The synthesis method of ethylbenzene

A synthesis method and ethylbenzene technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of low investment and operating costs, cheap and easy availability of ethanol raw materials, low ethanol utilization rate, large energy consumption, etc. , to achieve the effect of low operating cost, simple process and large-scale solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

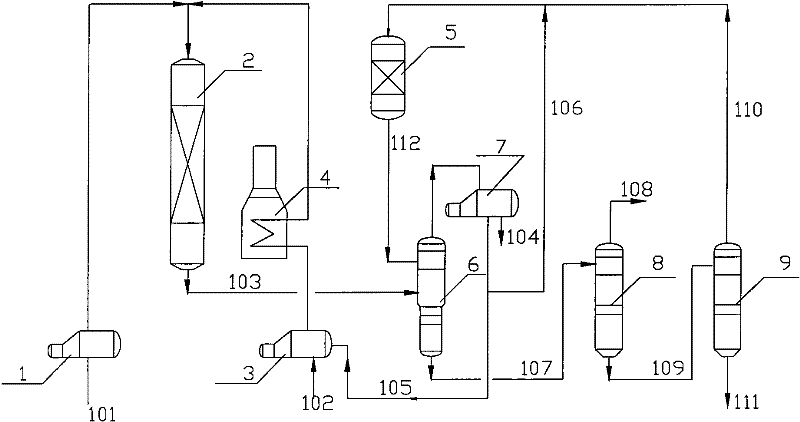

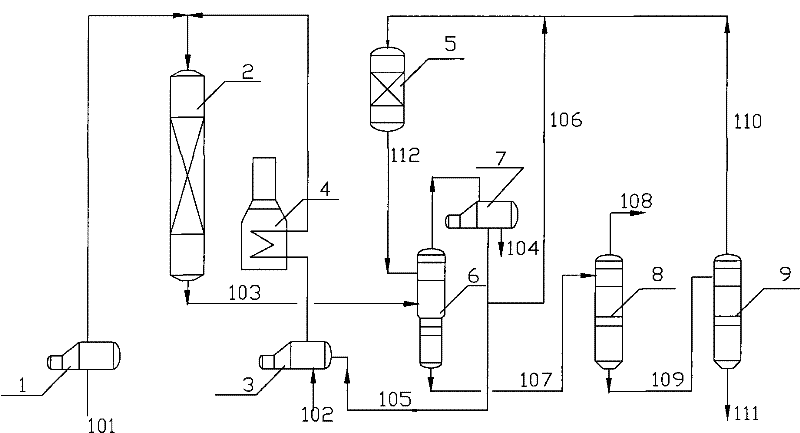

[0020] A 30,000-ton / year ethanol and benzene one-step synthesis of ethylbenzene plant adopts figure 1 As shown in the ethylbenzene synthesis technology, 95% pure raw material ethanol is heated and gasified, and then mixed with the heated raw material benzene and recycled benzene into the alkylation reactor equipped with ZSM-5 nano-scale molecular sieve catalyst. The molar ratio of ethanol is 6:1, the inlet temperature of the alkylation reactor is 380℃, the pressure is 1.2MPaG, and the ethanol weight space velocity is 1.5 hours. -1 After the reaction, the discharge temperature is 400℃, of which the weight percentage of ethylbenzene is 16%, and the weight percentage of diethylbenzene is 1.6%. The reaction product enters the benzene tower. The operating pressure at the top of the benzene tower is 1.0MPaG, the top temperature is 160℃, and the bottom temperature is 250 ℃, reflux ratio 1 uses 45 float valve trays, the top stream is condensed by the condenser at the top of the benzene ...

Embodiment 2

[0023] In a 30,000-ton / year ethanol and benzene one-step synthesis of ethylbenzene, the molar ratio of benzene to ethanol in the alkylation reactor is 5:1, and the other process flow and operating parameters are the same as in Example 1. The alkylation reactor outlet The weight percentage of ethylbenzene in the material is 15%, and diethylbenzene is 2.0%.

[0024] The total raw material cost of this device is 8,920 yuan / ton of ethylbenzene, the purity of ethylbenzene is 99.8%, the content of xylene in ethylbenzene is 700ppm, the unit consumption of ethanol is 446 kg / ton of ethylbenzene, and the energy consumption is 920 MJ / ton of ethylbenzene.

Embodiment 3

[0026] A 60,000-ton / year ethanol and benzene one-step synthesis of ethylbenzene plant, the transalkylation reactor inlet temperature is 220℃, the pressure is 3.0MPaG, the weight ratio of benzene to polyethylbenzene is 7:1, and the liquid weight space velocity is 2 hours -1 , The conversion rate of polyethylbenzene is 70%, and the other process flow and operating parameters are the same as in Example 1.

[0027] The total raw material cost of the device is 8870 yuan / ton of ethylbenzene, the purity of ethylbenzene is 99.82%, the content of xylene in ethylbenzene is 650ppm, the unit consumption of ethanol is 442 kg / ton of ethylbenzene, and the energy consumption is 920 MJ / ton of ethylbenzene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com