Semiconductor device, liquid crystal display device equipped with semiconductor device, and process for production of semiconductor device

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problems of inability to etch wiring films and difficulty in copper thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

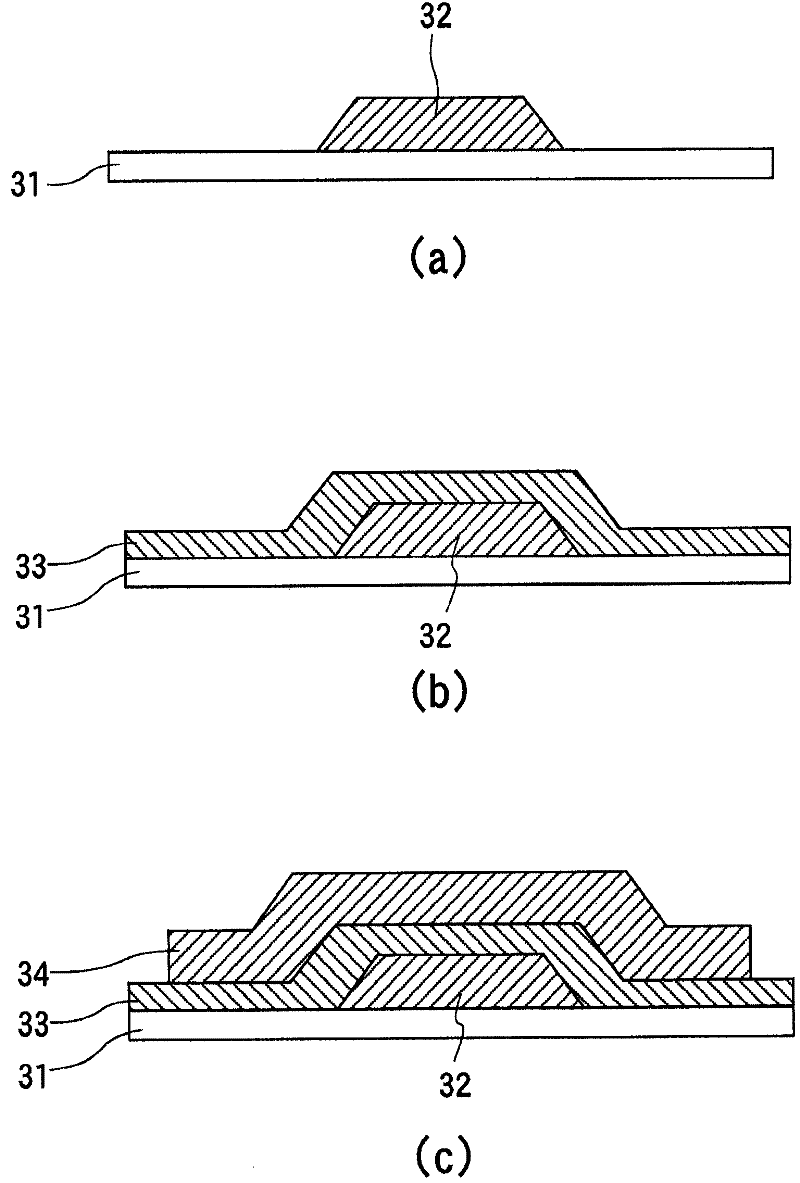

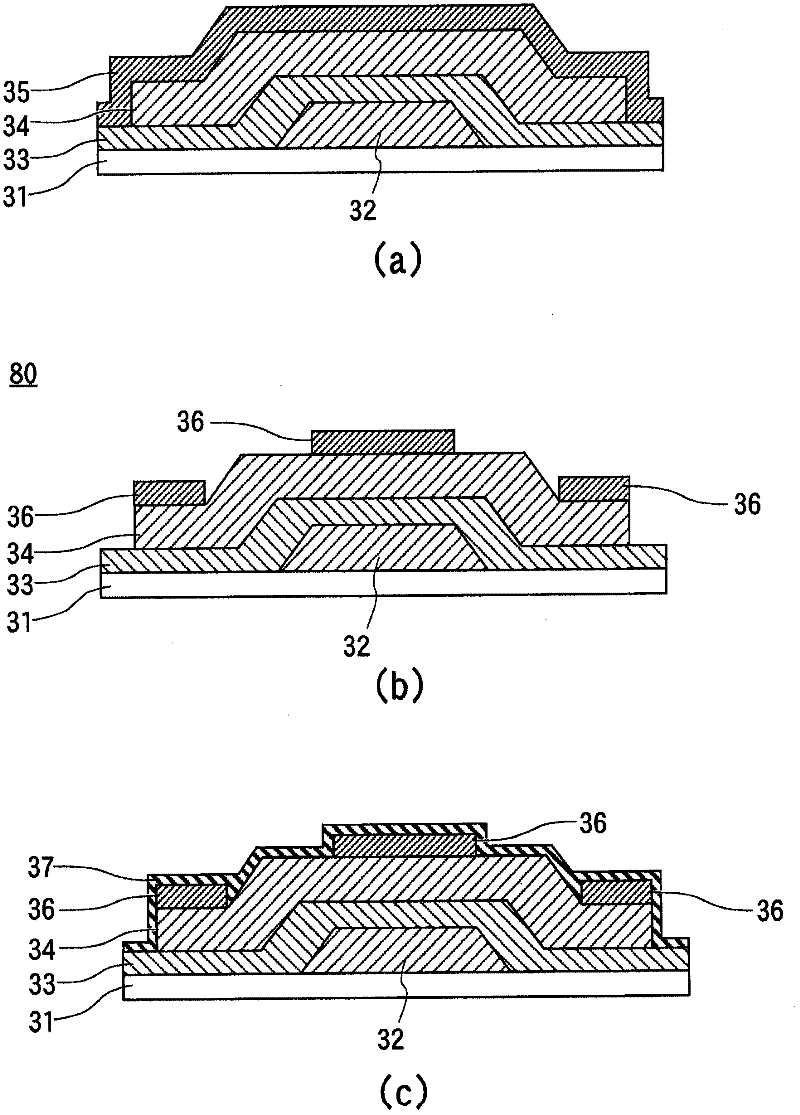

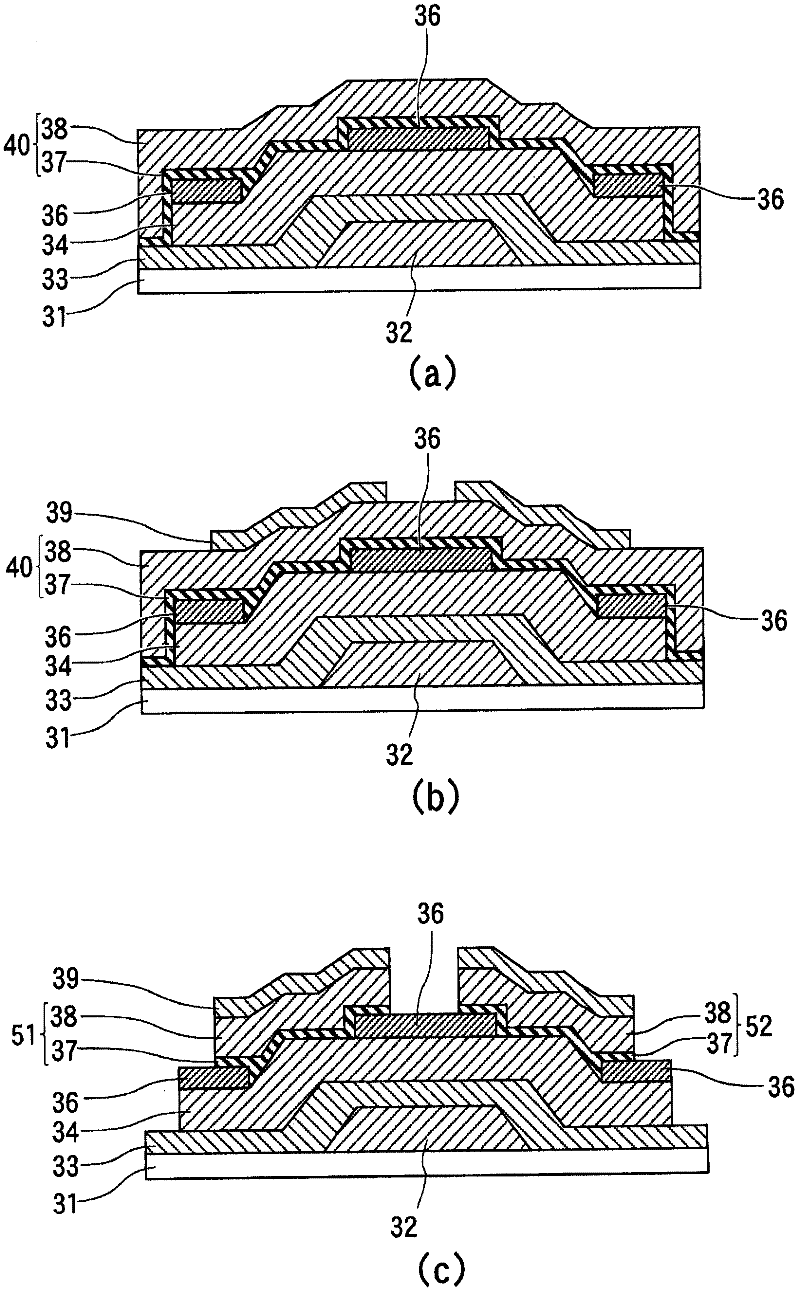

[0089] Cu (copper) is the main component, and Mg (magnesium) and Al (aluminum) are contained in a specific ratio to make a target, and the target is sputtered, and an insulating film made of oxide (here, SiO 2 thin film) or oxide semiconductor thin film (here, IGZO film: InGaZnO), a high-adhesive barrier film composed of Cu-Mg-Al with the same composition as the target is formed, and formed on the formed high-adhesive barrier film pure copper thin film to form an electrode layer composed of a high-adhesion barrier film and a pure copper thin film.

[0090] Adhesion and barrier properties of high-adhesion barrier films with different addition ratios of magnesium and aluminum were evaluated.

[0091] Table 1 shows the evaluation results for oxide semiconductors, and Table 2 shows the evaluation results for insulating thin films.

[0092] [Table 1]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com