Multi-angle, multi-layer, 360-degree air supply sinter cooling tower

A sinter and cooling air technology, applied in the field of multi-angle, multi-layer, 360-degree air-supply sinter cooling tower system, can solve the problems of inability to realize heat energy recovery and environmental protection, inability to use belt coolers and ring coolers, etc. Achieve the effects of small footprint, no dust diffusion, and no wind damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

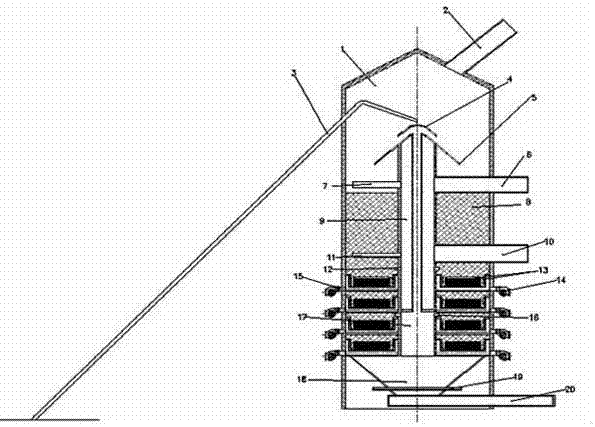

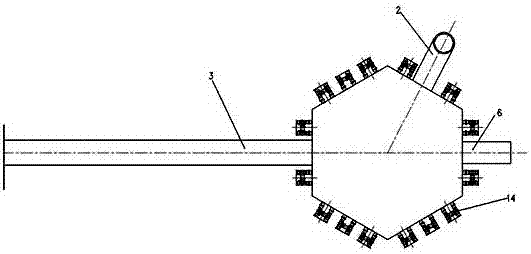

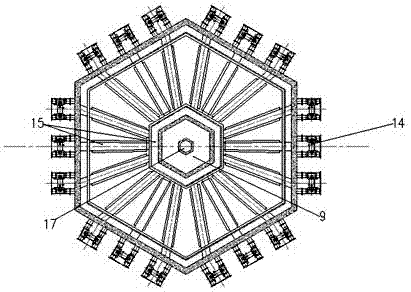

[0010] The invention consists of a feeding inclined bridge, a cloth dust waste gas collection room, a dust removal pipeline, a material distribution device, a high-temperature heat energy recovery system (high-temperature heat energy recovery air holes, high-temperature heat energy recovery pipes), a boiler circulating air recycling system (boiler circulating air pipes, boiler circulation air hole), medium temperature cooling recovery system (cooling fan, cooling air duct, cooling air louver ventilation style, medium temperature heat energy recovery hole, medium temperature heat energy recovery pipeline), low temperature cooling system (cooling fan, cooling air duct, Cooling wind louver ventilation style, low-temperature exhaust gas vent, low-temperature exhaust gas pipeline), unloading system (unloading hopper, gate, conveyor).

[0011] The figure shows that the feeding inclined bridge 3 sends the sintered ore into the multi-angle, multi-faceted and multi-layered 360-degree ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com