Electromagnetic slurry magnetic separator

A technology of magnetic separator and slurry, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc. It can solve the problems of large number of sets required for capacity expansion, influence on the purity of concentrate, uneven distribution of fluid, etc., and achieve distribution Uniformity, high concentrate grade and purity, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] For ease of description, in the present invention, fluid flow from top to bottom is defined as the "forward" direction, and fluid flow from bottom to top is defined as the "reverse" direction. Among them, the term "communication" should be understood in a broad sense, and it can be that two elements are directly connected or indirectly connected through an intermediary. For those of ordinary skill in the art, the meaning of this term can be understood according to the specific situation. Concrete meaning.

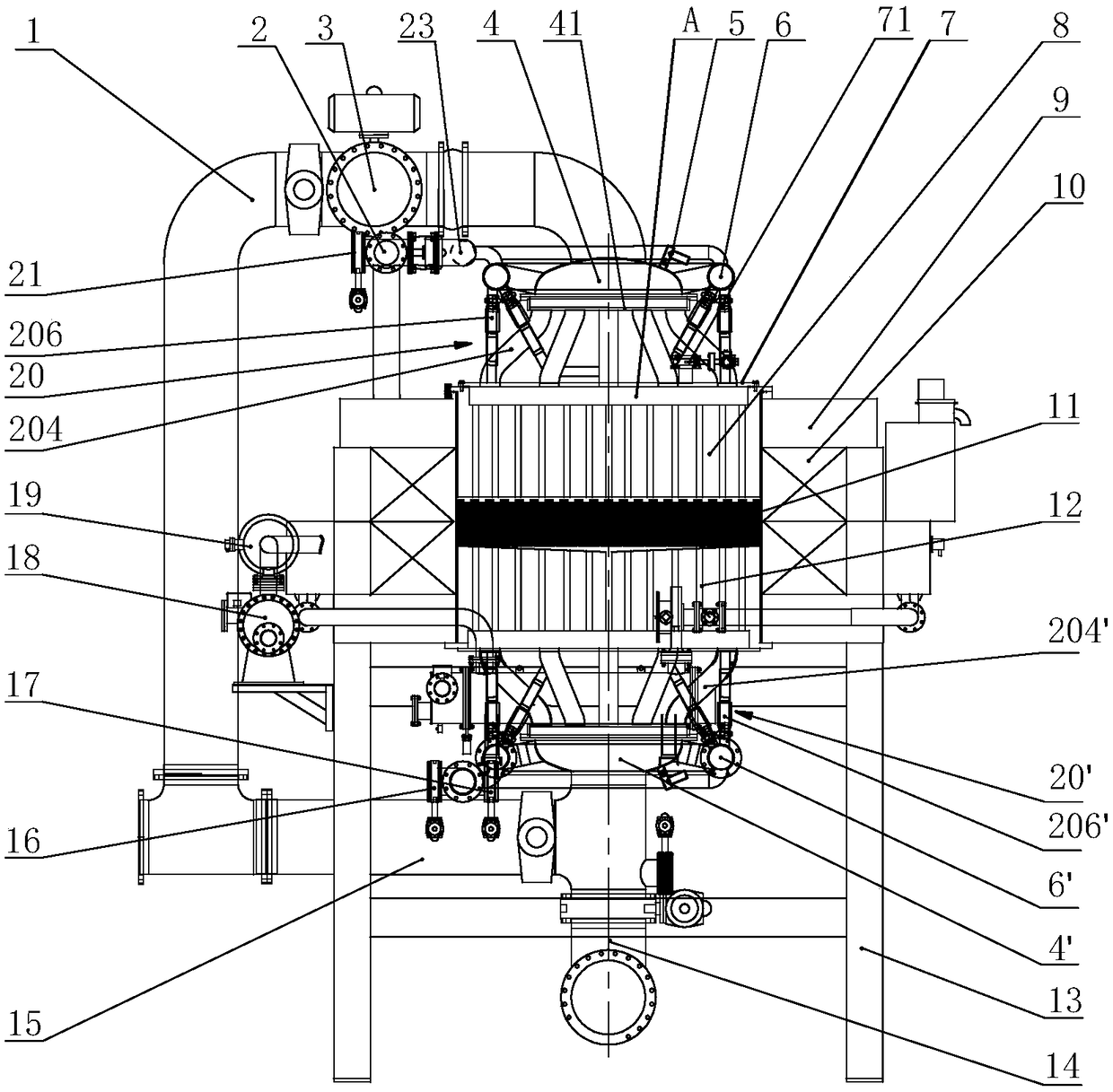

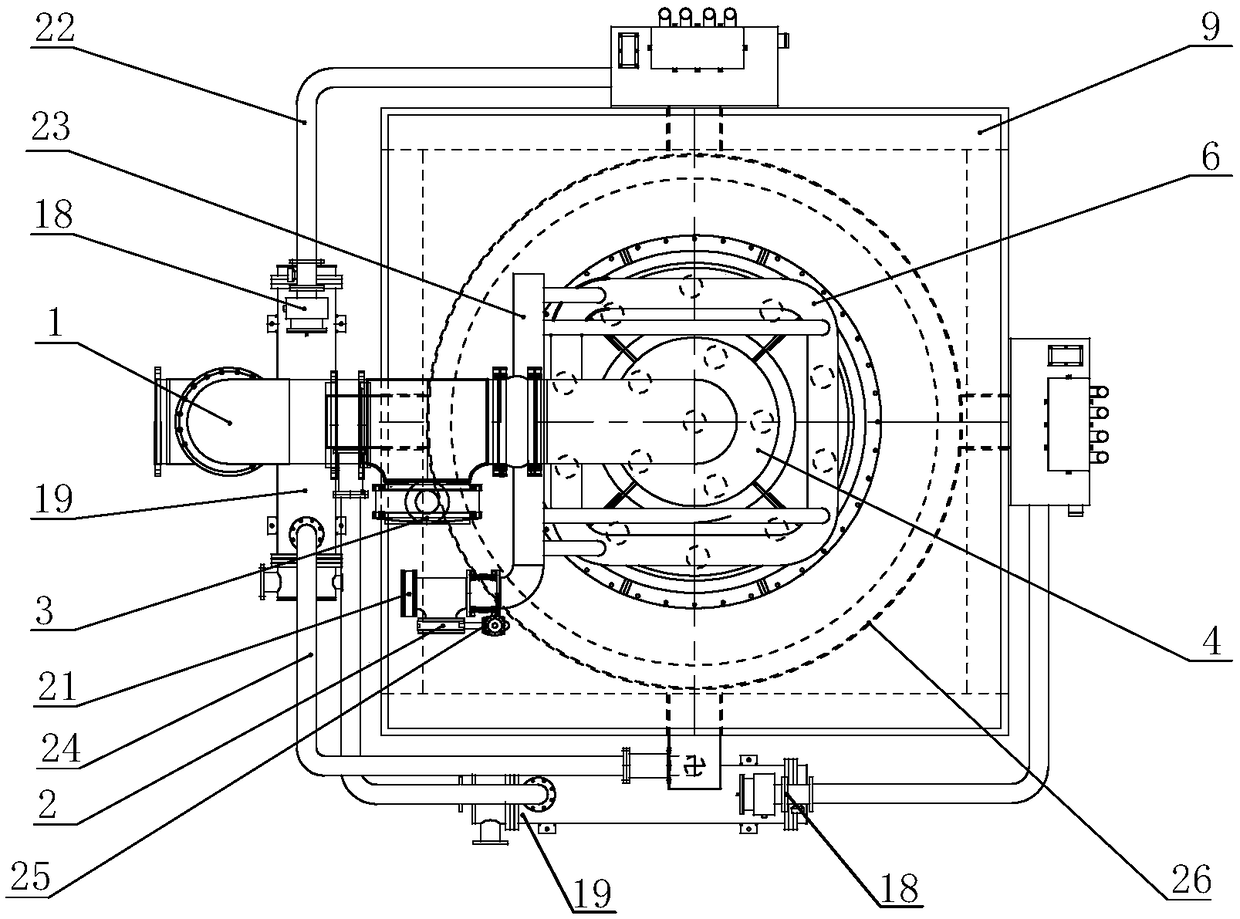

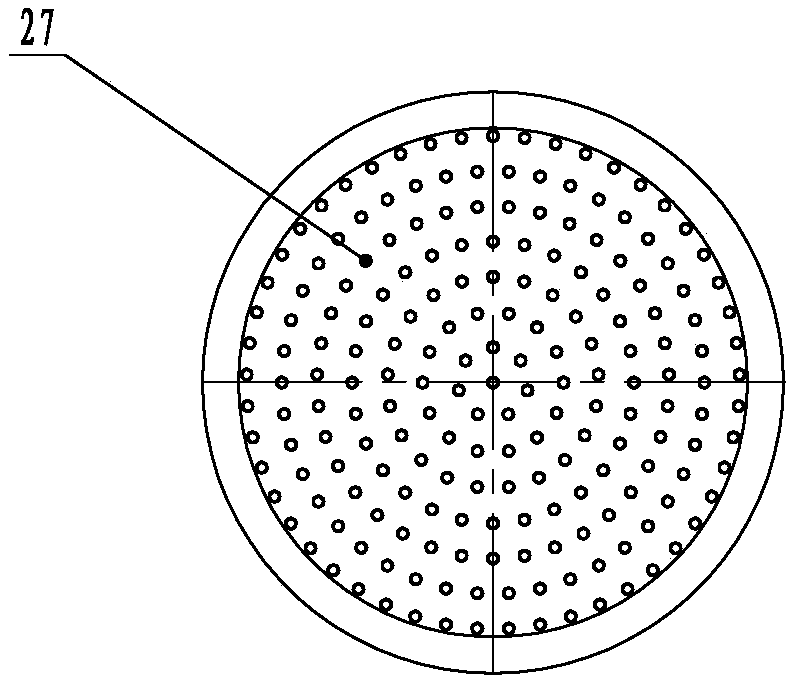

[0027] The electromagnetic slurry magnetic separator of the present invention includes a magnetic separation device, a flow diversion device, a flow confluence device and a cooling device arranged on the frame 13 .

[0028] Such as figure 1 and figure 2 As shown, wherein, the magnetic separation device includes: a coil 10 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com