Cloth special-purpose sucker and work method thereof

A suction cup and cloth technology, applied in the direction of cloth feeding mechanism, textile and papermaking, sewing equipment, etc., can solve the problems that the suction force is difficult to control, cannot adapt to mechanical automation sewing, and cannot send cloth to other problems, so as to avoid adsorption multi-layer cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

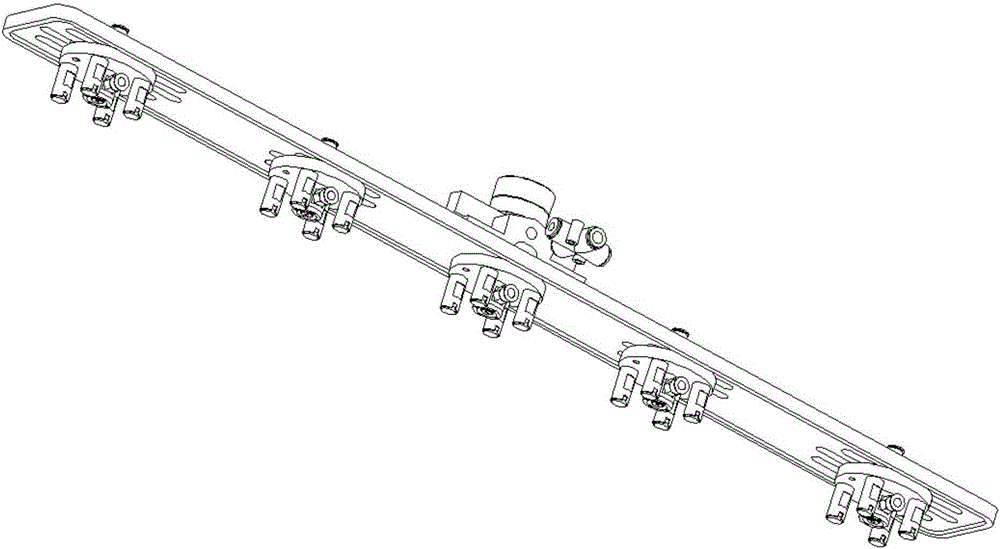

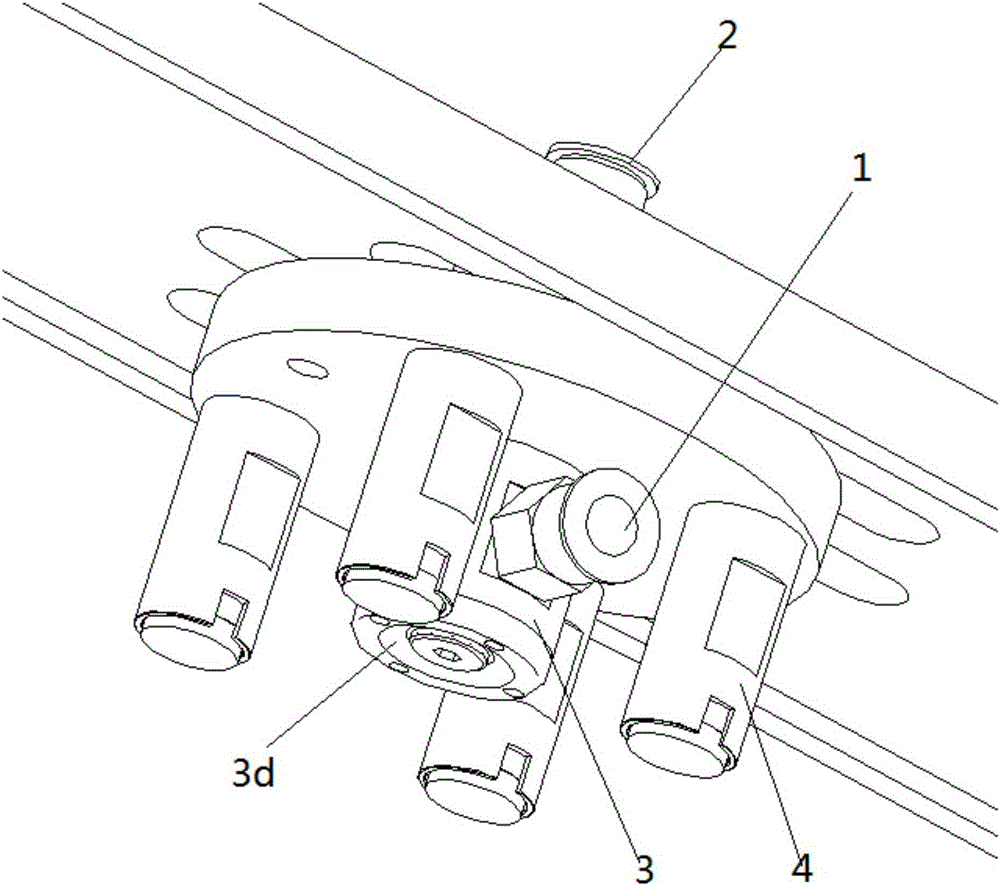

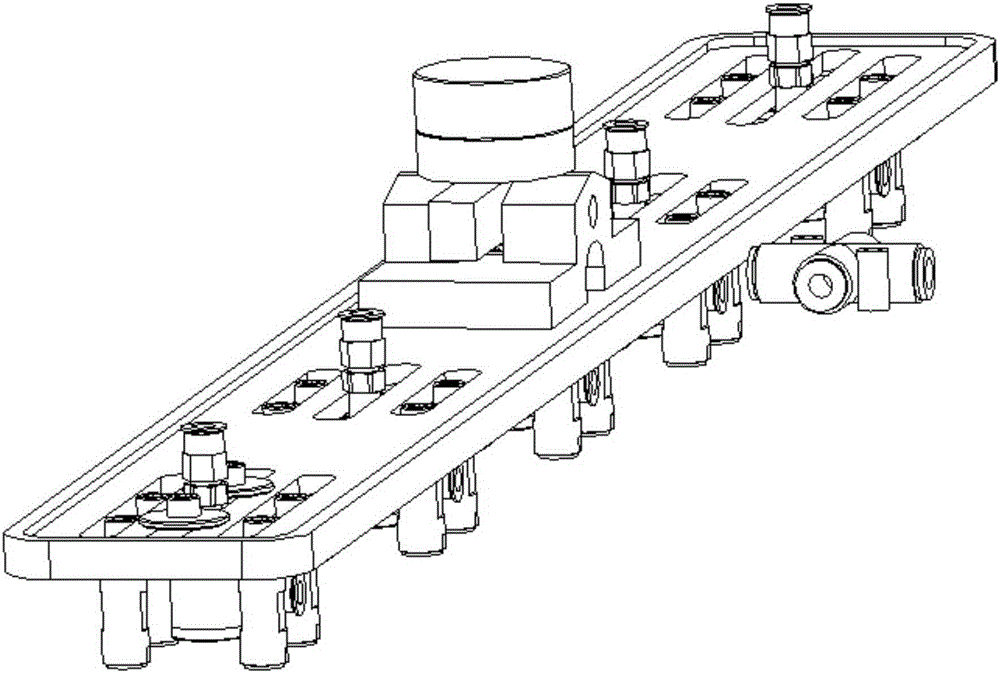

[0026] see Figure 1-Figure 5 , a special suction cup for cloth, including a mobile bracket, a group of suction cup units are fixedly connected to the bottom of the mobile bracket; the suction cup unit includes an air blowing port 1, an air suction port 2, a suction cup core 3, and a cloth pressing support column 4; The suction cup core 3 is a columnar body, the blowing port 3b on its side is connected to the blowing port 1, and the blowing port 1 is connected to the blowing pressure device, and there is a negative pressure generating area 3d below the non-contact suction cup 3c at the bottom of the suction cup core 3 There is a vertical suction channel in the center of the suction cup core 3, the suction port 3a at the top of the suction channel is connected with the suction port 2, and the suction port 2 is communicated with the suction press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com