Novel jet cleaning robot for sewage pipes

A technology for cleaning robots and sewage pipes, which is applied in the direction of cleaning sewer pipes, waterway systems, water supply devices, etc. It can solve the problems of difficult cleaning of pipes and imperfect pipeline robots, etc., and achieve good use effects, reasonable structural design, and good performance. adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

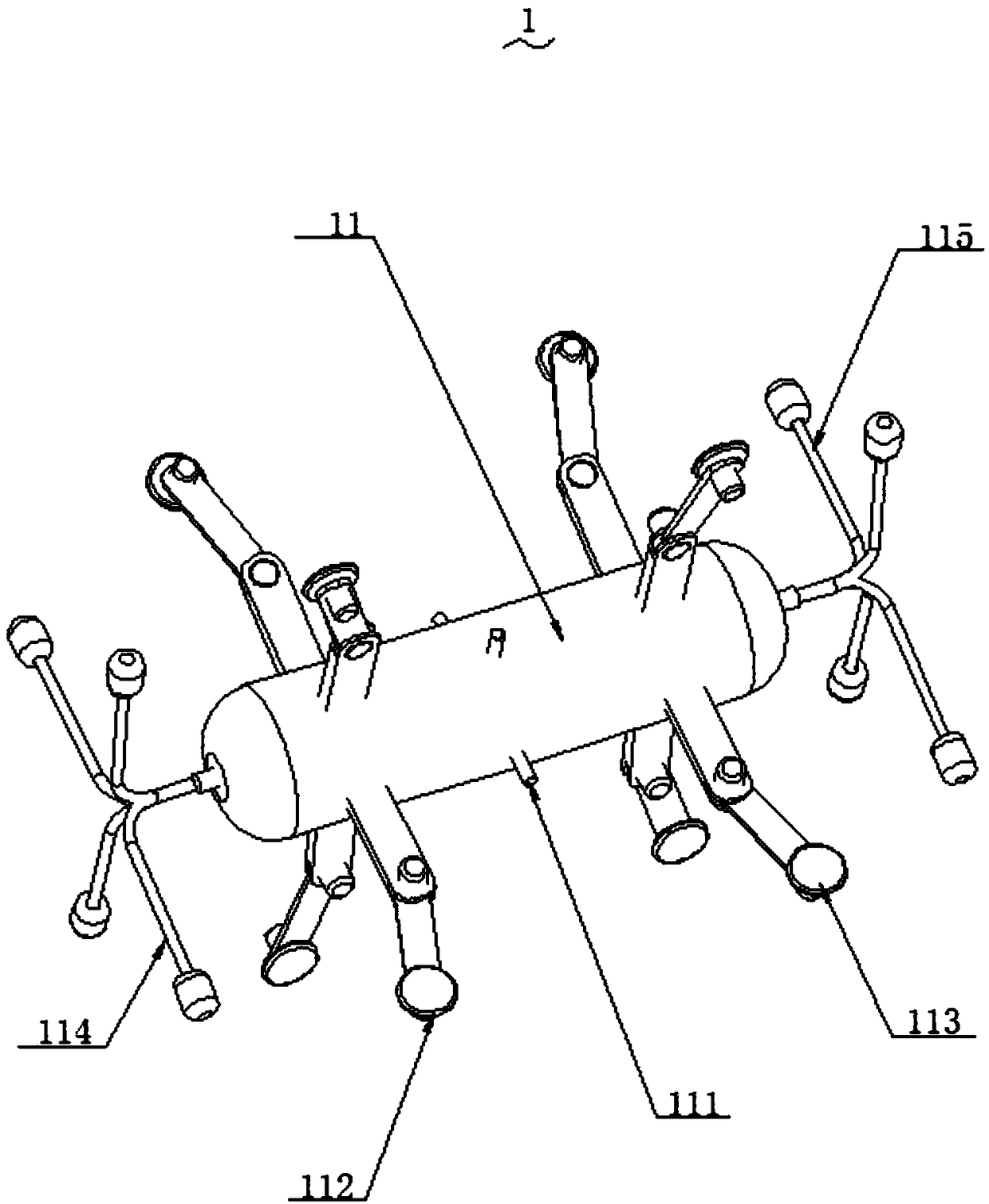

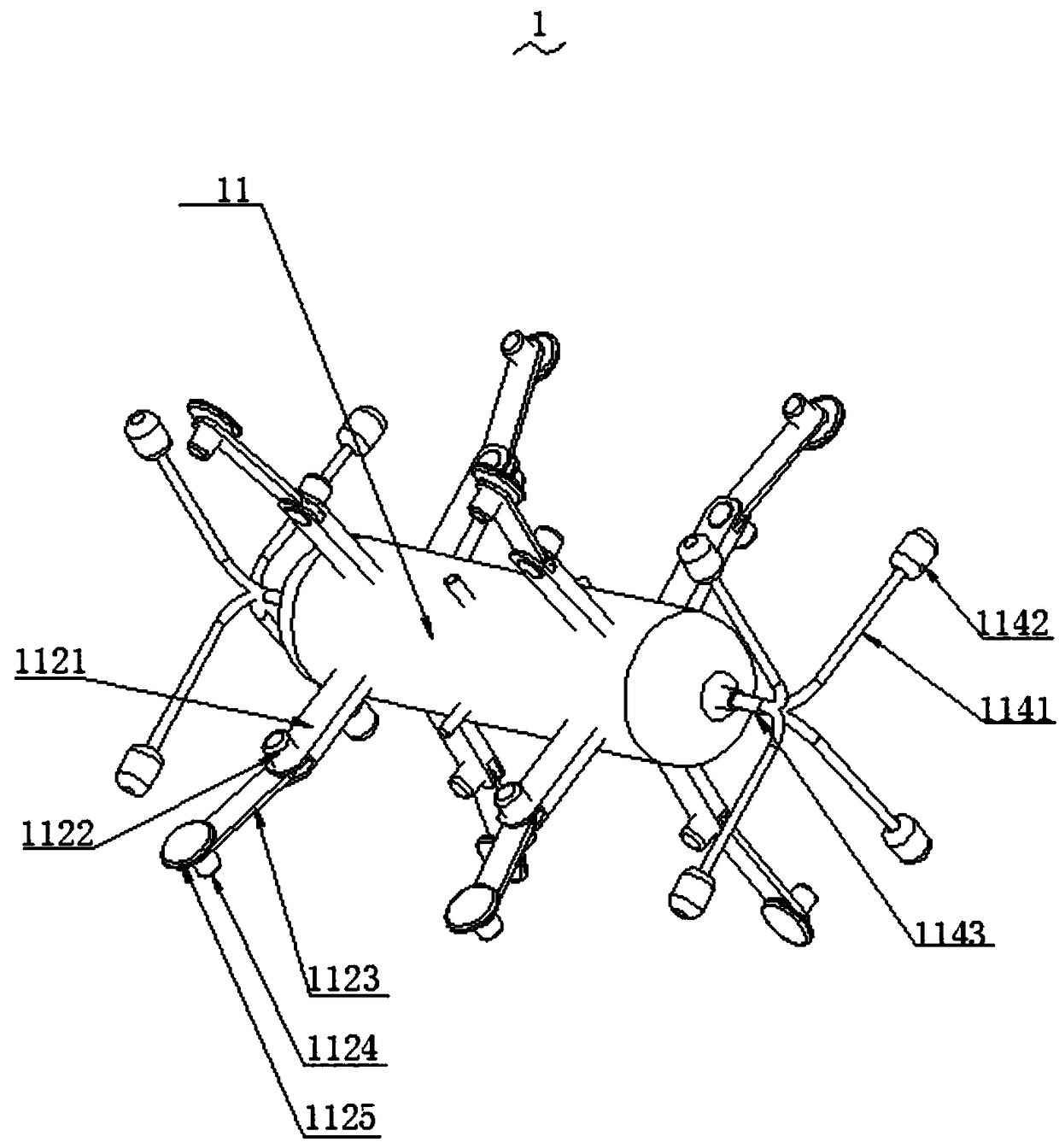

[0014] see figure 1 and figure 2 A novel jet-type sewage pipe cleaning robot 1 of the present invention includes a robot main body 11 and a power supply, a controller, a wireless communication transmission unit, a data memory, an alarm and a temperature sensor arranged inside the robot main body 11; The wireless communication transmission unit, the data memory, the alarm and the temperature sensor are electrically connected to the controller; the main body 11 of the robot is in the shape of a cylinder; The first cleaning mechanism 114 and the second cleaning mechanism 115; the first cleaning mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com