Flat plate type micro loop heat pipe for changing capillary force of capillary core

A loop heat pipe and capillary force technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the uneven temperature of steam pipes, uneven local heat transfer, and uneven fluid distribution To achieve the effect of improving heat transfer and cooling efficiency, increasing heat transfer distance, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

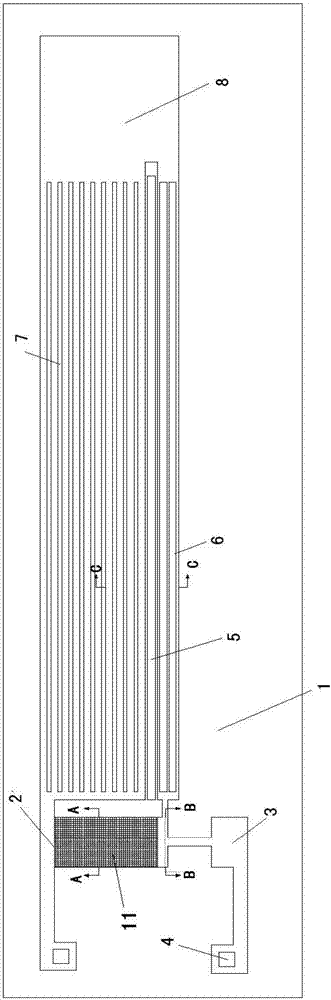

[0033] A flat micro-loop heat pipe, comprising a main board 1 and an upper cover plate 10, the upper cover plate 10 is packaged with the main board 1, the main board 1 includes an evaporation chamber 2, a condensation chamber 8, an evaporation chamber 2 and a condensation chamber 8 are connected to the steam pipeline 7 and the liquid pipeline 6, and the steam pipeline 7 and the liquid pipeline 6 are separated by a thermal insulation through hole 5.

[0034] In the loop heat pipe of the present invention, the steam pipe 7 and the liquid pipe 6 are all arranged on a main board 1, so that the structure is miniaturized, can be directly attached to the surface of a microchip, and the heat is directly taken away, and the heat dissipation efficiency is high, which can be widely used For heat dissipation of tiny components such as electronic chips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com