Drop-out fuse connecting structure and drop-out fuse

A drop-type fuse and connection structure technology, applied in emergency protection devices, circuits, electrical components, etc., can solve the problems of poor diversion effect, large contact area, good diversion effect, etc., and achieve good contact and large contact area. , good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

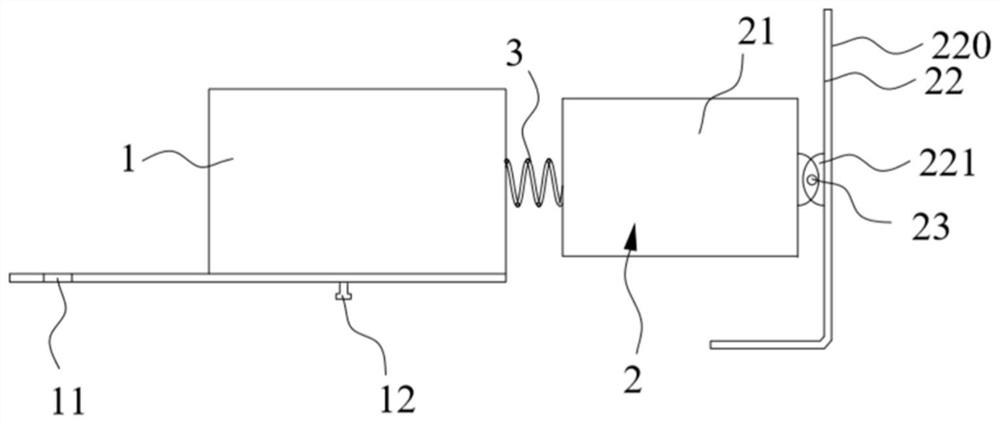

[0035] This embodiment provides a drop-out fuse connection structure, such as figure 2 As shown, the flow diversion between the moving contact and the static contact of the drop-out fuse includes a fixed part 1 and a movable part 2. Among them, one end of the fixed part 1 can be connected with the static contact (including the upper static contact 41 and the lower static contact 42); the movable part 2 has a connecting part 21 and a rotating part 22, and the connecting part 21 is connected to the other end of the fixed part 1. Sliding connection to make the rotating part 22 close to or away from the fixed part 1, the rotating part 22 is rotatably connected to the connecting part 21, the rotating part 22 has a contact plane 220, the contact plane 220 can fit the movable contact (including the upper movable contact 51 and the lower The connecting surface 7 of the moving contact 52). In this embodiment, both the fixed part 1 and the movable part 2 are made of copper to achieve t...

Embodiment 2

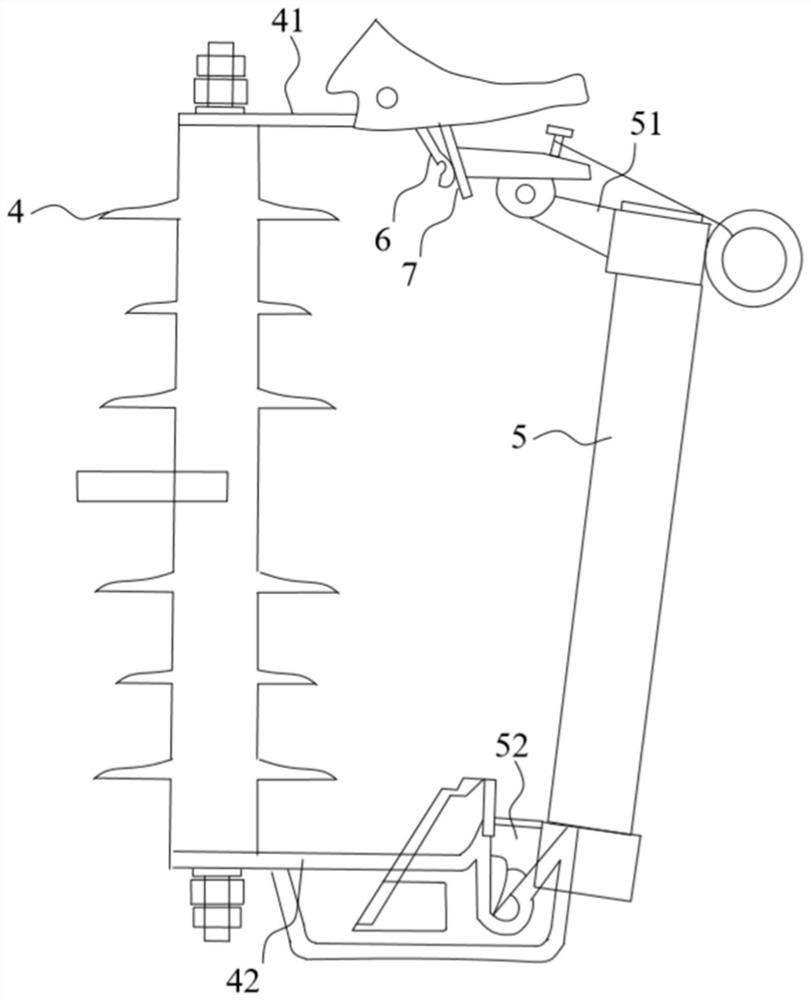

[0044] This embodiment is the same as or corresponding parts of the first embodiment using the same reference numerals. For brevity, only the difference from the first embodiment is described. The difference is that: this embodiment provides a drop-out fuse, including implementation Example 1: The drop-out fuse connection structure provided. The drop-out fuse uses the drop-out fuse connection structure provided in the first embodiment to replace the existing copper shrapnel 6, so that the contact area of the diversion is increased, the diversion effect is good, and the original diversion contact area is reduced. The probability of failure is small, which in turn improves the stability of grid operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com