Counter flow type plate heat exchanger comprising independent flow guide plates

A technology of plate heat exchangers and deflectors, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of poor diversion effect and uneven distribution of fluid in the diversion area, and achieve Reduced pressure, reduced heat transfer dead zone, and small flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention patent will be further described below in conjunction with the accompanying drawings.

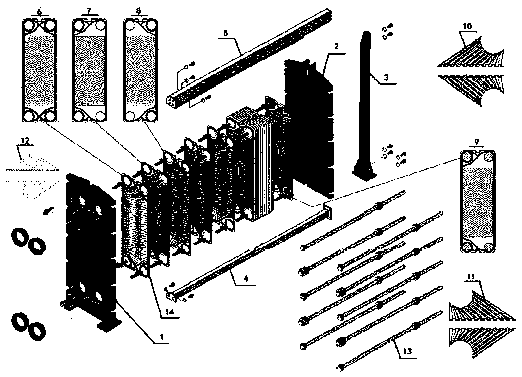

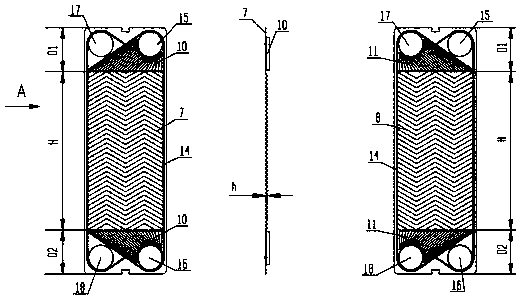

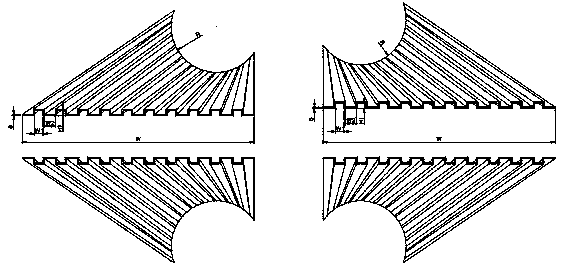

[0026] Such as figure 1 As shown, the counter-flow plate heat exchanger with independent deflectors provided by the patent of the present invention is mainly composed of a certain number of heat transfer plates, sealing gaskets 14, mounted on the heat transfer plates A7 and the rear end plate 9 Independent deflector 10 and independent deflector 11 mounted on heat transfer plate B8, fixed compression plate 1, movable compression plate 2, fastening bolts and nuts 13, upper and lower guide rods 4 and 5, guide rod bracket 3, etc. components. The heat transfer plate A7 and the heat transfer plate B8 are two adjacent heat transfer plates, forming a flow channel, which is the core component of the plate heat exchanger. The sealing gasket 14 is pasted on the heat transfer plate, and the heat transfer plate pasted with the sealing gasket 14 is placed on the fixed compression p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com