Screw thread welding integral narrow slit type coaxial pulse-tube refrigerator

A slit-type refrigerator technology, which is applied in the direction of gas cycle refrigerators, refrigerators, refrigeration and liquefaction, etc., can solve the problems of poor laminarization effect, reduce the empty volume of the cold end, ensure reliability, reduce The effect of the possibility of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

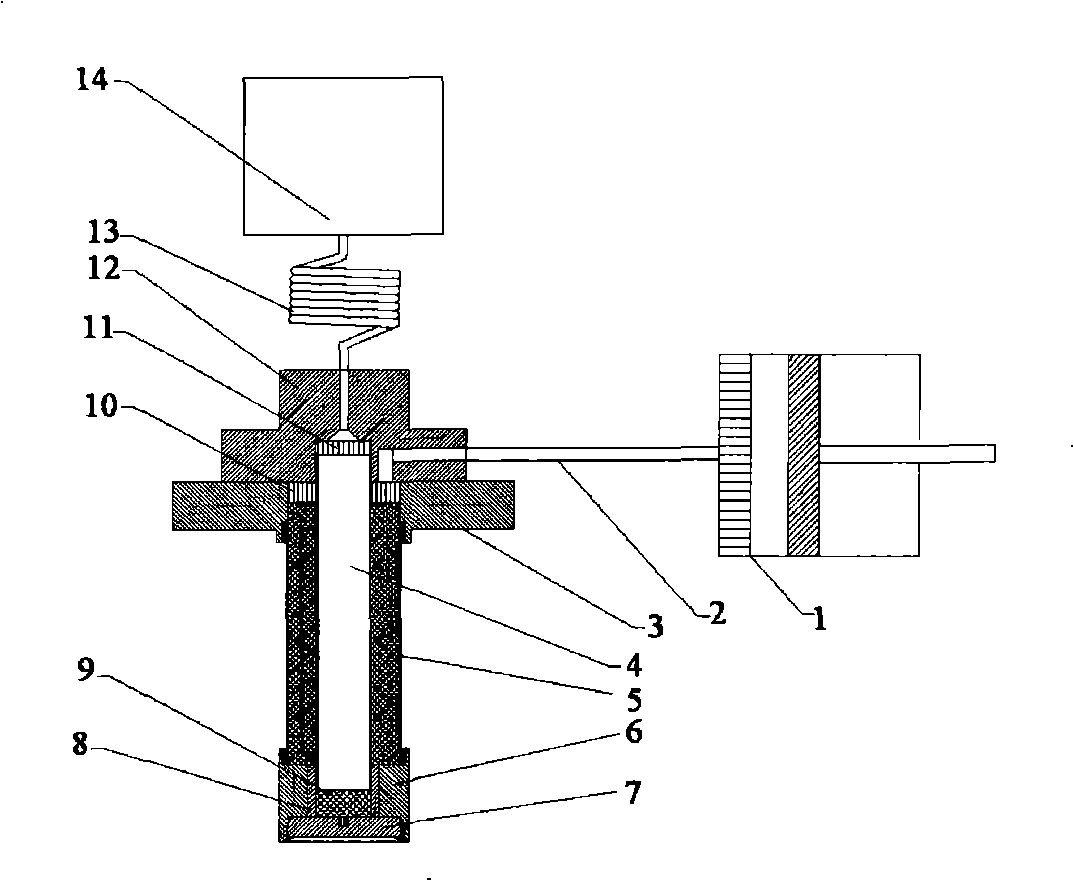

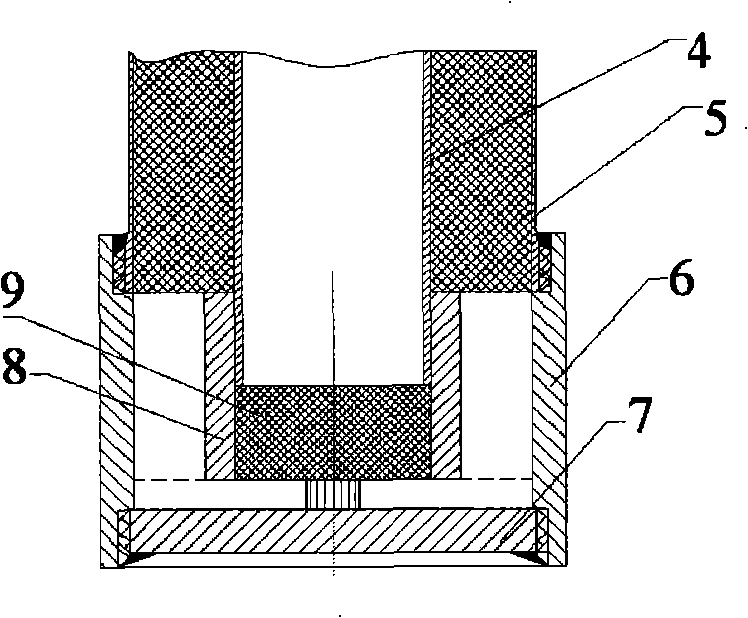

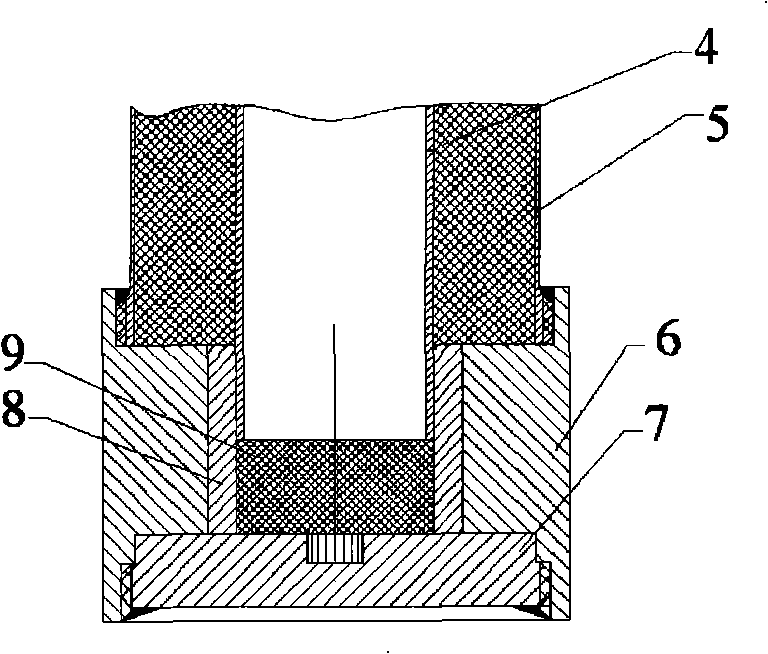

[0015] figure 1 As shown, this embodiment includes: linear compressor 1, air intake pipeline 2, hot end flange 3, pulse tube 4, regenerator 5, upper cold head 6, lower cold head 7, cold end baffle plate 8, copper wire Net 9, first hot-end deflector 10, second hot-end deflector 11, regenerator plug 12, long neck pipe 13 and gas storage 14. The linear compressor 1 provides pressure fluctuations, and is connected to the hot end of the regenerator 5 coaxially sleeved outside the pulse tube 4 through the intake pipeline 2 and via the regenerator plug 12 and the hot end fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com