Patents

Literature

38results about How to "High heat recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

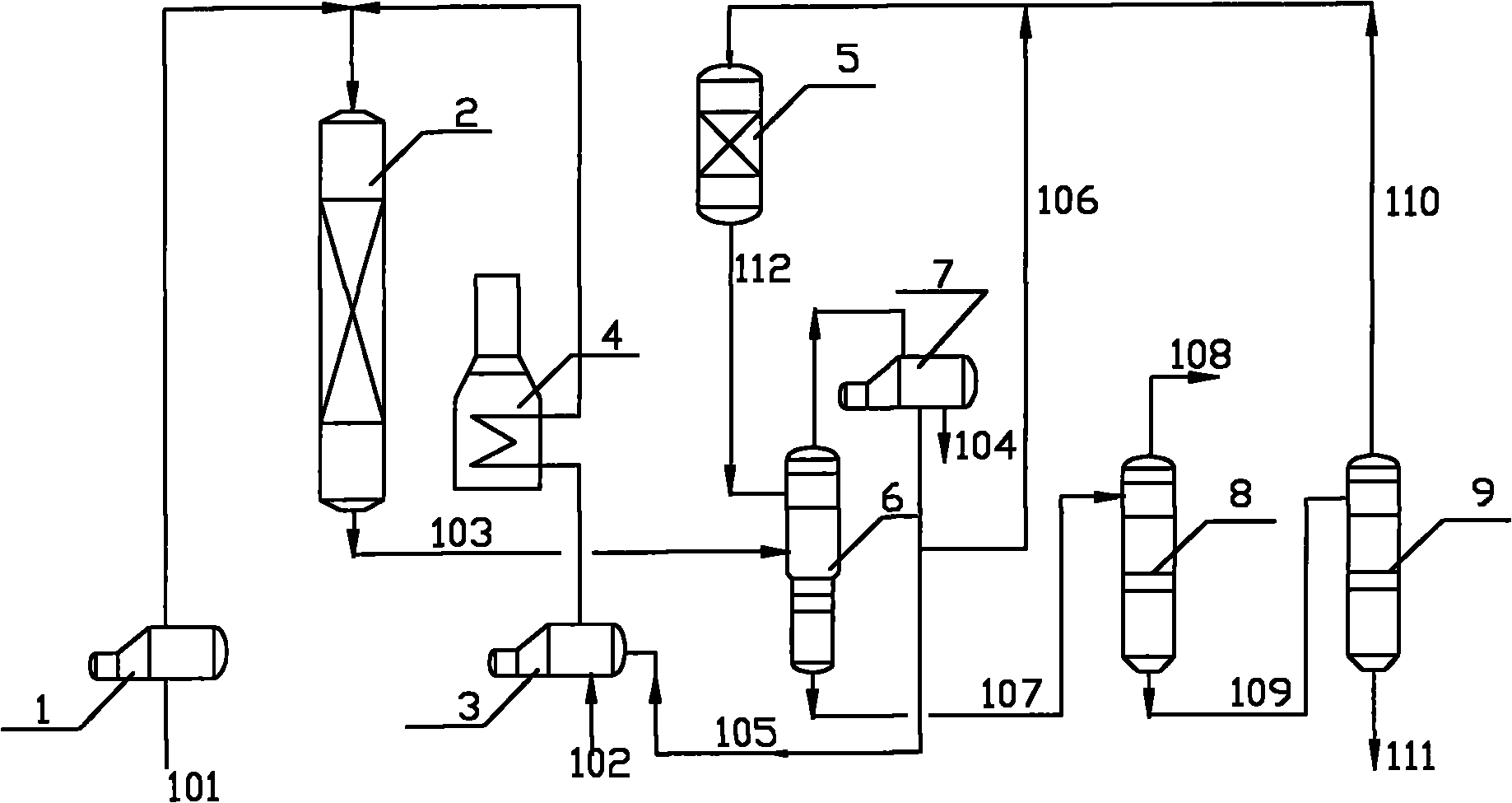

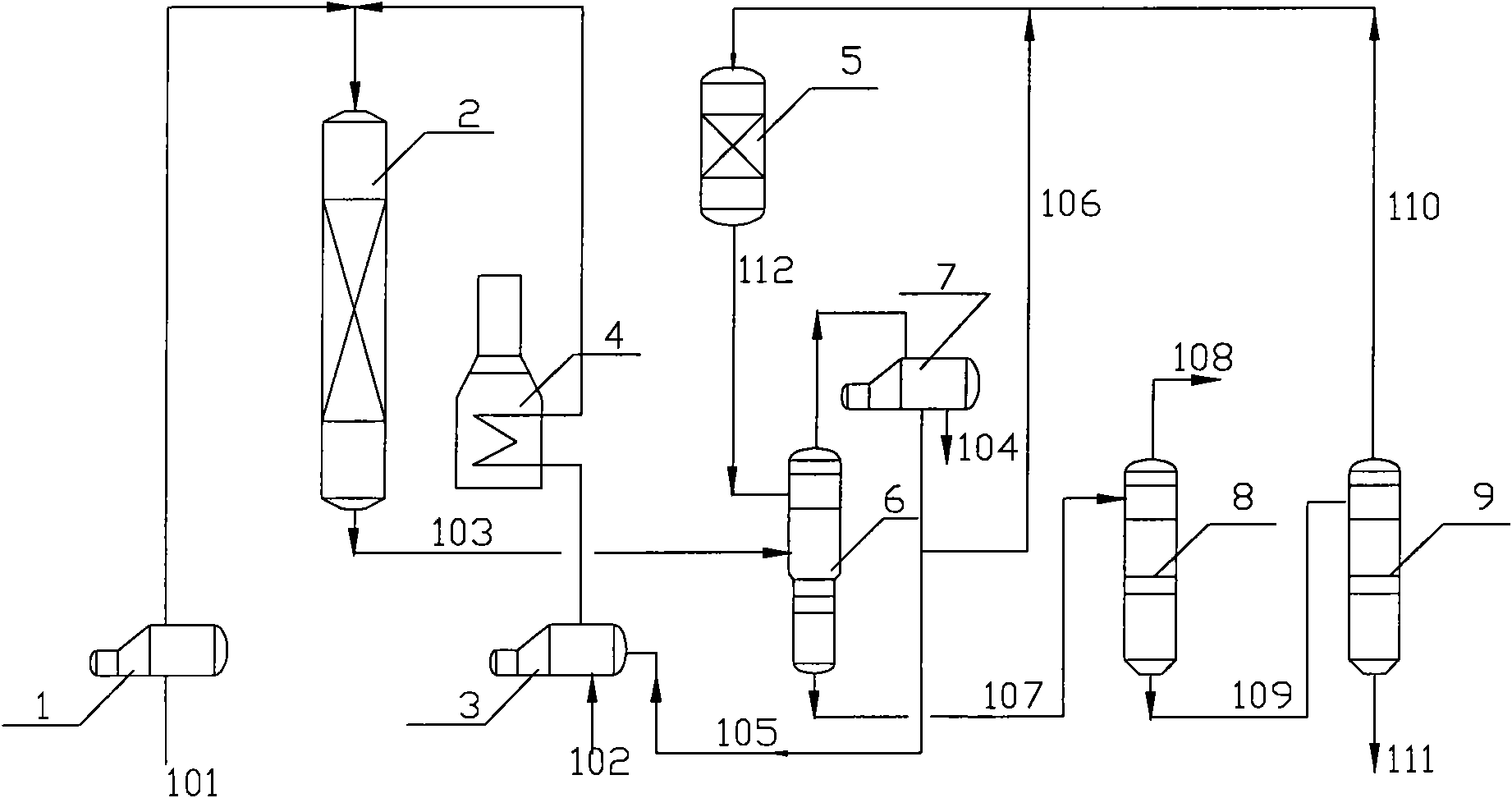

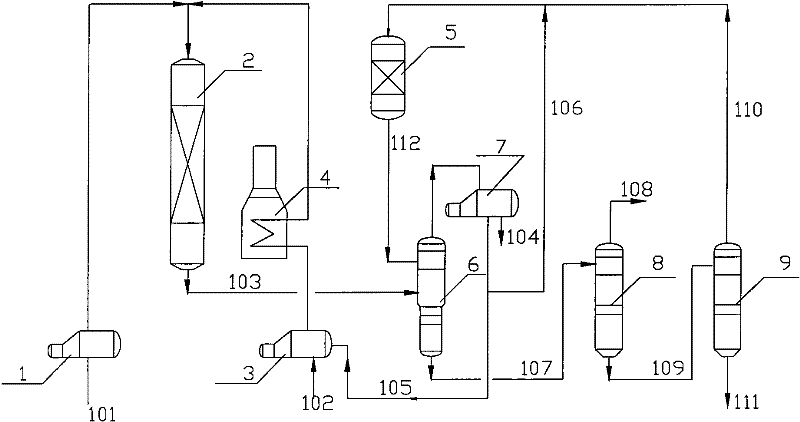

The synthesis method of ethylbenzene

ActiveCN102276410AHigh heat recovery rateNo corrosionHydrocarbonsHydrocarbon preparationMolecular sieveGas phase

The invention relates to a method for synthesizing ethylbenzene, and mainly solves the problems that ethylene must be taken as a raw material, the cost of the raw material is high and the content of dimethylbenzene is high in the product ethylbenzene in the conventional ethylbenzene production process. The method comprises the following steps that: a) benzene and ethanol enter an alkylation reactor loaded with a ZSM-5 nanoscale molecular sieve catalyst in a molar ratio of (2-8):1 under gas phase conditions and react to form a mixture 103 comprising benzene, ethylbenzene, diethylbenzene and water; b) the mixture 103 sequentially passes through a benzene recovery tower, an ethylbenzene recovery tower and a polyethylbenzene recovery tower so as to separate the water, the benzene, the ethylbenzene and the diethylbenzene from the mixture 103; and c) the partial benzene and diethylbenzene which are obtained through the separation enter a transalkylation reactor in a weight ratio of (2-10):1 under liquid phase conditions and are contacted with a Beta molecular sieve catalyst for a transalkylation reaction so as to generate the ethylbenzene. The technical scheme better solves the problems; in the scheme, the ethylbenzene is synthesized by using the ethanol as the raw material instead of the ethylene, the cost of the raw material is low, and the content of the dimethylbenzene in the product ethylbenzene is low; and the technical scheme can be used for the industrial production of the ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

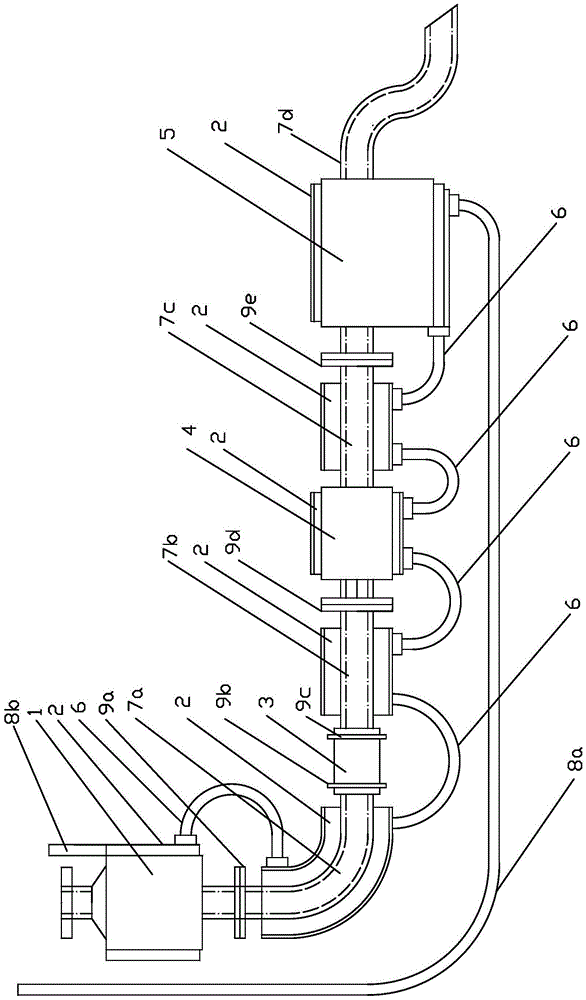

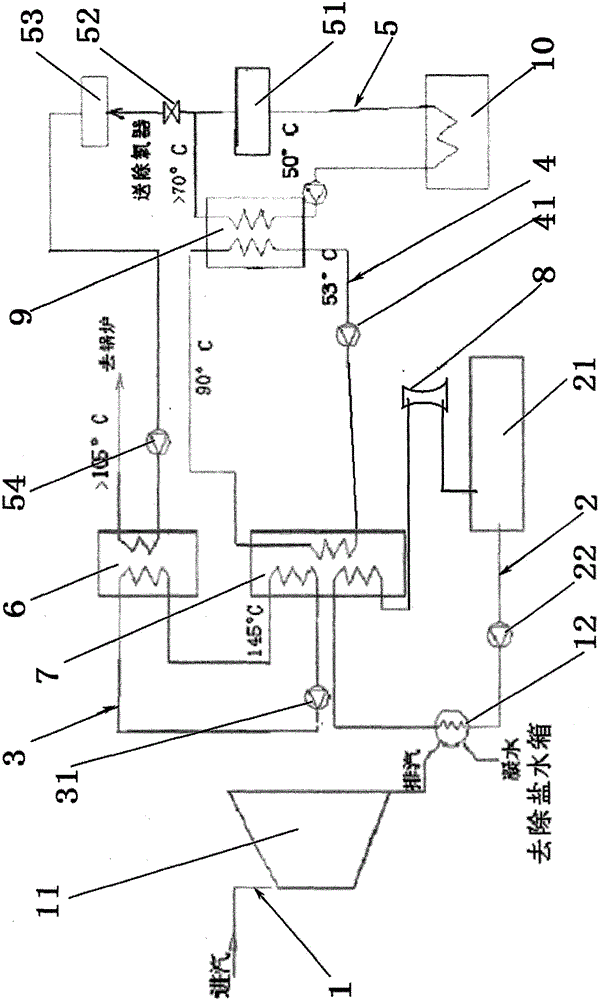

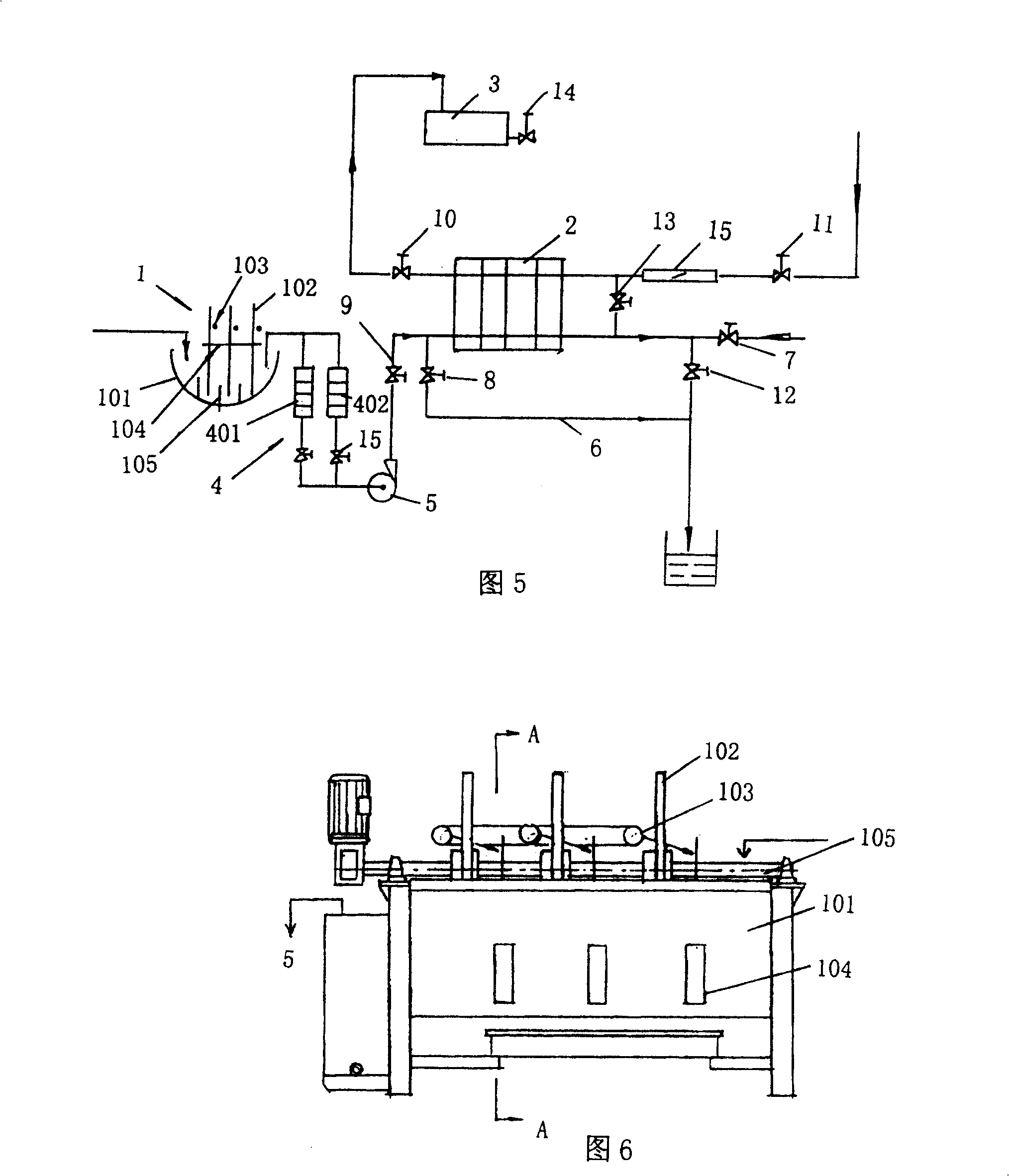

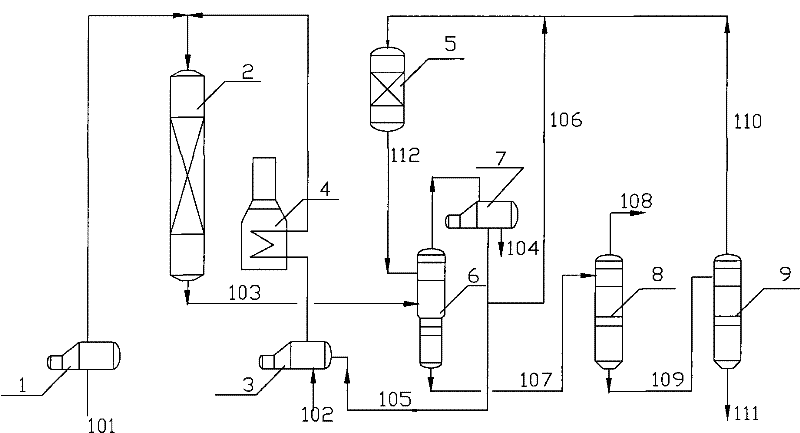

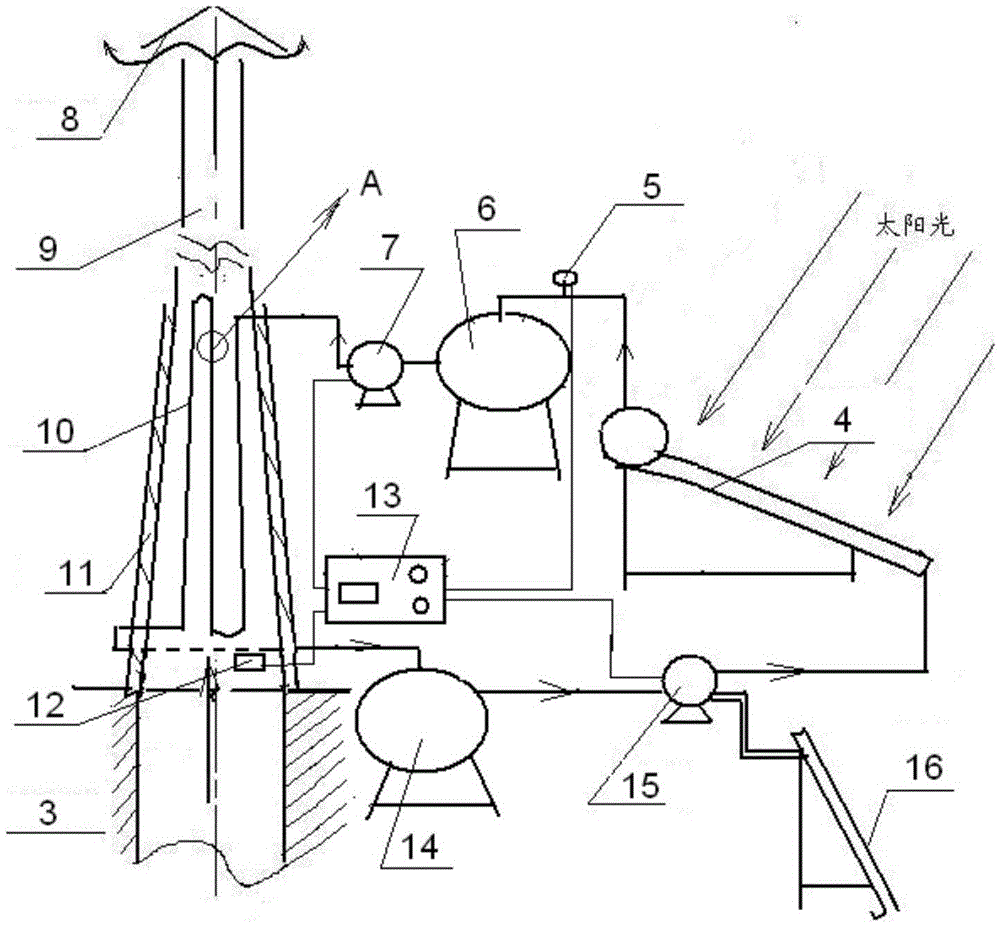

System and method for independently carrying out natural ventilation of tunnel through solar air pump

ActiveCN105604599AAchieve natural ventilationRealize the function of natural ventilationTunnel/mines ventillationThermal energyNatural ventilation

The invention discloses a system and a method for independently carrying out natural ventilation of a tunnel through a solar air pump. The system comprises a ventilation shaft arranged on a mountain above the tunnel in a penetration manner, wherein a sola air pump system is arranged at the outlet end of the ventilation shaft; the sola air pump system is capable of heating the air of the outlet end of the ventilation shaft and pumping polluted air in the tunnel out via negative pressure formed after the hot air quickly flows out of the ventilation shaft; the solar air pump system comprises a solar water heater unit and a chimney; the solar water heater unit is arranged on the mountain and constituted by a plurality of parallel solar water heaters; the chimney is connected to the outlet end of the ventilation shaft; a heat exchanger is arranged in the chimney; the outlet end of the solar water heater unit is connected to the inlet end of the heat exchanger; the outlet end of the heat exchanger is connected to the inlet end of the solar water heater unit. According to the system and the method, the cooperation of a power-driven ventilator is not needed; through heat energy storage of intermediate medium water, the ideal effect of independently carrying out natural ventilation of the tunnel under the condition without power consumption is ensured.

Owner:SHAANXI UNIV OF SCI & TECH

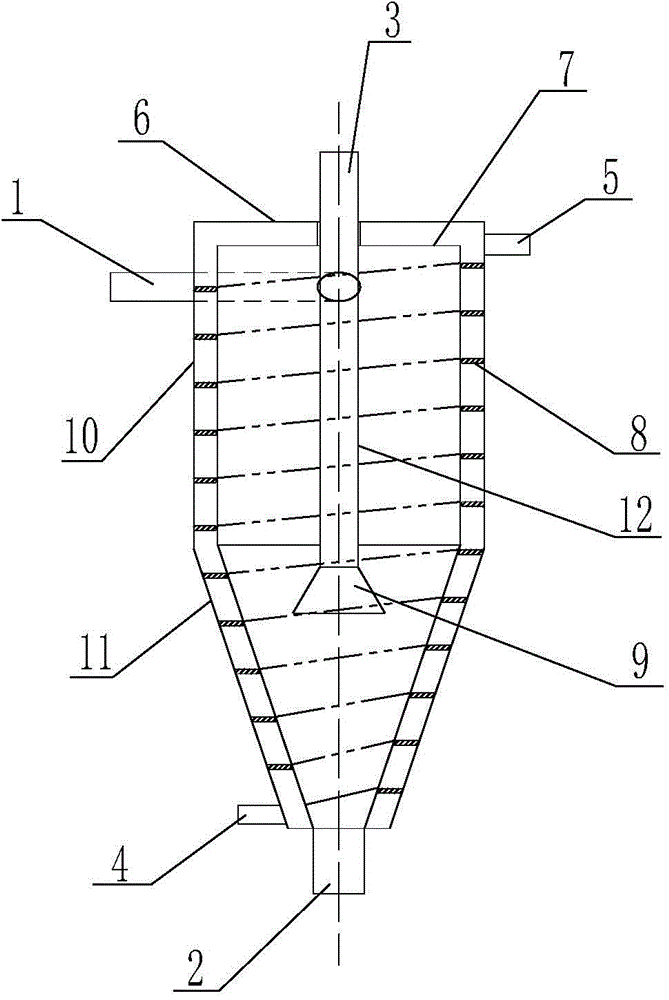

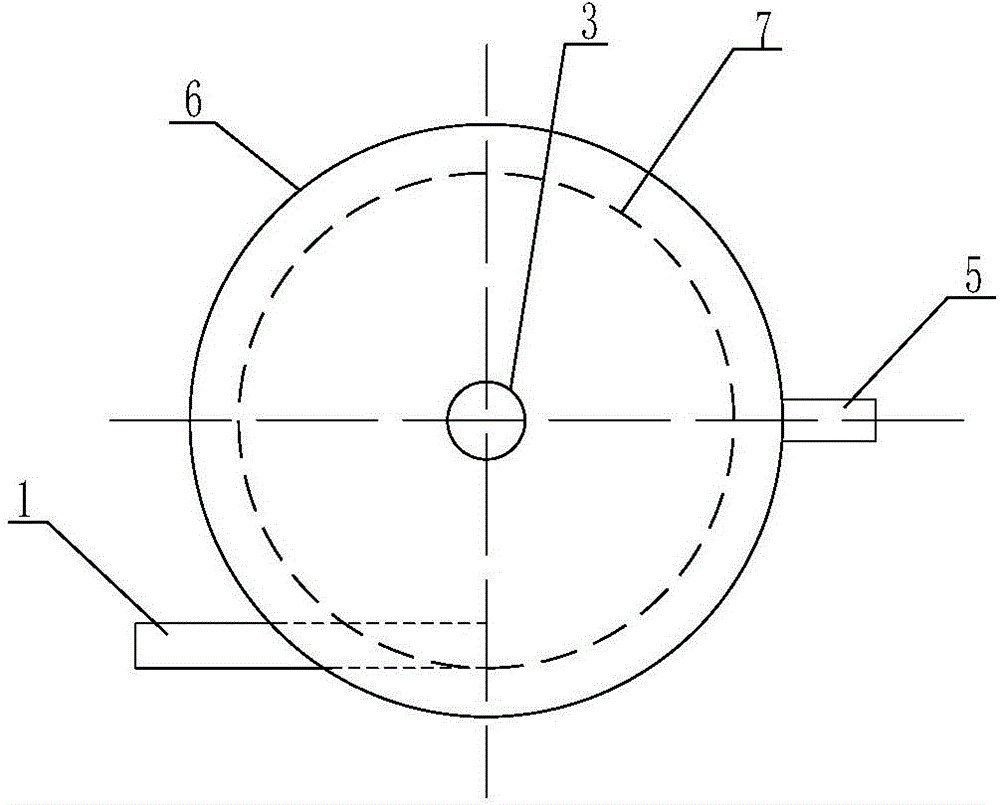

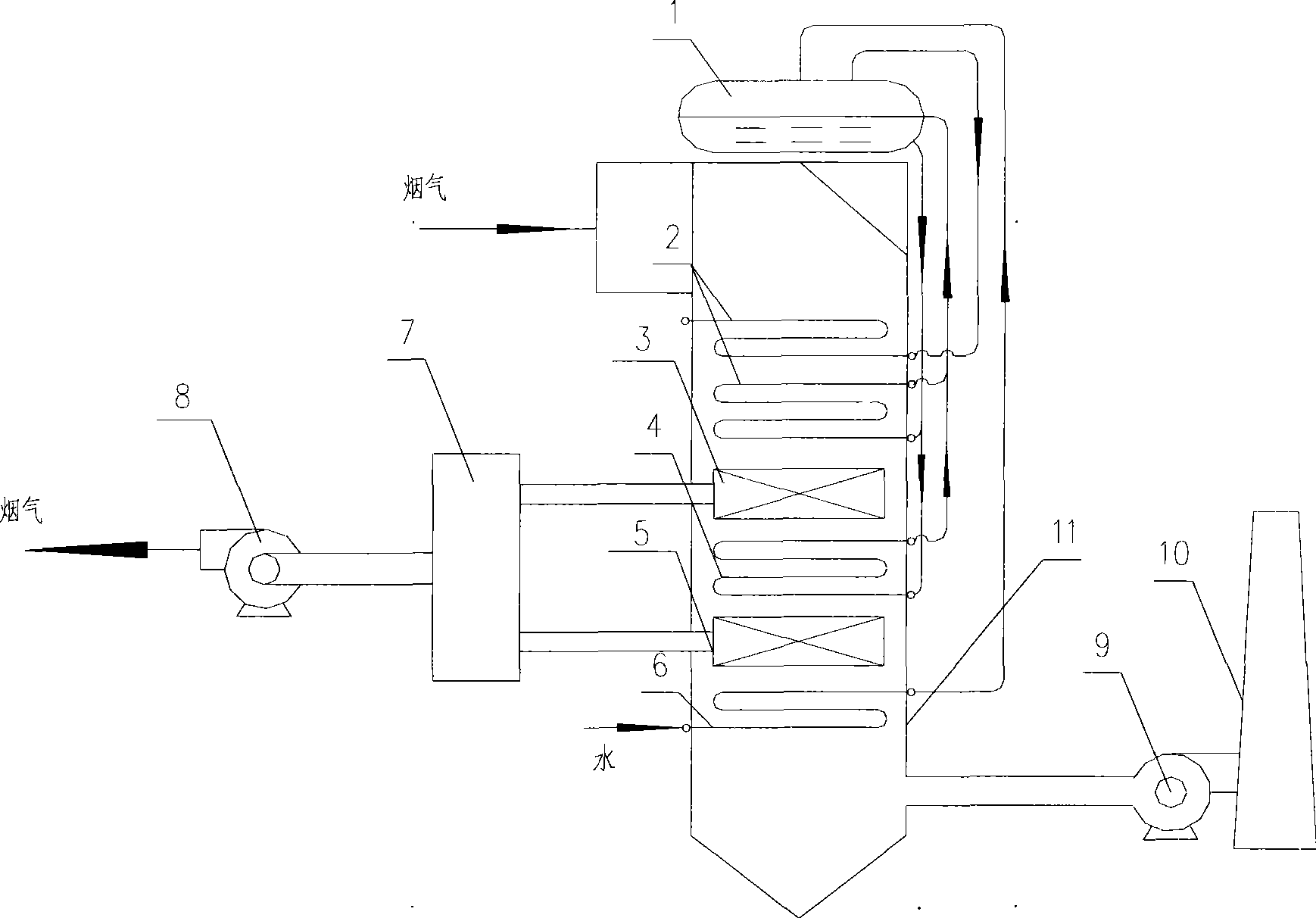

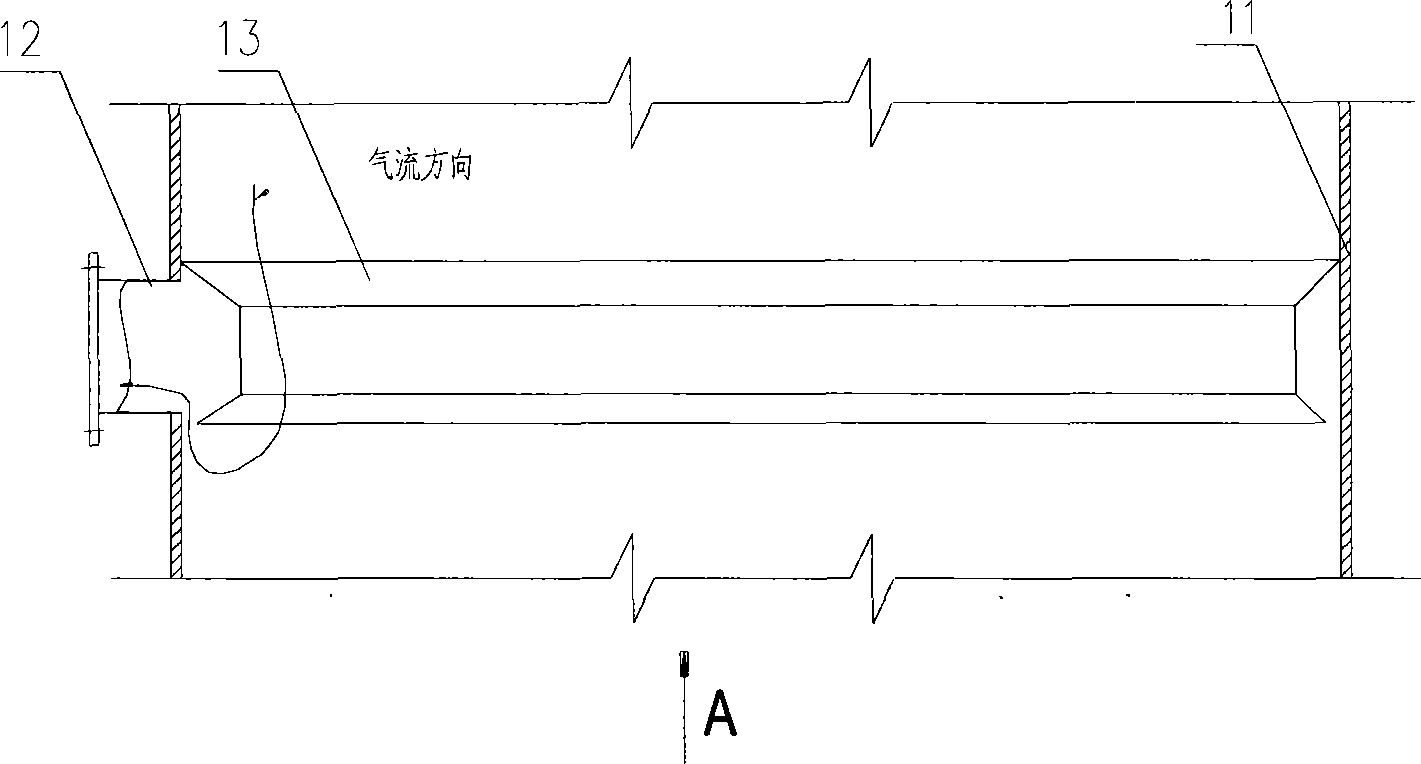

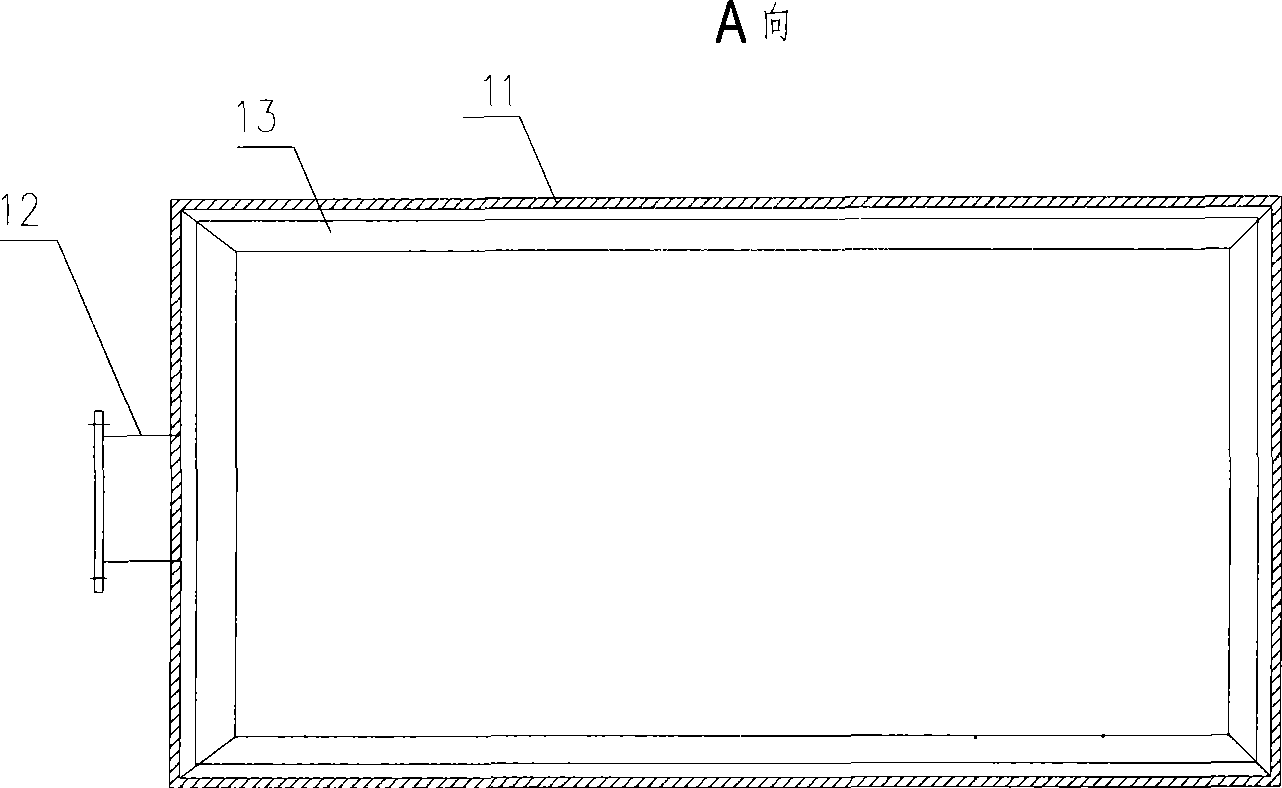

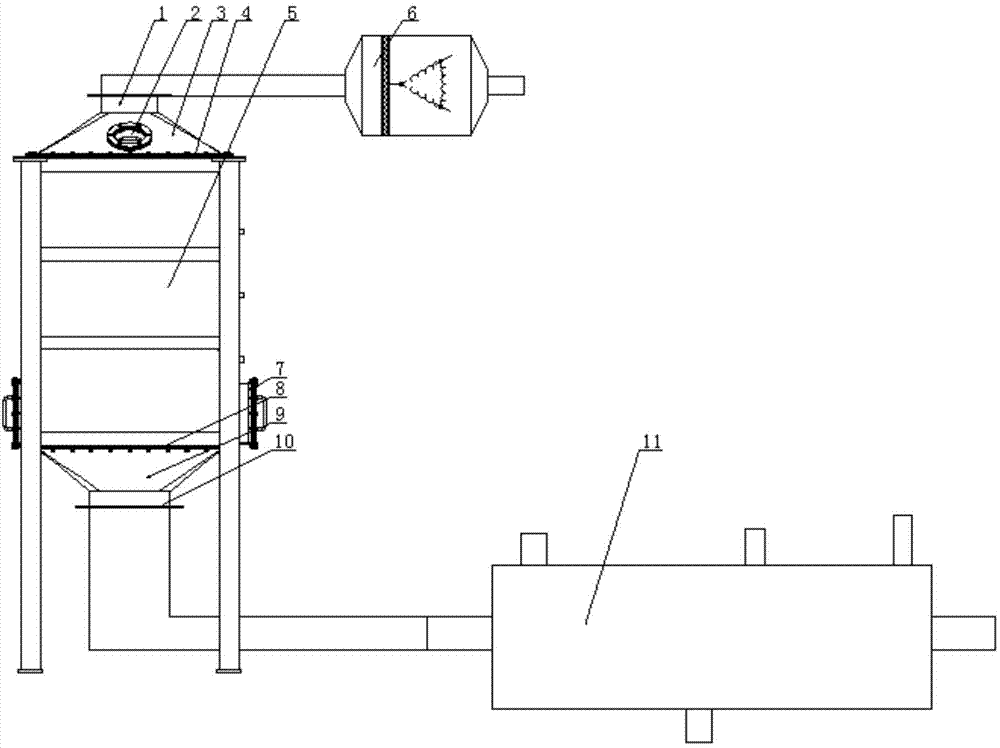

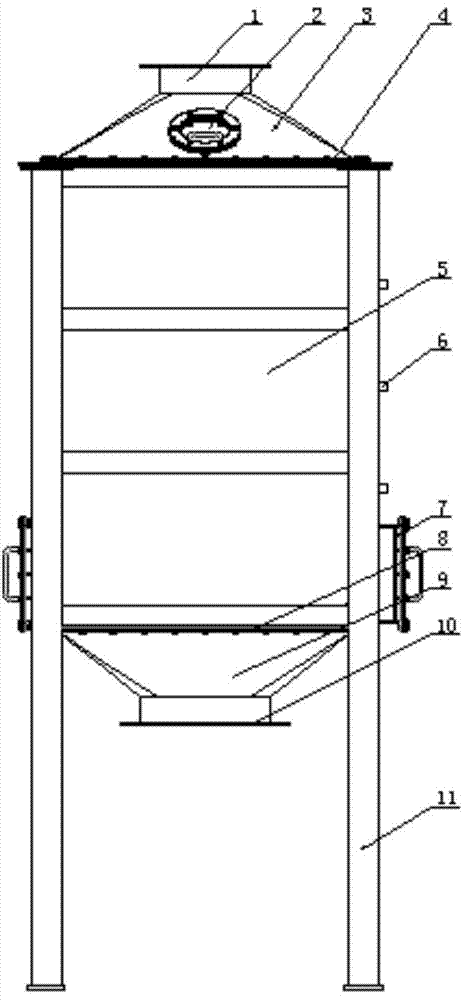

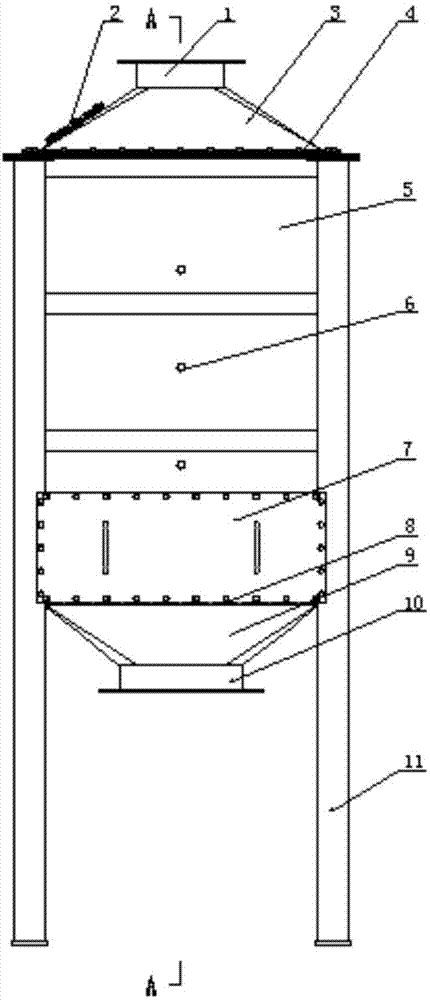

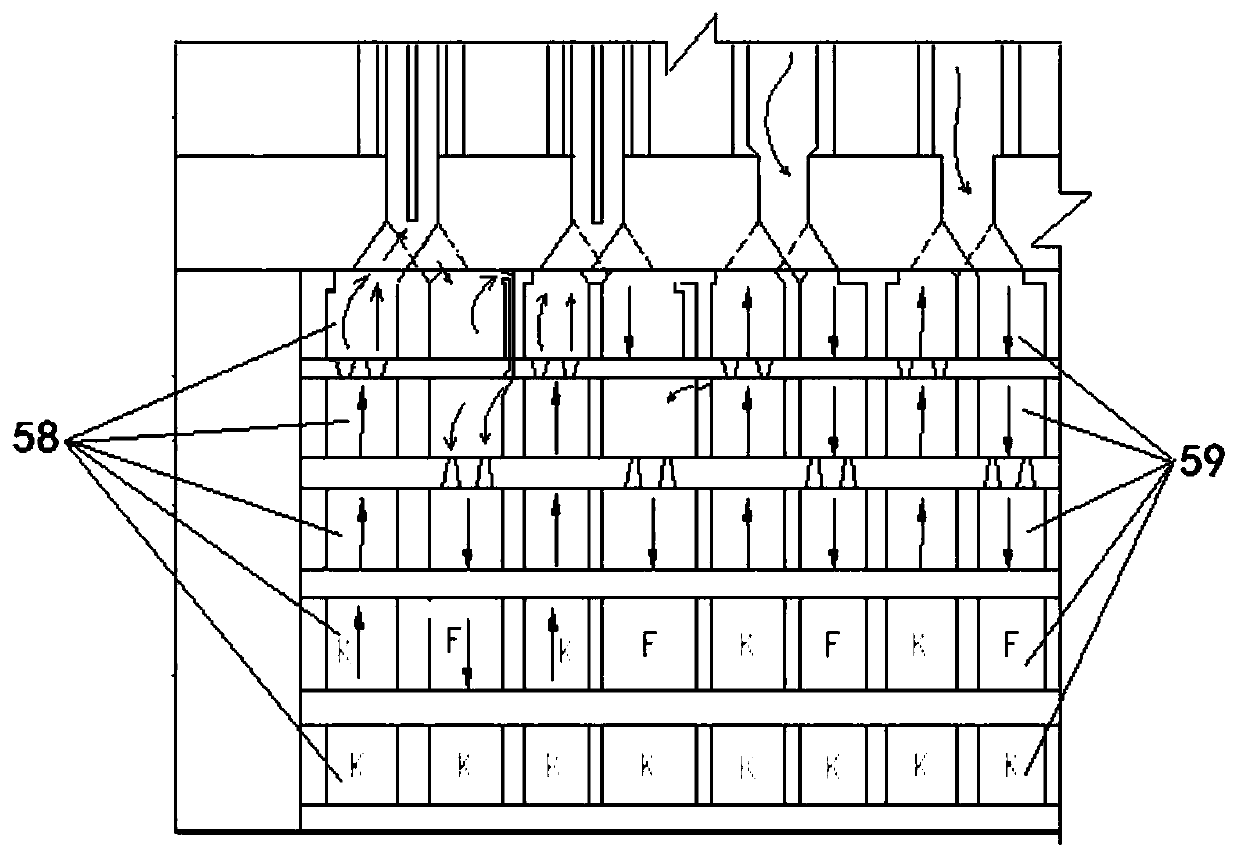

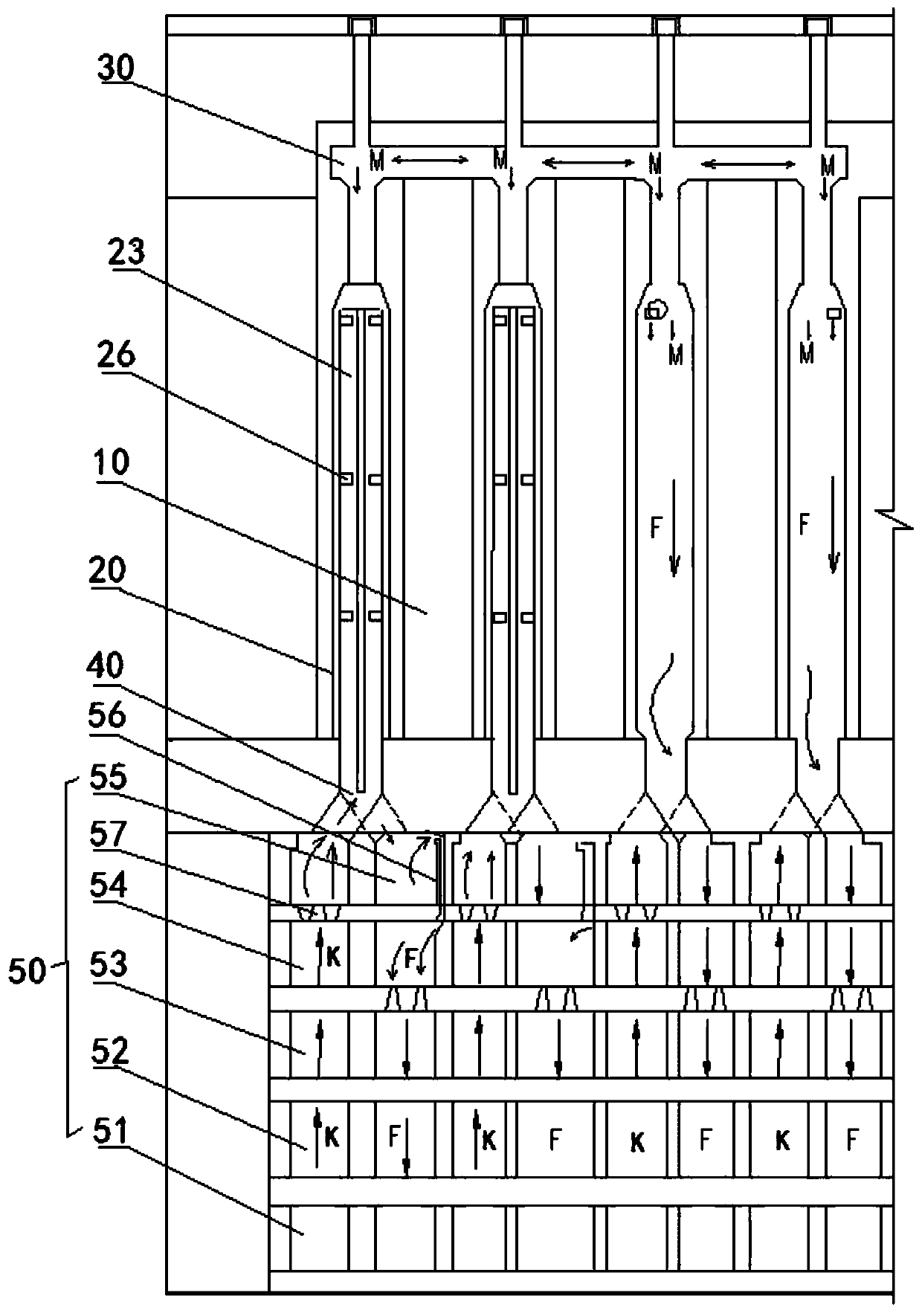

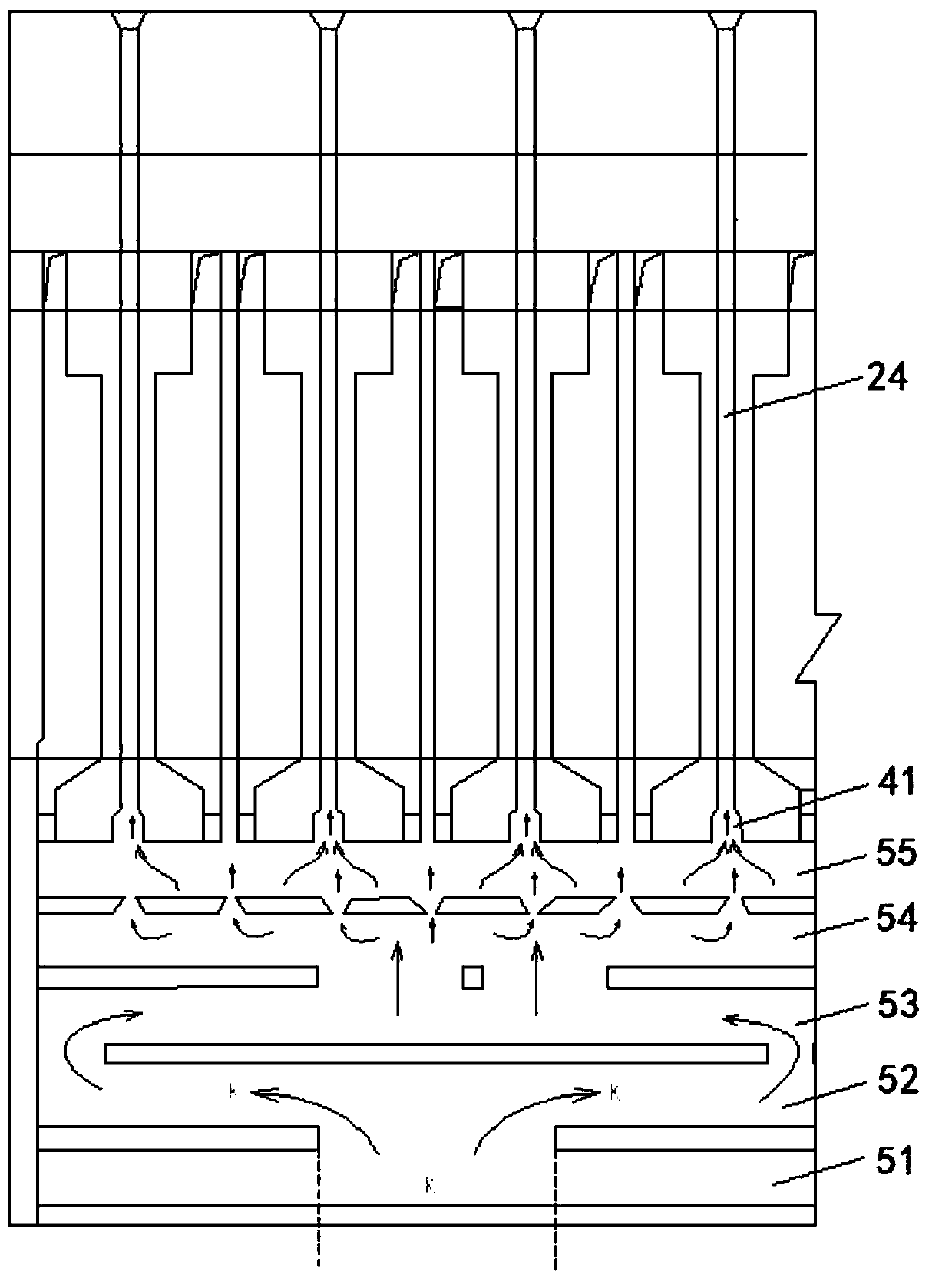

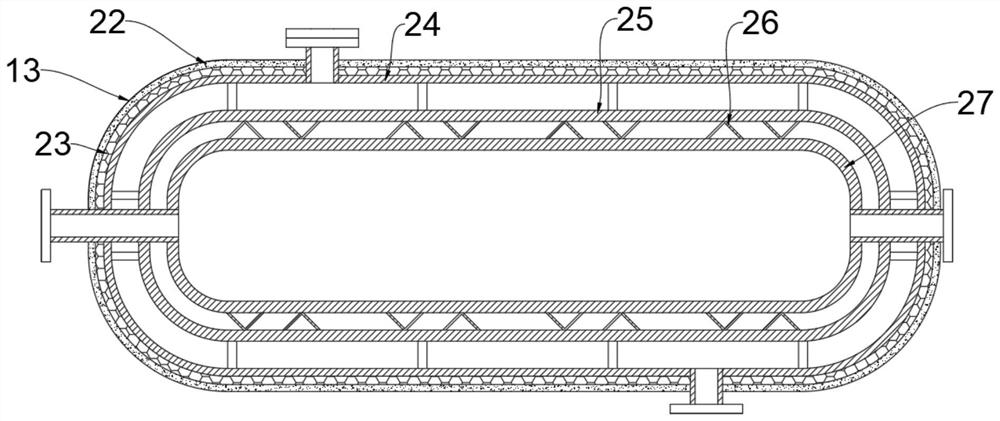

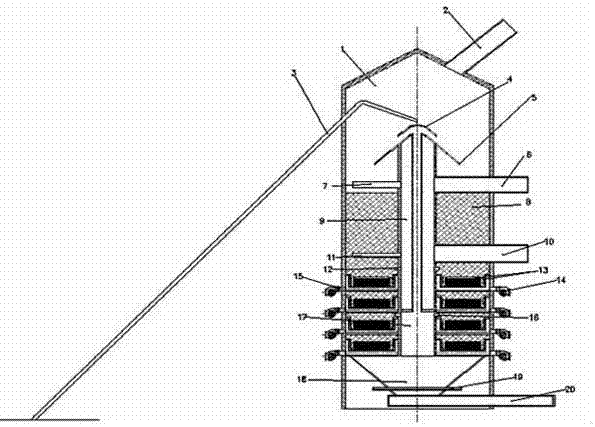

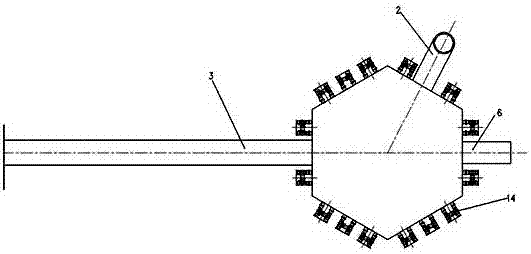

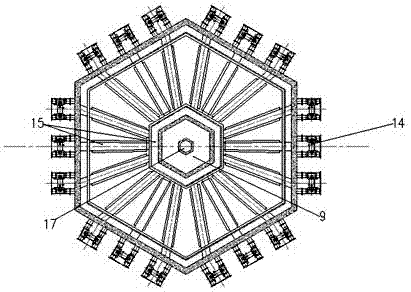

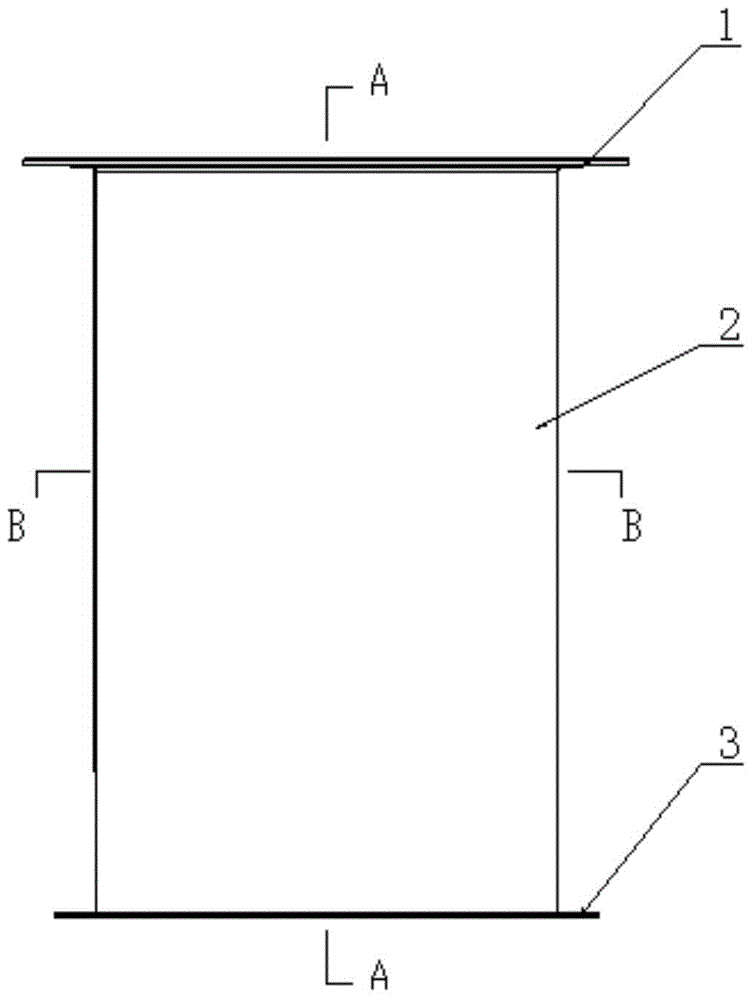

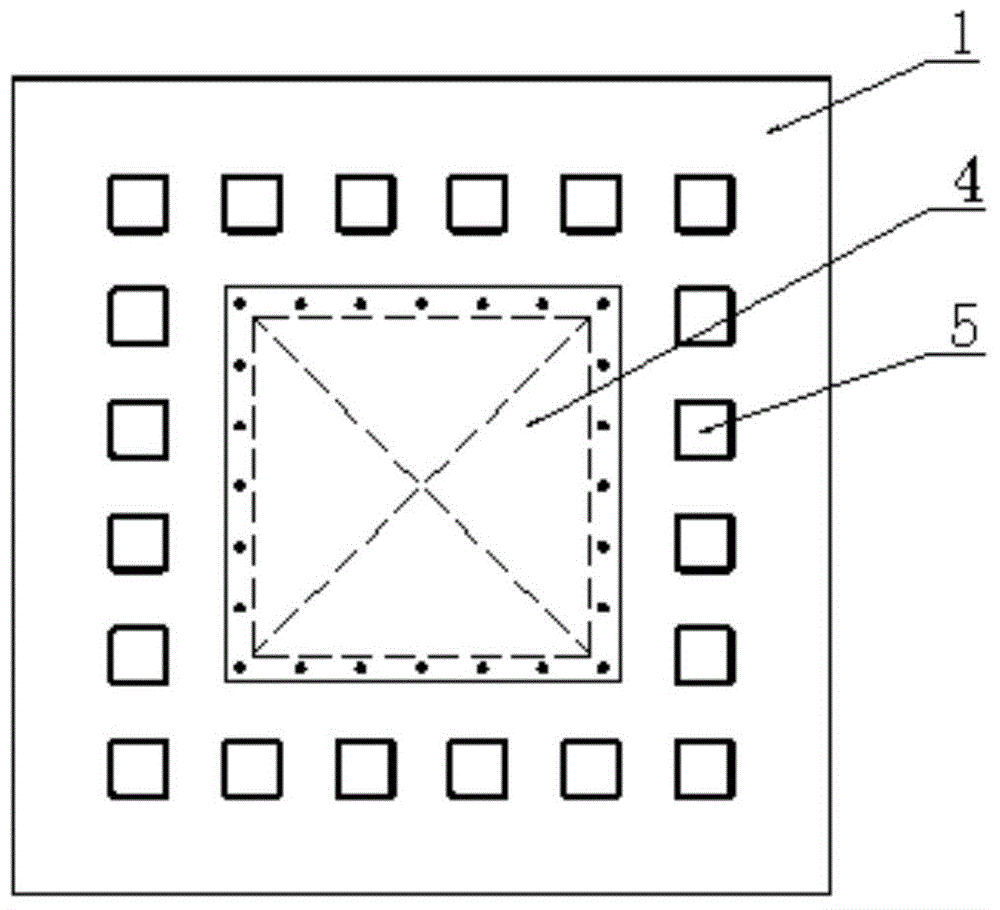

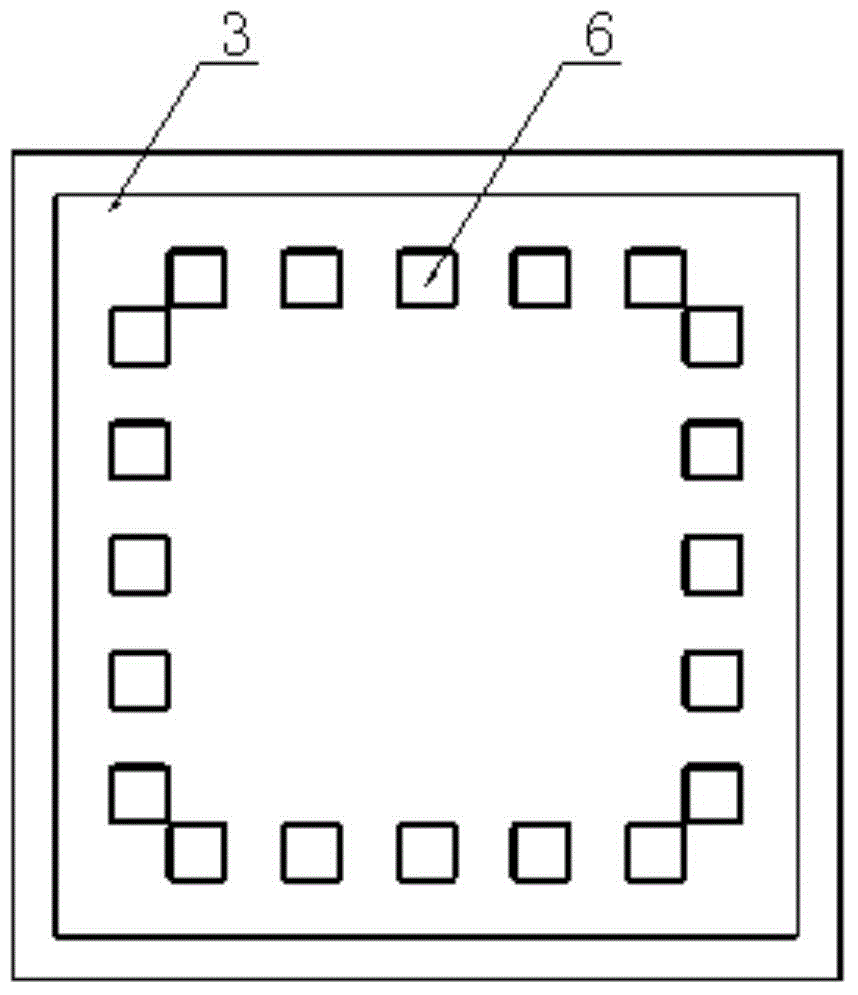

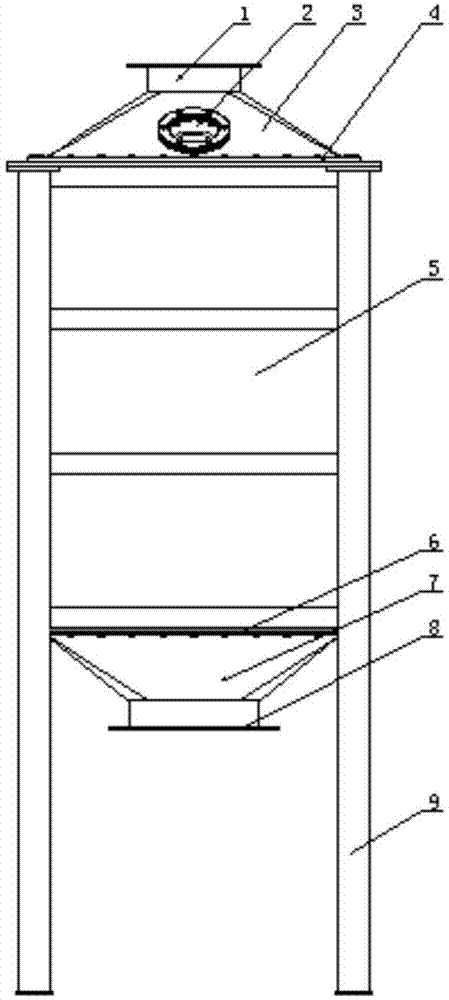

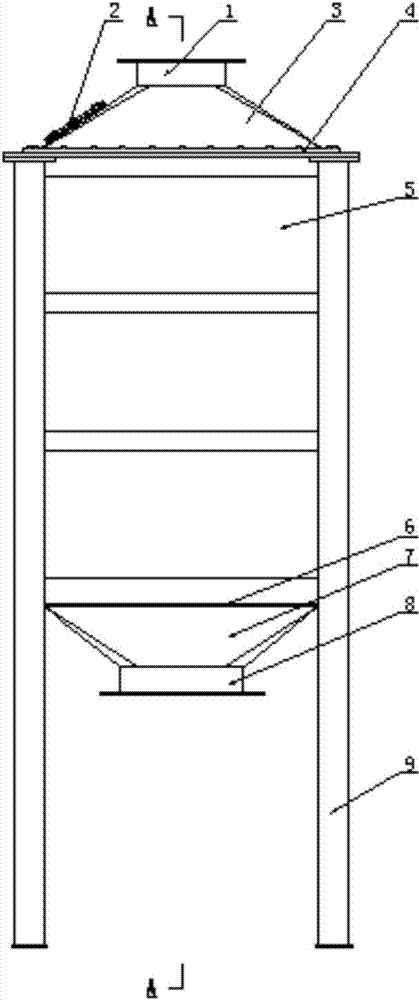

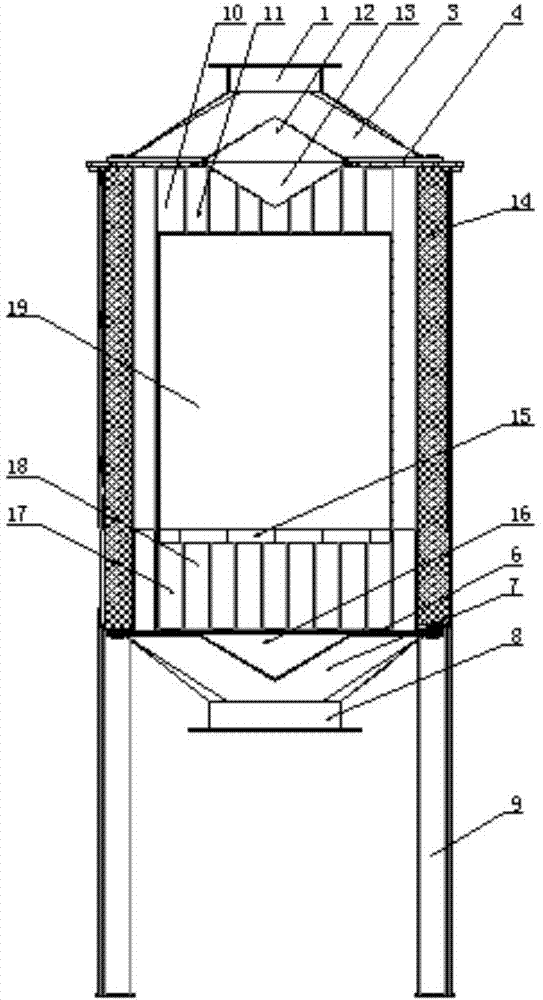

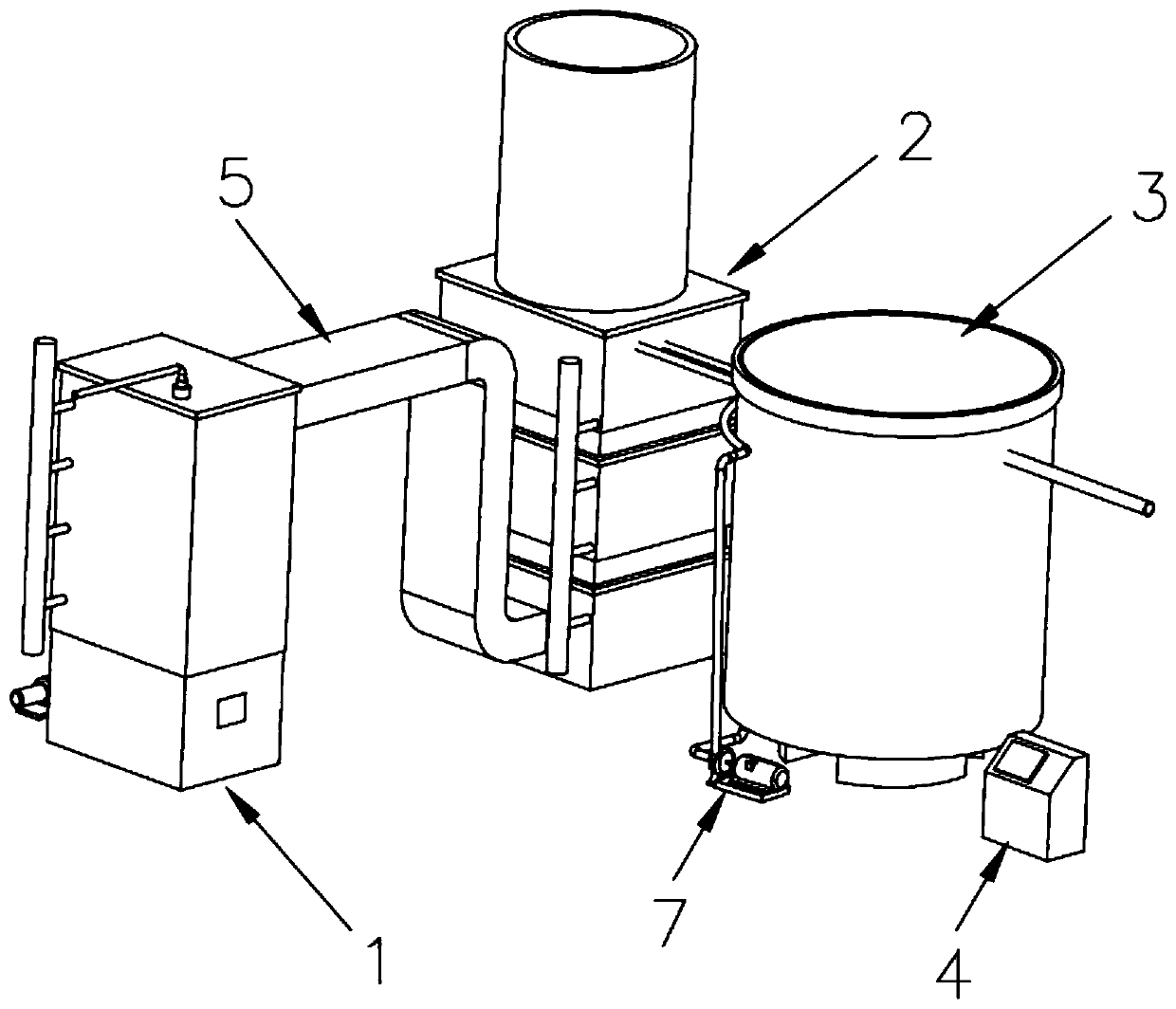

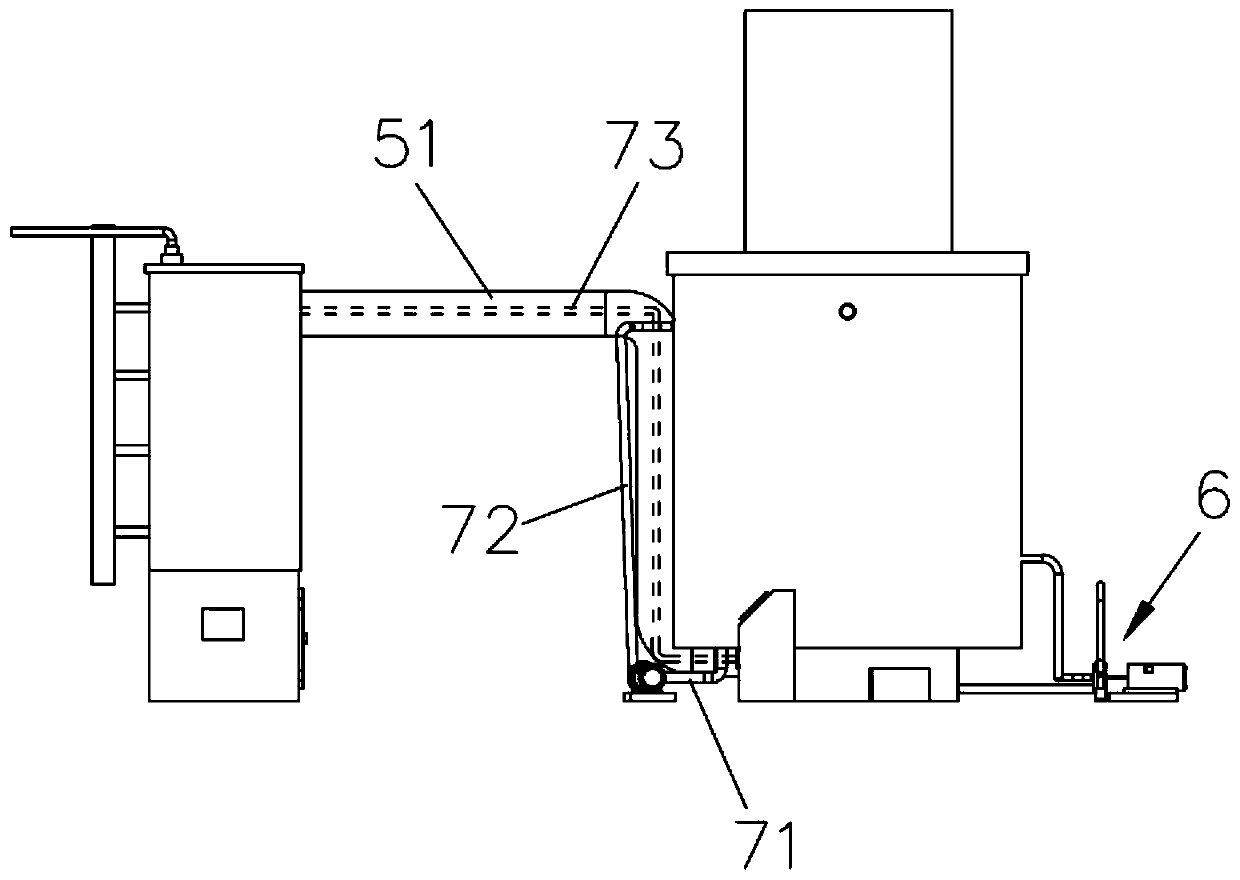

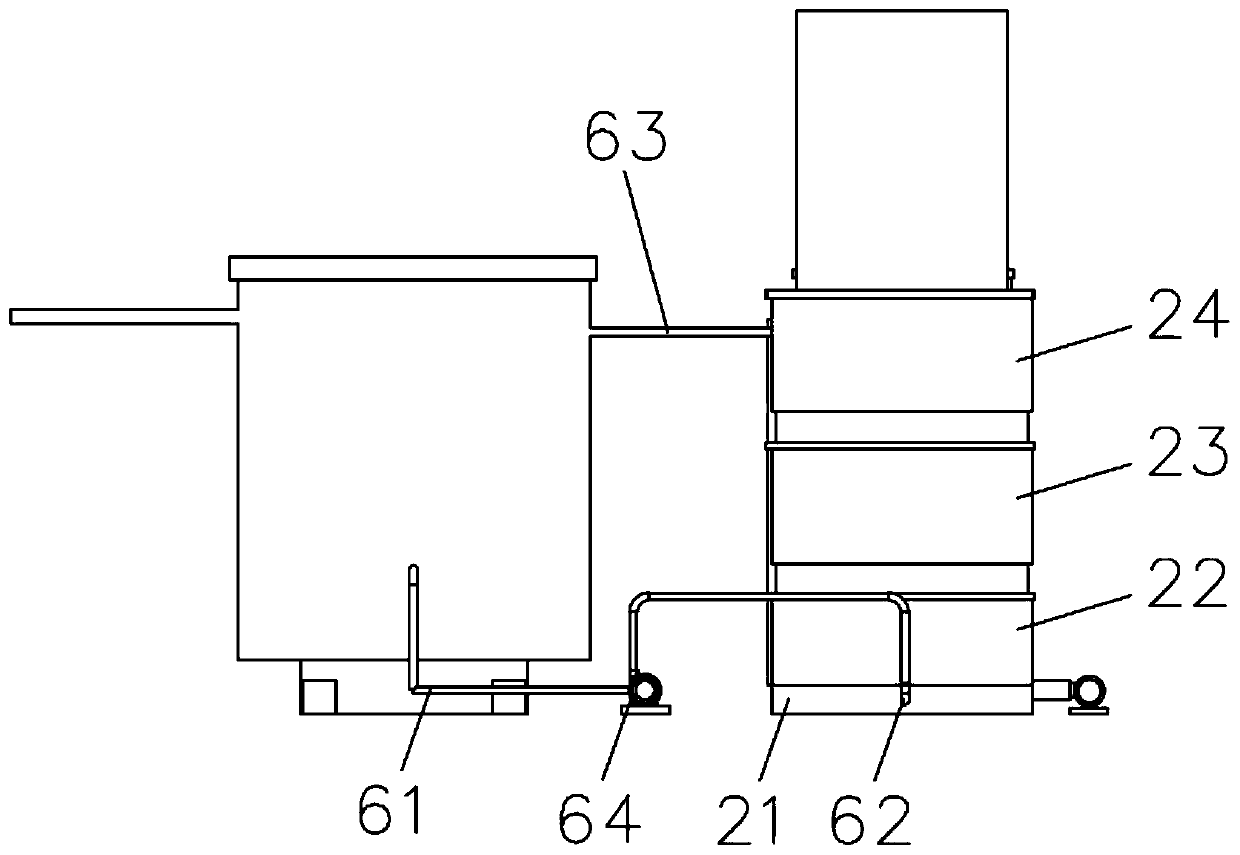

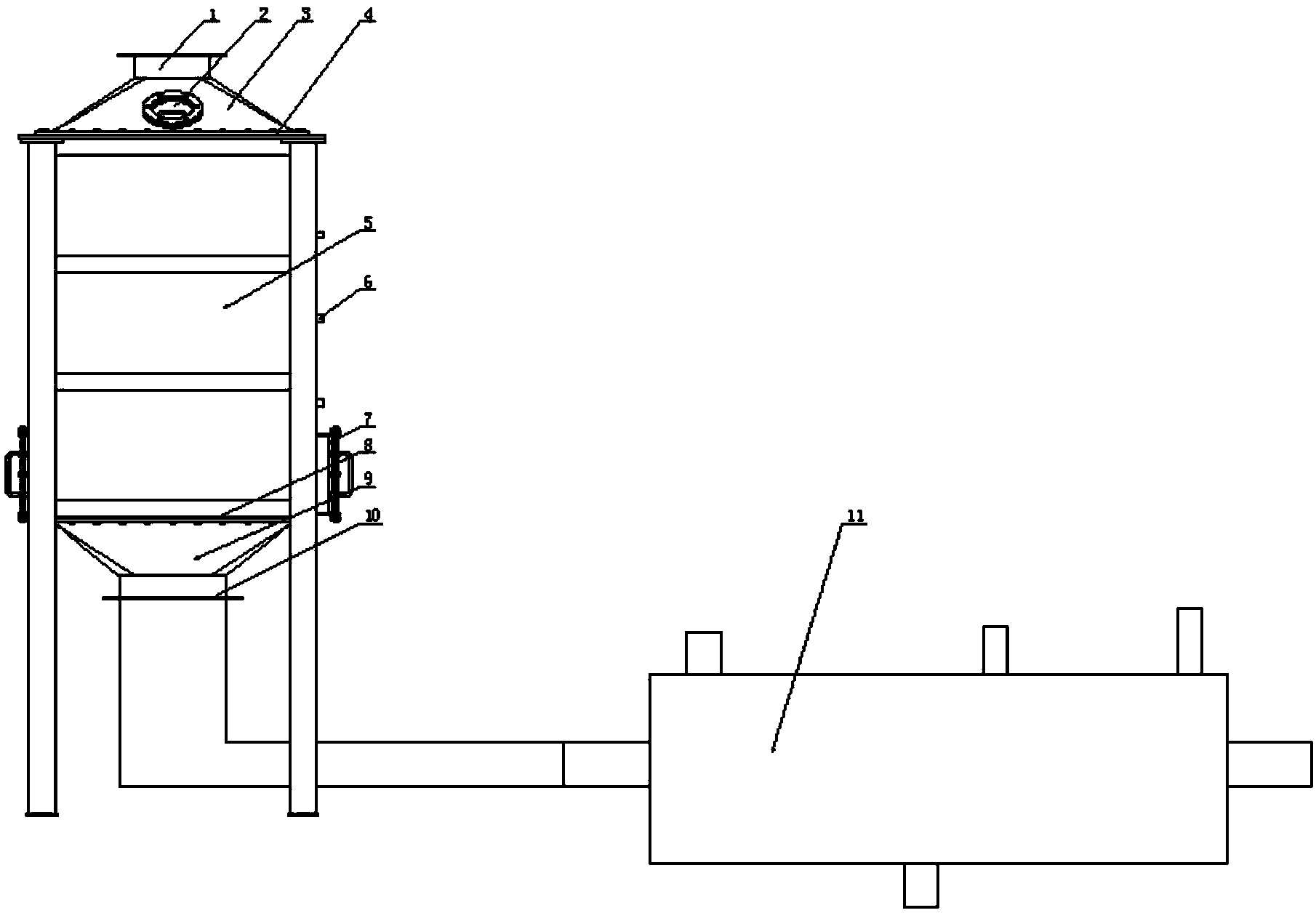

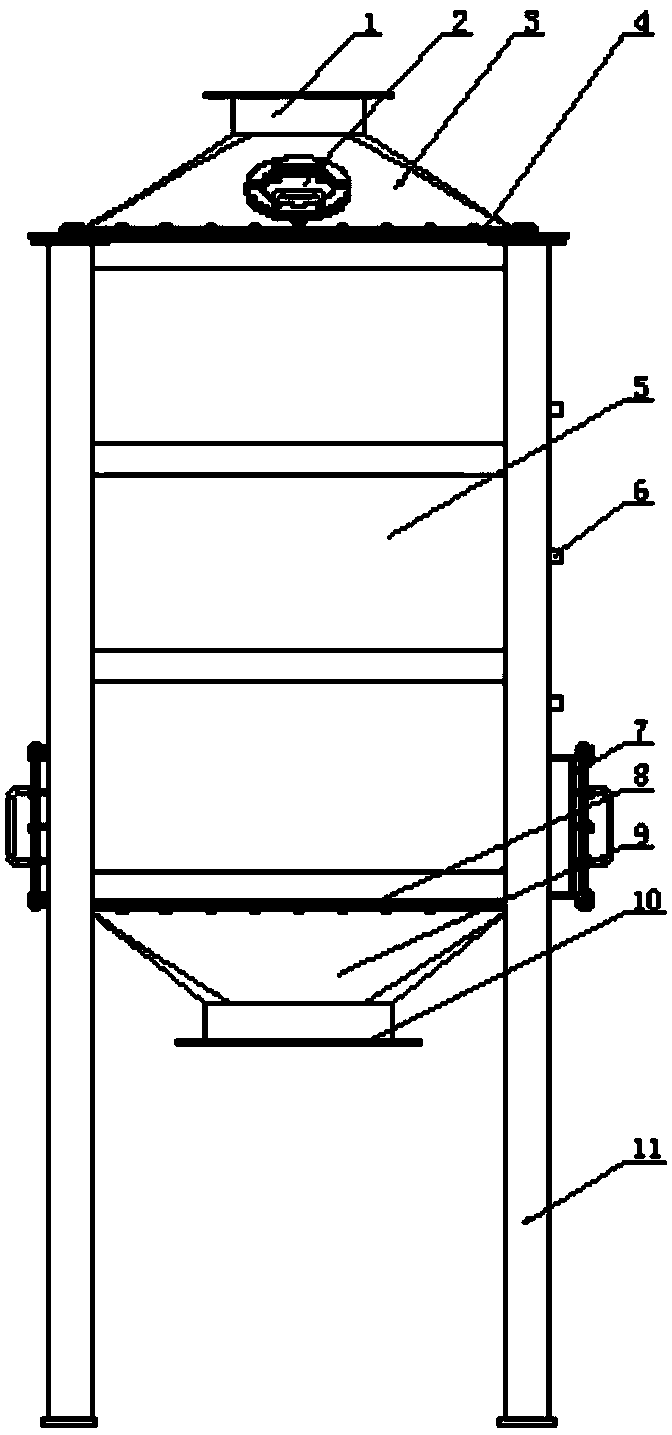

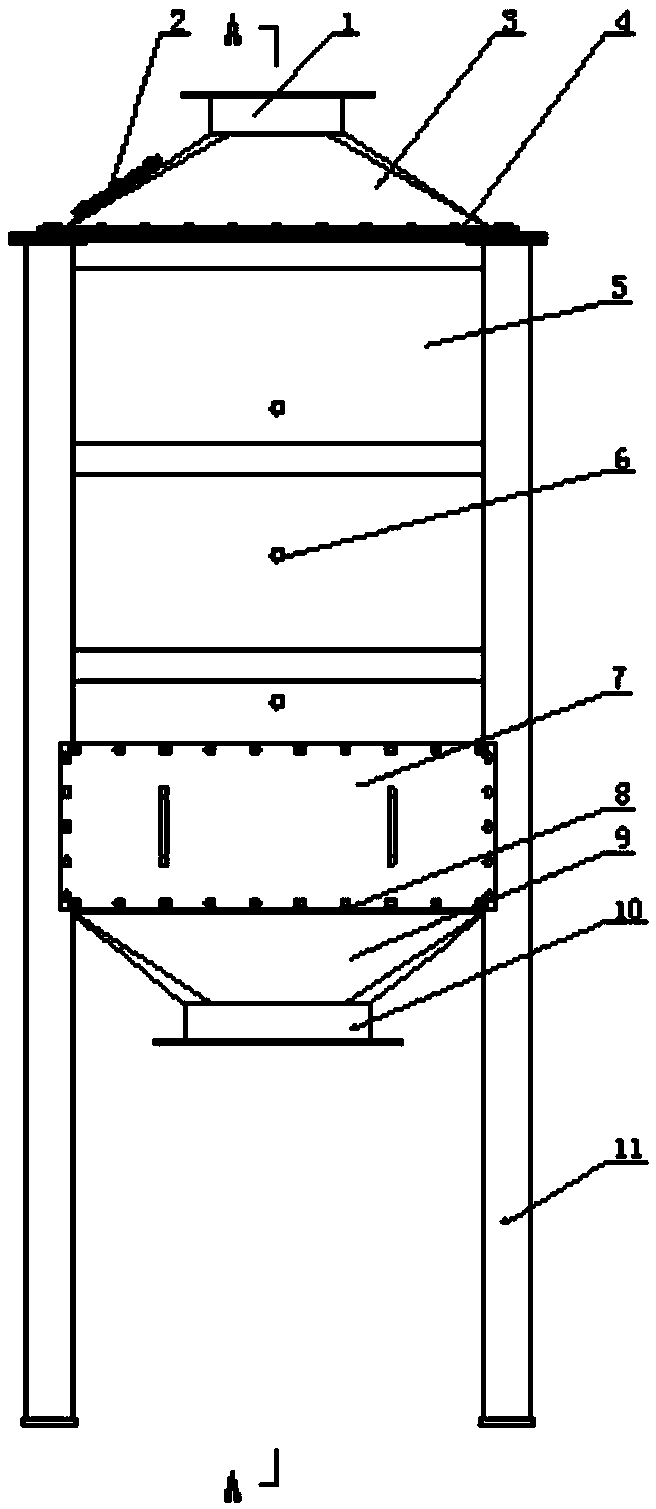

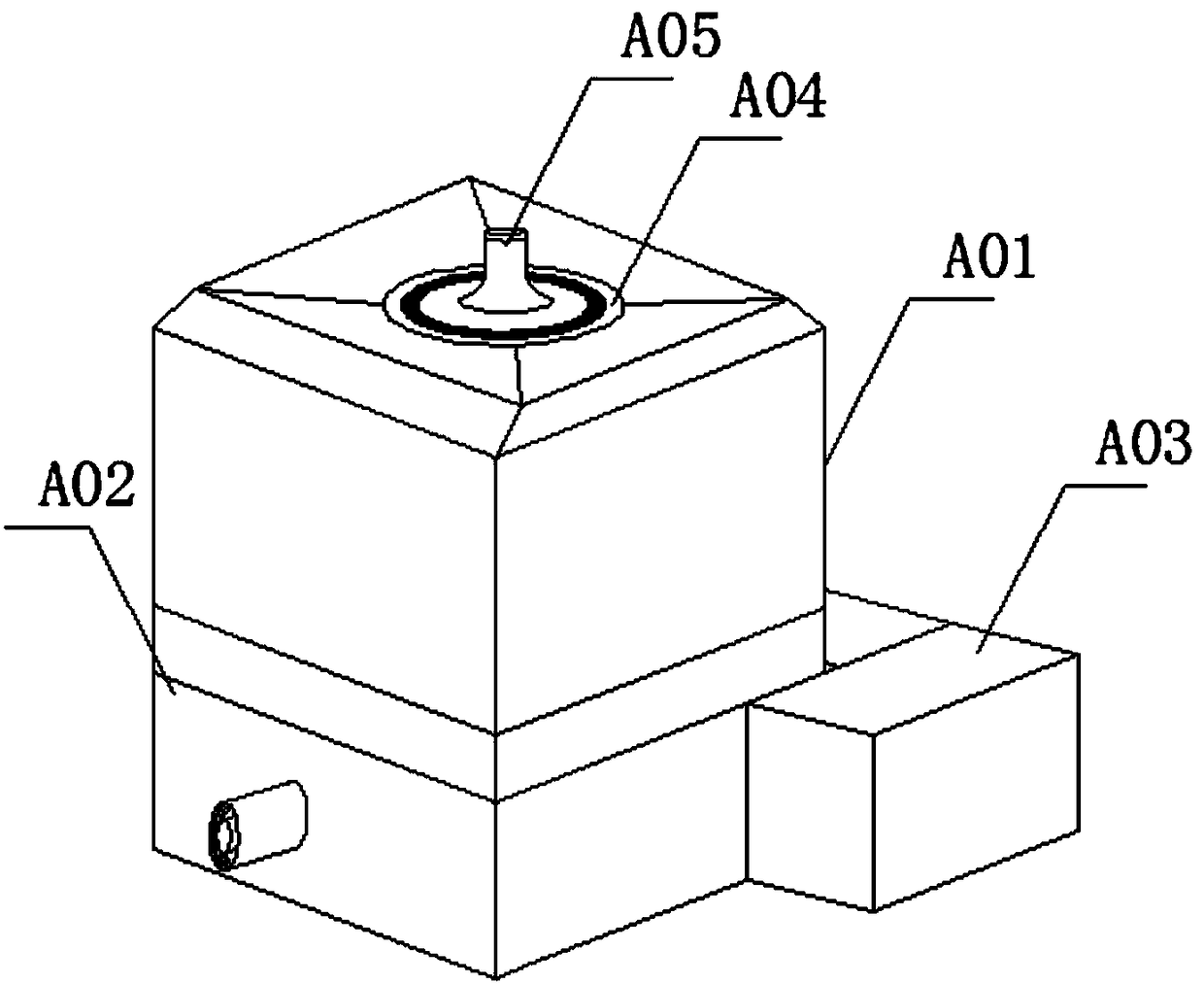

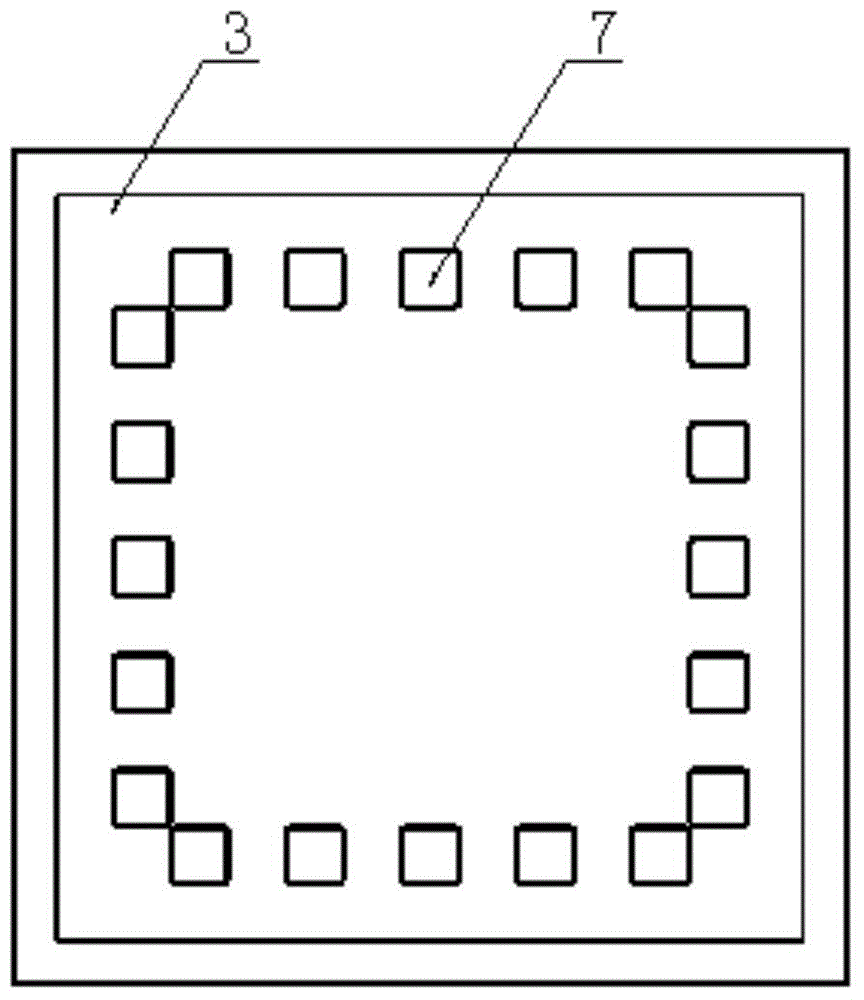

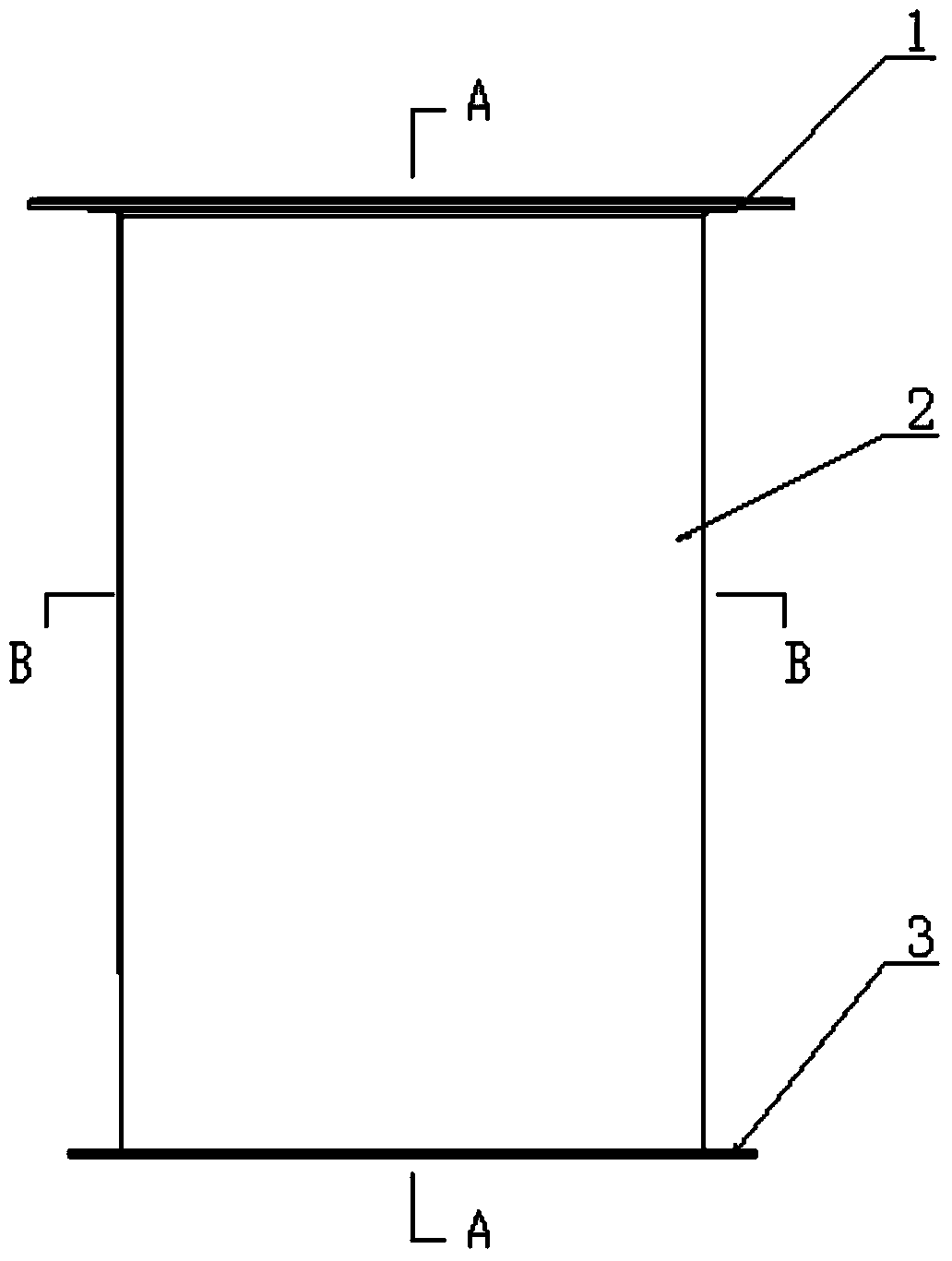

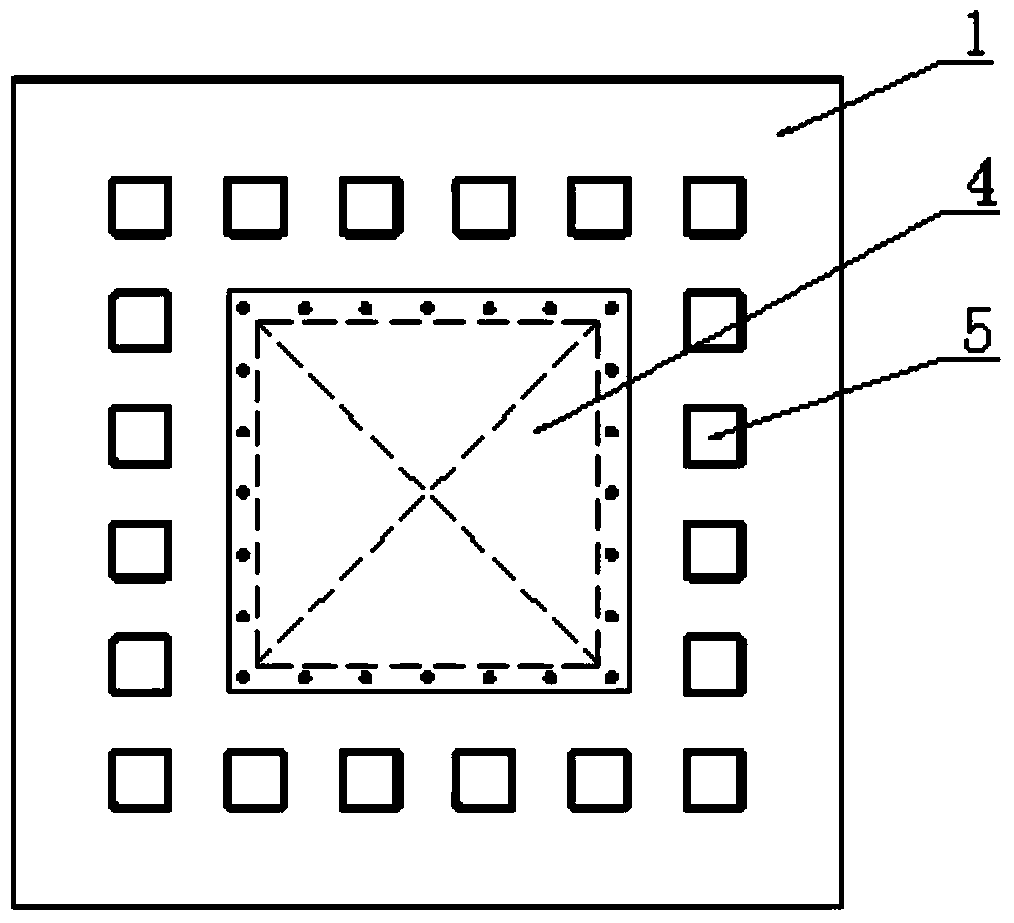

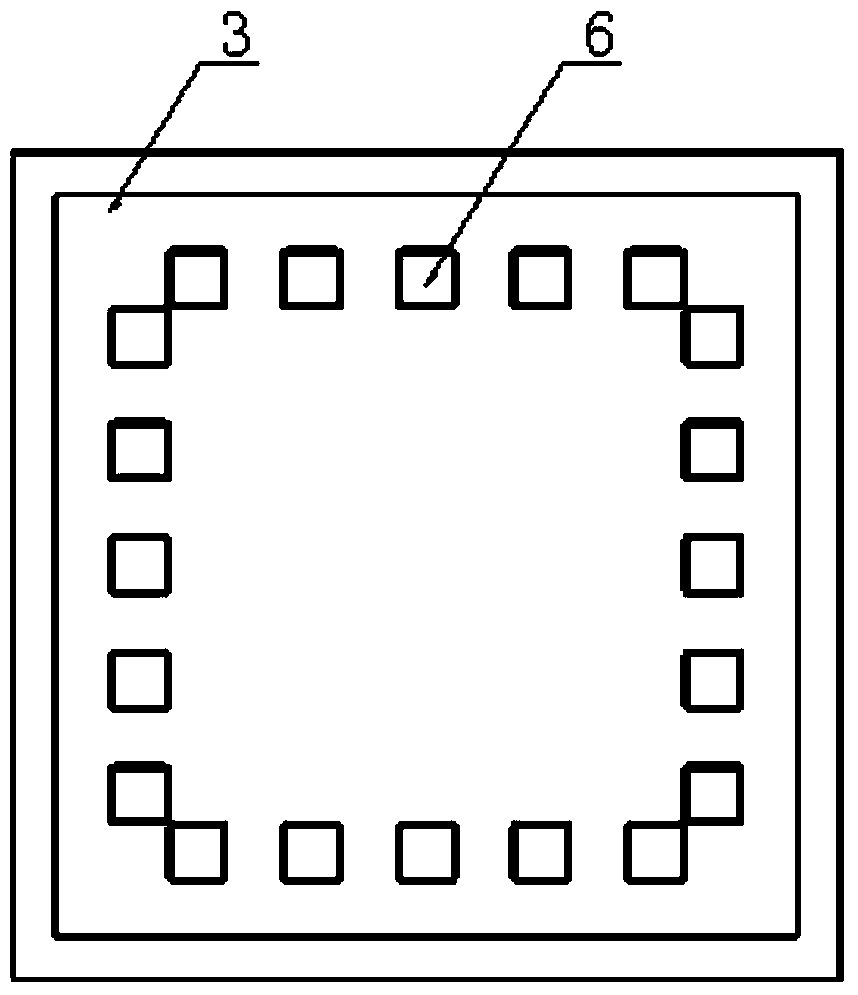

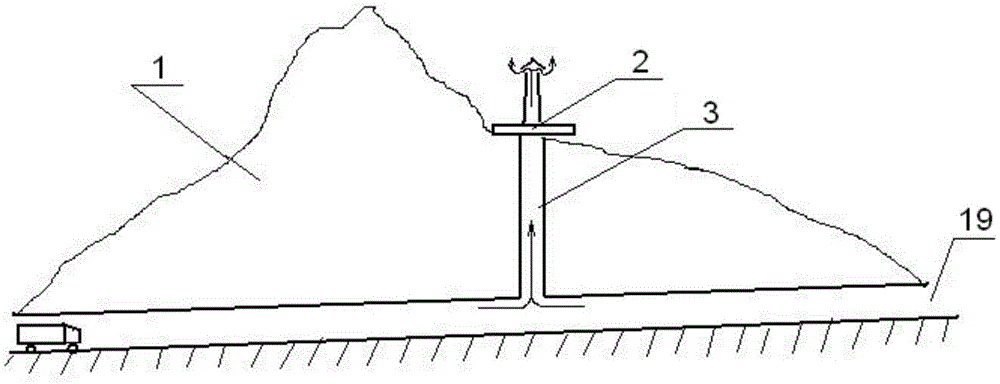

High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method

ActiveCN105036168AReduce the temperatureEfficient use ofAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesFlue gasProcess engineering

The invention relates to the technical field of non-metal novel materials and particularly provides a high-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and a novel method. In the invention, a cyclone preheater group (may comprises two stages, three stages and four stages), and a cooling apparatus are added at the tail of a hollow long kiln to cooling high-temperature-calcined materials. The cyclone preheater group is fully utilized to reduce the temperature of high-temperature flue gas at about 400 DEG C at the tail of a hollow rotary long kiln to 160-220 DEG C. Meanwhile, by means of the unique cooling apparatus, more than 60% of heat energy can be recycled. The apparatus can save fuel by more than 30% when compared with an apparatus in the prior art. The apparatus and the method fully utilize the heat energy in the tail gas of the rotary kiln, can effectively recycle the heat energy in the calcined materials, can greatly reduce the temperature of tail gas and recycle the heat energy when the product is cooled as more as possible, thereby achieving energy saving and emission reduction and laying the foundation of non-metal new material industry.

Owner:SHANDONG LUBEI ENTERPRISE GROUP +1

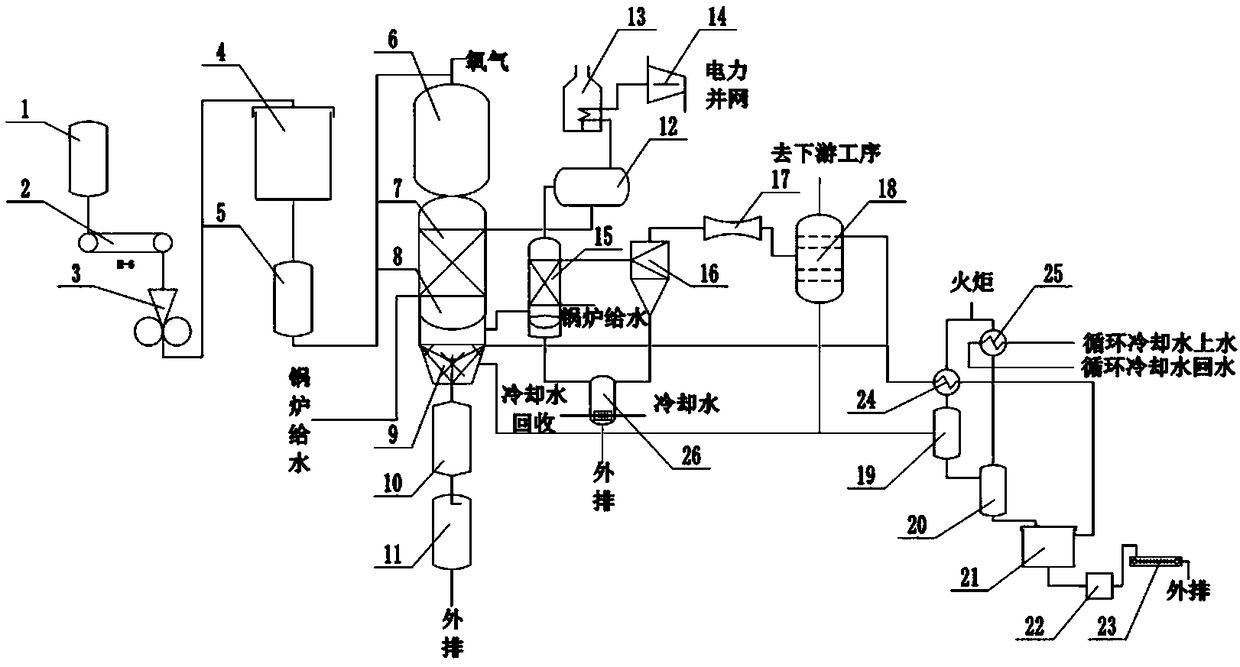

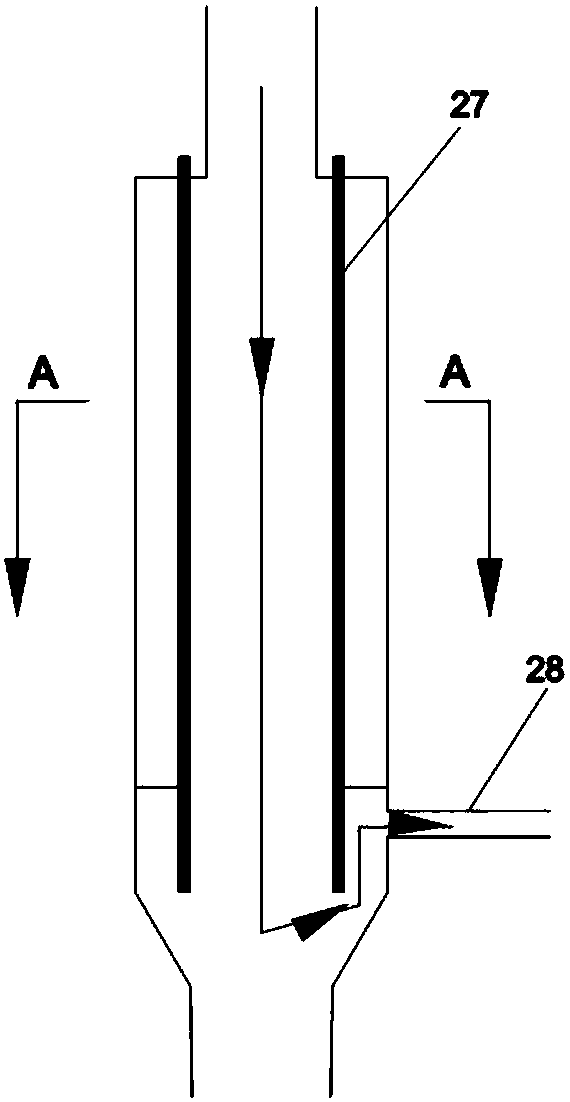

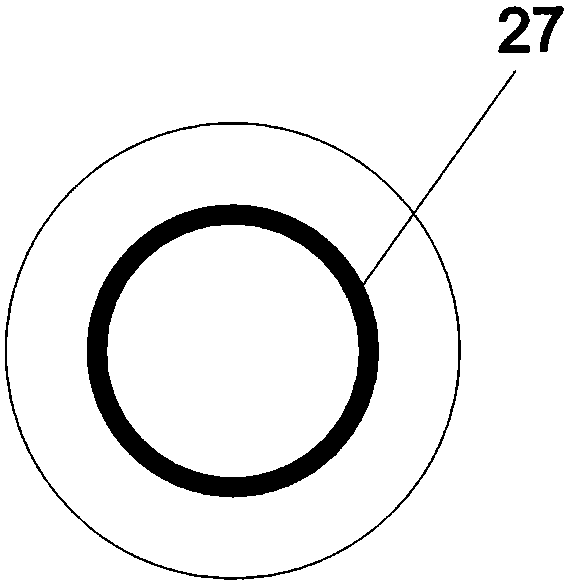

Gasification system for recycling high-temperature sensible heat

InactiveCN108165311AHigh heat recovery rateReduce manufacturing costEnergy inputGasification processes detailsChemical industrySlag

The invention belongs to the field of energy and chemical industry and relates to a gasification system for recycling high-temperature sensible heat. The system includes the following process steps: 1. a pretreatment process; 2. a gasification process; 3. a sensible heat recovery and utilization process; 4. a waste heat convection recovery and ash separation process; 5. a dry ash removal process;6. a cooling washing process; 7. a slag treatment process; and 8. a black water treatment process. High-grade heat energy generated by gasification can be recovered while synthesis gas producing, by-product steam is used for power generation, the heat energy recovery rate of the gasification system is improved, the production cost of coal chemical products is effectively reduced, pollutant emission is reduced, and environmental indicators are superior.

Owner:宁夏神耀科技有限责任公司

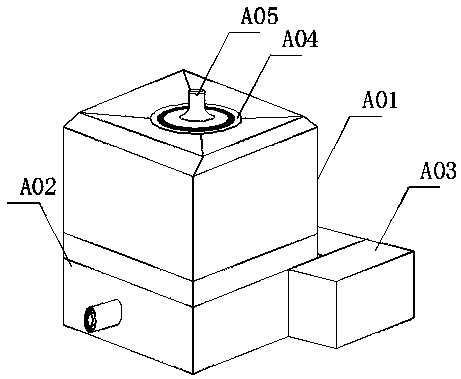

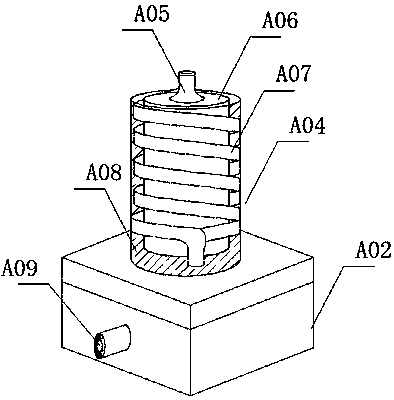

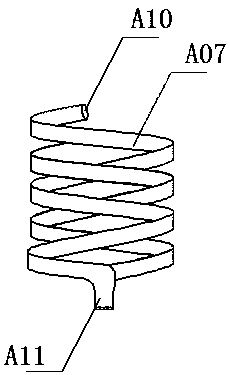

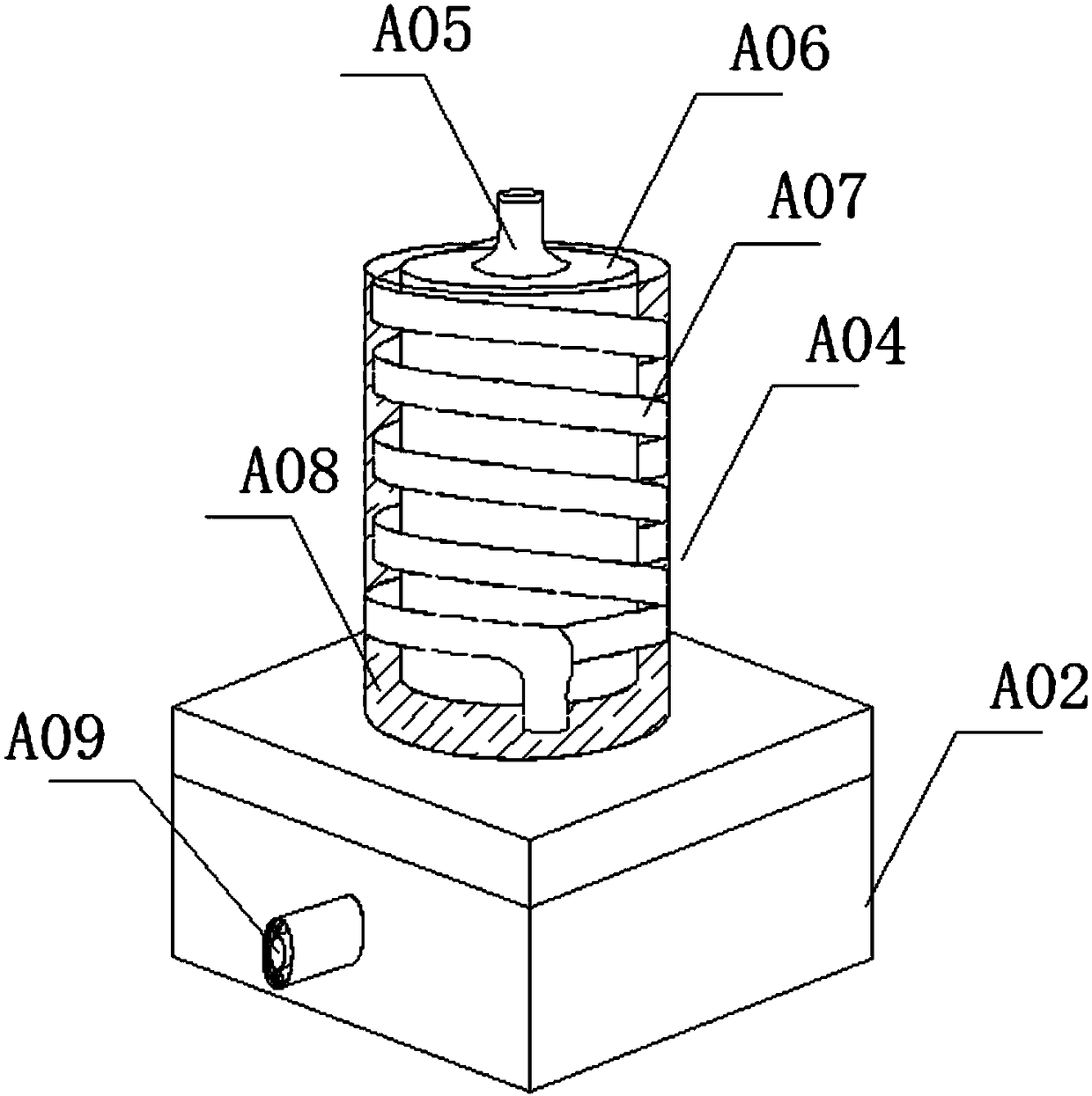

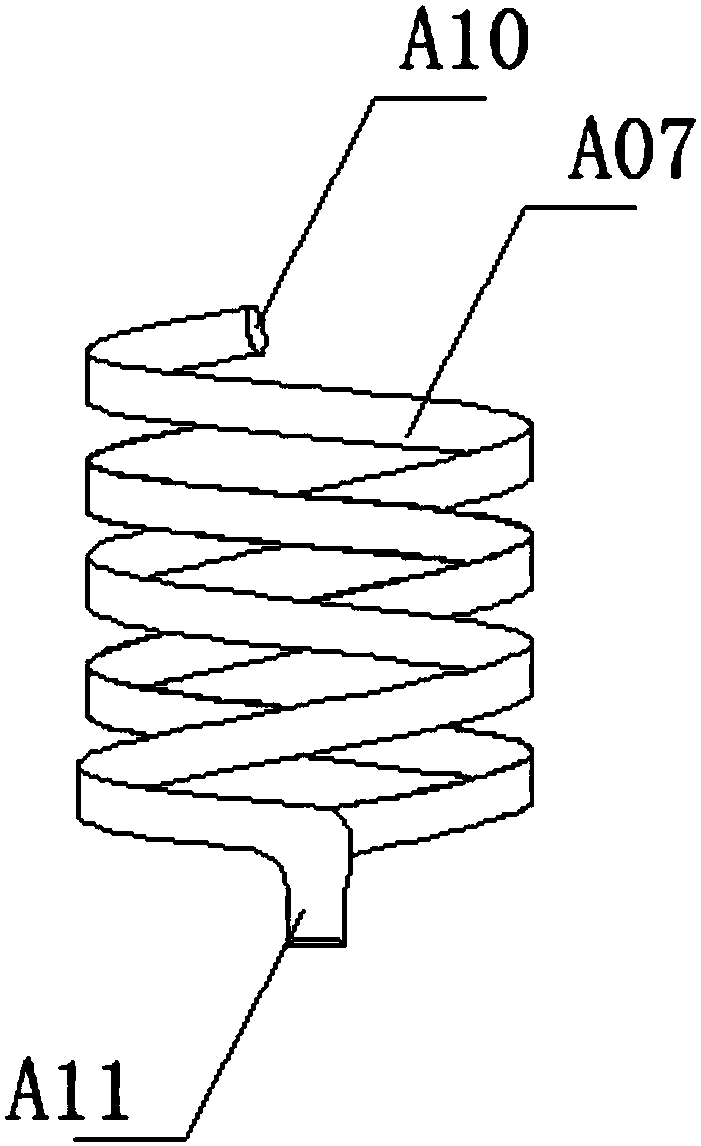

Gas-solid separation and heat recovery integration device

InactiveCN104353288AGood dust removalImprove economyGas treatmentDispersed particle separationSmall footprintEngineering

The invention relates to a gas-solid separation and heat recovery integration device, comprising a barrel, wherein a heat exchange medium channel is formed by a partition plate between the inner wall and the outer wall of the barrel; a gas-solid feeding hole and a heat exchange medium outlet are formed in the upper part of the barrel; a solid material outlet and a heat exchange medium inlet are formed in the lower part of the barrel; a center pipe is arranged in the middle of the barrel along the axis direction; a gas material outlet is formed in the upper end of the center pipe; the barrel is composed of an upper straight section and a lower conical section; the gas-solid feeding hole is formed along the tangential direction of the barrel wall; a conical gas collecting opening is formed in the lower part of the center pipe; the partition plate is arranged in a spiral shape along the axis direction of the barrel; and the partition plate is fixedly connected with the inner wall or the outer wall of the barrel. Compared with the prior art, the gas-solid separation and heat recovery integration device has the beneficial effects that gas-solid separation and heat recovery processes are finished once on the same device; a relatively high heat recovery rate is achieved while a good dust removal effect is obtained; and the device is simple in structure, small in floor area, low in investment and good in economical efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Comprehensive utilization apparatus for flue gas exhaust heat

InactiveCN101482261AHigh heat recovery rateReduce heat transfer temperature differenceFire-tube steam boilersSteam generation using hot heat carriersFlue gasProcess engineering

The invention provides a comprehensive utilization device for smoke gas exhaust heat, comprising a steam dome, a flue-type furnace and a flue-type exhaust heat boiler which is arranged in the flue-type furnace and formed by a heating surface of vapouring water and a heating surface of heating water; at least two smoke gas take-away devices are additionally arranged in the furnace, one is arranged between the heating surface of vapouring water and the heating surface of heating water to form a low-temperature smoke gas take-away device and the other is inserted in the middle of the heating surface of vapouring water to form a high-temperature smoke gas take-away device; the delivery outlets of the two smoke gas take-away devices are combined to a smoke gas delivery outlet by a smoke gas adjusting device and the smoke gas delivery outlet is connected with a draught fan and delivers hot smoke gas outwards. The comprehensive utilization device for smoke gas exhaust heat can not only heat water to generate steam by the heating surface of vapouring water and the heating surface of heating water, but also deliver hot smoke gas with controllable flow and temperature by the low-temperature smoke gas take-away device and the high-temperature smoke gas take-away device for manufacturing technique, thereby remarkably improving the utilization ratio of the smoke gas exhaust heat.

Owner:BEIJING CENTURY BENEFITS

Energy-saving type catalytic bed system with controllable temperature

InactiveCN103486601AUniform air intakeUniform adsorptionIncinerator apparatusDesorptionHeat exchanger

The invention relates to an energy-saving type catalytic bed system with the controllable temperature. The energy-saving type catalytic system comprises a gas inlet heater, a catalytic bed and a heat exchanger. A gas inlet channel and a gas outlet channel are alternately formed between a furnace body inner surrounding plate and a furnace body outer surrounding plate. The inlet of the gas inlet channel is formed in an upper end plate, and the outlet of the gas inlet channel is formed between a lower end plate and the furnace body inner surrounding plate. The inlet of the gas outlet channel is formed between the upper end plate and the furnace body inner surrounding plate, and the outlet of the gas outlet channel is formed in the lower end plate. The heater is arranged in a furnace body corresponding to the outlet of the gas inlet channel. A gas outlet flow guide cover is arranged on the lower face of the middle of the lower end plate corresponding to the outlet of a gas outlet cover. A catalytic tail gas inlet, a catalytic tail gas outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet are formed in the heat exchanger. By the adoption of the energy-saving type catalytic bed system, heat efficiency of the catalytic bed is effectively improved, the heat loss is reduced, the heat recovery utilization rate, combustion efficiency and the purification rate are improved, heat exchange is increased, heat energy is more reasonably utilized, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

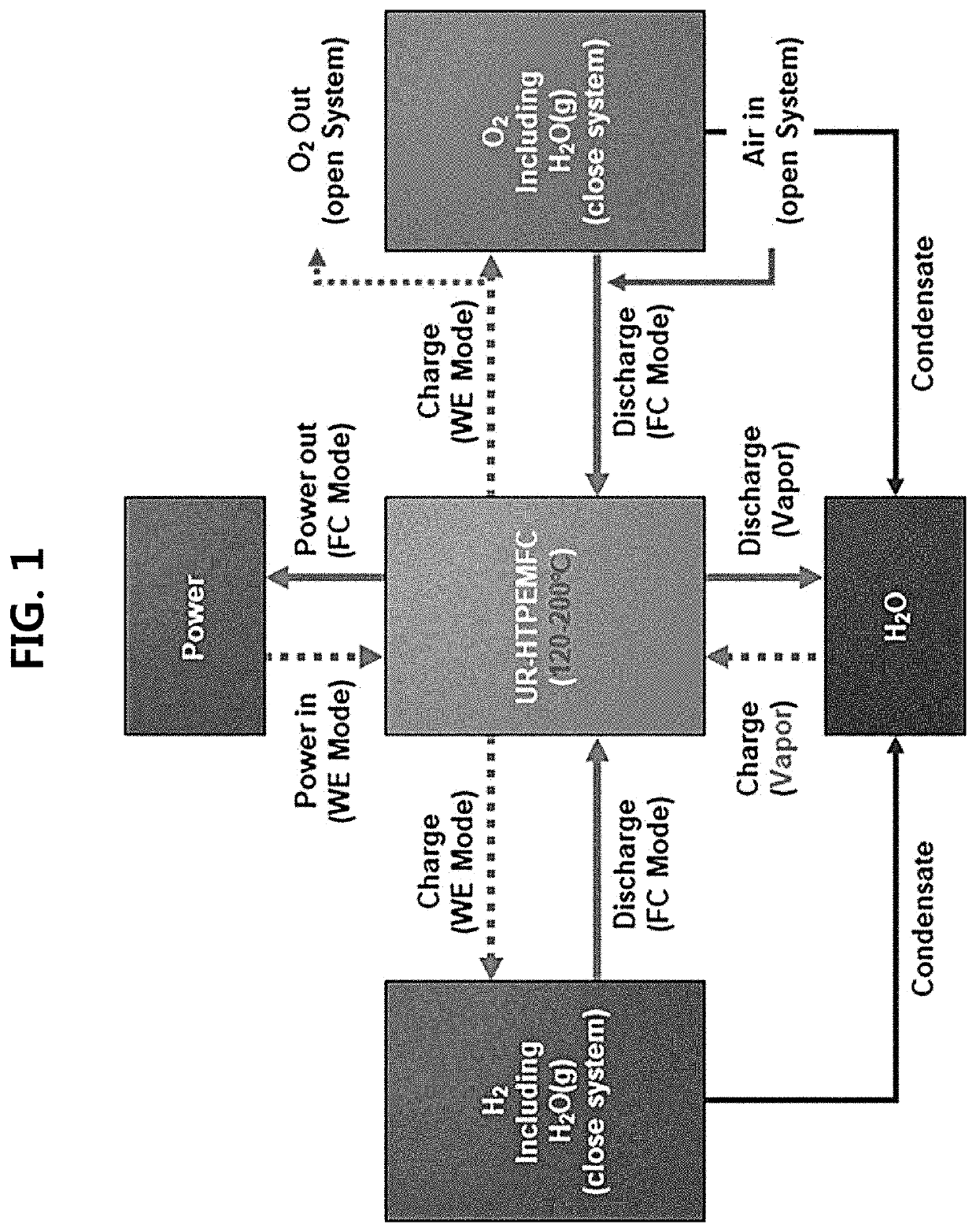

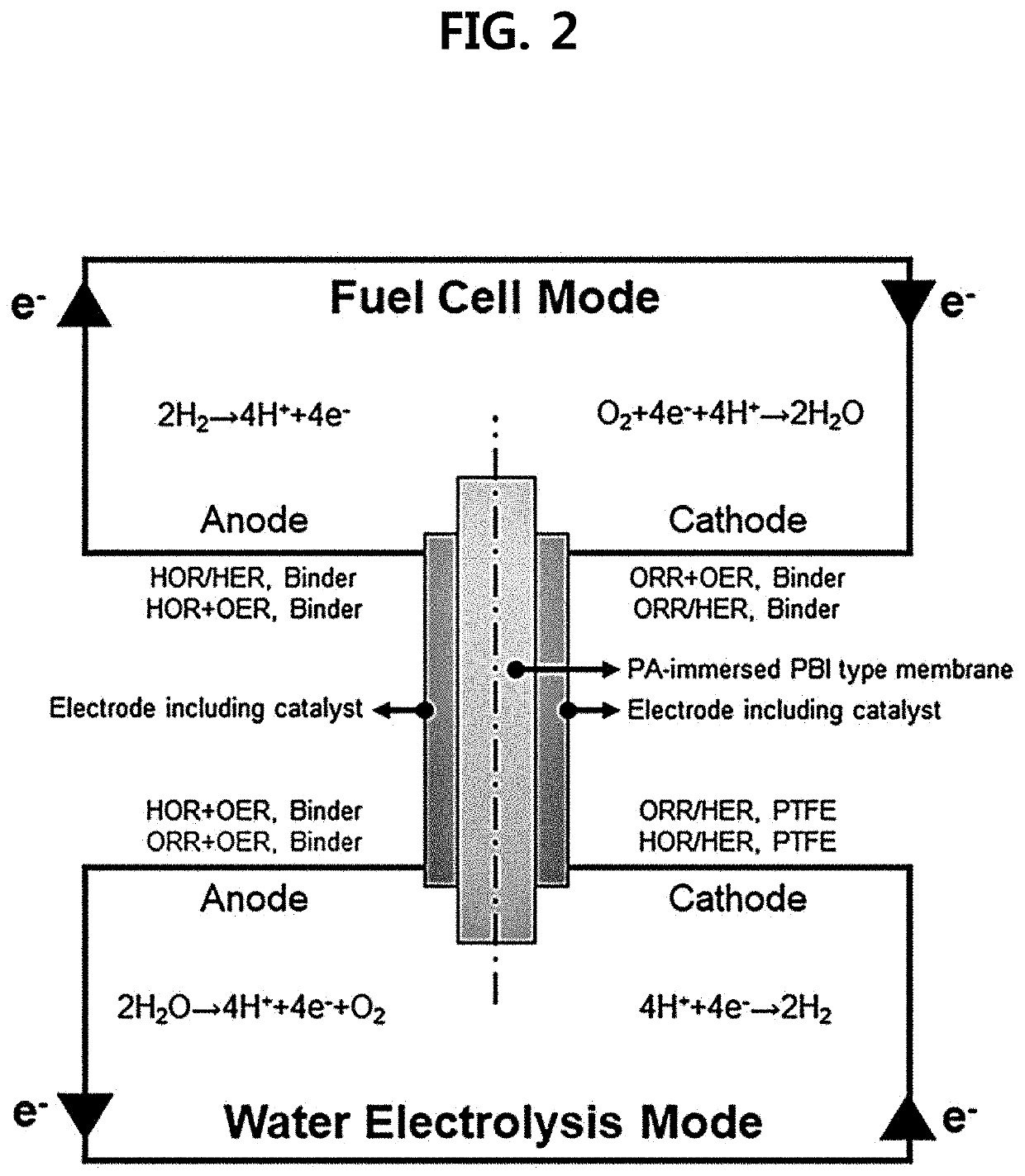

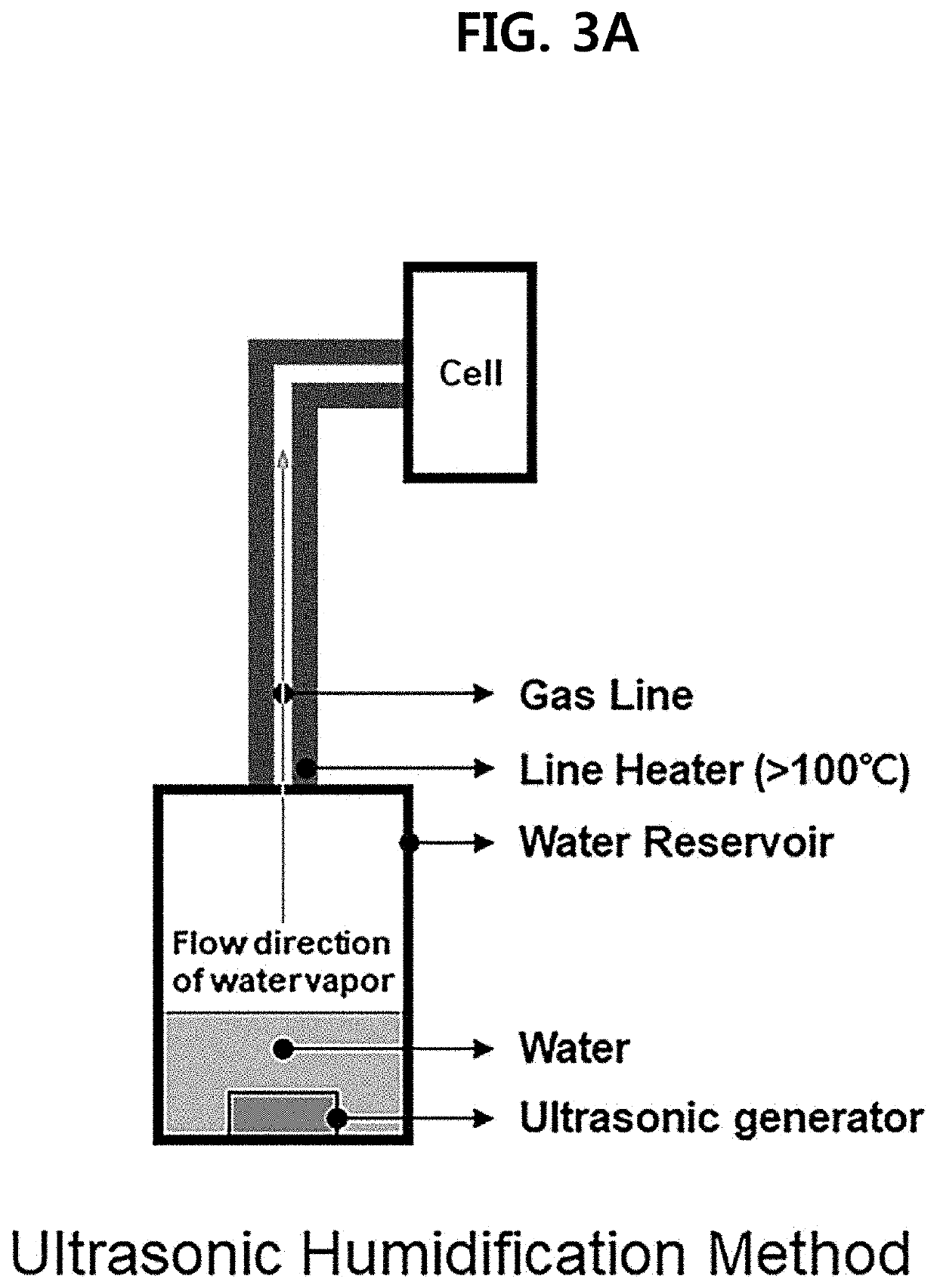

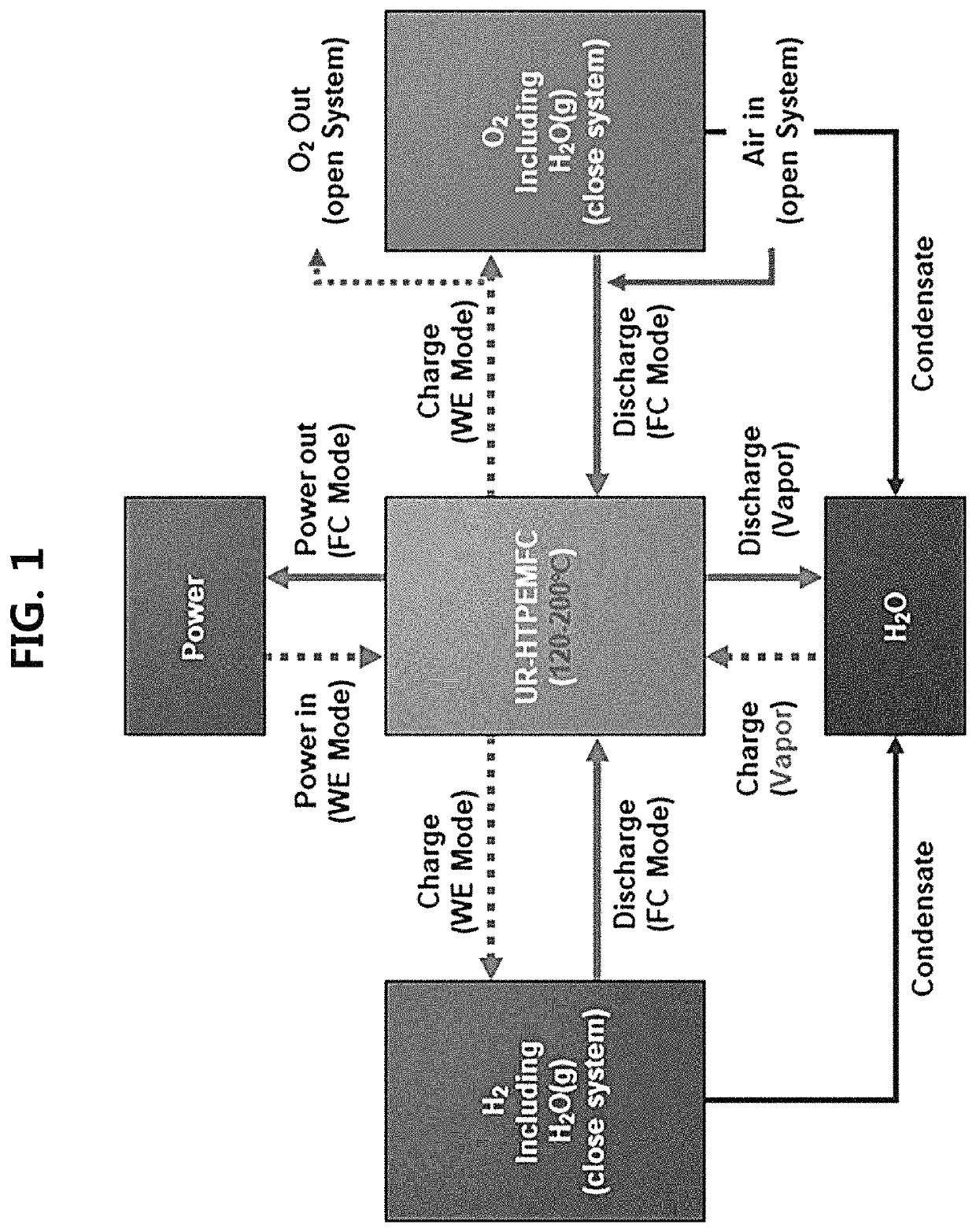

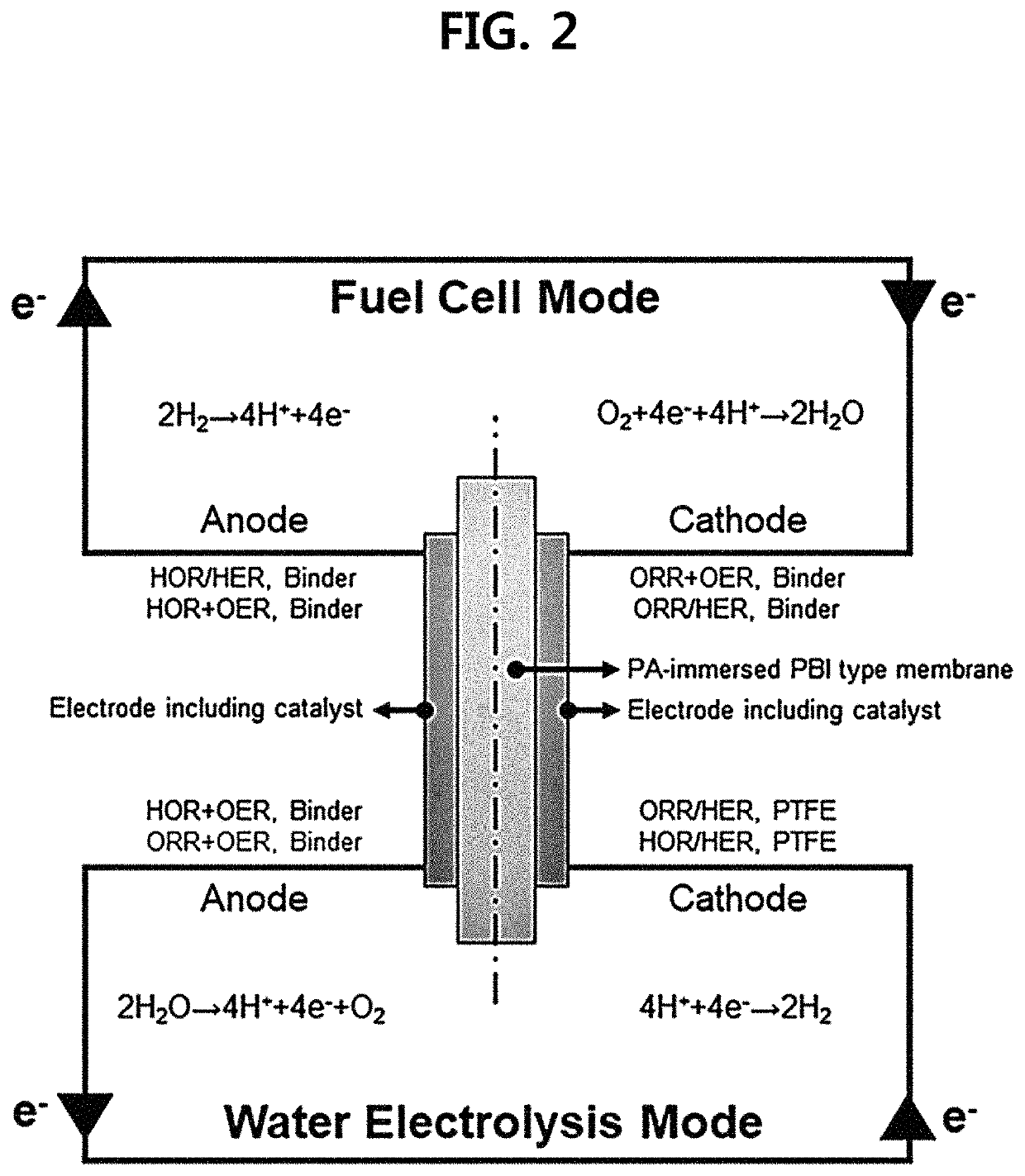

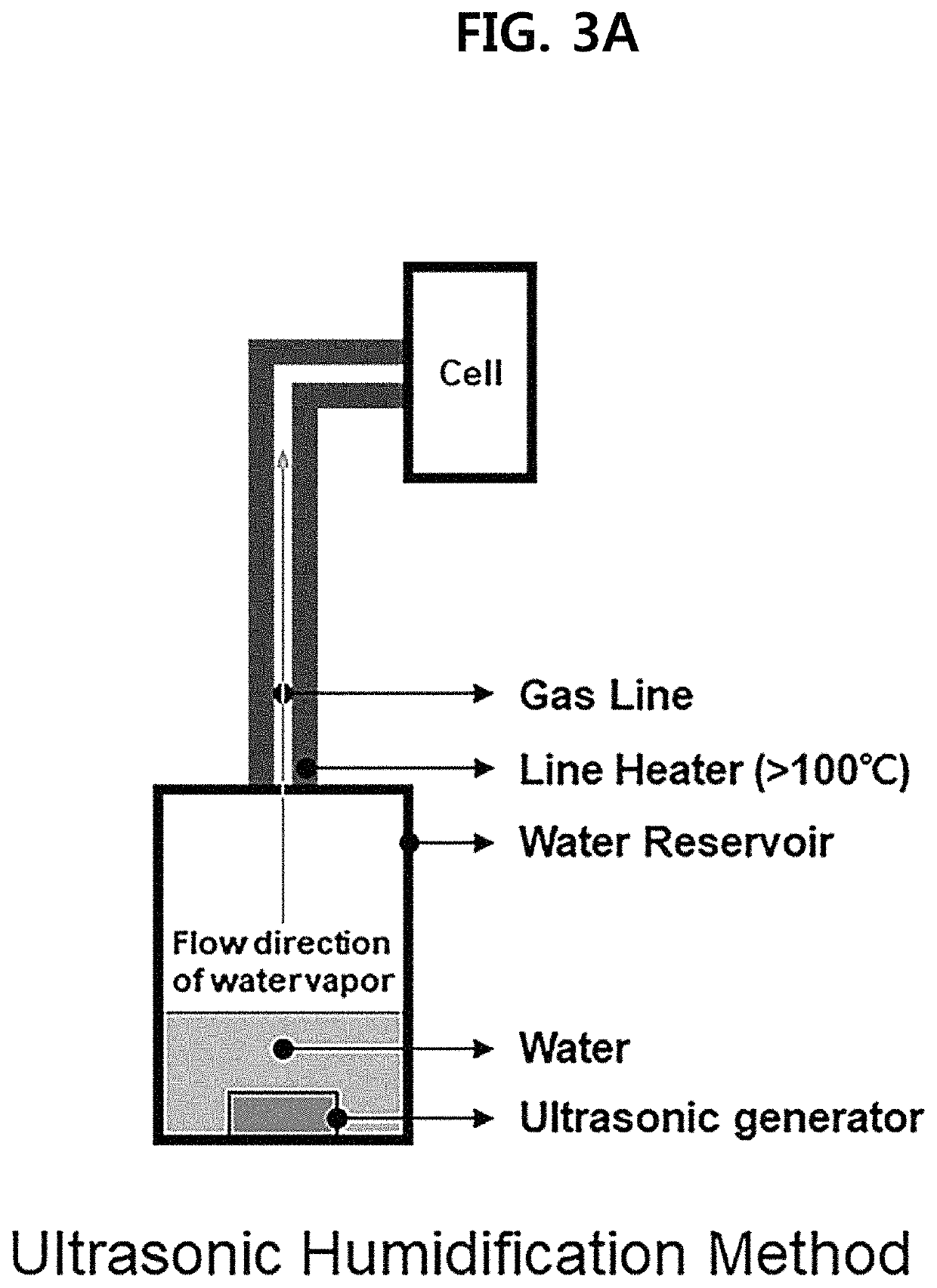

High temperature-type unitized regenerative fuel cell using water vapor and method of operating the same

ActiveUS20210066741A1High heat recovery rateLower threshold voltageCellsSolid electrolytesUnitized regenerative fuel cellThermodynamics

Disclosed is a high temperature-type unitized regenerative fuel cell using water vapor, which exhibits high hydrogen (H2) production efficiency and superior power generation ability.

Owner:KOREA INST OF SCI & TECH

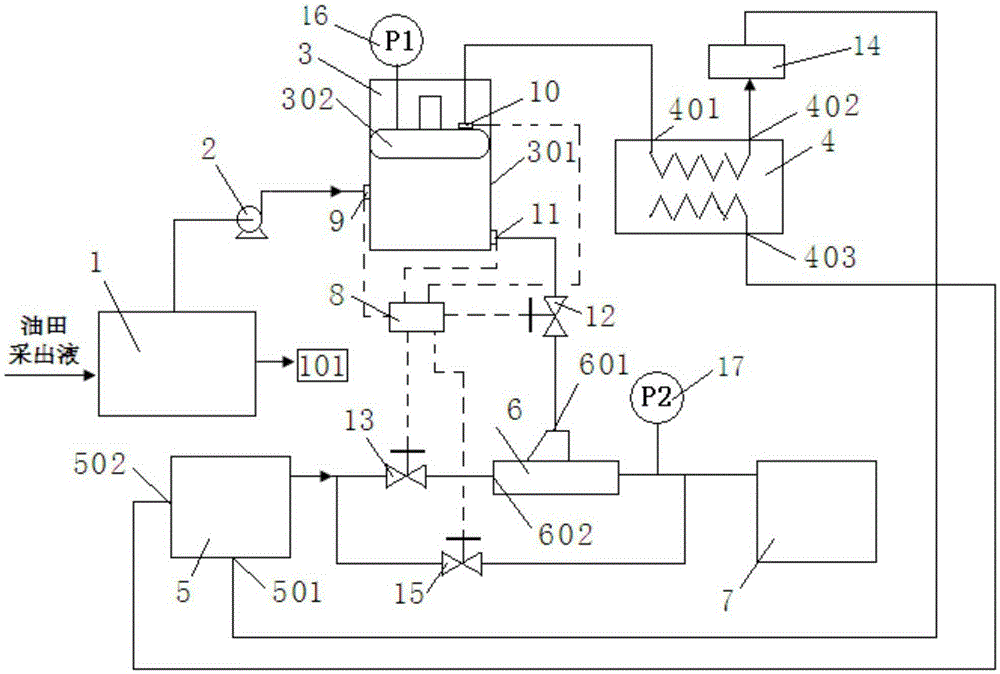

Oilfield produced fluid heat energy recovery device and method

ActiveCN105484716AEfficient recyclingTake advantage ofEvaporator accessoriesFluid removalGas phaseEngineering

The invention discloses an oilfield produced fluid heat energy recovery device and method, and belongs to the technical field of heat energy recovery. In the device, a volume-variable separation tank comprises a tank body and a piston arranged in the tank body, wherein the piston can axially move in the tank body and divide the tank body into an upper cavity and a lower cavity; a check valve is arranged in the middle of the tank body, a first control valve is arranged at the upper portion of the piston, and a second control valve is arranged at the lower portion of the tank body. The gas phase outlet of a steam separation tank, a pressurizing pump, the check valve and the feed port in the middle of the volume-variable separation tank are sequentially connected; the outlet of the lower portion of the volume-variable separation tank, the second control valve, a third control valve and one inlet of an ejector are sequentially connected; the first control valve, the outlet of the upper portion of the volume-variable separation tank, the associated gas inlet of a heat exchanger and the associated gas outlet of the heat exchanger, the fuel inlet of a steam boiler, a fourth control valve, the other inlet of the ejector, the outlet of the ejector and a thick oil heater are sequentially connected; and the boiler water feed outlet of the heat exchanger is connected with the boiler water feed inlet of the steam boiler.

Owner:PETROCHINA CO LTD

Reutilization method of low-pressure byproduct steam in maleic anhydride production process

InactiveCN102635845AReduce moisture contentFast heatingOrganic chemistryClimate change adaptationVaporizationPulp and paper industry

The invention discloses a reutilization method of low-pressure byproduct steam in a maleic anhydride production process. The low-pressure byproduct steam the pressure of which is 0.7-04MPa in the maleic anhydride production process is collected to a flash drum by a pipeline, when the pressure of the steam aggradated in the flash drum achieves a setting value, steam is subjected to steam-water separation in the flash drum and is subjected to flash vaporization so as to obtain flash steam, and the flash steam is output through a one-way valve of the flash drum and is utilized. The moisture content of the flash steam obtained by the method is low, the heating speed is rapid, the utility value is high, the flash steam contains less water content, the heat recovery use ratio is improved, and the purposes of the energy saving, emission reducing and consumption reducing are realized.

Owner:江苏钟腾化工有限公司

Heat conduction effect and heat radiation effect combining type cascading automobile exhaust heat exchange device

ActiveCN105422227ALow manufacturing costHigh heat recovery rateInternal combustion piston enginesExhaust apparatusThermal radiationEngineering

The invention discloses a heat conduction effect and heat radiation effect combining type cascading automobile exhaust heat exchange device and belongs to the technical field of automotive energy-saving devices. The heat conduction effect and heat radiation effect combining type cascading automobile exhaust heat exchange device comprises a catalytic purifier, a set of heat exchange units, a corrugated pipe, an auxiliary silencer, a main silencer, a set of cascading pipes, a first exhaust pipe, a second exhaust pipe, a third exhaust pipe, an exhaust tail pipe, a heat exchange device input pipe and a heat exchange device output pipe. The catalytic purifier, the first exhaust pipe, the corrugated pipe, the second exhaust pipe, the auxiliary silencer, the third exhaust pipe, the main silencer and the exhaust tail pipe are connected in sequence. Every two adjacent heat exchange units are communicated through the corresponding cascading pipe. The heat exchange device input pipe is connected to the heat exchange unit outside the main silencer. The heat exchange device output pipe is connected to the heat exchange unit outside the catalytic purifier. According to the heat conduction effect and heat radiation effect combining type cascading automobile exhaust heat exchange device, the manufacturing cost is reduced, and the recovery rate of heat energy is increased; heat energy is conducted to fluid heat-conducting media for the second time through the heat radiation effect, and thus the recovery rate of the exhaust heat energy is further increased.

Owner:常熟市知识产权运营中心有限公司

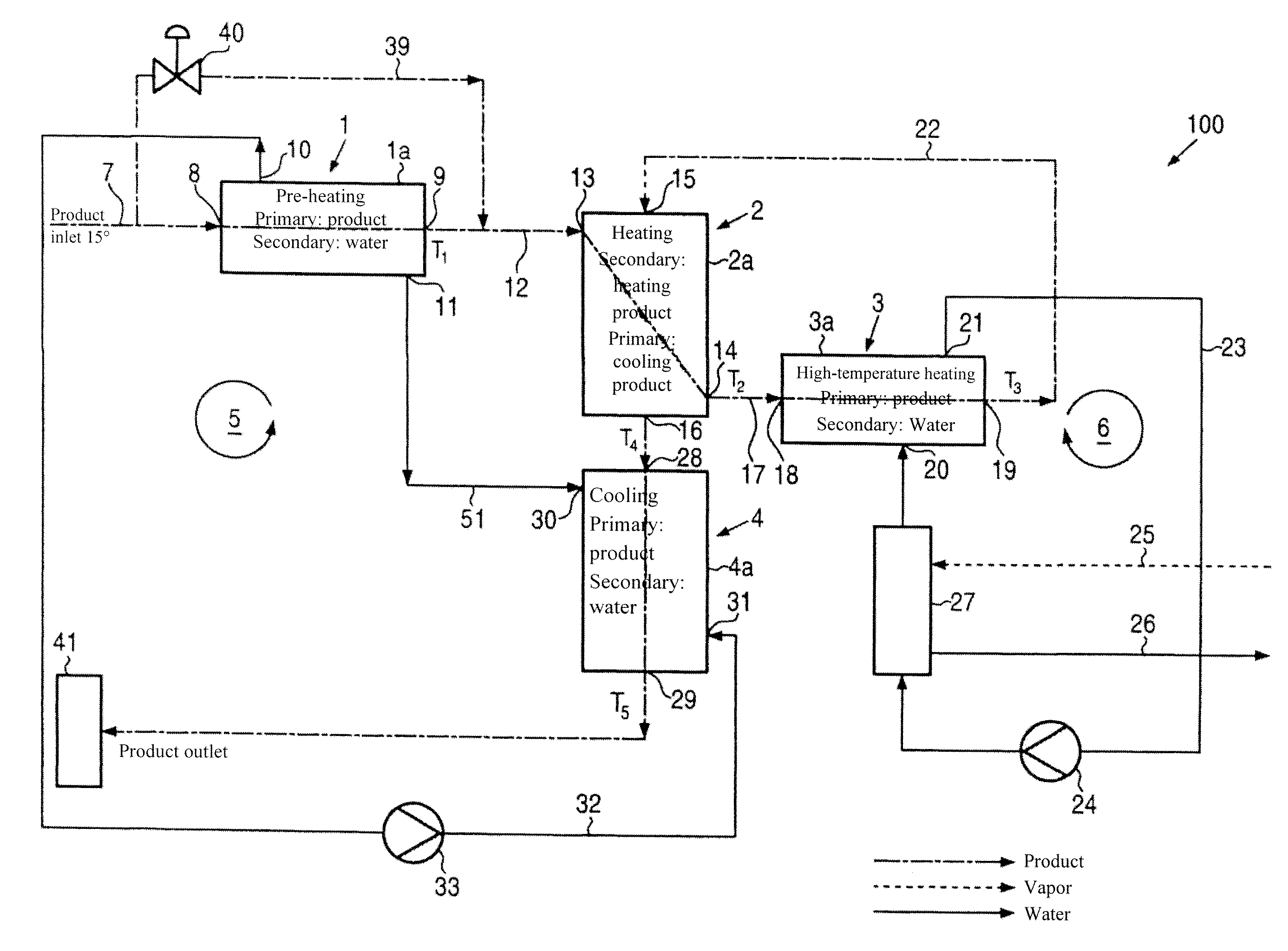

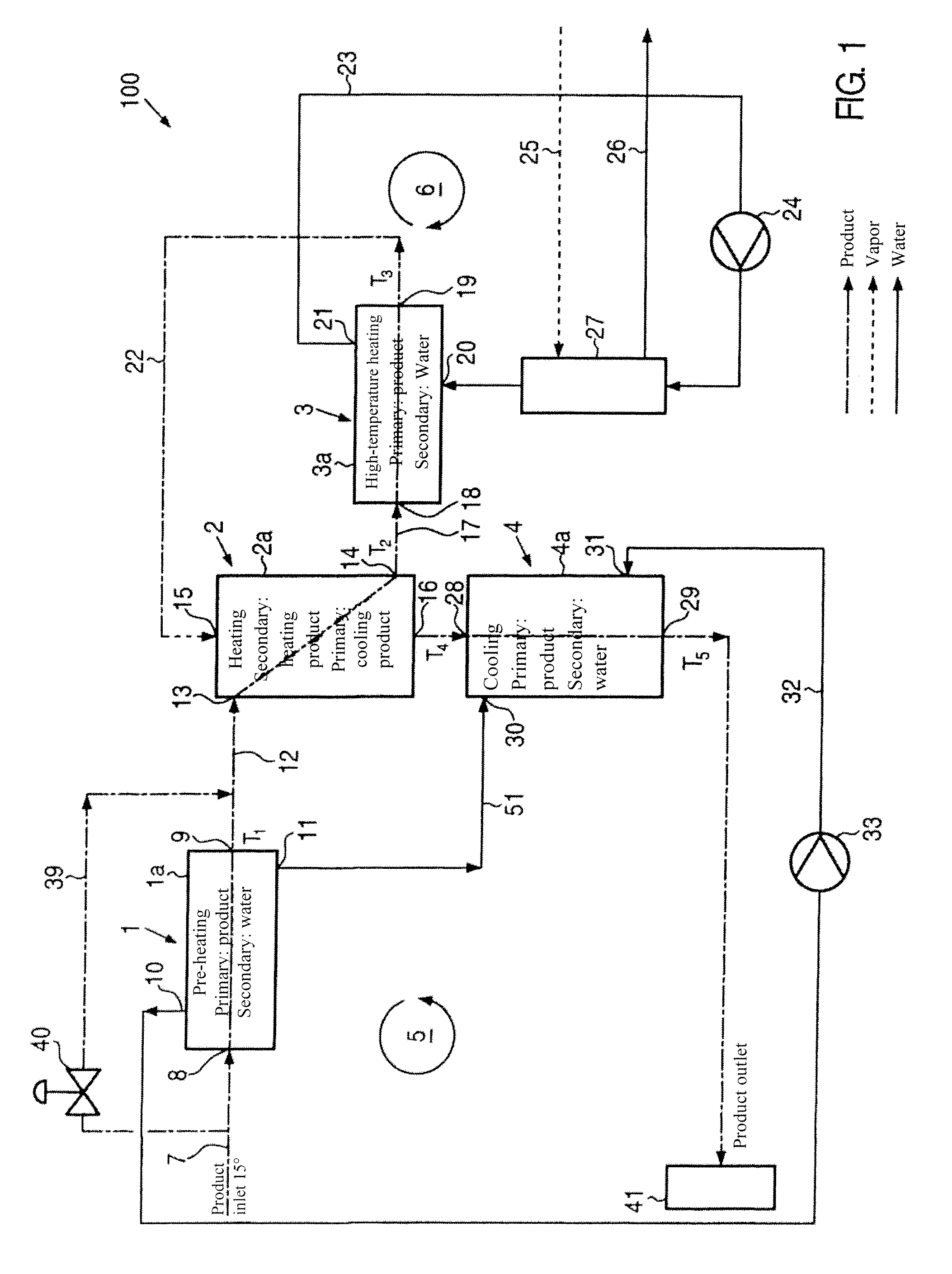

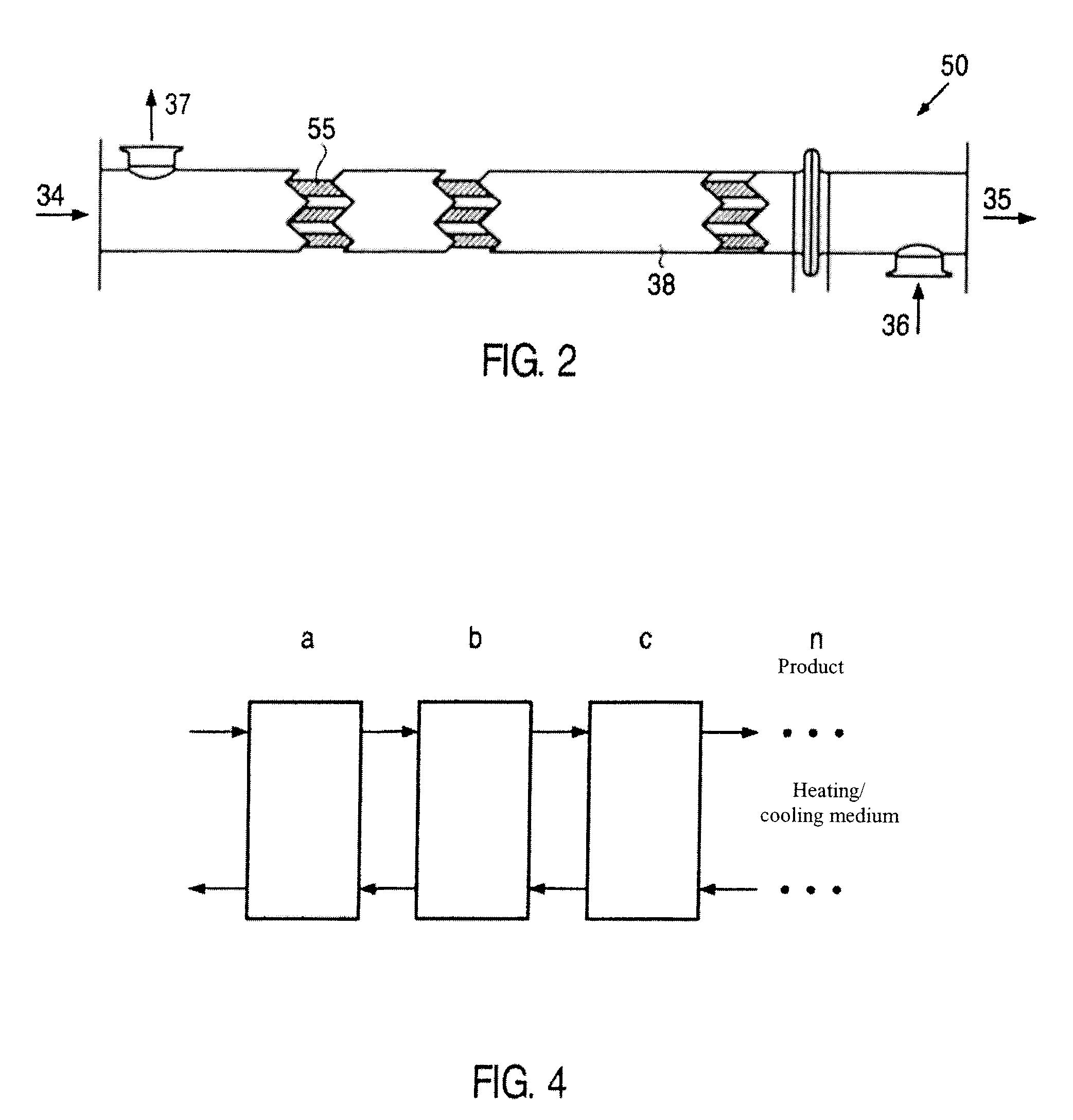

Method and Device for Heating, In Particular Highly Viscous Products

InactiveUS20110030918A1Low investment costImproved heat recoveryFood preservationHeating and refrigeration combinationsEngineeringProcess engineering

A method for heating, in particular of highly viscous products, and a device for performing the method, wherein the product is pre-heated to a first temperature T1 in a first step with at least one product / water heat exchanger section with water as the heating medium, wherein the water cools down. The product is further heated to a second temperature T2 in a second step with at least one product / product heat exchanger section 2a with the product as a heating medium, wherein the returning product serving as heating medium is cooled down, and is then further heated to a third temperature T3 in a third step with at least one product / water heat exchanger section 3a with water as the heating medium, wherein the water cools down and wherein the heated product is then recirculated as heating medium for heating the product.

Owner:KRONES AG

Heat exchange chamber of coke oven and coke oven

PendingCN110982538AImprove stabilityImprove reliabilityDirect heating destructive distillationIndirect and direct heating destructive distillationCombustion chamberFlue gas

The invention discloses a heat exchange chamber of a coke oven. The heat exchange chamber of the coke oven comprises a chamber body, the interior of the chamber body is of a multi-layer structure, anair channel and a flue gas channel are arranged in each layer of the multi-layer structure in a penetrating mode, the layers of the multi-layer structure are sequentially communicated, the air channelis used for being communicated with the external environment, and the flue gas channel is used for being communicated with the external environment. And the flue gas channel is used for communicatingwith a vertical flame path of a combustion chamber in the coke oven. The invention also provides the coke oven adopting the heat exchange chamber. The heat exchange chamber is simple in structure, and the heat exchange efficiency of the coke oven can be effectively improved.

Owner:HUATAI YONGCHUANG BEIJING TECH CO LTD

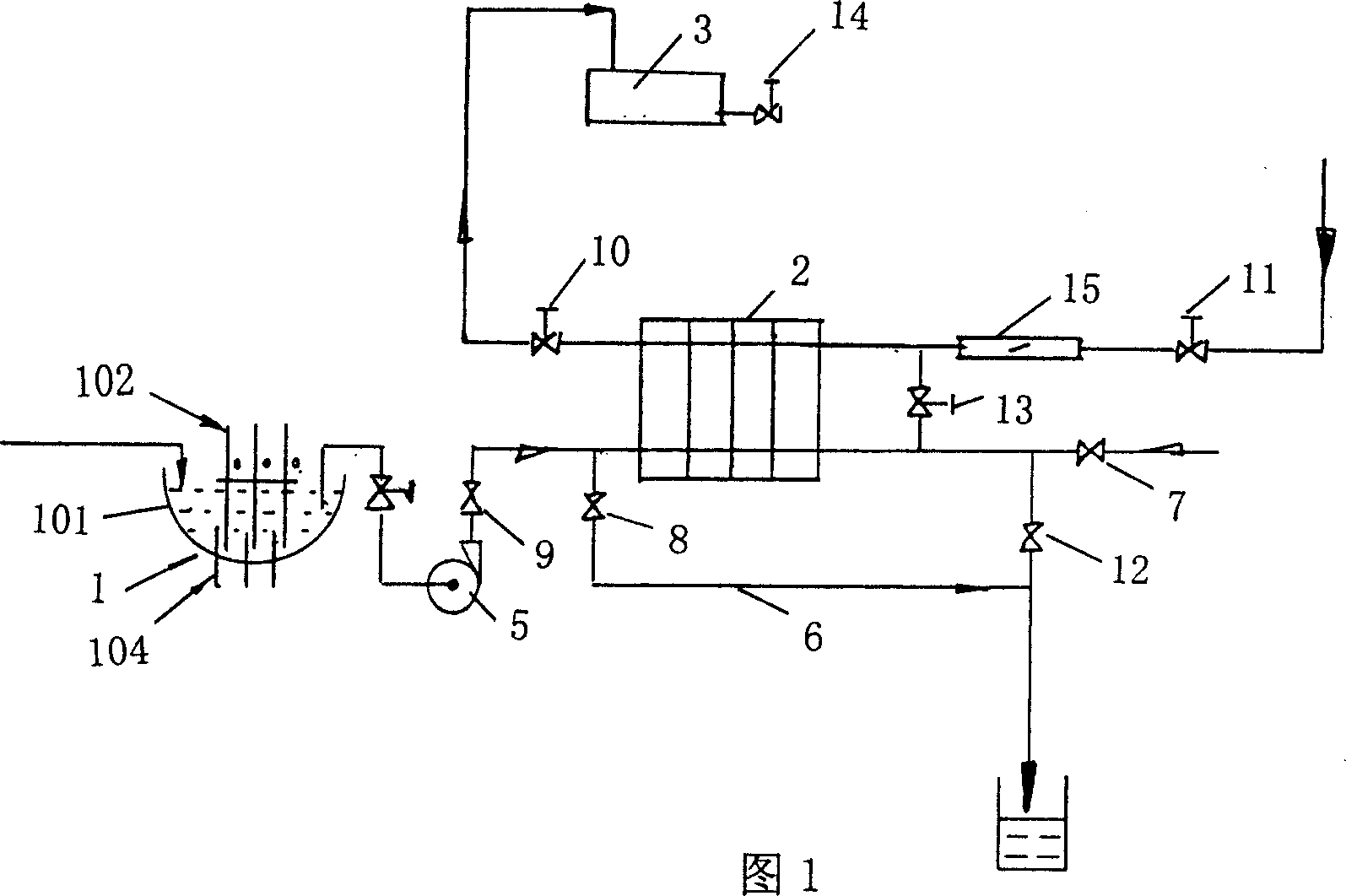

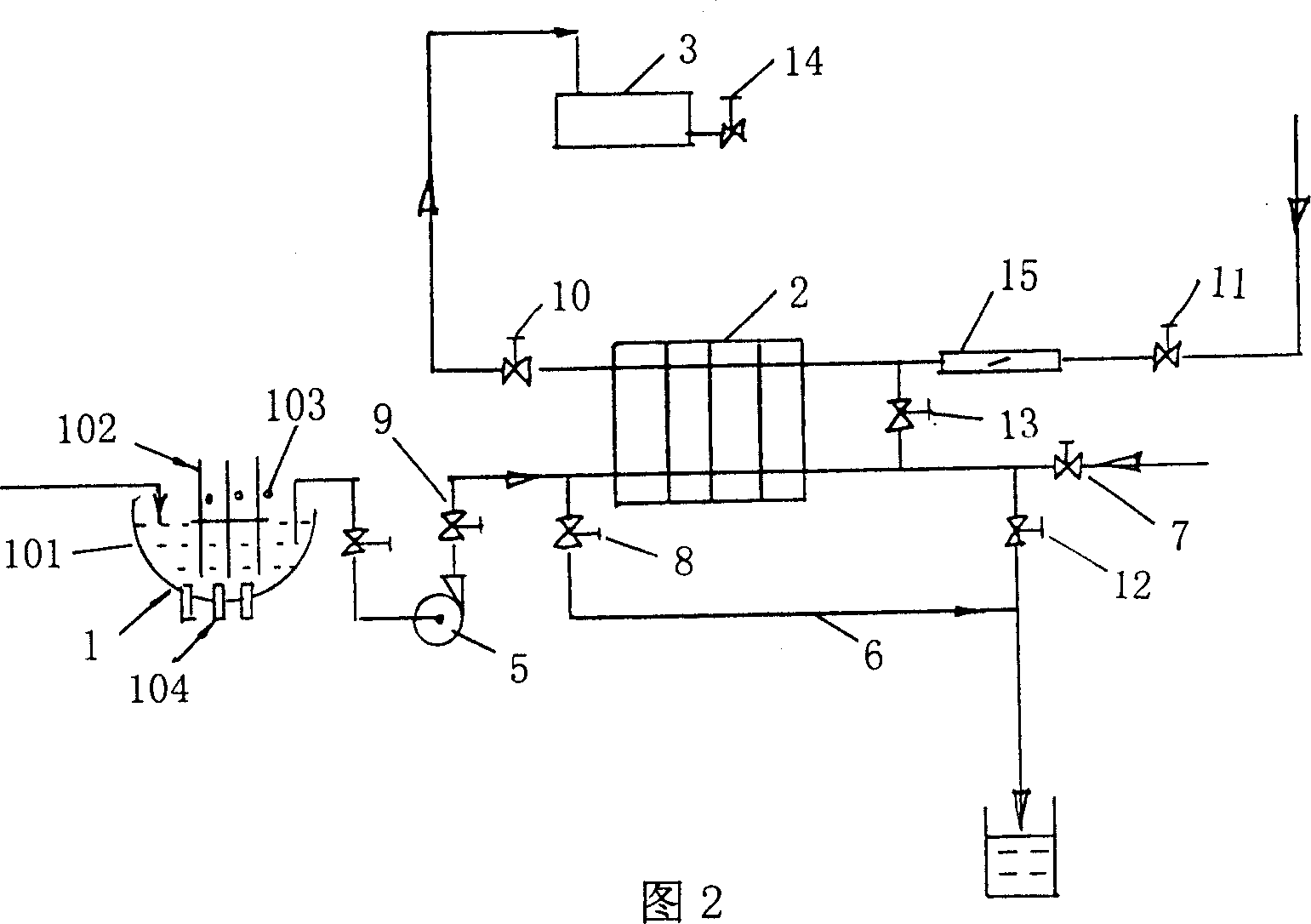

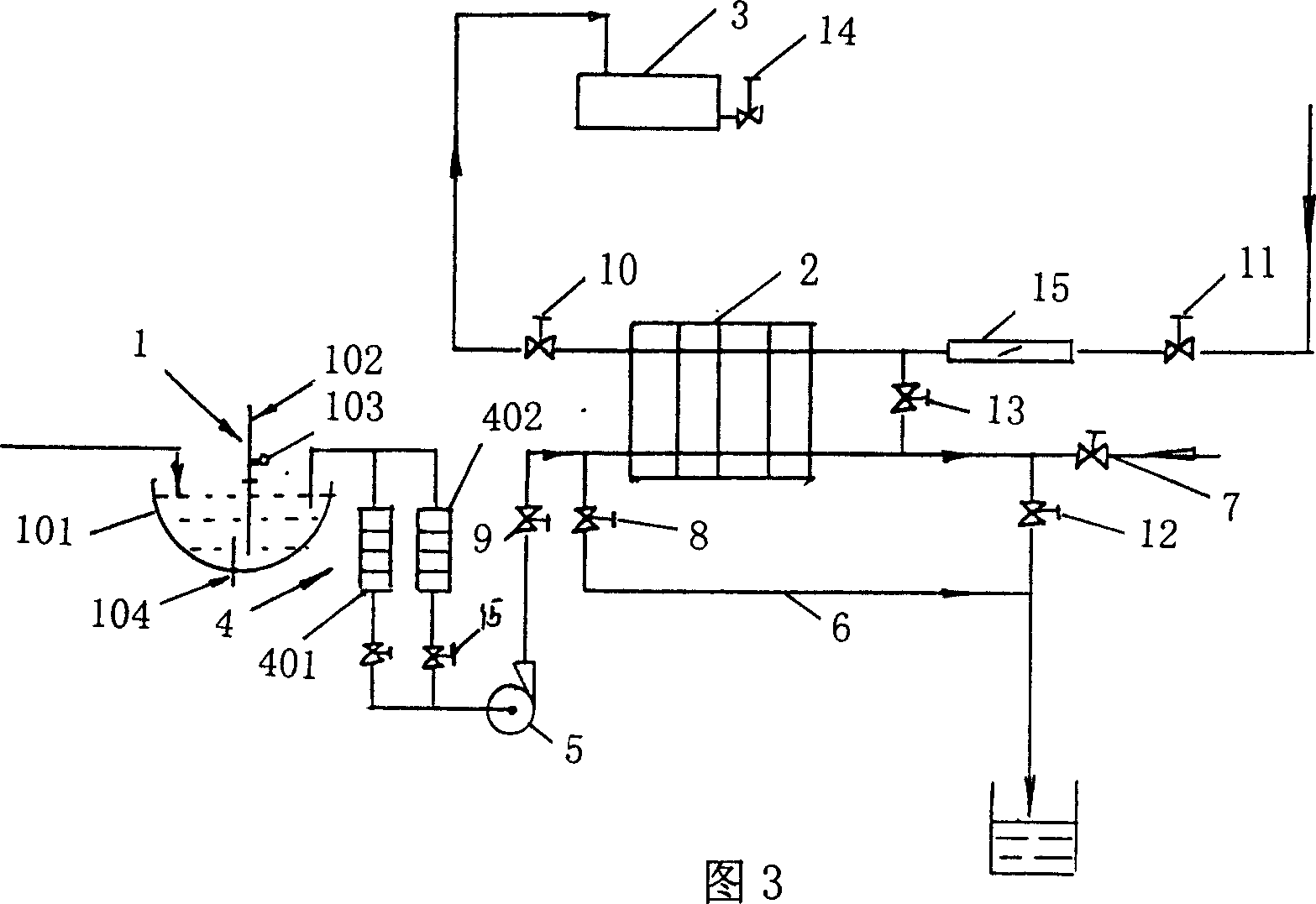

Method for synthesizing ethylbenzene from ethanol and benzene

ActiveCN102276411BHigh heat recovery rateNo corrosionHydrocarbonsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveGas phase

The invention relates to a method for synthesizing ethylbenzene from ethanol and benzene. The method is used for mainly solving the problems that the traditional ethylbenzene production process must depend on ethylene as a raw material and has high raw material cost. The problems are well solved by adopting the technical scheme as follows: the method comprises the following steps: (a) the benzene and the ethanol enter an alkylation reactor filled with a ZSM-5 nano-scale molecular sieve catalyst to be reacted under a gaseous phase condition according to the mol ratio of (2-8):1 so that a mixture 103 including benzene, ethylbenzene, diethylbenzene and water is obtained; (b) the mixture 103 sequentially passes through a benzene recovery tower, an ethylbenzene recovery tower and a poly-ethylbenzene recovery tower so that the water, the benzene, the ethylbenzene and the diethylbenzene in the mixture are separated; and (c) a part of the separated benzene and the diethylbenzene enter an alkyl transfer reactor under a gaseous phase condition according to the weight ratio of (2-10):1 and are in contact with the ZSM-5 molecular sieve catalyst to carry out alkyl transfer reaction so that the ethylbenzene is generated. According to the method, the ethylene is replaced by ethanol as a raw material; the ethanol and the benzene are used for synthesizing the ethylbenzene; the raw material cost is low; and the method can be applied in the industrial production of the ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biomass power plant smoke wind waste heat recovery device

The invention relates to a heat recovery device, and discloses a flue gas waste heat recovery device of a biomass power plant. The flue gas waste heat recovery device comprises a steam line, a cooling water circulation line, a desalted water line and a flue gas heat exchange line, wherein a flue gas heat exchanger is arranged on the flue gas heat exchange line, and flue gas returns to the flue gas heat exchanger after heat is absorbed by an absorption heat pump. The flue gas waste heat recovery device recovers waste heat in flue gas and slag of the biomass power plant in a heat exchange mode and has the advantages of high recovery use ratio of heat energy, energy conservation, environmental protection and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for synthesizing ethylbenzene

ActiveCN102276410BHigh heat recovery rateNo corrosionHydrocarbonsHydrocarbon preparationGas phaseZSM-5

The invention relates to a method for synthesizing ethylbenzene, and mainly solves the problems that ethylene must be taken as a raw material, the cost of the raw material is high and the content of dimethylbenzene is high in the product ethylbenzene in the conventional ethylbenzene production process. The method comprises the following steps that: a) benzene and ethanol enter an alkylation reactor loaded with a ZSM-5 nanoscale molecular sieve catalyst in a molar ratio of (2-8):1 under gas phase conditions and react to form a mixture 103 comprising benzene, ethylbenzene, diethylbenzene and water; b) the mixture 103 sequentially passes through a benzene recovery tower, an ethylbenzene recovery tower and a polyethylbenzene recovery tower so as to separate the water, the benzene, the ethylbenzene and the diethylbenzene from the mixture 103; and c) the partial benzene and diethylbenzene which are obtained through the separation enter a transalkylation reactor in a weight ratio of (2-10):1 under liquid phase conditions and are contacted with a Beta molecular sieve catalyst for a transalkylation reaction so as to generate the ethylbenzene. The technical scheme better solves the problems; in the scheme, the ethylbenzene is synthesized by using the ethanol as the raw material instead of the ethylene, the cost of the raw material is low, and the content of the dimethylbenzene in the product ethylbenzene is low; and the technical scheme can be used for the industrial production of the ethylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste gas residual heat recycling device for organic silicon production technology

InactiveCN109870045AIncrease profitNo unrecovered heatHeat exchanger casingsStationary tubular conduit assembliesButt jointRetention time

The invention discloses a waste gas residual heat recycling device for an organic silicon production technology. The waste gas residual heat recycling device comprises a heat insulation box, a gathering box, a fixed frame, an outer chimney, a gas leakage pipe, an inner chimney, a spiral pipe, a water collector, a gas inlet pipe, a butt joint opening, a collection opening, short bulges, gaps and long bulges. The waste gas residual heat recycling device disclosed by the invention has the beneficial effects that the plurality of short bulges and long bulges are arranged on an inner wall of the inner chimney; the long and short bulges are symmetrically arranged; the gap with a Z-shaped structure is formed by each two groups of the long and short bulges; and waste gas passes through the gaps with the Z-shaped structure in a circulation process so that the retention time is prolonged. The spiral pipe matched with the distance between the inner wall of the outer chimney and an outer wall of the inner chimney is arranged between the inner wall of the outer chimney and the outer wall of the inner chimney; the spiral pipe is wound on the outer wall of the inner chimney and the butt joint opening of the spiral pipe is communicated with the gas leakage pipe; when excessive gas enters in one step, the gas is leaked; and meanwhile, the leaked gas is directly guided into the collection opening of the spiral pipe and the heat of the waste gas guided into the spiral pipe also can be recycled.

Owner:李凤英

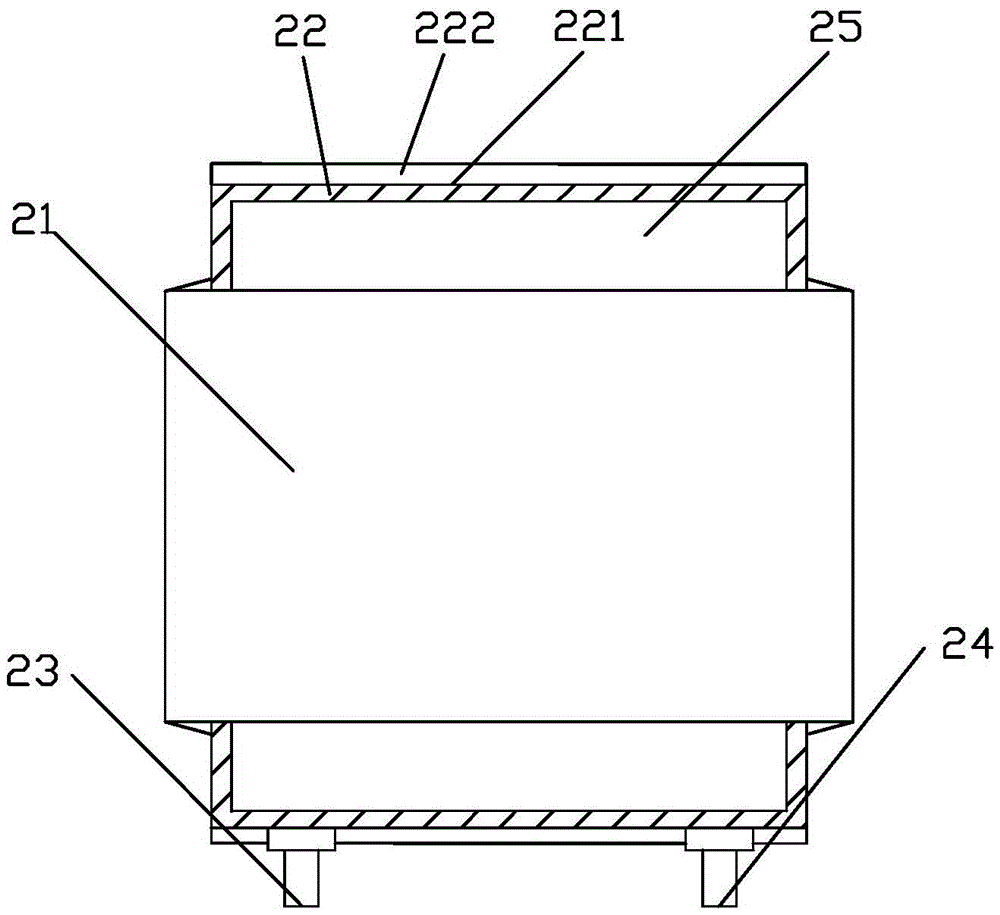

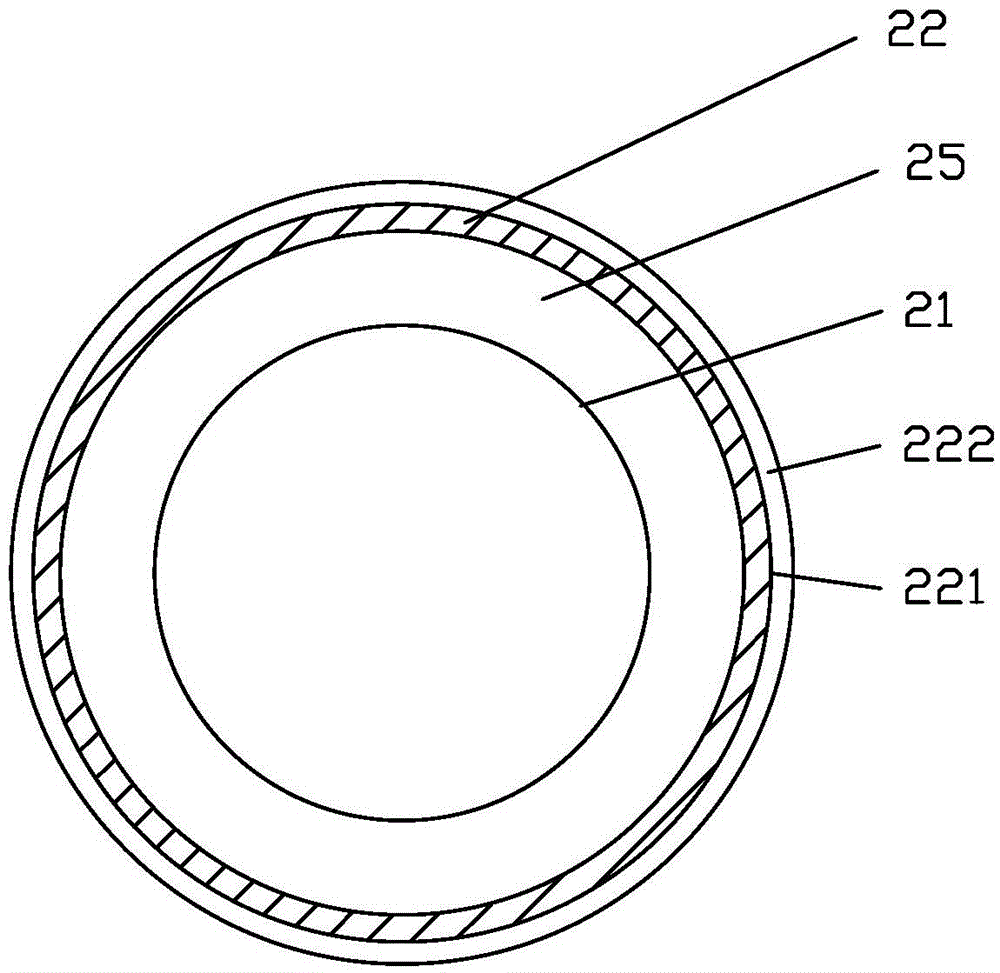

Double-unit series heat recovery system

InactiveCN112696960AReduce lossesImprove insulation effectHeat pumpsHeat storage plantsWater storage tankEngineering

The invention discloses a double-unit series heat recovery system, relates to the technical field of heat recovery, and aims to solve the problem that most heat in an existing heat pump is directly radiated to the outside in a heat radiation mode, and consequently serious waste is caused. According to the system, a first mounting plate is mounted at the upper end of one side in a body bracket, a compressor is mounted at the upper end of the first mounting plate, and a water storage tank is mounted on the other side in the body bracket and is fixedly connected with the body bracket; and the water storage tank comprises heat preservation sponge, heat insulation rubber, an outer isolation layer, a heat conduction layer, a supporting bracket and a hot water storage tank, the heat insulation rubber, the outer isolation layer, the heat conduction layer, the supporting bracket and the hot water storage tank sequentially adjoins the inner side of the heat preservation sponge, the heat preservation sponge is connected with the heat insulation rubber and the outer isolation layer adjacently in a glued mode, the outer isolation layer is fixedly connected with the heat conduction layer through a supporting plate, and the heat conduction layer, the supporting bracket and the hot water storage tank are adjacently connected in a welded mode.

Owner:ANHUI TULIP NEW ENERGY TECH

Multi-angle, multi-layer, 360-degree air supply sinter cooling tower

InactiveCN105444580BNo diffusionSmall footprintHandling discharged materialCooling towerCooling effect

The invention discloses a multi-angle multi-surface multi-layer 360-degree air-supplying sinter ore cooling tower and belongs to the technical field of sintering equipment for iron making. The multi-angle multi-surface multi-layer 360-degree air-supplying sinter ore cooling tower is used for cooling sinter ores and recycling heat energy and consists of a feeding skew bridge, a distribution dust and waste air collection chamber, a dust collecting pipeline, a distributing device, a high-temperature heat energy recycling system, a boiler circulating air reutilization system, a medium-temperature cooling recycling system, a low-temperature cooling system and an unloading system. The sinter ores are uniformly packed into the cooling tower via the feeding skew bridge by a distributor; the high-temperature heat energy recycling system is used for sending utilizable hot air to a boiler; circulating air of the boiler is returned to a high-temperature section of the boiler by the boiler circulating air reutilization system so as to cool the sinter ores; cooling fans are uniformly mounted at a low-temperature section in the cooling tower in a layered way so as to cool the sinter ores; air vents and ventilating pipelines are respectively arranged at a medium-temperature section and the low-temperature section to realize flowing of cooling air inside the tower so that the sinter ores can be cooled. The multi-angle multi-surface multi-layer 360-degree air-supplying sinter ore cooling tower disclosed by the invention has the characteristics of being small in floor area, near in wind run, free of wind loss, high in wind utilization rate, high in heat energy collection rate, good in cooling effect and free of dust diffusion.

Owner:张志良

Catalytic bed furnace core structure with guide shield

The invention relates to a catalytic bed furnace core structure with a guide shield. The structure comprises an upper end plate, a lower end plate and a furnace core outer peripheral plate; the upper end plate and the lower end plate are respectively fixedly mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate. The catalytic bed furnace core structure is simple in arrangement and scientific and reasonable in design, the heat efficiency of the furnace core structure can be effectively improved, the heat loss is reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure is more uniform during burning, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Special catalytic bed for industrial volatile organic pollutants in pm2.5

InactiveCN103486600BUniform air intakeUniform reflowCombustion using catalytic materialIncinerator apparatusParticulatesInsulation layer

The invention relates to a catalyzing bed special for industrial volatilizable organic pollutants in PM2.5 (particulate matter 2.5). The catalyzing bed is characterized in that heat insulation layers are fixedly and uniformly mounted on the outer wall of a furnace body exterior plate, a furnace body interior plate is arranged in the furnace body exterior plate, air incoming ways and air outgoing ways are alternatively arranged between the furnace body interior plate and the furnace body exterior plate, an inlet of each air incoming way is arranged on an upper end plate while an outlet of the same is arranged between a lower end plate and the furnace body interior plate, an inlet of each air outgoing way is arranged between the upper end plate and the furnace body interior plate while an outlet of the same is arranged on a lower end plate, an incoming air guide cover is arranged above the middle portion of the upper end plate corresponding to an air incoming cover inlet, a combustion gas guide cover is arranged above the lower portion of the upper end plate, and an outgoing air guide cover is arranged below the middle portion of the lower end plate corresponding to an air outgoing cover outlet. Heat efficiency of the catalyzing combustion bed is effectively improved, heat loss is reduced, temperature in the catalyzing combustion bed is more uniform during combustion, and combustion efficiency and purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

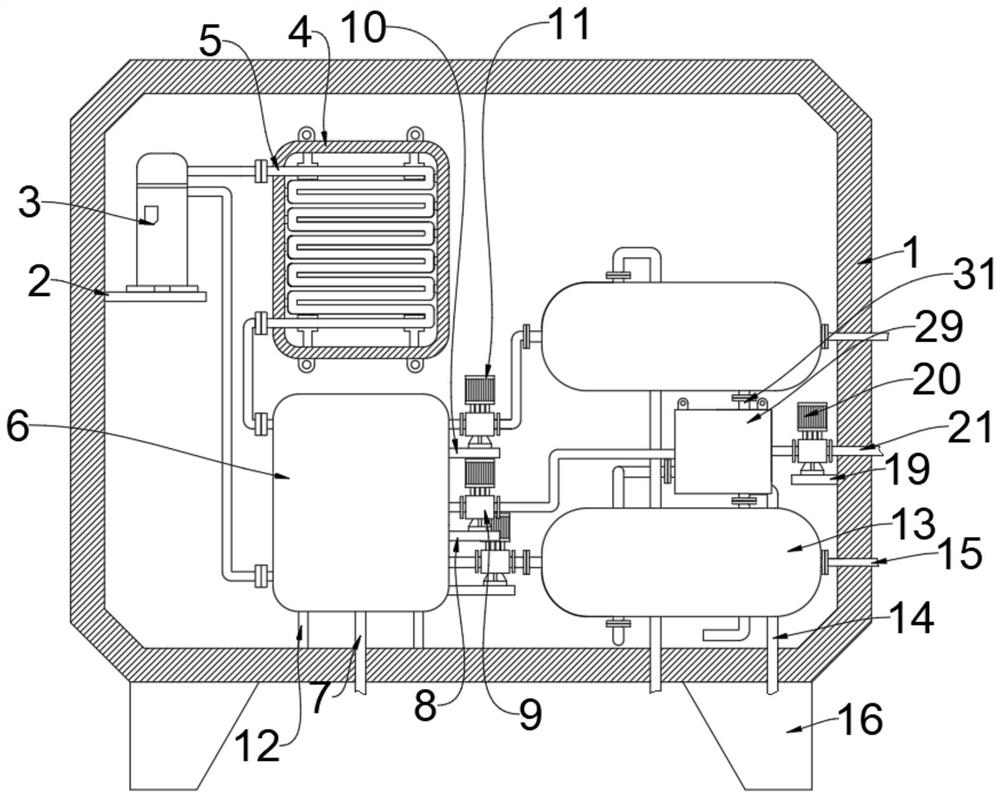

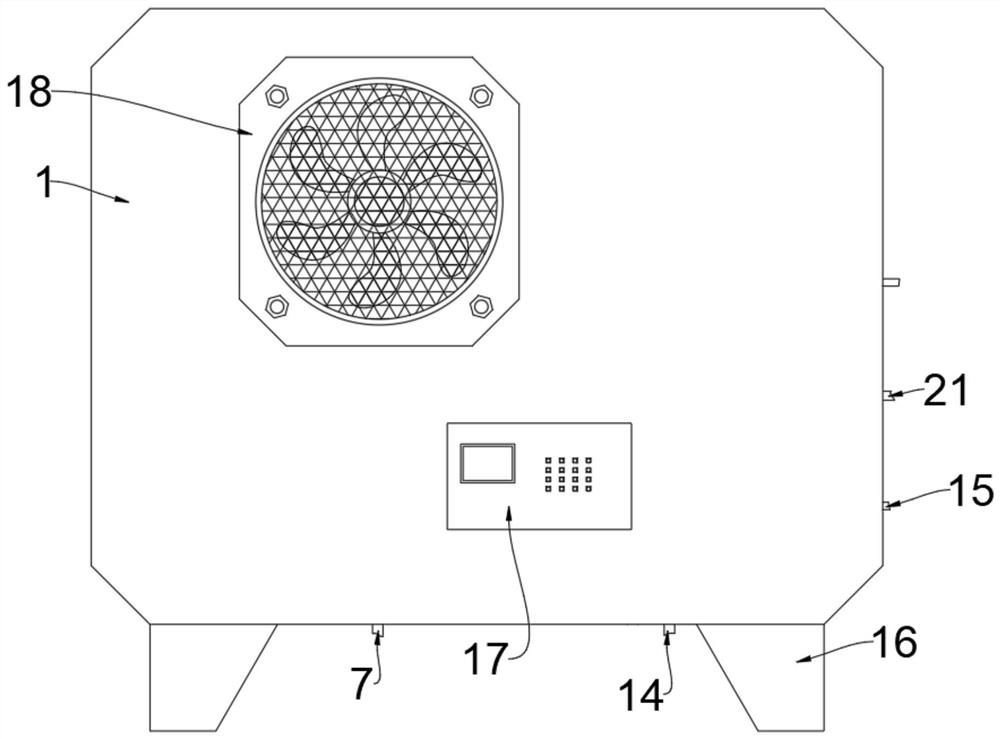

Boiler system with heat energy recovery function and heat energy recovery method of boiler system

PendingCN110410765ALower discharge temperatureSave fuelSteam boilersSteam boilers componentsRecovery methodWater storage

The invention relates to the technical field of steam systems, and discloses a boiler system with a heat energy recovery function. The boiler system comprises a boiler assembly, and further comprisesa heat energy recovery assembly, a water storage device and a control device, and the boiler assembly is connected with a flue device. According to the boiler system, flue gas heat energy is recoveredby a heat exchange tube, then water which has been heated is delivered to the boiler assembly from the inside of the flue device through a second pumping device, thus, fuels for heating a boiler is reduced, the fuels are saved by 35% or above, and the heat efficiency recovery rate is high. The invention also provides a heat energy recovery method of the boiler, in the recovery method, heat energyis recovered in a mode that recovery heat pipes distributed along a flue gas channel are opposite to flue gas emission, so that the flue gas at high temperature with high heat can be recovered to themaximum extent, the flue gas emission temperature is lower than 100 DEG C, and the energy-saving effect is obvious.

Owner:苏明均

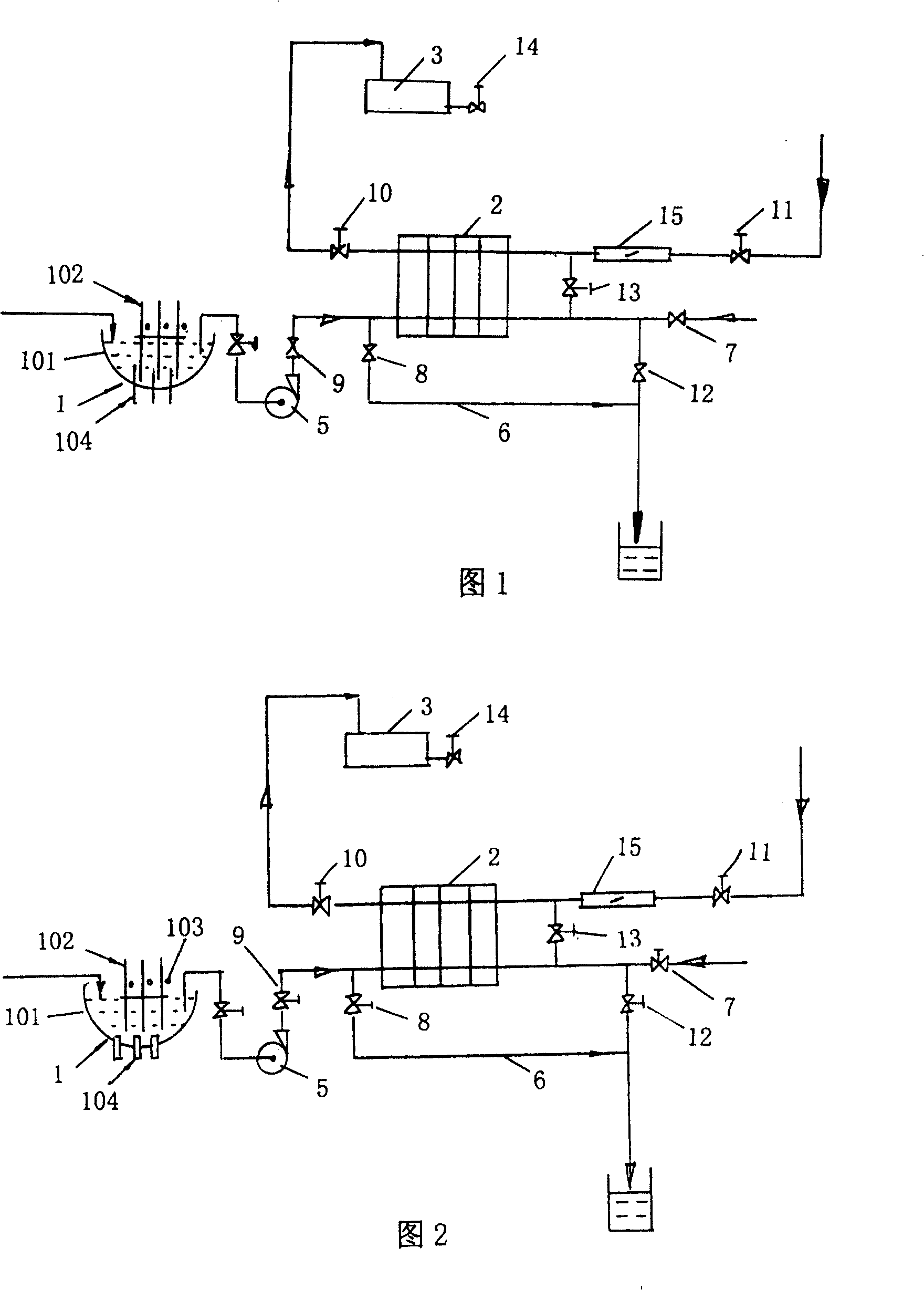

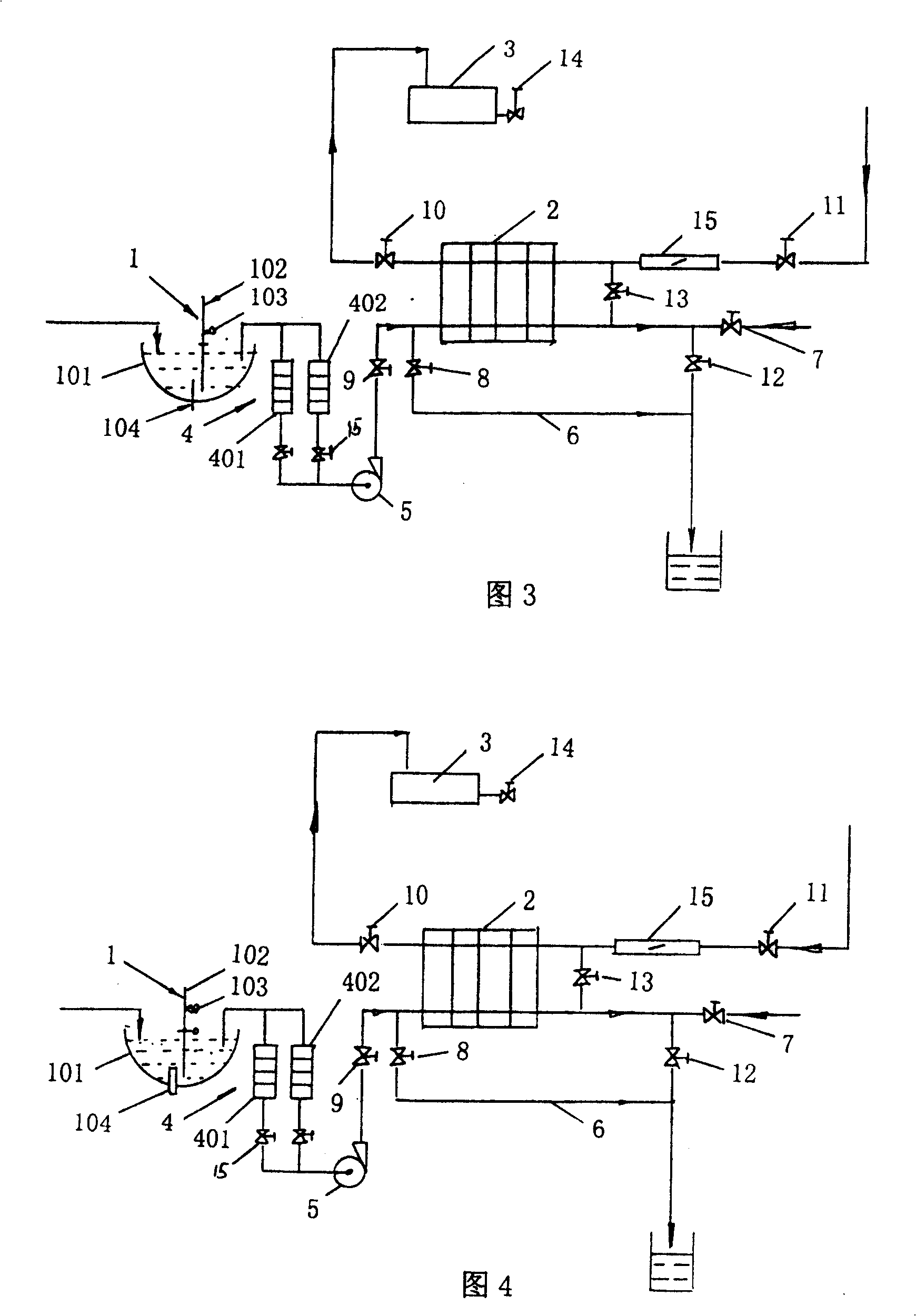

Thermal energy recovery system containing waste hot water

InactiveCN1975313AHigh heat recovery rateImprove filtering effectCorrosion preventionHeat exchange apparatusWater sourceWastewater

The invention discloses heat energy recovery system with filtrating equipment that is not easily plugged and of high recovery efficiency against plugged easily of filter and low recovery efficiency problems of existing heat energy recover device of wastewater. It comprises wastewater filtrating equipment, heat exchanger, hot-water boiler, the inlet of wastewater filtrating equipment connects of the wastewater source, its output end connects hot-water side of heat exchanger, the heat exchanger is connected with the discharge pipe, the cold-water side of the heat exchanger is connected with cold clear water and hot-water boiler, its characteristics are the said wastewater filtrating equipment is composed of the wastewater box, at least one rotary screen filter screen, air knife, the impurity retainer, the said rotary screen filter screen is installed on the rotating shaft, air knife and the impurity retainer were installed both side of rotary screen filter screen each, feed mouth of air knife and the impurity retainer are higher than the liquid level of wastewater. It has characteristics of high efficiency and can meet the requirements of environmental protection.

Owner:NANJING MASITE MACHINERY

Energy-saving catalytic bed system

The invention relates to an energy-saving catalytic bed system which comprises an air inlet cover, a furnace body, an air outlet cover and a heat exchanger; air inlet channels and air outlet channels are alternatively arranged between the inner coaming of the furnace body and the outer coaming of the furnace body; the inlet of each air inlet channel is arranged on an upper end plate, and the outlet of each air inlet channel is arranged between a lower end plate and the inner coaming of the furnace body; the inlet of each air outlet channel is arranged between the upper end plate and the inner coaming of the furnace body, and the outlet of each air outlet channel is arranged on the lower end plate; a heater is arranged in the furnace body which corresponds to the outlets of the air inlet channels; an air outlet deflection cover is arranged below the middle part of the lower end plate which corresponds to the outlet of the air outlet cover; the heat exchanger is provided with a catalytic exhaust inlet, a catalytic exhaust outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet. According to the energy-saving catalytic bed system, the heat efficiency of a catalytic bed is effectively improved, the heat loss is reduced, the heat recovery and utilization rate is improved, the burning efficiency and purification rate are improved, heat exchange is increased, the heat energy is utilized more reasonably, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

Exhaust gas waste heat recycling device used in organic silicon production process and application method

The invention discloses an exhaust gas waste heat recycling device used in an organic silicon production process and an application method thereof. The device comprises a heat preservation box, a gathering box, a fixing frame, an outer chimney, a gas leakage pipe, an inner chimney, a spiral pipe, a catchment, a gas inlet pipe, an abutting joint port, a collection port, short protrusions, gaps andlong protrusions. The device has the advantages that a plurality of short protrusions and long protrusions are symmetrically arranged on the inner wall of the inner chimney, one gap of a Z-shaped structure is formed between every two short protrusions and long protrusions, exhaust gas passes through the gaps of the Z-shaped structures, and the standing time is prolonged. The spiral pipe matched with the inner chimney and the outer chimney in spacing distance is installed between the inner wall of the outer chimney and the outer wall of the inner chimney and winds the outer wall of the inner chimney, and the abutting joint port of the spiral pipe is communicated with the gas leakage pipe; when too much gas flows inside at a time, gas leakage occurs, and leaked gas is directly introduced into the collection port of the spiral pipe at this moment so that the heat of the waste gas introduced into the spiral pipe can also be recycled.

Owner:陈彪

Thermal energy recovery system containing waste hot water

InactiveCN100412496CHigh heat recovery rateImprove filtering effectCorrosion preventionHeat exchange apparatusWater sourceWastewater

The invention discloses heat energy recovery system with filtrating equipment that is not easily plugged and of high recovery efficiency against plugged easily of filter and low recovery efficiency problems of existing heat energy recover device of wastewater. It comprises wastewater filtrating equipment, heat exchanger, hot-water boiler, the inlet of wastewater filtrating equipment connects of the wastewater source, its output end connects hot-water side of heat exchanger, the heat exchanger is connected with the discharge pipe, the cold-water side of the heat exchanger is connected with cold clear water and hot-water boiler, its characteristics are the said wastewater filtrating equipment is composed of the wastewater box, at least one rotary screen filter screen, air knife, the impurity retainer, the said rotary screen filter screen is installed on the rotating shaft, air knife and the impurity retainer were installed both side of rotary screen filter screen each, feed mouth of air knife and the impurity retainer are higher than the liquid level of wastewater. It has characteristics of high efficiency and can meet the requirements of environmental protection.

Owner:NANJING MASITE MACHINERY

High temperature-type unitized regenerative fuel cell using water vapor and method of operating the same

ActiveUS11127967B2High heat recovery rateLower threshold voltageCellsSolid electrolytesUnitized regenerative fuel cellThermodynamics

Disclosed is a high temperature-type unitized regenerative fuel cell using water vapor, which exhibits high hydrogen (H2) production efficiency and superior power generation ability.

Owner:KOREA INST OF SCI & TECH

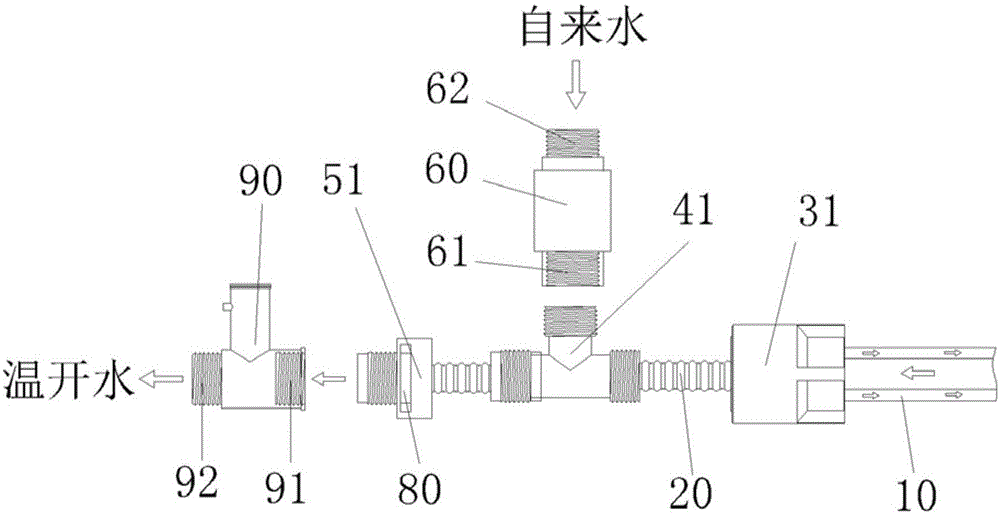

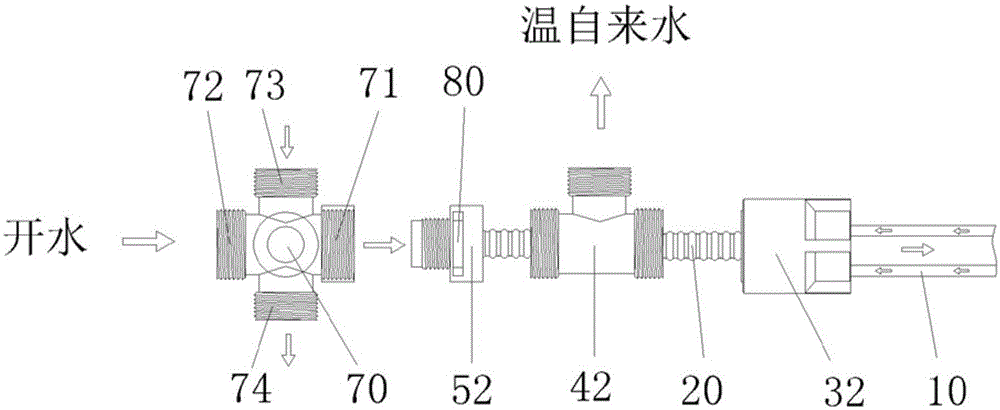

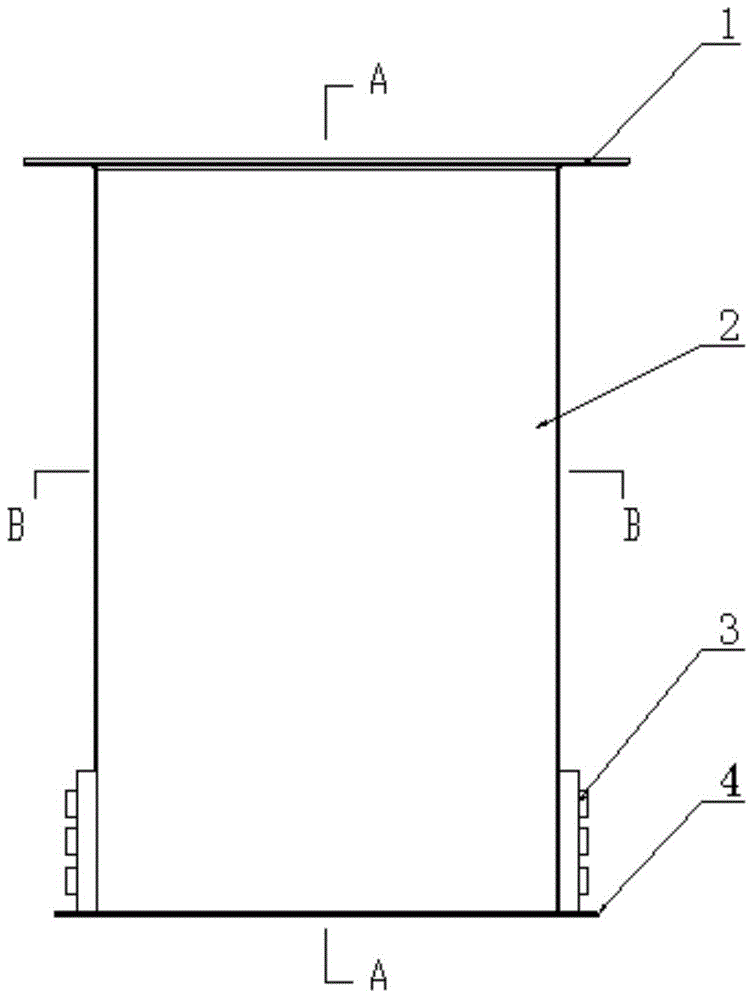

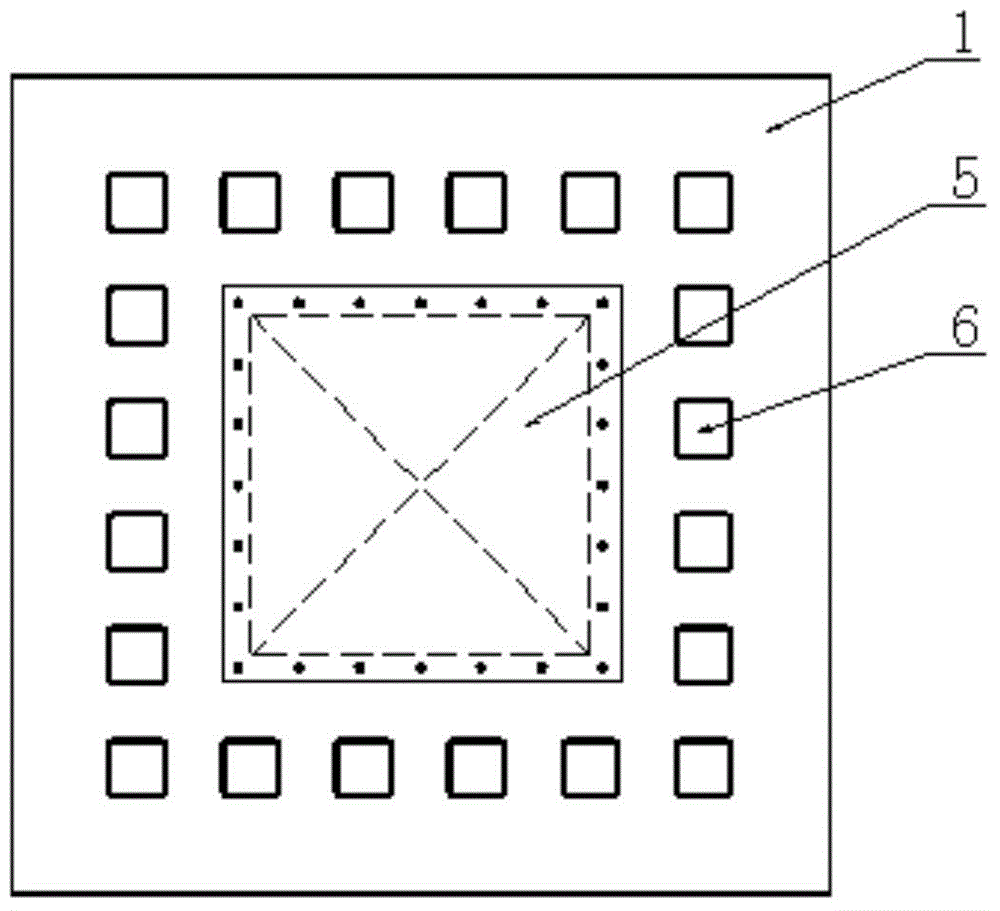

Water dispenser heat exchanger

InactiveCN103960981BEasy to installLow costBeverage vesselsHeat exchanger casingsWarm waterHeat control

The invention discloses a heat exchanger of a water dispenser which comprises an outer pipe, an inner pipe arranged in the pipe cavity of the outer pipe, a first PPR inner wire straight joint and a second PPR inner wire straight joint, wherein the first PPR inner wire straight joint and the second PPR inner wire straight joint are connected at the two ends of the outer pipe respectively. One end of the first PPR inner wire straight joint is connected with a first stainless steel outer wire three joint, a first stainless steel inner and outer wire straight joint and a decompression valve in sequence, wherein the first stainless steel outer wire three joint is further connected with a check valve. One end of the second PPR inner wire straight joint is connected with a second stainless steel outer wire three joint, a second stainless steel inner and outer wire straight joint and a cross-shaped heat control valve. The inner side of the first stainless steel inner and outer wire straight joint and the inner side of the second stainless steel inner and outer wire straight joint are provided with isolation seal rings. Tap water enters from the check valve to be subjected to heat exchanging and flows back a water container, boiled water enters from the cross-shaped heat control valve to be subjected to heat exchanging, then the temperature of the boiled water is reduced, and the boiled water becomes warm water which can be drunk directly. The heat exchanger of the water dispenser is convenient to install, free of welding, low in manufacturing cost, easy to maintain, high in heat recovery utilization efficiency and long in service life.

Owner:衢州广川电气有限公司

Catalytic combustion bed core structure with heater

InactiveCN103471115BGood for auxiliary heatingFast heatingCombustion using catalytic materialIncinerator apparatusHeat lossesEngineering

The invention relates to a catalytic combustion bed furnace core structure with a heater. The structure comprises a furnace core outer peripheral plate as well as an upper end plate and a lower end plate which are respectively mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a gas guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate; the heater is arranged in the furnace core body corresponding to the outlet of each gas inlet path and is fixedly mounted on the furnace core outer peripheral plate. The catalytic combustion bed furnace structure is simple in arrangement, the heat efficiency of the furnace core body can be effectively improved, the heat loss can be reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure can be more even during combustion, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Catalytic bed furnace core structure with guide shield

The invention relates to a catalytic bed furnace core structure with a guide shield. The structure comprises an upper end plate, a lower end plate and a furnace core outer peripheral plate; the upper end plate and the lower end plate are respectively fixedly mounted on the upper end and the lower end of the furnace core outer peripheral plate; a furnace core inner peripheral plate is arranged in the furnace core outer peripheral plate; gas inlet paths and gas outlet paths are alternatively arranged between the furnace core inner peripheral plate and the furnace core outer peripheral plate; the inlet of each gas inlet path is arranged on the upper end plate; the outlet of each gas inlet path is arranged between the lower end plate and the furnace core inner peripheral plate; the inlet of each gas outlet path is arranged between the upper end plate and the furnace core inner peripheral plate; the outlet of each gas outlet path is arranged on the lower end plate; a guide shield with an inversed rectangular pyramid structure is arranged at the lower face of the middle of the upper end plate. The catalytic bed furnace core structure is simple in arrangement and scientific and reasonable in design, the heat efficiency of the furnace core structure can be effectively improved, the heat loss is reduced, the heat recovery utilization rate can be improved, the temperature in the furnace core structure is more uniform during burning, and the burning efficiency and the purifying rate are improved.

Owner:赛智环保科技(天津)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163456.png)

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163505.png)

![High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method High-temperature-calcined [alpha]-Al2O3 production energy-saving apparatus and novel method](https://images-eureka.patsnap.com/patent_img/ea3dff81-53be-4567-bec7-f83e0d2d6bfa/150520163510.png)