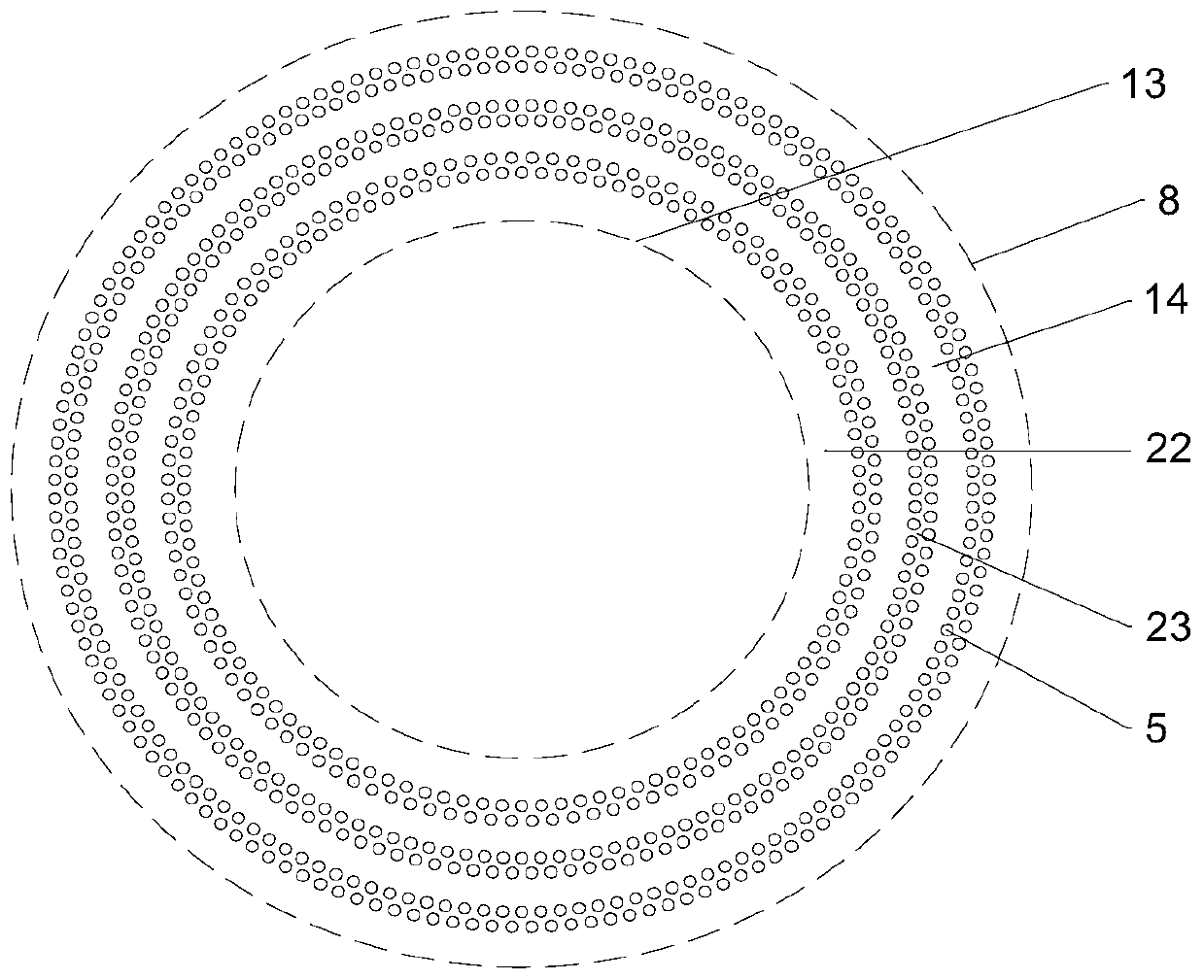

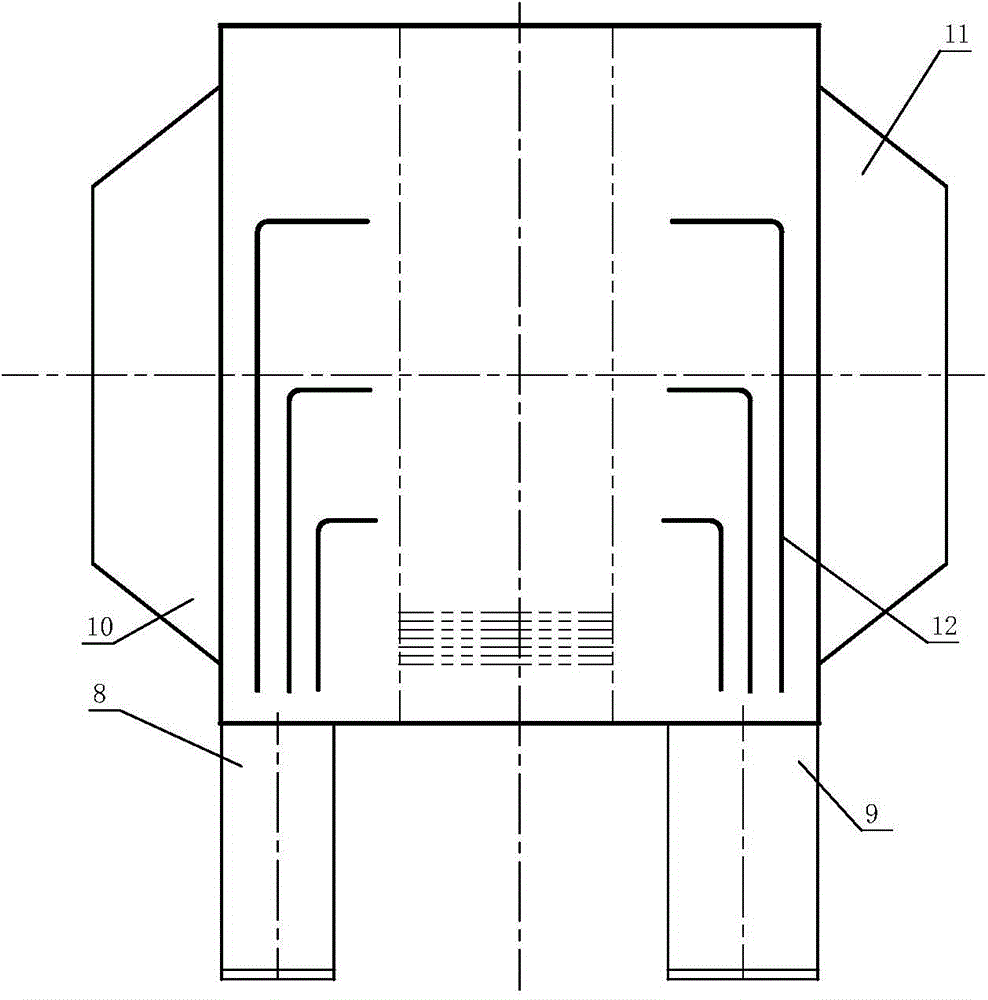

Radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling

PendingCN111589378AEliminate temperature differencesAvoid overheatingPreparation by carbon monoxide or formate reactionChemical/physical processesCarbonylationFixed bed

The invention discloses a radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling. The reactor comprises a cylindrical vessel composed of an upper end socket, acylindrical barrel and a lower end socket in sequence from top to bottom. A reaction gas feeding port, a reaction gas discharging port, a heat exchange medium inlet, a heat exchange medium outlet, acatalyst feeding port and a catalyst discharging port are formed in the outer portion of the cylindrical vessel. The catalytic bed layer is divided into a heat insulation area and a heat exchange areafrom inside to outside, and the heat exchange area is provided with multiple groups of heat exchange tubes which are concentrically arranged in two rows as a group. The radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling has the characteristics of uniform distribution of reaction gas along the axial direction, reasonable bed layer temperature distribution, high catalyst utilization rate, small reactor pressure drop and the like, is suitable for a reaction for producing oxalate through carbonylation coupling, and is also suitable for other exothermicgas-solid phase catalytic reactions.

Owner:EAST CHINA UNIV OF SCI & TECH

Novel heat exchanger impingement baffle

PendingCN110749227AGuaranteed uptimeExtended service lifeHeat exchanger casingsEngineeringMechanical engineering

The invention discloses a novel heat exchanger impingement baffle. The impingement baffle comprises a pipe plate. The lower end of the pipe plate is provided with a shell side cylinder, the two edgesof the inner side of the shell side cylinder are symmetrically provided with heat exchange pipes, and anti-impact check rods are symmetrically arranged on the sides, away from the shell side cylinder,of the symmetrically-arranged heat exchange pipes. An anti-impact rod is arranged on the portion, between the two symmetrically-arranged anti-impact check rods, of the lower end of the pipe plate, the lower end of the anti-impact rod is provided with an impingement baffle body, the lower end of the impingement baffle body is provided with a baffle plate, and one side of the shell side cylinder isfurther provided with a medium inlet. The novel heat exchanger impingement baffle has the advantages that after the impingement baffle is applied to a heat exchanger, fluid distribution is even, theimpingement baffle can be effectively prevented from falling off, wear and leakage of the heat exchange pipes are reduced, safe and reliable operation of the heat exchanger is guaranteed, and the service life of the heat exchanger is prolonged. The novel heat exchanger impingement baffle is simple in structure, reasonable in design and low in equipment cost and has a good anti-impact effect, and the impingement baffle does not need to be additionally welded.

Owner:YONGSHENG MACHINERY IND KUNSHAN

Plate type air-air heat exchanger

InactiveCN104677153ASolve thermal expansionEasy to blow sootStationary plate conduit assembliesEngineeringExpansion joint

The invention relates to a heat exchanger, and in particular relates to a plate type air-air heat exchanger. The structure of the plate type air-air heat exchanger is that each layer of plate bundle component at a plate bundle component hot end of the plate type air-air heat exchanger is connected with an expansion joint, so that the problem that the plate bundle component is expanded when being heated is effectively solved. A heat-transfer element of the air-air heat exchanger is a heat-transfer plate used by an octagonal welding plate type heat exchanger, and the surface of the plate is smooth and does not have a flowing dead area, so that dust is convenient to blow and the problem that the dust is accumulated in equipment is thoroughly solved. The plate bundle component of the air-air plate type heat exchanger is horizontally arranged, and the air-air plate type heat exchanger is low in production difficulty, adopts modular arrangement, achieves large-scale equipment, and is applicable to the large device production scale. A fluid distribution region connected with two kinds of medium inlet and outlet pipe boxes is adopted, and a medium pipe box flow guide plate and a flow distributing part of a medium distributing box flow guide plate are arranged in a medium pipe box and a medium distributing box, so that the problem of non-uniform fluid distribution of wide-width pipe boxes of large-scale heat exchange equipment is successfully solved.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

Polishing pad and its preparation method and application

ActiveCN110815038BCompensate for differences in linear velocityImproved polishing planarization efficiencyAbrasion apparatusLapping toolsWaferingPolishing

The invention discloses a polishing pad, a preparation method and application thereof. The polishing pad has a combination sheet and a backing, the combination sheet is fixed on the backing, the combination sheet together forms a polishing layer, and the polishing layer has a central polishing area, one or more intermediate polishing areas arranged in turn around the central polishing area, and surrounding middle polishing areas. The outer edge polishing area is set in the polishing area, and the central polishing area is circular, the middle polishing area is annular, and the outer edge polishing area is annular; an annular gap is formed between two adjacent polishing areas, and the annular gap is used to receive Polishing fluid in the polishing process; the Shore hardness of the polishing layer decreases successively along the direction from the center polishing area to the outer edge polishing area; the Shore hardness gradient of two adjacent polishing areas is 0.5‑5D. The hardness of the polishing pad decreases gradually along the diameter direction, and its wear rate remains basically consistent during the mechanical polishing process, so the surface of the wafer to be polished can be flattened, and the flattening efficiency is high.

Owner:HUBEI DINGLONG CO LTD +1

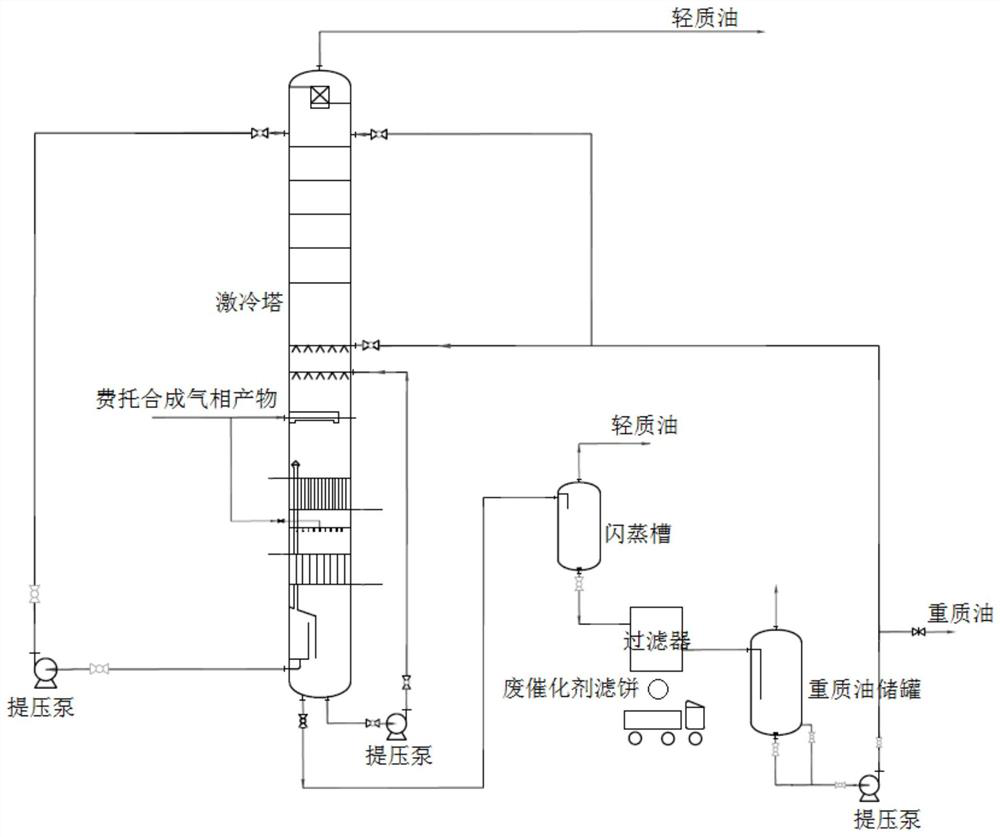

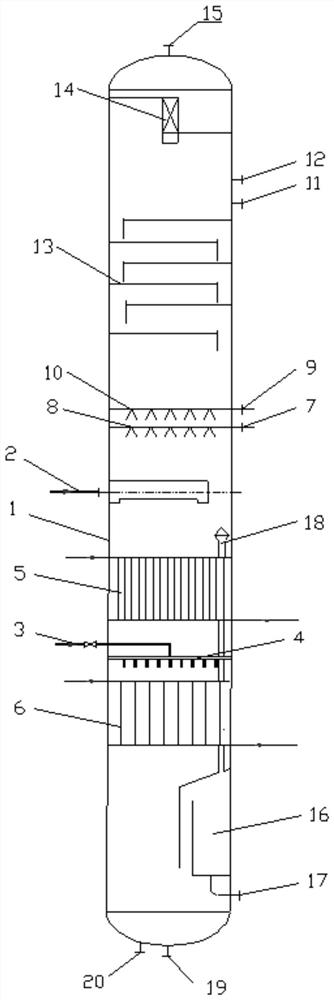

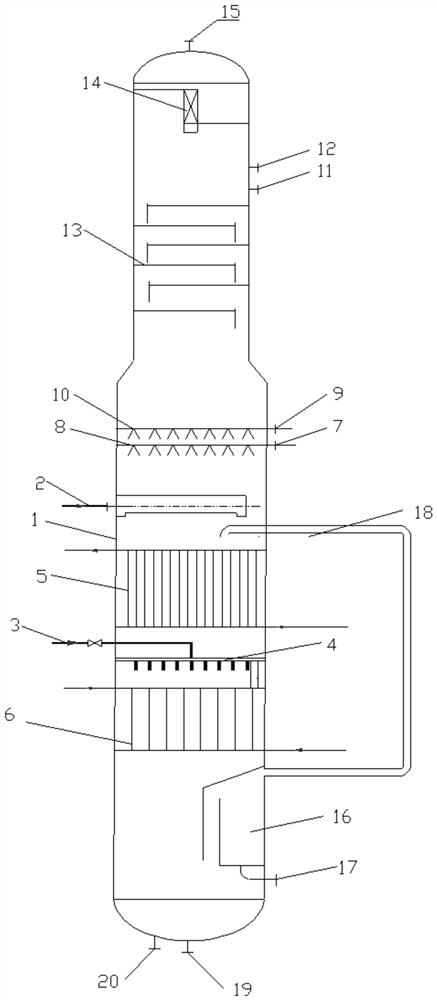

A kind of chilling tower for separation of Fischer-Tropsch synthesis products and its process system

ActiveCN111560273BReasonable design structureEven fluid distributionRecuperative heat exchangersChemical industryFluid phaseCooling tower

The invention relates to a quenching tower and its process system for the separation of Fischer-Tropsch synthesis products, comprising a quenching tower body, a main feed system, an auxiliary feed system, heat exchange elements, a spray washing system and a tray system, The upper part of the quench tower body is a gas phase area, and the lower part is a liquid phase area, the main feeding system is arranged in the gas phase area, and the spray washing system and the tray system are sequentially arranged above the main feeding system , the auxiliary feed system and the heat exchange element are arranged in the liquid phase region. Compared with the prior art, in the present invention, the gas phase product of the Fischer-Tropsch synthesis reactor is washed, cooled and distilled multiple times in the quenching tower, so as to realize the effective separation of Fischer-Tropsch synthesis light oil and heavy oil, and the quenching tower The design structure and layout are reasonable, and it has the characteristics of high product separation efficiency, large operating flexibility, simple process system, low system resistance, high heat recovery efficiency, etc., and is more suitable for the operation of large-scale Fischer-Tropsch synthesis process systems.

Owner:YANKUANG ENERGY R&D CO LTD

A Flat Micro Loop Heat Pipe with Capillary Capillary Force Variation

ActiveCN107091582BQuick suctionIncrease the number ofIndirect heat exchangersCooling/ventilation/heating modificationsMicro-loop heat pipePorous medium

Owner:SHANDONG UNIV

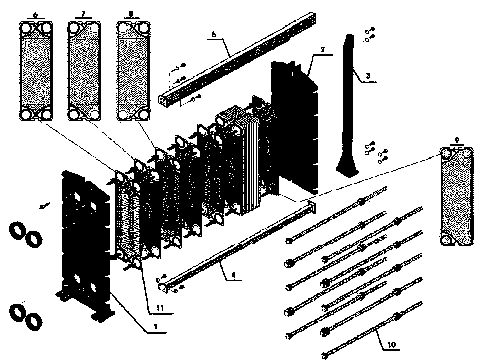

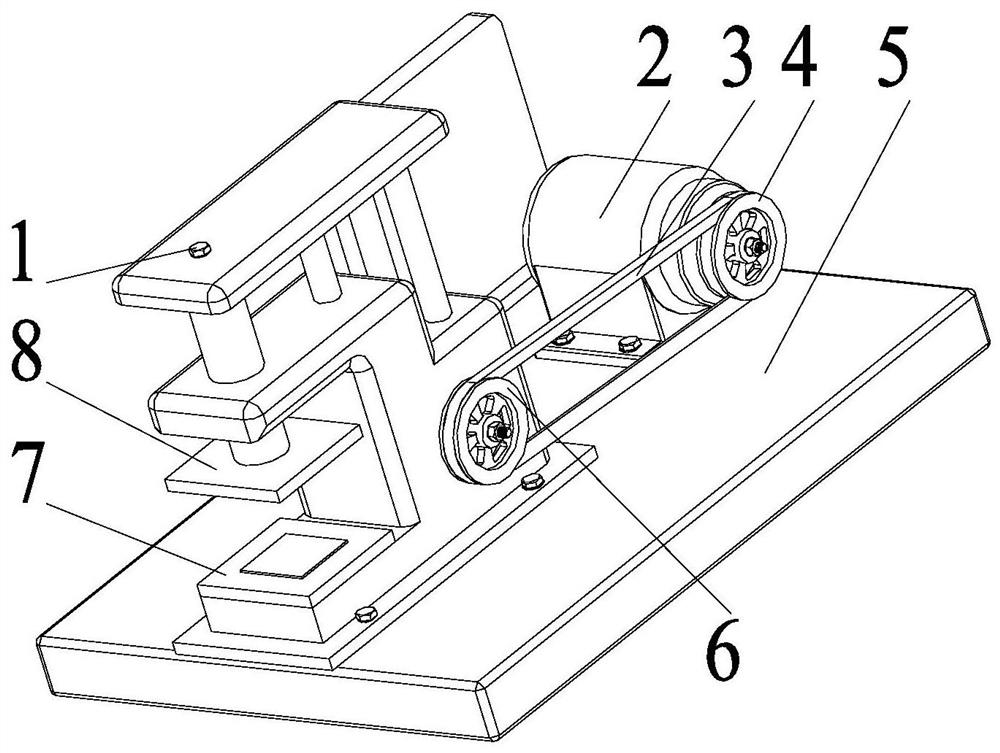

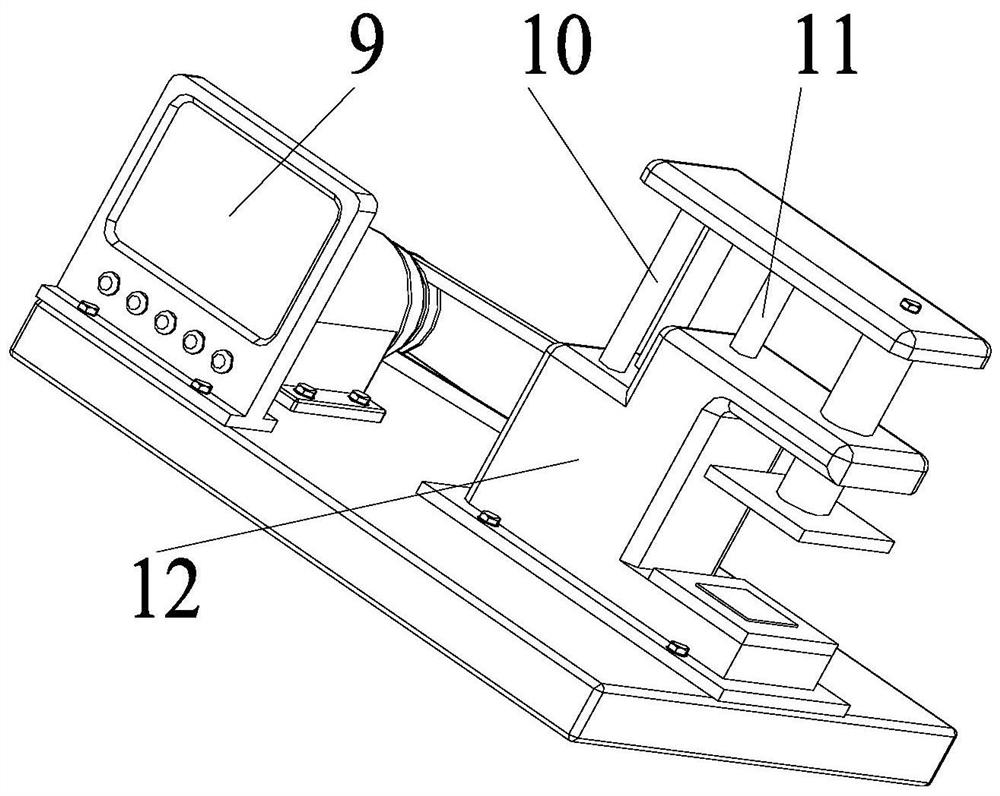

Intelligent fuel cell assembling machine and assembling method

PendingCN112968200AEliminate misalignmentImprove sealingFinal product manufactureFuel cellsFuel cellsBattery pack

The invention belongs to the technical field of fuel cells, and discloses an intelligent fuel cell assembling machine and an assembling method. The assembling method comprises the steps of: assembling a membrane electrode assembly and assembling a fuel cell pack. The upper side of an assembling plate is fixedly provided with a battery pack assembling machine main machine, a power driving device and a display control device through bolts, the power driving device is connected with the battery pack assembling machine main machine through a triangular belt, and the display control device is connected with the battery pack assembling machine main machine and the power driving device through connecting lines. According to the features of a membrane electrode assembly and a battery pack, the membrane electrode assembly and battery pack intelligent processing equipment is designed by utilizing a sensor technology, an automatic control technology, a heating technology and a machining technology, and the membrane electrode assembly and the battery pack can be rapidly and efficiently processed and manufactured with high quality. Meanwhile, the invention further provides a membrane electrode assembly and battery pack processing technology, which can ensure the performance of the fuel cell.

Owner:ZHAOQING UNIV

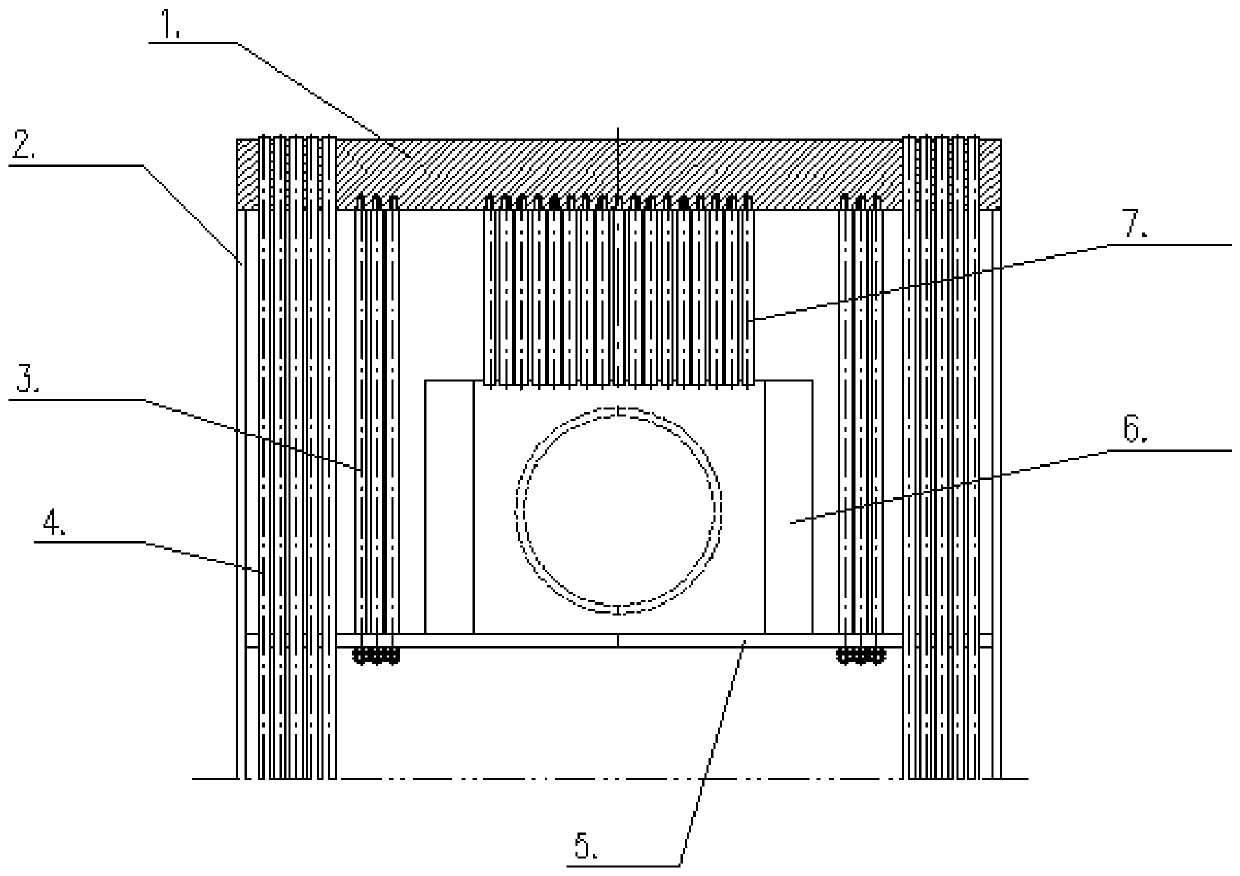

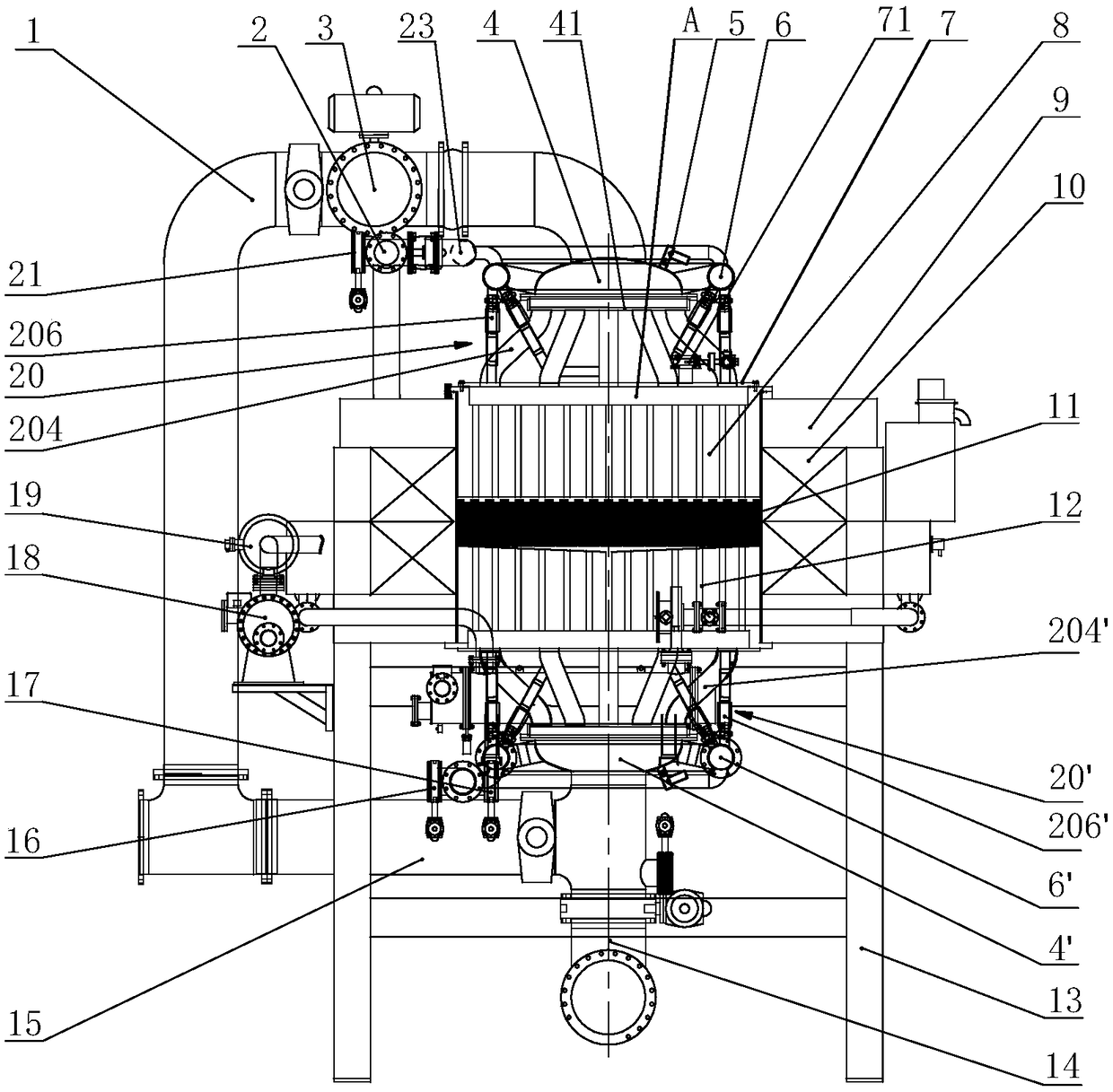

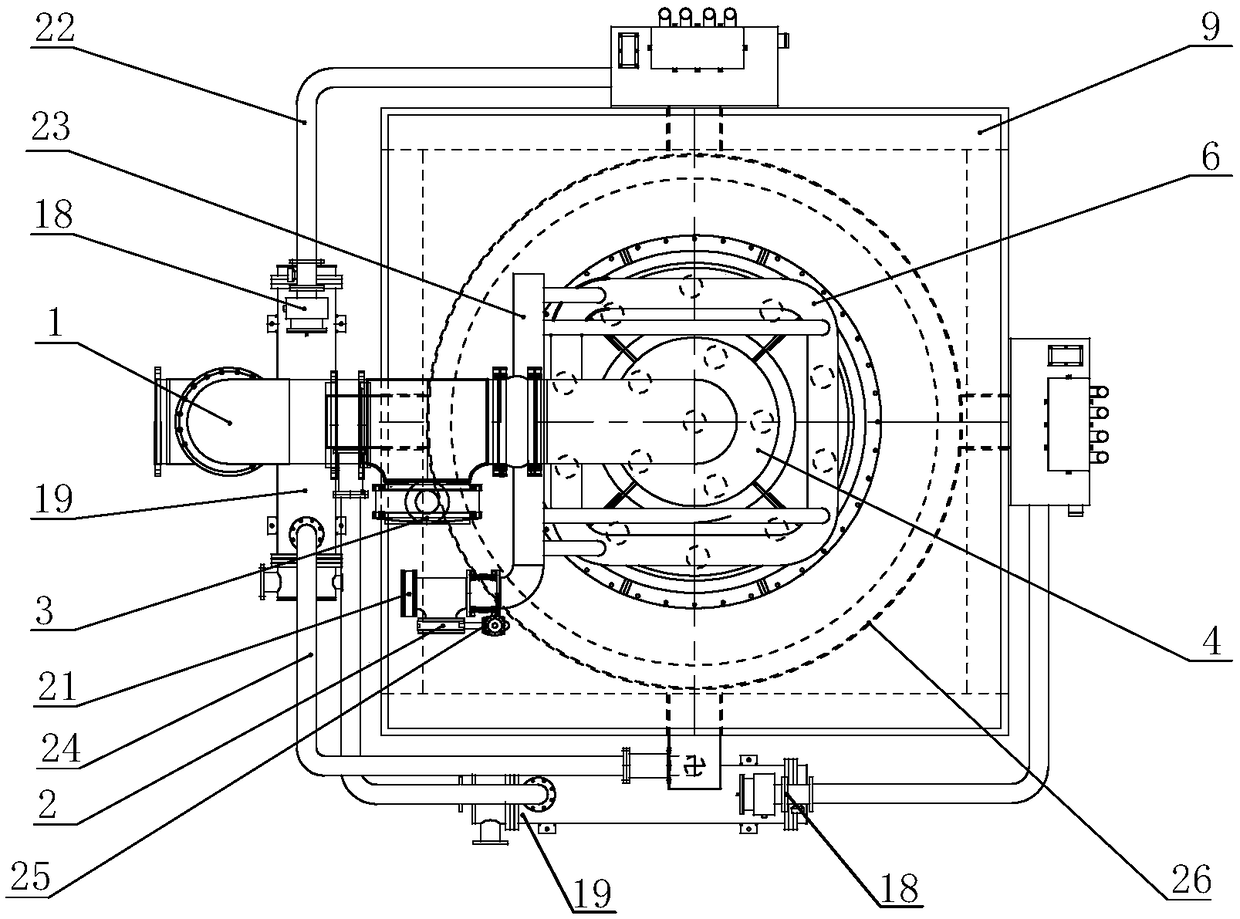

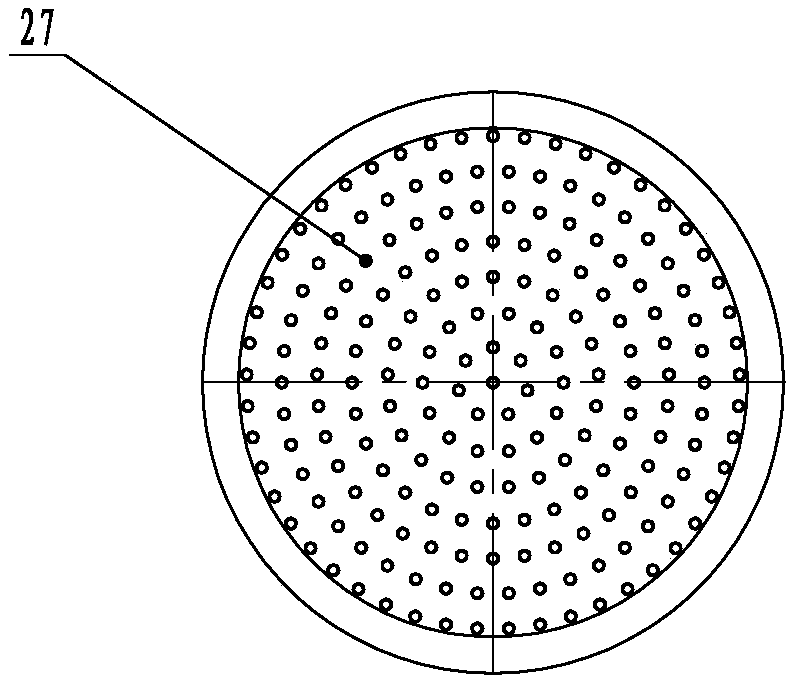

Electromagnetic slurry magnetic separator

PendingCN109127125AReduce wasteImprove cooling effectMagnetic separationMagnetic mediaCooling effect

The invention discloses an electromagnetic slurry magnetic separator. The electromagnetic slurry magnetic separator comprises a magnetic separation device, a splitting device, a converging device anda cooling device. The magnetic separation device comprises a coil arranged in a wire box, and an upper magnetic pole, a magnetic medium device and a lower magnetic pole communicated with one another to form a magnetic separation cavity are arranged in an air gap in the middle of the coil; the splitting device is arranged above the upper magnetic pole and comprises a multi-pipeline splitting interface, a splitter and a water separator; the multi-pipeline splitting interface comprises a plurality of splitting pipes communicated with the splitter and the magnetic separation cavity and a pluralityof water dividing pipes communicated with the water separator and the magnetic separation cavity; the converging device is arranged below the lower magnetic pole, is substantially as same as the splitting device in structure, and the two are symmetrical; and the cooling device adopts a forced oil circular cooling mode. According to the electromagnetic slurry magnetic separator, a pipeline channelwhere slurry and flushing water are separated, a flow is distributed uniformly, the concentrate grade and purity are high, and waste of the slurry is small; the cooling effect of the coil is good, the diameter of the coil is great, the exciting power is small, the ton energy consumption is low, the output is high and the occupied area is small.

Owner:SHANDONG HUATE MAGNET TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com