A kind of chilling tower for separation of Fischer-Tropsch synthesis products and its process system

A Fischer-Tropsch synthesis and chilling tower technology, which is applied in the field of chemical equipment and devices, can solve the problems of uneven distribution of fluid in the chilling tower, low system heat recovery rate, incomplete product separation, etc., and achieves reasonable design structure and operation. Stable and reliable, high heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

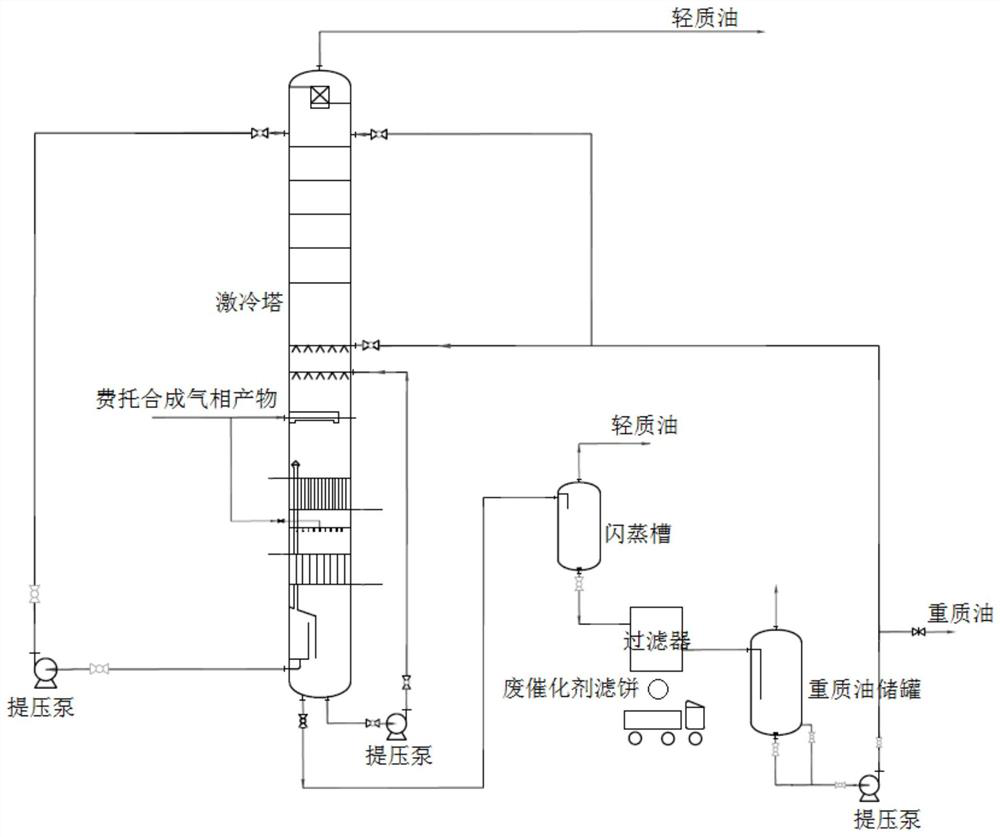

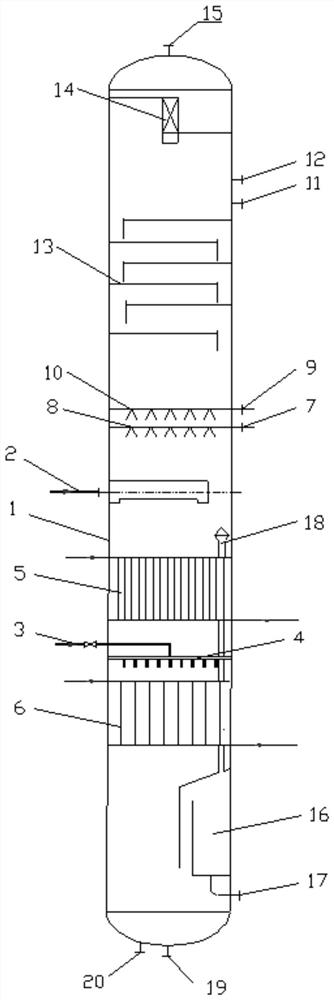

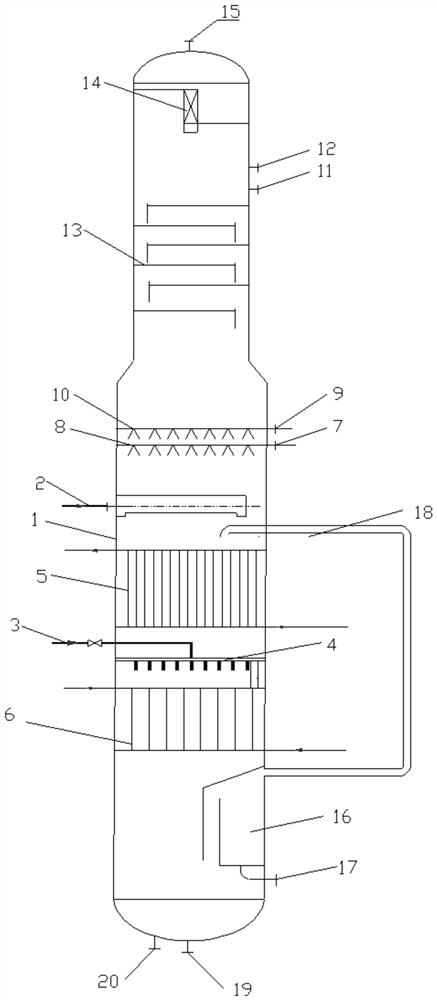

[0056] A process system for the separation of Fischer-Tropsch synthesis products, the process flow is as follows Figure 7As shown, the gaseous product from the top of the Fischer-Tropsch synthesis reactor with a temperature of about 320°C enters the quenching tower through the main and auxiliary feed systems, and in the quenching tower, it undergoes spray washing, cooling, tray washing, cooling and condensation After separation, the heavy oil enters the bottom of the tower after being condensed and separated from the gas phase product, and the solid particles entrained in the gas phase product enter the liquid phase product at the bottom of the tower after being sprayed and washed. The light oil and the tail gas after the reaction are sent to the subsequent process through the tower top discharge system in the form of gas phase products. The heavy oil in the liquid phase at the bottom of the tower is cooled by the heat exchange element, and part of it is sent to the liquid ci...

Embodiment 2

[0059] A process system for the separation of Fischer-Tropsch synthesis products, the flow process is as follows Figure 8 As shown, the gaseous product from the top of the Fischer-Tropsch synthesis reactor with a temperature of about 345°C enters the quenching tower through the main and auxiliary feed systems, and in the quenching tower, it undergoes spray washing, cooling, tray washing, cooling and condensation After separation, the heavy oil enters the bottom of the tower after being condensed and separated from the gas phase product, and the solid particles entrained in the gas phase product enter the liquid phase product at the bottom of the tower after being sprayed and washed. The light oil and the tail gas after the reaction are sent to the subsequent process through the tower top discharge system in the form of gas phase products. The heavy oil in the liquid phase at the bottom of the tower is cooled by the heat exchange element, and part of it is sent to the liquid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com