Range hood

A technology for range hoods and fans, which is applied to the removal of oil fumes, household stoves/stoves, heating methods, etc. It can solve the problems of reduced effect of range hoods, damage to the negative pressure distribution of fume collection hoods, and inability to greatly improve the suction rate of range hoods, etc. , to achieve the lifting effect and the effect of increasing the central negative pressure area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

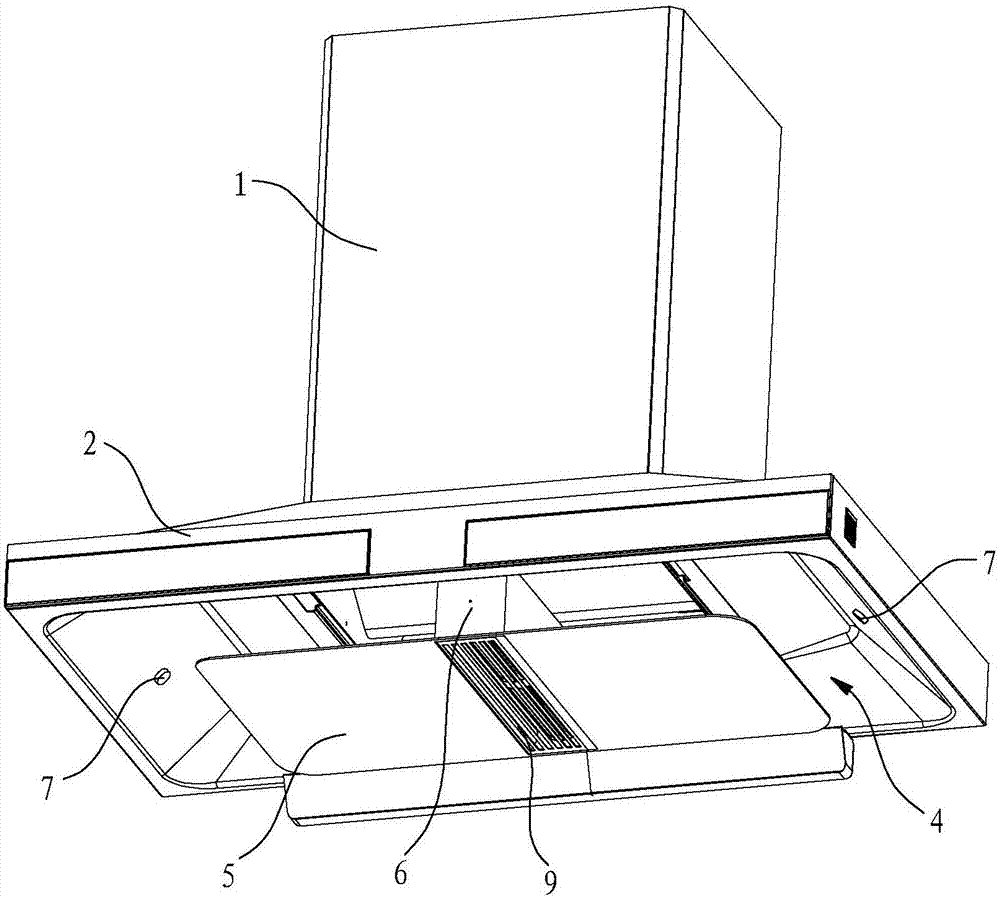

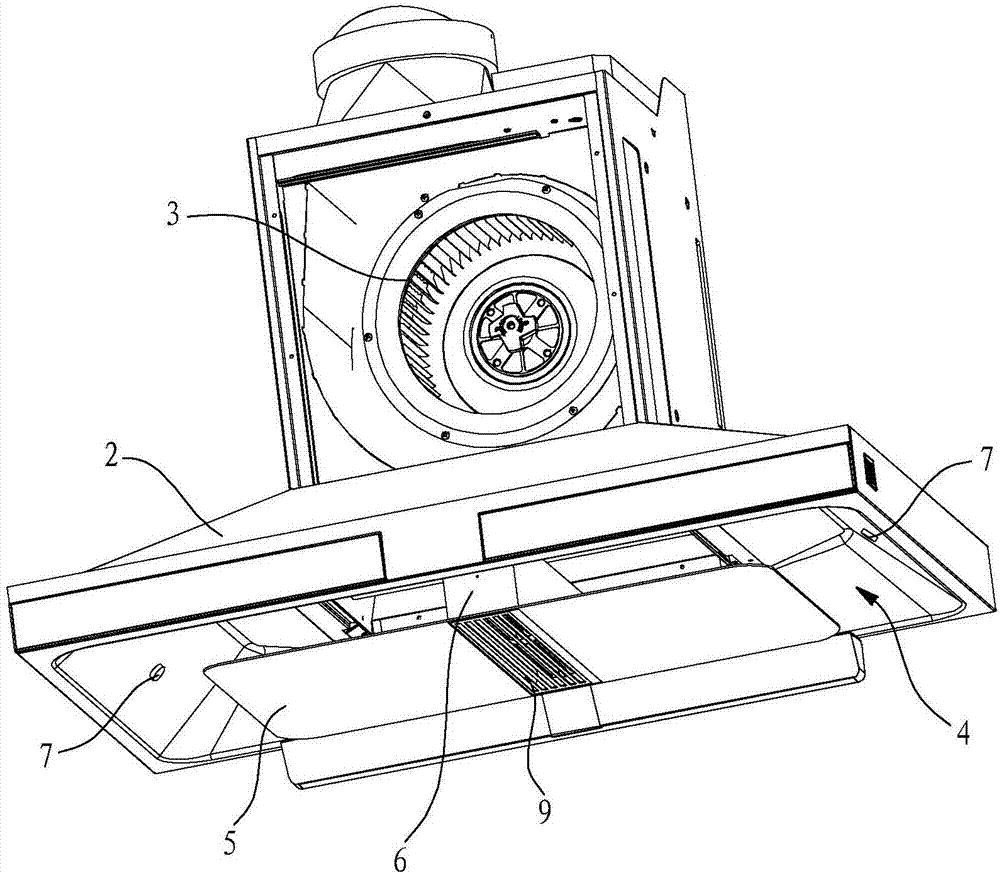

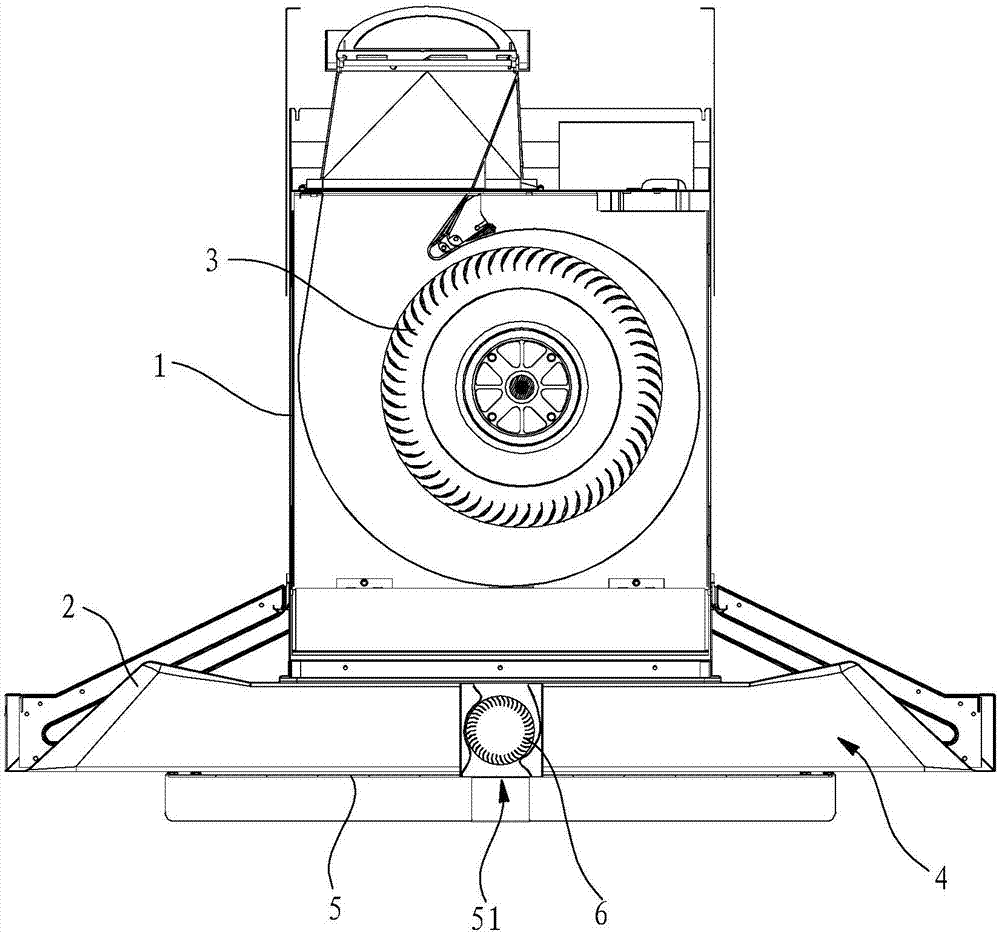

[0021] Such as Figure 1 to Figure 4 As shown, the range hood in this embodiment is a single-fan range hood, which includes a fan housing 1, a smoke collection hood 2, a main fan 3 and a rectifying plate 5, wherein the main fan 3 has one and is installed on Inside the fan housing 1, the main fan 3 is a centrifugal fan. The smoke collecting hood 2 is located below the fan housing 1, and a rectifying chamber 4 is formed below the fume collecting hood 2, and a rectangular rectifying plate 5 is installed in the rectifying chamber 4. The above-mentioned installation structure is the same as that of the existing range hood and will not be described in detail.

[0022] The range hood in this embodiment also includes a cross-flow fan 6, a smoke sensor 7 and a controller (not shown in the figure), and a strip-shaped air inlet 51 is opened in the middle of the rectifying plate 5, and the strip-shaped air inlet 51 is distributed in front and back , that is, the length direction of the s...

Embodiment 2

[0026] Such as Figure 5 and Figure 6 As shown, compared with the first embodiment, the range hood in this embodiment has a main fan 3 added in the fan housing 1, which constitutes a dual-fan range hood. The two main fans 3 are arranged in parallel and are respectively located on the left and right sides directly above the cross-flow fan 6 , and the central axes of the two main fans 3 and the central axis of the cross-flow fan 6 are parallel to each other. An air outlet cover 8 is installed on the fan housing 1 , the planes where the air inlet ends of the two main fans 3 are located are located on the same vertical plane, and the air outlets of the two main fans 3 are connected on the air outlet cover 8 .

[0027] The working principle of the double-fan range hood to improve the effect of the range hood through the cross-flow fan is the same as that of the single-fan range hood in Embodiment 1, and will not be further described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com