Thermal energy recovery system containing waste hot water

A technology for heat energy recovery and waste water, which is applied in filtration circuits, heat exchange equipment, lighting and heating equipment, etc. It can solve the problems of easy blockage of filters and recovery efficiency, and achieve the effect of compact structure, reasonable design and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

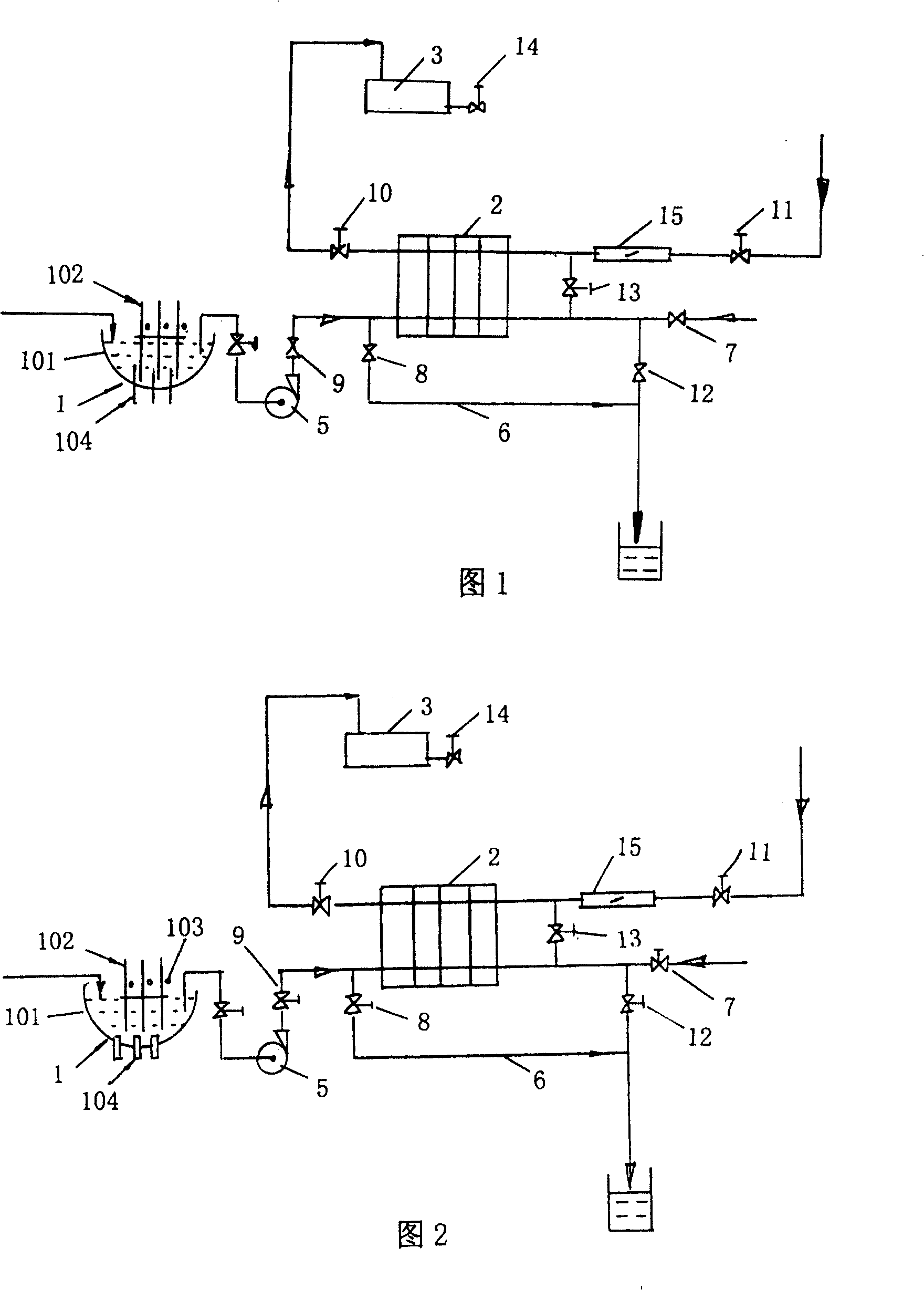

[0032] As shown in Figures 1, 6, 7, and 8.

[0033] A thermal energy recovery system for heated waste water, comprising a waste water filtering device 1, a heat exchanger 2 (a plate heat exchanger may be used, the same below), a hot water boiler 3, the water inlet end of the waste water filtering device 1 is connected to a hot sewage source, Its output is connected to the water inlet end of the hot water side of the heat exchanger 2 through the valve 15, the variable water pump 5, and the valve 9, and the water outlet end of the hot water side of the heat exchanger 2 is connected to the discharge pipe through the valve 12. A recoil steam valve 7 is installed on the pipeline between the outlet end of the hot water side of 2 and the valve 12, so as to carry out back flushing when the heat exchanger 2 is cleaned. A valve 13 for supplying clear water during cleaning is also installed on the pipeline between the water outlets on the heat source water side. In addition, in order to ...

Embodiment 2

[0036] As shown in Figures 2, 6, and 7.

[0037] A thermal energy recovery system for heated waste water, comprising a waste water filter device 1, a heat exchanger 2, and a hot water boiler 3, the water inlet end of the waste water filter device 1 is connected to a hot sewage source, and its output is through a valve 15, a variable water pump 5, and a valve 9 is connected to the water inlet end of the hot water side of the heat exchanger 2, the water outlet end of the hot water side of the heat exchanger 2 is connected to the discharge pipe through a valve 12, and the water outlet end of the hot water side of the heat exchanger 2 is connected to the valve 12 The backflush steam valve 7 is installed on the pipeline between them, so as to backwash the heat exchanger 2 when cleaning. A valve 13 for supplying clear water during cleaning is also installed. In addition, in order to protect the normal operation of the equipment during cleaning, a short-circuit discharge pipe 6 is in...

Embodiment 3

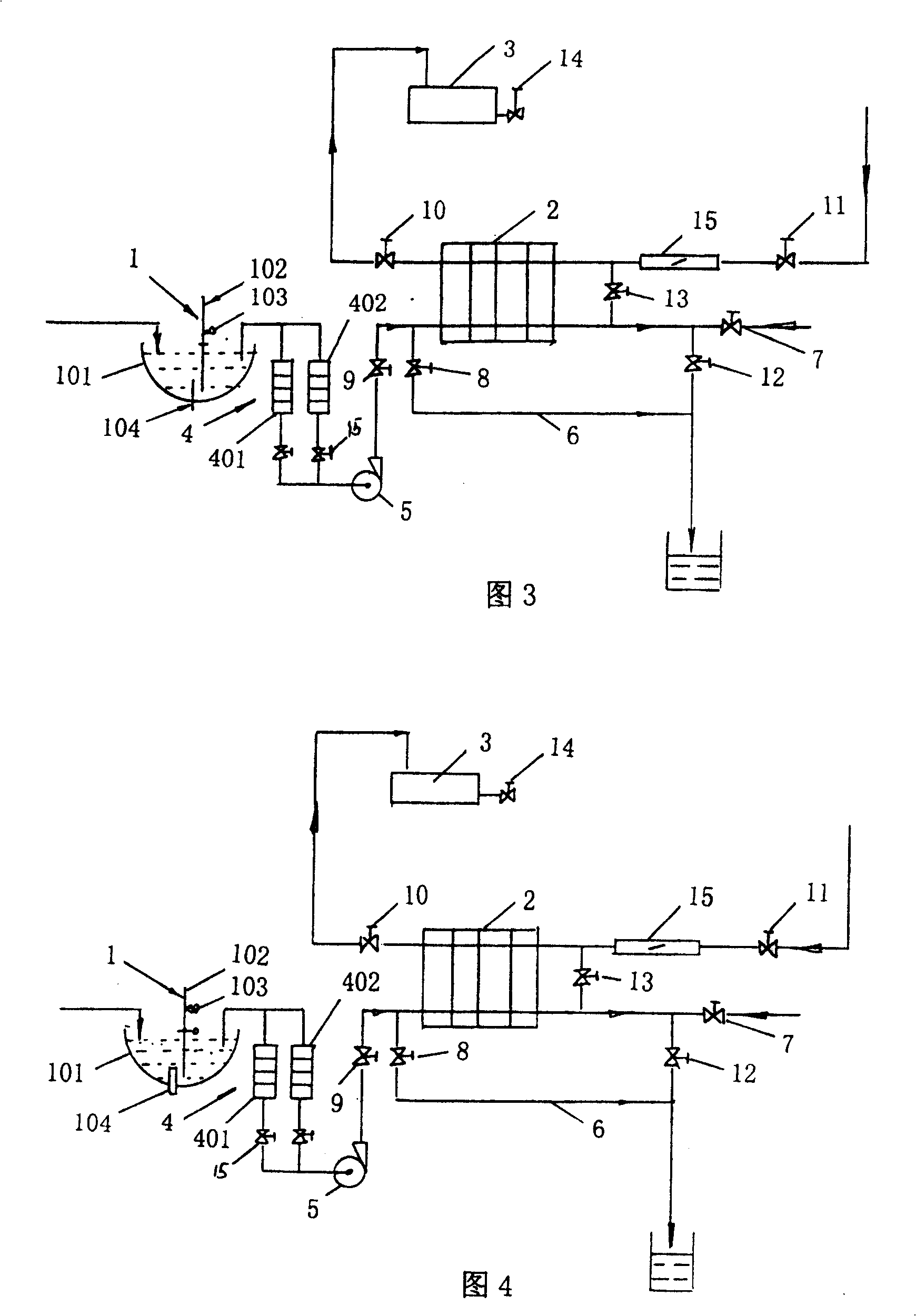

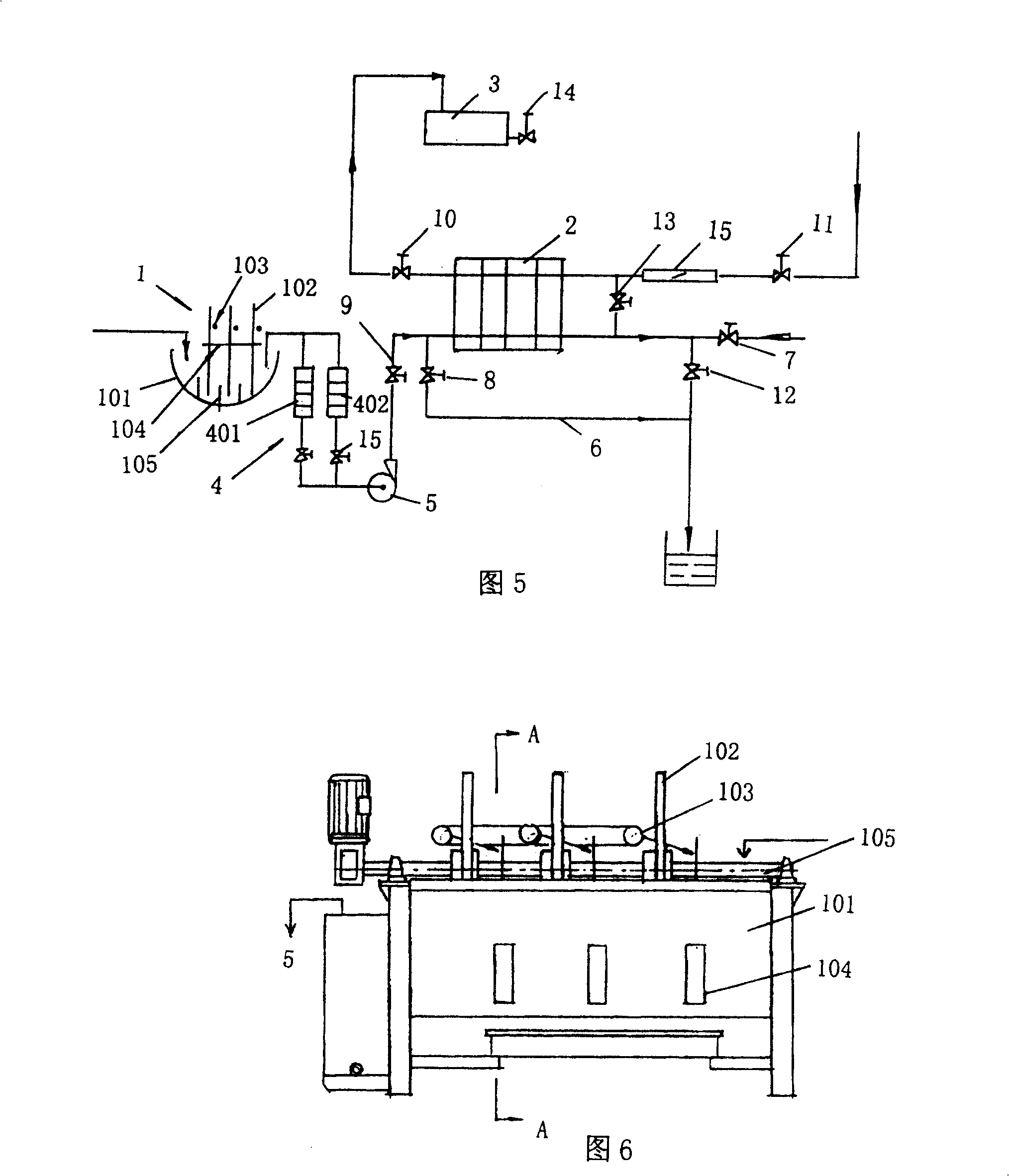

[0040] As shown in Figures 3, 6, 7, 8, 9, and 12.

[0041]A thermal energy recovery system for heated waste water, comprising a waste water filter device 1, a heat exchanger 2, and a hot water boiler 3, the water inlet end of the waste water filter device 1 is connected to a hot sewage source, and its output is through a valve 15, a variable water pump 5, and a valve 9 is connected to the water inlet end of the hot water side of the heat exchanger 2, the water outlet end of the hot water side of the heat exchanger 2 is connected to the discharge pipe through a valve 12, and the water outlet end of the hot water side of the heat exchanger 2 is connected to the valve 12 The backflush steam valve 7 is installed on the pipeline between them, so as to backwash the heat exchanger 2 when cleaning. A valve 13 for supplying clear water during cleaning is also installed. In addition, in order to protect the normal operation of the equipment during cleaning, a short-circuit discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com